I restored a set of rims from an '86 GT. The paint was pretty good but the edges were really bad.

Sanding wasn't going to cut it. I had to remove some metal. This is how I did it...

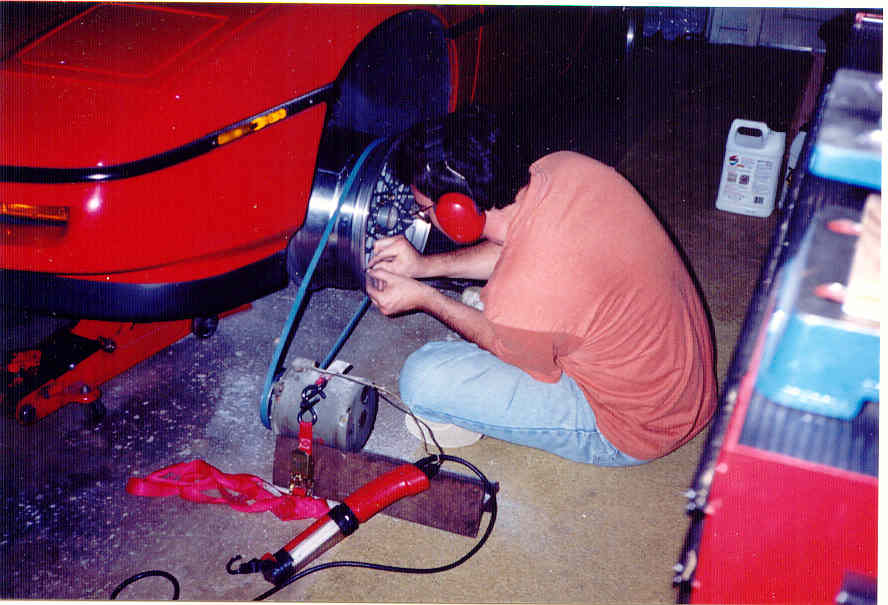

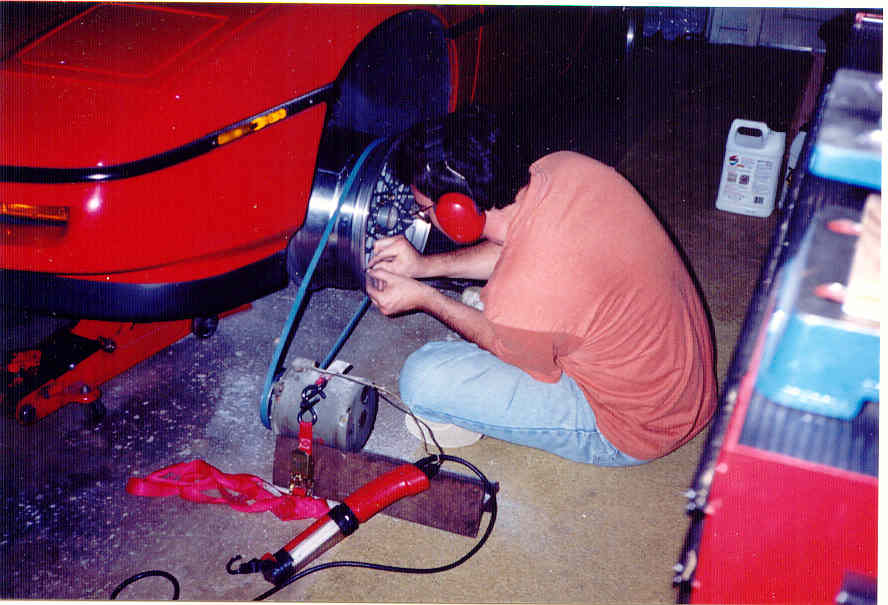

I strapped an old oil furnace motor to a short section of railroad rail.

A pulley and long lawn mower belt from the farm supply store got things going.

I think the motor was turning about 1750 R.P.M.

I used a carbide tipped cutter from my 7 x 10 lathe. After finishing with carbide

cutter I started to wet sand but found it made too much mess, so I took the

rims to the bathtub for about 8 hours (each) of wet sanding by hand.

I aways treated the rotating mass with great respect

and never had any trouble with tool kickback.

Using the powertrain of car didn't seem nessesary or prudent to me.

I didn't have to run the engine for extended periods of time and burn gas.

I was able to keep the garage door shut. (Winter time -20F)

I didn't have to run the cv joints and boots at extreme angles for extened periods.

If the wheel decided to reach out and grab me and not let go, the powertrain, even at idle,

would no doubt be quite merciless.

If I had to do this alot, I think I would rig up a circular trough around the rim edge to

do the wet sanding right in the garage.

[This message has been edited by cone shark (edited 03-15-2009).]