|

| Trinten's SBC/F23 build - The work has begun! (Page 57/69) |

|

Trinten

|

NOV 10, 01:17 AM

|

|

Thanks Will, once we were under the car we spotted where it it could run, and worked out nicely.

Page 15 of the build thread, November 2021

It's been a while since I've done an update. I think that's because we're getting down to some of the stuff that is a little time consuming. And by we, I mean Mike. I often play go-fer. Though Mike has (reluctantly) said that a few of my ideas were really good. And only reluctantly because "why didn't I think of that!"

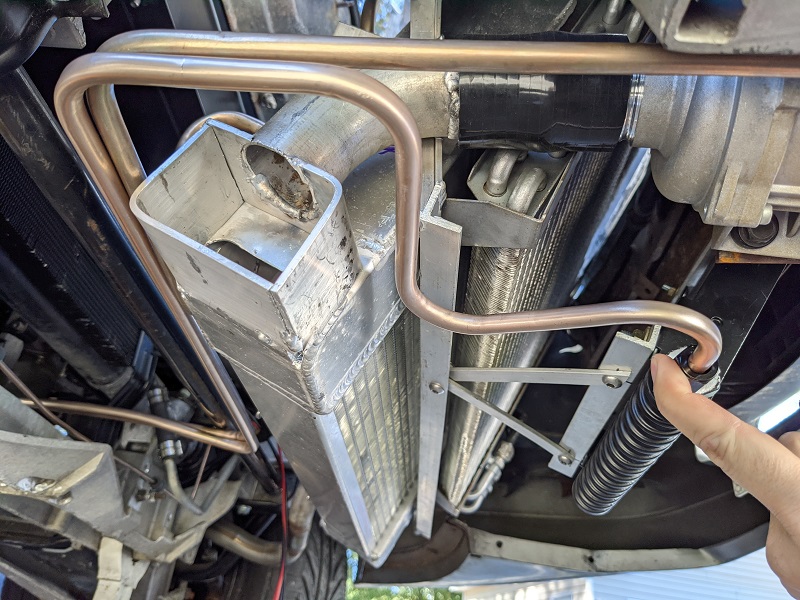

Anyhow - I mentioned before about modifying the radiator a bit more for the coolant piping to/from the water pump. Mike then tackled starting to run the transmission cooler lines. In my previous post I think I showed a pic of that getting started, and he finished it up (at least going back to the rear bulkhead, more on that later).

We did have to pull the radiator again, which lead to a good, but unexpected, test of how well it could go in/out around the transmission lines. It requires lifting the driver side first, but then it slides out without an issue. Could probably be done by one person, though two is definitely better (at least with the hood on).

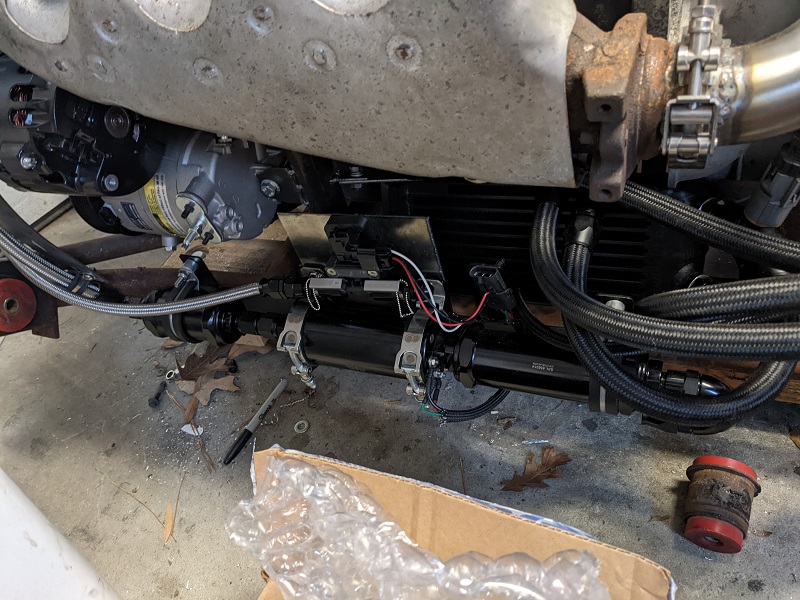

We also took apart the bracket setup for the FAST so we could mount the TecMotive pump control on it. Check out the cool little connector channel! This thing is way smaller than I expected. At least it makes it super easy to package!

Okay so now onto the stuff I'm really excited about. We slide my drivetrain skid under the cradle, unbolted the engine, and the skid worked exactly as intended, supporting the cradle, engine, transmission AND the A-Arms, so they didn't drag. We unbolted the upper control arm... then used the neat new lift point Mike put in before to life up the body of the car!

This also worked as planned, the cherry picker legs stayed clear of the skid/cradle. Now that he knows it works, he'll make the final version of the bolt that screws into the reinforced mounting point.

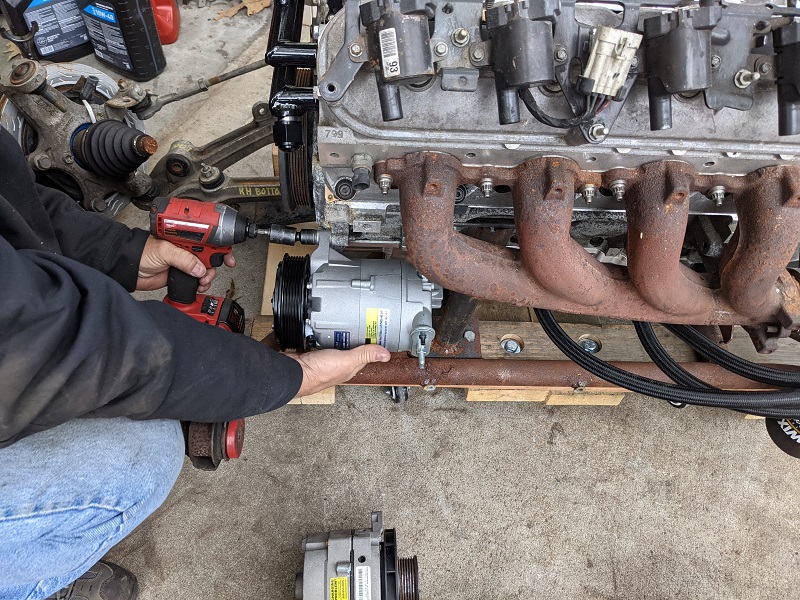

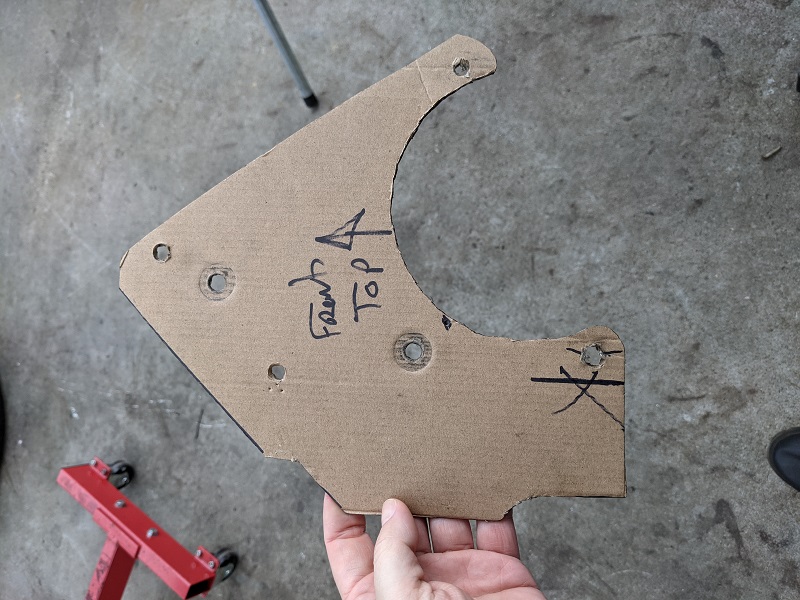

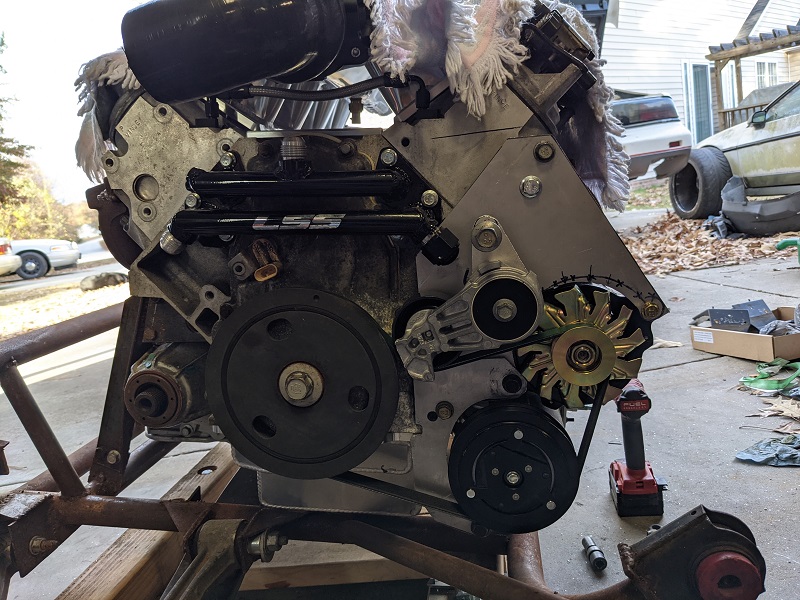

Once the drivetrain was out, we rolled it into the garage so Mike could start working on packaging accessories. The AC Compressor will use one of the original mounting points. Then he used some cardboard to start working out the template for the alternator, going as far as even bolting it up to the block, and I would hold the altnerator as he checked things out.

This bracket will be spaced out from the block to get the alternator pulley into alignment, with it sitting as test fitted, it is backspaced about .75". It's made from .25" 6061 aluminum. The spacers will be made from the same.

I'll be using a CS130 alternator from Power Master. I've used their alternators in the past and have had great luck with them, plus their tech support and pre-sales guys have always been great. Also, the last two alternators I got from them had higher than advertised amperage. They (used to) do a bench test and have a tag attached to it with the exact amps that unit put it out. The alternator in the mockup is an SI12 case, which has the same mounting hole distance and orientation as the unit I ordered.

Solid color wire from ADI shipped out this week - well, most of the colors, a few were on backorder. We're also still waiting on the metal pieces for Mike to start mocking up the gas tank.

And this was just a funny picture after we put the wheels back under the car without the drivetrain.

[This message has been edited by Trinten (edited 03-26-2023).]

|

|

|

Trinten

|

DEC 01, 09:00 PM

|

|

You may recall from the last update that we dropped the cradle (using my spiffy skid and the spiffy lift point Mike made) so we could work on the accessory location and bracket(s). And by we, I mean Mike. But hey, I'm always there for moral support, and to take pictures. And gofer. And now and then I have a good idea.

This time out, while Mike started working on the accessory brackets, I cleared out what was left of the old nasty insulation in the Fiero engine compartment.

I will be replacing it with Thermo-Tec insulation, part 13590. I emailed them describing where it was going to be used, and this is what they suggested, so, we'll give it a shot! We'll also be putting back in the super-awesome Decklid brackets that FieroGuru made for my last Fiero, which will require us to fabricate the spreader bar that went in above the 'lip' (there are square holes cut out in there already) to help offer support. I'm going to go back in this thread and find that section to make sure I have the information handy for Mike. We'll also be reinstalling the super nice heatshield/smoothplate he made, which means I'll be taking off all those little stands off the bulkhead.

I also have some TechFlex SRF28.0SV material that we'll be using in other temp critical places, like on the manifold shields (definitely the inside of them). This stuff is crazy expensive, but that's partially because you can normally only get it in giant rolls. Thankfully a seller on eBay sells it in 2" cuts. I think this stuff is literally something used by NASA. If it's good enough for things being shot into space, it's good enough for me!

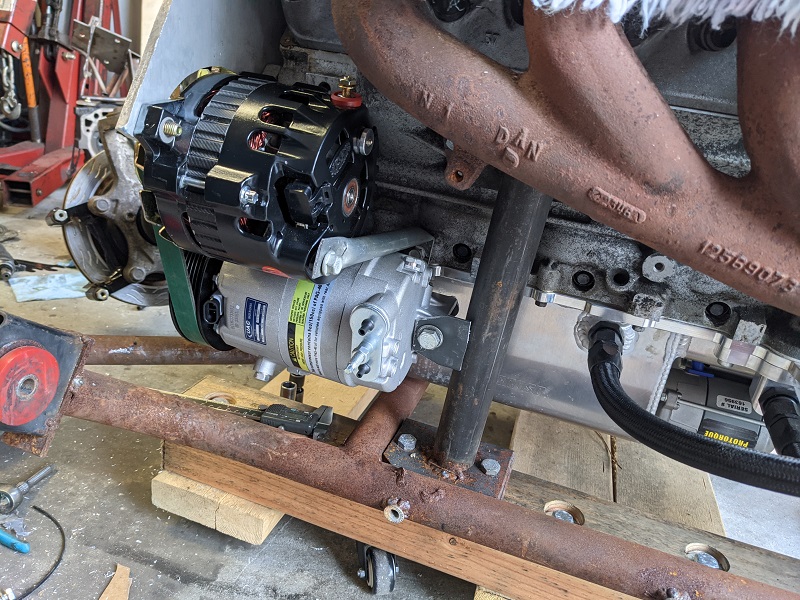

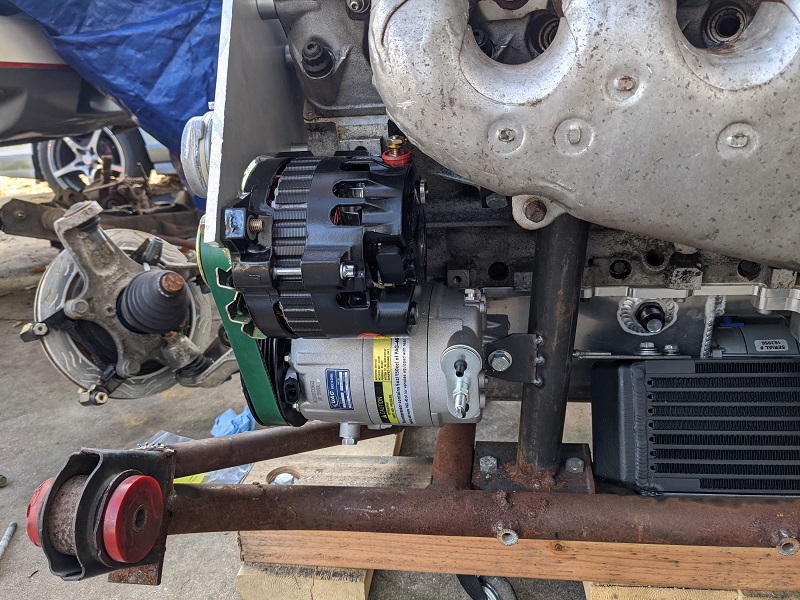

Mike wanted to create a second bracket that would also wrap down to give the A/C Compressor some additional rigidity. This bracket means he has to rework one of the arms on the cradle a little, you can see where he cut through the spot weld, and the arm is kind of dangling there. Yes, the cradle has held the drivetrain for well over a year with just spot welds. Including while the car was bouncing along on a trailer to PA, and us lowering lifting it, rocking and rolling it. Crazy!

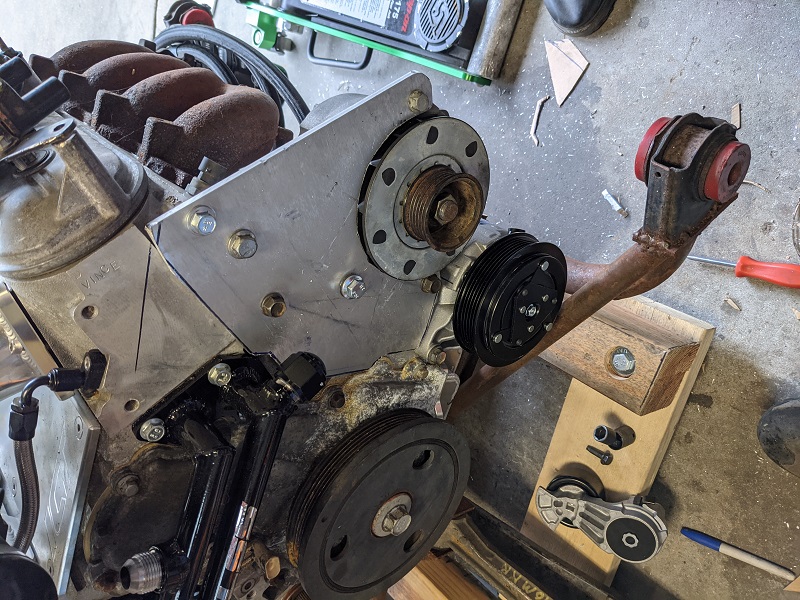

He also trimmed a bit of the 'lip' off the belt tensioner pulley. It wasn't coming into contact with the crank pulley, but it was so close that you'd be lucky if a piece of paper could slip between the space. Mike felt trimming of a bit of the lip was better than worrying about the lip scraping the pulley during movement with vibration.

He also rigged up some extra brackets for the back of the alternator and the compressor. On the compressor there is this little 'U'. So you can see that tab in a mock up position that will weld to the upright support on the cradle, and the bolt will fit snugly into that U. There is also more clearance between the alternator and the manifold that that angle would make you think.

So I had to buy a bunch of proper length bolts to put all this together, along with some sensors and other adapters for the transmission (ICT Billet makes coolant fittings for this transmission that go directly to AN, versus whatever the factory connection is, eliminating a potential leak point).

I also bought heavier-duty casters for my Skid. What I didn't consider, and which did happen, is what happens when the drivetrain does not come down onto the skid evenly? Well, then it's likely a wheel's load rating will be exceeded. That happened, so one of the wheels acts a little wonky now. Fixed that by getting casters that are each rated in excess of the drive trains weight.

I scored a pristine, no cracks, center console skeleton from the junkyard. Mike got the tail lights (notchie), we picked up some other odds and ends. But I won't be using that. Instead, I'll be using one of the fantastic 3D printed units from PFF's very own mmeyer86gt/gtp!

It showed up in a very compact box, very well packaged (each piece was wrapped in bubble wrap). Looks pretty spiffy!!

I also took advantage of the Discount Tire black Friday sale and bought new tires for the stock coupe Corvette wheels I have on there, so those will go on this Saturday. The tires that are on there now are pretty well cracked, and these have the same ratio number, so the car will have a very slight rake and the rear tire will fill up the wheel well a little better. I'll post up pictures of those once the wheels are back on the car. Fronts are 255/40 R17, and the back are 275/40 R18. With the discounts, I effectively got a free tire.

[This message has been edited by Trinten (edited 03-26-2023).]

|

|

|

Will

|

DEC 02, 10:33 AM

|

|

| quote | Originally posted by Trinten:

I scored a pristine, no cracks, center console skeleton from the junkyard. Mike got the tail lights (notchie), we picked up some other odds and ends. But I won't be using that. Instead, I'll be using one of the fantastic 3D printed units from PFF's very own mmeyer86gt/gtp!

It showed up in a very compact box, very well packaged (each piece was wrapped in bubble wrap). Looks pretty spiffy!!

|

|

I could go for one of those... link to thread?

|

|

|

Will

|

DEC 02, 10:34 AM

|

|

| quote | Originally posted by Trinten:

I will be replacing it with Thermo-Tec insulation, part 13590. I emailed them describing where it was going to be used, and this is what they suggested, so, we'll give it a shot!

I also have some TechFlex SRF28.0SV material that we'll be using in other temp critical places, like on the manifold shields (definitely the inside of them).

|

|

Thanks for sharing the specific products you're using!

|

|

|

Trinten

|

DEC 02, 12:07 PM

|

|

|

|

Trinten

|

DEC 08, 11:03 PM

|

|

Last weekend I did not get to doing the engine bay stuff. Mike had other people dropping by, and I took a detour to get the new tires put on my stock Vette wheels. Sometime in the future I will need to budget to either replace these or get them stripped and re-chromed, it's bubbling up in more places. Doesn't look bad, but they're showing their age. I didn't bother with pics of those.

So what did get done, you ask? Well, Mike had finished up the mods to the engine cradle to allow safe clearance for the belt. So accessories are finalized.

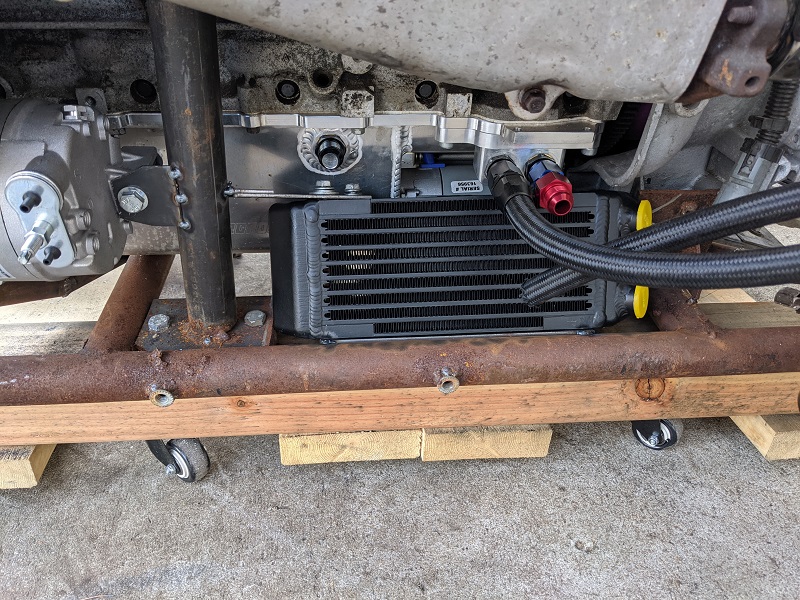

He also tacked in the mounting points for the oil cooler. Even though it doesn't appear there will be much air flow there, Mike says it'll be okay and he's going to be putting some scoop/ducting under there at some point. And even ambient cooling is going to help a little. The red/blue AN fitting is for mock-up, a black one was delivered, it also has the port on there for the turbo-oil feed.

I had gotten some fittings to replace the stock coolant fittings on the 4T80 with ones that had AN connections, discovered one of them had this weird little tube on it. ICT made ones for the 4L80. We hoped they would be the same... they are a touch different. Thankfully we know someone with a lathe! So it'll be turned down a little.

Mike gave me a list of other fittings to get so he can finish the oil and fuel line connections, including the connection for the flex fuel sensor. ICT had some really nice ones that I liked, but didn't have the right AN size on them. I didn't want to put in size reducers if I didn't need them, so I got others from Earl's. Hopefully they'll work just as well!

We also hunted for the parts to get the rear corvette sway bar tacked/mocked up... but they were displaced. Replacements are easy to get, Mike (correctly) says they should be around there somewhere, and not to order them yet. He's going to try to find them. This is one of the rare instances where I couldn't put my hands on one of the parts within a few minutes.

Once all the remaining hoses are made, and rear sway bar mock up is done, drivetrain will go back into the car for a test fit. If there are no issues, it'll come back out, drivetrain comes off, final welding, and off it goes for powder coating!

Excluding A/C hose, that'll be almost last - I need to get another Fiero A/C hose and a GXP LS4 hose and take them to the hydraulic hose shop that has done other things for me, ask them to work their magic on those once we know the hose length.

Once it's back, we need to take measurements for axles and get those ordered. All the new rear suspension components will go on then. Then it's wiring! So. Much. Wiring.

Oh, and I'm still waiting on a back-ordered hose to connect all the A2W intercooler components (heat exchanger, tank, pump, actual intercooler). That should be here by the end of the month. If it isn't, I'll cancel the order and chase it down someplace else.

Sadly, the delays in getting things done are making me worried about having the car ready to go to Pisa in time for all of the body mods and paint. I really wanted that to be done in 2022, so the car would be "Show & Go" ready for the 40th. Right now, it looks like it'll be more that SNL skit from the 80s, where it showed a car that was just totally terrible on the outside to deter thieves, but had awesome performance and interior. ... I probably won't put the awesome interior in until the body is done. Just doesn't seem right.

Speaking of interior parts. I had a facepalm moment. Three trips to the junkyard to get things off the Fieros, and I never considered the big seals that go around the door opening to seal around the door/door-glass. So that is on my go back and check out, see if it's still in good shape and get that off the cars. If anyone has ever removed that seal and can give any tips on how to do it without tearing it, I would appreciate it. Is it just glued in? Do I just use body panel tools and a lot of patience?

And lastly, I got stuff from Rodney to rebuild a few sets of the 87-88 headlight motors! Though the gears looked good in the two I took apart, I went ahead and got a set of Rodney's metal gears, along with a few sets of the delrin pins and gaskets and ball bearings. Better to have extras, right?

[This message has been edited by Trinten (edited 03-26-2023).]

|

|

|

Will

|

DEC 09, 09:46 AM

|

|

| quote | Originally posted by Trinten:

Speaking of interior parts. I had a facepalm moment. Three trips to the junkyard to get things off the Fieros, and I never considered the big seals that go around the door opening to seal around the door/door-glass. So that is on my go back and check out, see if it's still in good shape and get that off the cars. If anyone has ever removed that seal and can give any tips on how to do it without tearing it, I would appreciate it. Is it just glued in? Do I just use body panel tools and a lot of patience?

|

|

I'm not sure they're even glued in... just grip the pinch weld around the door.

The Fiero Store used to have door weatherstrip, but I don't see it on their website now.

|

|

|

Trinten

|

DEC 09, 10:12 AM

|

|

Yeah it's one of those "wish I would have bought it when...." items. I even found the GM part number for it and googled it. It came up on a bunch of those "GM Direct" sites (which a lot of them are actually the same company, just different DBAs). So of course it was "sold out" / "discontinued" everywhere I looked so far.

If anyone had a new set they would be willing to part with, I would definitely make sure they made a profit on it! Last time I posted about it in the mall, I didn't have any luck with any that were in better shape than mine.

|

|

|

Trinten

|

JAN 25, 12:58 AM

|

|

So we are getting to some of the smaller and time consuming stuff, where we realize we need a particular fitting after figuring out the best way to route something.

The oil hoses is now all buttoned up.

The steamvent kit I got from TrickFlow is nice, and modular (it uses AN fittings), which is great because Mike wasn't completely happy with it (and the fittings let others adjust things to deal with clearance issues). It's mostly done but I have a few more fittings on the way.

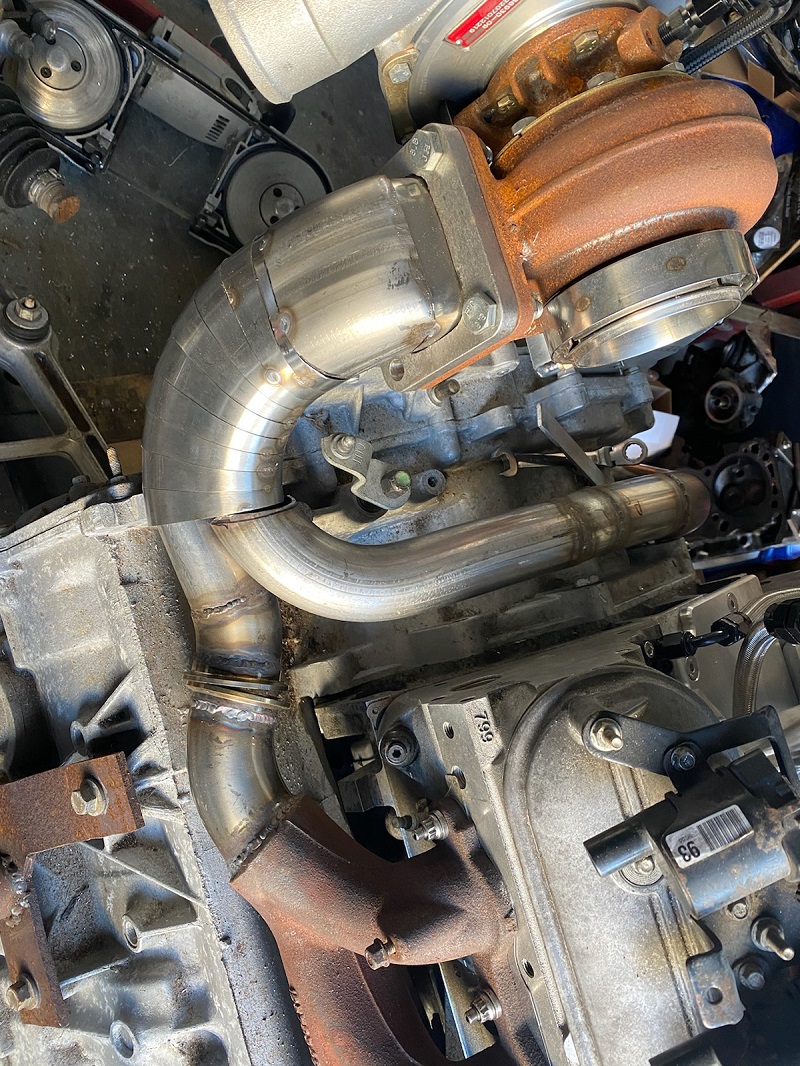

Mike has the MAC Turbo solenoid mounted and made a neat shield for it to help protect it from heat. This will be in addition to getting the turbo housing coated and slapping a turbo blanket on it.

He also made a shield that will protect the fuel line from the belt, in both unexpected movement/contact abbrassion, or catastrophic belt failure (though with that greenstripe belt, it's not supposed to do that). I thought I took a picture of that mounted, but... I didn't? So I'll have to add that one later.

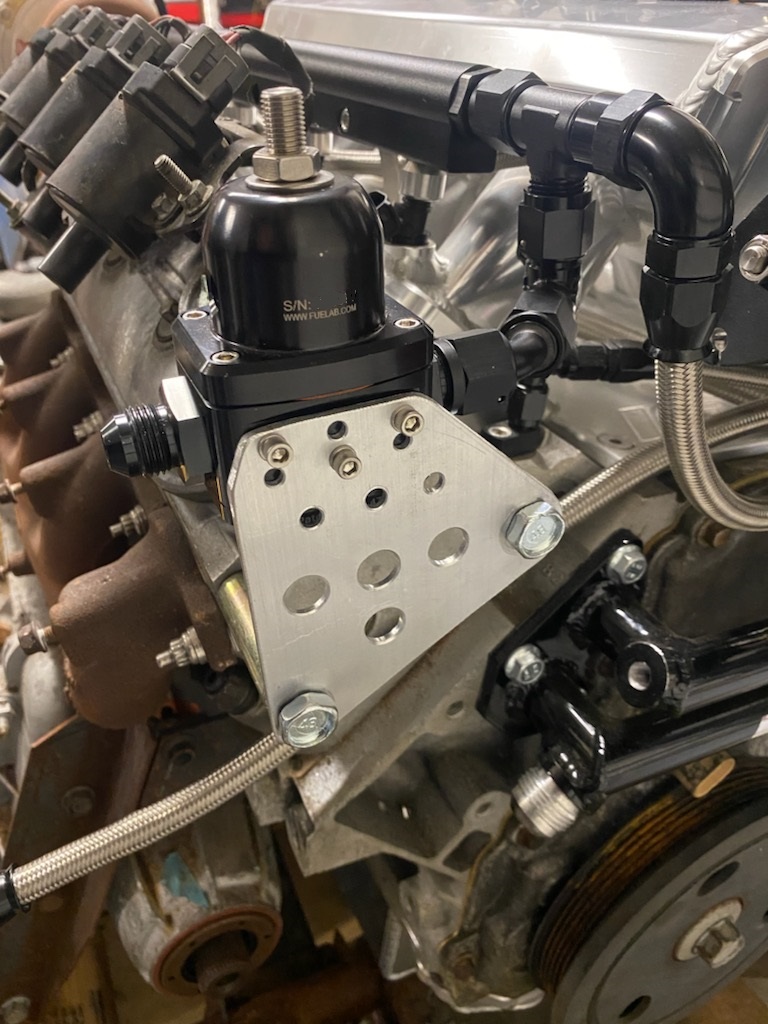

The fueling hoses are 99% routed and buttoned up. Fuel pressure regulator mounting bracket is done!

Smaller bit of flair, the ECU mounting bracket was powdercoated

Lastly, I took advantage of a sale that Discount Tire had going on. So I bought my Michelin's for the daily-driver wheels and got those mounted and balanced. One of the wheels required a fair amount of balancing weights. Sadly with the big spaces between spokes, it's easy to spot if the wheel is in the 4ish-to-8ish position.

I also made sure these tires had the same ratio for the front and back, making the outside diameter of the back wheels a little bigger, helps give the car a tiny bit of rake, which I like.

When I go to put tires on the z06 wheels, the backs will get DOT slicks, since those will be for the track, but still stand up to being (carefully) driven on roads so I don't need to trailer the car there or back.

Transmission note: Brandon Furches told me that I should make sure the piston was flipped around on the 2-3 shift. I emailed Dave at Triple Edge Performance. He couldn't remember if he had done this on my transmission. Brandon said it was the only thing that failed on his first 4T80E transmission, and he hasn't any any issues since doing that mode on bone-stock transmissions, so Mike and I will be opening the transmission up to get to that. I've bought the J-Kent parts to put the 4T80E in an tramission stand. Which requires two parts.

More fittings and sensors have been ordered. Mike wants to start mocking up the engine harness, starting by using the stock engine harness. Then once all the lengths and modifications are figured out, he'll use the new wiring to make a spiffy new harness.

Pretty soon the drivetrain will come off the cradle, final welds will be done on it, and then it'll go off for powdercoating.[This message has been edited by Trinten (edited 03-26-2023).]

|

|

|

Trinten

|

FEB 01, 11:02 PM

|

|

This weekend we put heavier duty wheels on my drive train skid.

We got a few more fittings for hoses and finished buttoning up the fuel system, including getting the fuel pressure transducer in the circuit. All of the steam vents are setup, and the port for it's tank is ready to go. The tank needs to be fabricated, we are running out of real estate, Mike has an idea of where he'll put it and how it'll be shaped.

He started doing the mock-up spot welds for the chargepipe and getting other elements of the exhaust.

A bunch of the stuff that was done is off for powdercoating now, including the valve covers. We were also going to measure for the pushrods, but we misplaced the tool I got to do it. The one Mike has doesn't have the right range. So that'll be on my task list to find next time. I checked the rolling tool cart that I saw it on a few months ago, no luck.

So here is mock-up progress.

[This message has been edited by Trinten (edited 03-26-2023).]

|

|

|

|