Fiero Store technician thinks:

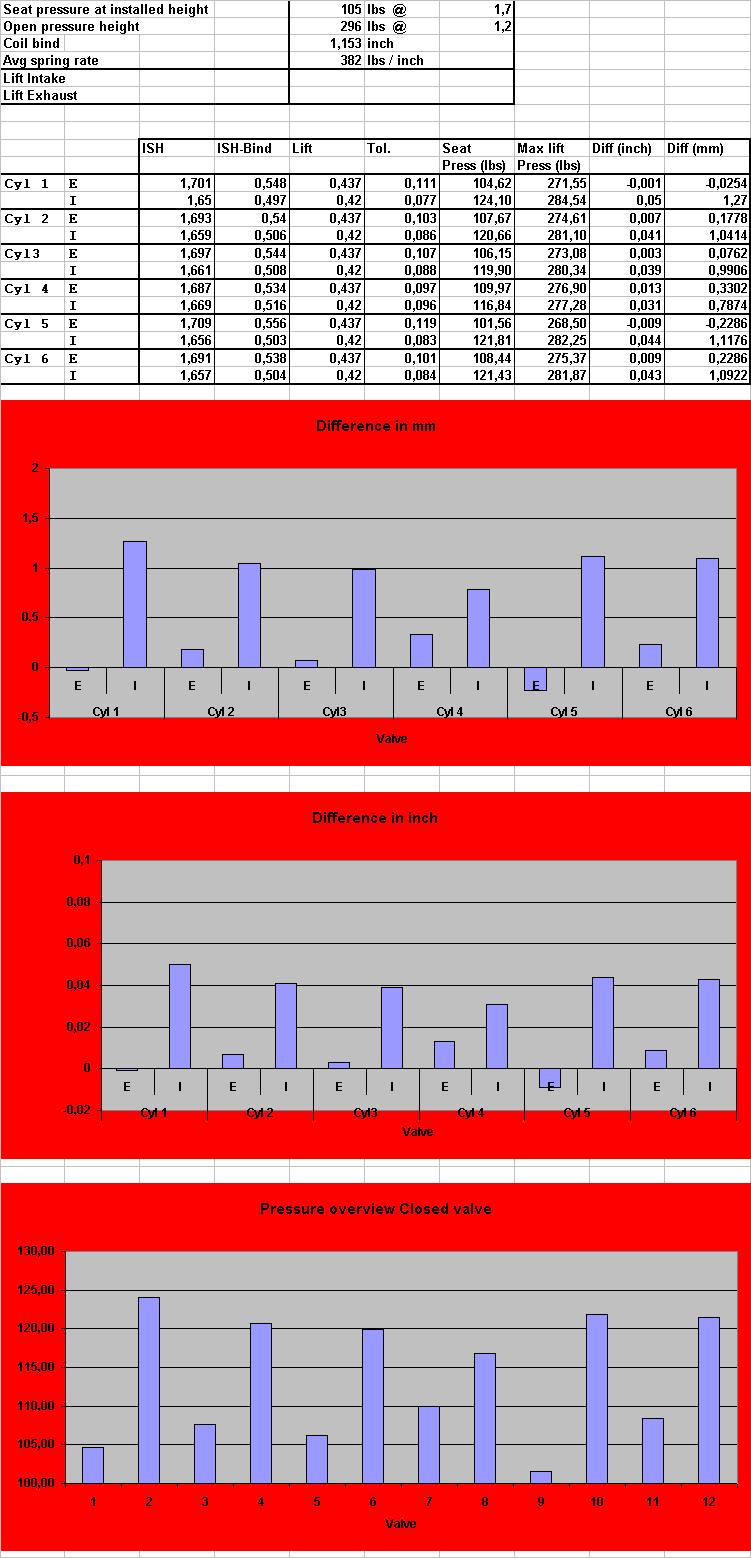

"We machine or shim accordingly to reach 105 on all valves. We do not

usually run pressures around 120. In this case, the spring seat of the

cylinder head should be machined to lower the spring height slightly

(which will also lower the seat pressure).

"

I guess they are right. To be on the safe side.

I added a column describing the actual diff (material to grind away) It is not Much really !

A related question:

I think I need to remove the studs to reach in with the milling machine.

Is there any feracious gremlins within the project to temporarily remove the studs ?

[This message has been edited by kjelle69 (edited 03-05-2008).]