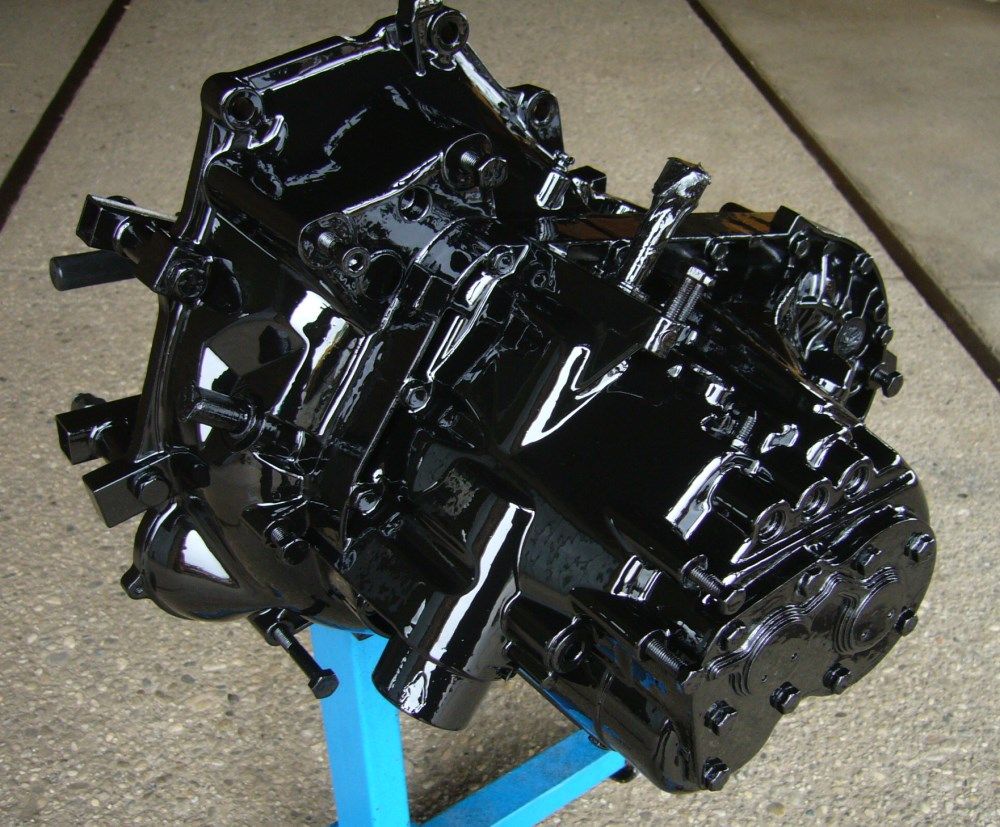

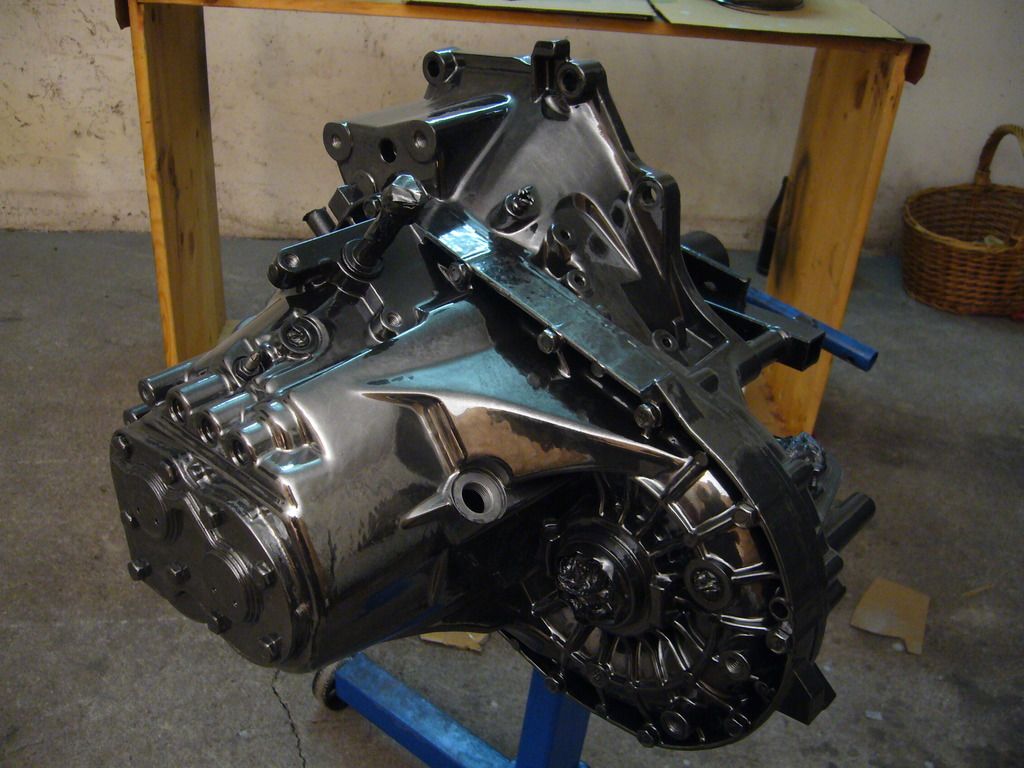

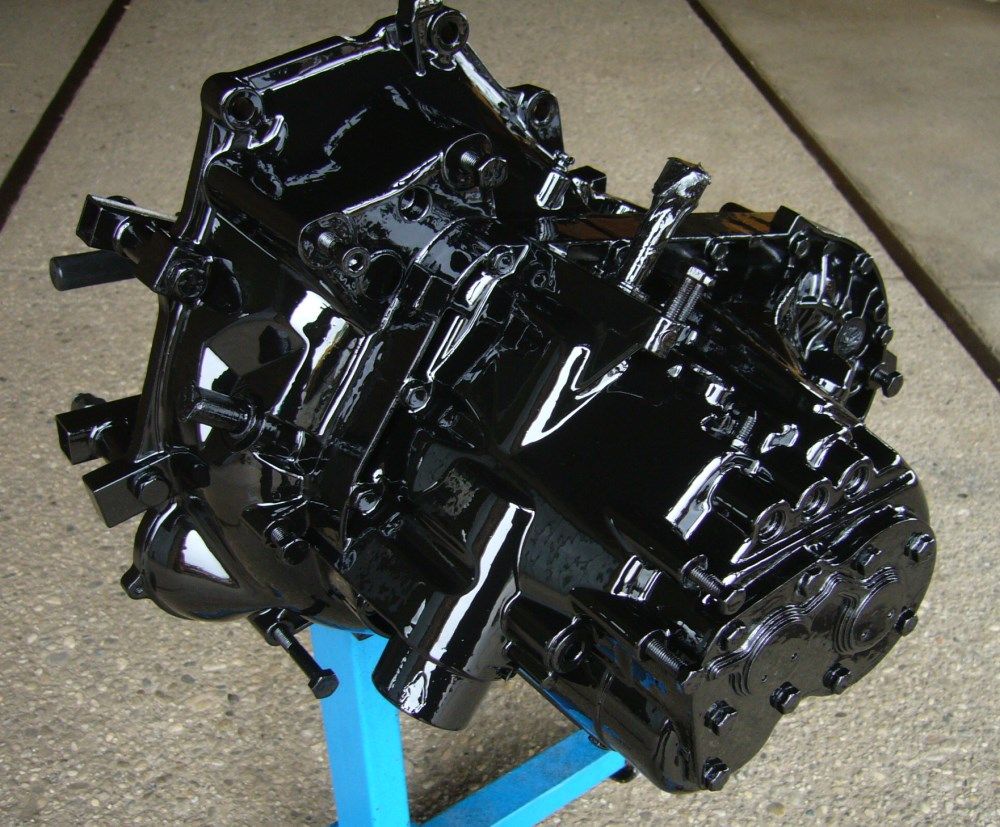

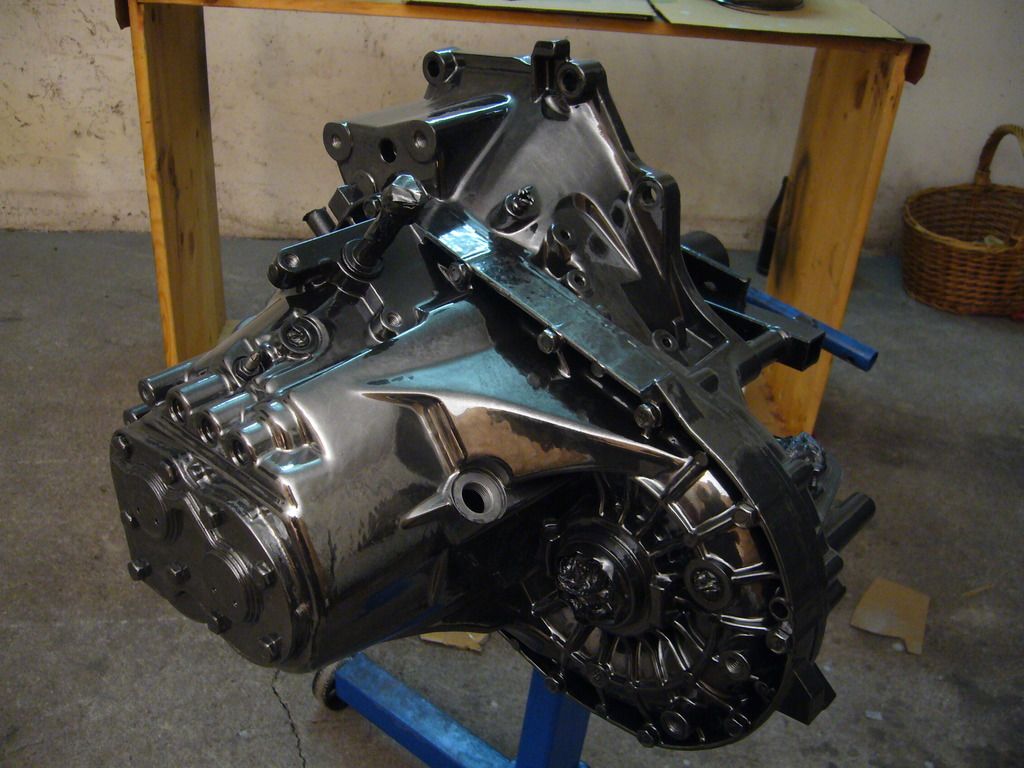

Final step - Painting: After rebuilding my Getrag trans I decided to paint it in nice and shiny chrome.

A lot of hard work was involved, including several test paintings, which have cost me a lot of time and money.

You must work extreme accurately and absolutely no mistakes are forgiven.

I needed several weeks to find out how to paint chrome and I have written

my own write-up with step-by-step instruction for future paint jobs.

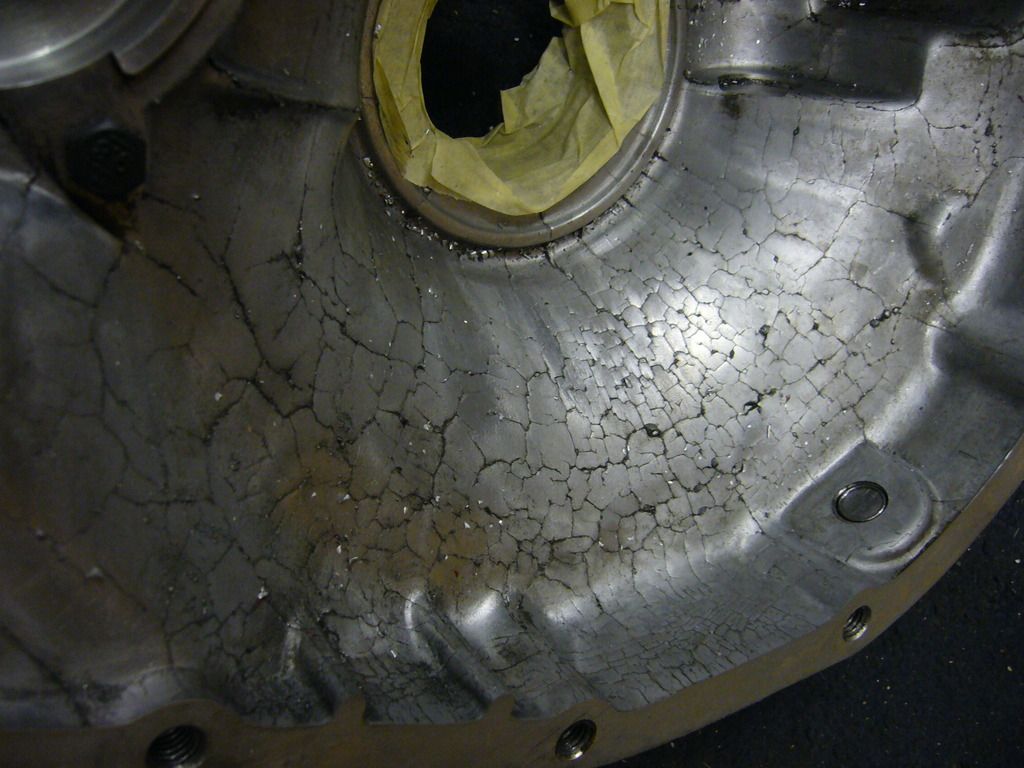

Chrome painting is almost a whole science of its own! Step 1 / Prep. Work: Before my transmission rebuild I have pre-cleaned the trans with a heavy-duty industrial degreaser.

However, this cleaner was an “oil” based product, which is not good for painting!

After bolting together my trans I have grinded away all the oxidation and then I have cleaned it with TSP (Trisodium phosphate).

If you use TSP for cleaning aluminum, you must swill the aluminum parts with a lot of clean water instantly

after applying the TSP (aluminum doesn´t like TSP). I recommend using another degreaser instead (tenside-based).

After thorough cleaning, you have to use AP-120 or METAL-READY for etching the

aluminum surface for ensuring proper adhesion of the black undercoat!

Applying AP-120 after cleaning:

After 2-3 minutes, you need to swill the trans with a lot of clean water!

(otherwise the chemicals may harm the metal)

Then use compressed air to dry the transmission.

After “pre-drying” use a heat-gun until the metal gets bone dry.

Next you need to spray on acetone or brake cleaner.

Wipe off this stuff off and the use silicone remover in order to get a 100% oil-free surface for painting!

(POR-15 is very sensitive against grease and oil residue)

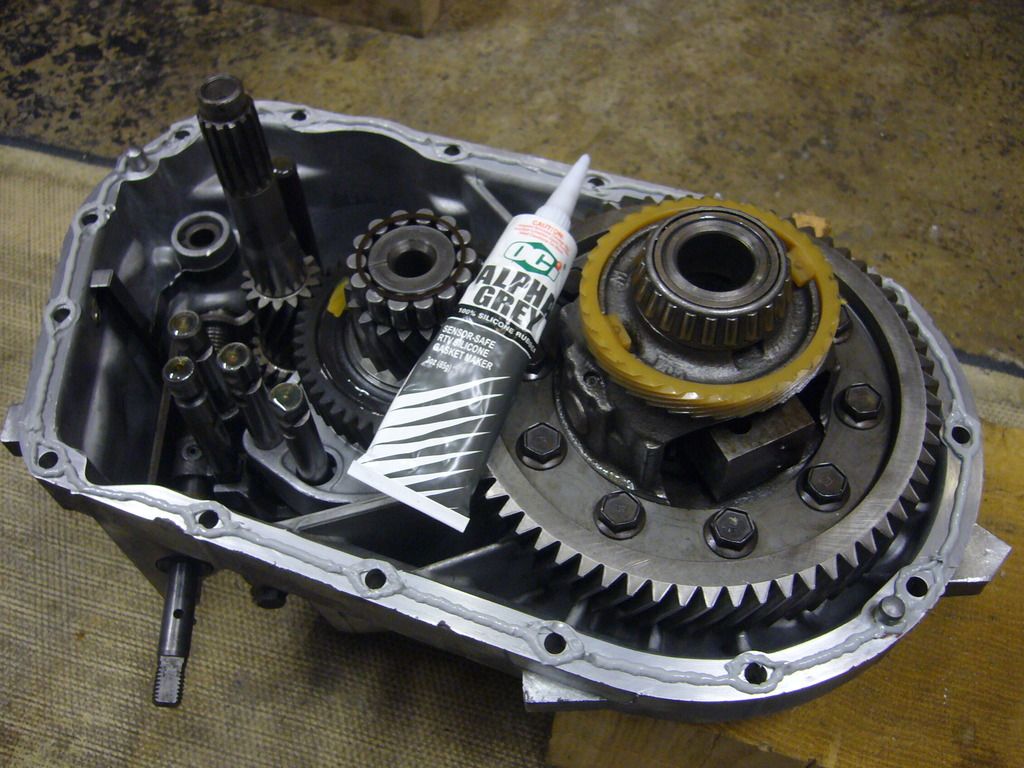

Step 2 / Black High-Gloss Urethane Undercoat: Mix POR-15 with a stick (DO NOT shake the can!)

Use a 190-micron filter and fill POR-15 into your spray gun (2.0 mm nozzle) without thinner.

Apply the first coat POR-15 with a pressure of 5.0 bar.

Next day grind the surface with a silicium carbid grinding fleece and apply the second coat POR-15 diluted with 10% Xylol at a pressure of about 4.8 bar:

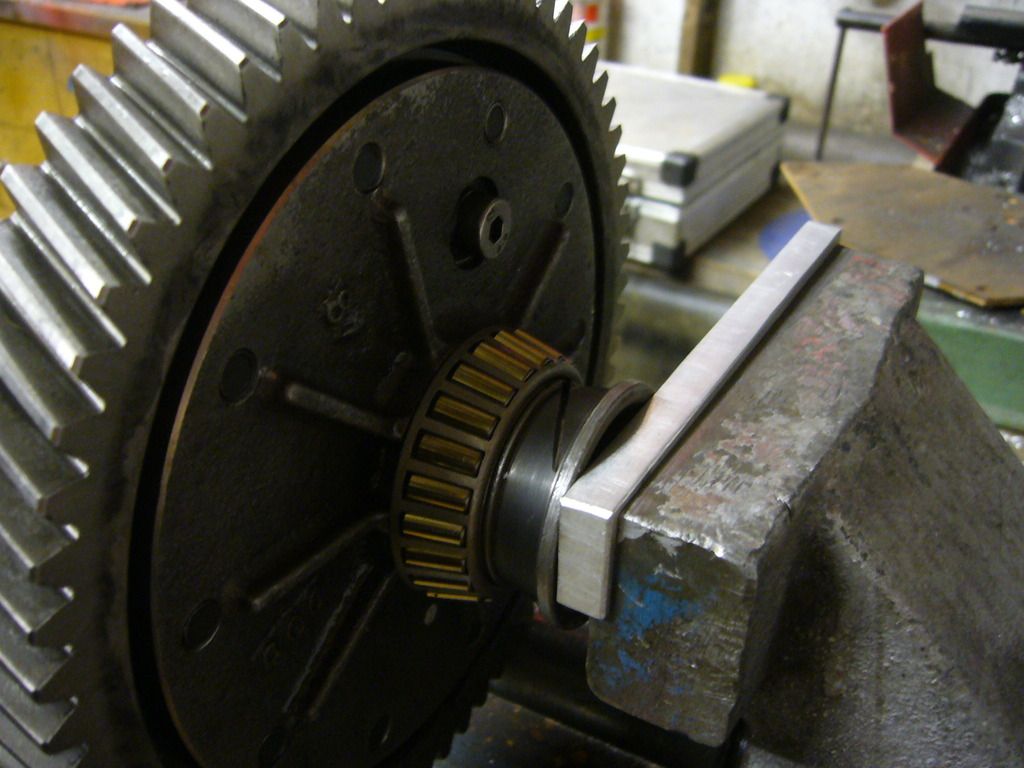

Step 3 / Polishing:

Step 3 / Polishing:Next day polish the POR-15 undercoat with Alu Magic and clean the surface thoroughly with silicon remover and compressed air.

(DO NOT do this in your painting room)

Step 4 / Chrome Paint (Sparkling Chrome):

Step 4 / Chrome Paint (Sparkling Chrome): Finally, you can apply the chrome paint.

Here you need to shake the can as much as possible in order to get an uniform distribution of chrome pigments.

I have used an airbrush (0.5 nozzle) @ 4.0 bar air pressure for finest atomization of chrome pigments.

Apply at least 3 – 4 coats of chrome paint (wait about 5 minutes between each coat).

Spray distance should be about 20 – 30 cm (3/4” – 1 ¼”).

Tips for airbrushing:

Move the airbrush in a smooth motion and always check the paint level in the airbrush.

BEFORE the chrome paint gets empty refill it immediately, otherwise the airbrush will suck in air bubbles.

ALWAYS shake the chrome paint can before refilling the airbrush.

When you need to paint the top and bottom surfaces, you need to turn the tranny on your engine/trans stand.

NEVER tilt the airbrush too much, always keep it horizontally!

My results:

Step 5 / Urethane Clear Coat (Glisten PC):

Step 5 / Urethane Clear Coat (Glisten PC): First, you need to polish the chrome coat with a soft cotton wool or soft microfiber cloth.

Carry the tranny into another room for preventing contamination of the painting room.

Do not apply to much pressure when you polish the chrome paint, otherwise you may rub

off the chrome paint on sharp edges!

Then clean it with compressed air and carry it back into your painting room.

Awesome! Isn´t it?

Mix Glisten PC urethane clear 3:1 with PU-activator.

(in case you have already used your Glisten PC can in the past, I recommend using a 190-mircron filter in this case).

DO NOT shake the can!!! Use a small stick instead and

SLOWLY mix the two components together.

DO NOT dilute the clear coat with paint thinner!!! Fill the urethane clear into a HVLP spray gun (1.7 mm nozzle) and use a stick

for piercing air bubbles while paint flows into the gun´s paint canister.

Set the air pressure at about 4.0 bar and begin to apply a first light coat.

Wait about 3 - 5 minutes and then apply a final heavy coat.

Initially you may get an orange peel clear coat.

Just wait some minutes and the orange peel will disappear and you should get a glossy finish in the end!

Picture of final chrome paint job with urethane clear coat:

Now let the clear coat cure at least 4 days...

Optimal conditions for spraying Glisten PC:

Temperature: 18 – 24°C

Humidity: < 60%

Properties of Glisten PC clear coat:

- Extremely UV resistant (UV index up to 17)

- Rock hard and very scratch resistant (similar to POR-15)

- Chemical resistant against oil, gasoline, diesel, cellulose thinner, etc.

- Temperature resistant up to 200°C!

Required Equipment:

- Air compressor with oil/water separator

- Two HVLP spray guns (2.0 and 1.7 mm nozzles)

- Air brush or MiniJet for chrome painting

- Gas mask, rubber gloves and head covering

BTW, with this detailed and proven “spray on chrome” instruction nearly everybody should be able to make his/her own chrome paint job.

These are the ONLY working instruction for chrome painting out there! I have invested quite a lot of time for research and I have found many products and instructions that are just bullshit.

Do not buy any chrome paint kits, because 99% of them are junk!

You just need to buy the chrome paint itself (e.g. Sparkling Chrome or Mirror Chrome).

The other used products are American polyurethane paints from POR-15.

It was not easy to find out this special combination of paints in order to get a chrome like finish...

[This message has been edited by Moar (edited 03-22-2016).]

)

)

(did you mean $20.-)

(did you mean $20.-)

)

)