|

| LS4 / F40 swap - fieroguru (Page 154/197) |

|

fieroguru

|

MAY 12, 08:09 PM

|

|

It will take a few weeks to arrive, but I purchased one of these, bundled with all the options and the razor cut 45.

https://www.langmuirsystems.com/crossfire

I have wanted a CNC plasma table for a long time, but space has always been an issue. I like the footprint and cantilevered setup with this one, so I don't have to cut down the sheet to make it fit on the table. It has been 20+ years since I worked as a CNC programmer for several punch and burn machines... shouldn't take much to learn the included software package.

This will really open up my options for making parts!

|

|

|

ericjon262

|

MAY 12, 08:27 PM

|

|

|

I've been eyeing the same table up as well, but I don't think I will be getting one anytime soon. I look forward to seeing your results with it! ------------------

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

cognita semper

http://www.fiero.nl/forum/Forum2/HTML/119122.html

|

|

|

Trinten

|

MAY 12, 10:08 PM

|

|

That is so cool! I thought it would be WAY more money than that! Hell, decent sized lathes are more than that!

Think of all the awesome stuff you could fabricate on that! Heck, you could have a whole side business just zapping out stuff for people and shipping it to them. "You send me your cad file, I ship your reality!" (tm). lol

|

|

|

Will

|

MAY 14, 09:19 AM

|

|

| quote | Originally posted by fieroguru:

I have wanted a CNC plasma table for a long time, but space has always been an issue. I like the footprint and cantilevered setup with this one, so I don't have to cut down the sheet to make it fit on the table. It has been 20+ years since I worked as a CNC programmer for several punch and burn machines... shouldn't take much to learn the included software package.

This will really open up my options for making parts! |

|

I've whipped up a LOT of stuff with laser cut sheet and light plate... GREAT methods for making things!

|

|

|

Steel

|

MAY 14, 12:09 PM

|

|

The plasma CNC is pretty neat. It's $3050.70 shipped with all the accessories. I have no idea if the plasma cutter they can supply, or the torch head, is any good.

|

|

|

fieroguru

|

MAY 16, 09:58 PM

|

|

| quote | Originally posted by Trinten:

That is so cool! I thought it would be WAY more money than that! Hell, decent sized lathes are more than that!

Think of all the awesome stuff you could fabricate on that! Heck, you could have a whole side business just zapping out stuff for people and shipping it to them. "You send me your cad file, I ship your reality!" (tm). lol |

|

This is my most expensive tool purchase but it will likely create more opportunities for parts. My oldest is an aspiring artist, so he might learn how to use it as well to bring his art alive in metal.

| quote | Originally posted by Will:

I've whipped up a LOT of stuff with laser cut sheet and light plate... GREAT methods for making things! |

|

I currently have metal shapes cut for the 13" brake kits, Lateral Link Relocation Brackets, LS4 starter bracket, F40 shifter bracket. This table will make it even easier to expand my product line.

It will also be easier on my elbows... back when I was doing a lot more swap work and fabrication, my right elbow really took a beating from the 4 1/2" hand held grinder with a cutoff wheel. It took about 18 months to stop hurting, so letting this plasma table do as much cutting as possible well avoid aggravating my elbow. I still do a lot of grinding with a flapper disk, but that seems to be easier on my elbow.

| quote | Originally posted by Steel:

The plasma CNC is pretty neat. It's $3050.70 shipped with all the accessories. I have no idea if the plasma cutter they can supply, or the torch head, is any good. |

|

Yes with all the options and the 45A plasma the total is about $3K. I decided to use their supplied plasma (Razor Cut 45) to help speed up the setup, training, and programming. It can always upgrade the plasma cutter at a later date if I don't like it.

Timing is pretty good as I am getting close to needing to replenish my inventory of cut parts for several parts, which normally is about $2K. So with this machine, I can bring the cutting of those parts back in house and offset the cost of the purchase.

Today I was busy with fixing the lawn mower, mowing the grass, and processing a few orders. I am planning to pull the mockup LS4/F40 drivetrain back out of the car and continue work on the turbo manifold on Sunday (locking down the placement of the wastegate and getting it welded to the manifold).

|

|

|

fieroguru

|

MAY 17, 08:42 PM

|

|

Didn't get as much done as I had wanted... decided to leave the mock up engine in the chassis for a while, so I put the original one up on the cradle fixture to work on the wastegate placement.

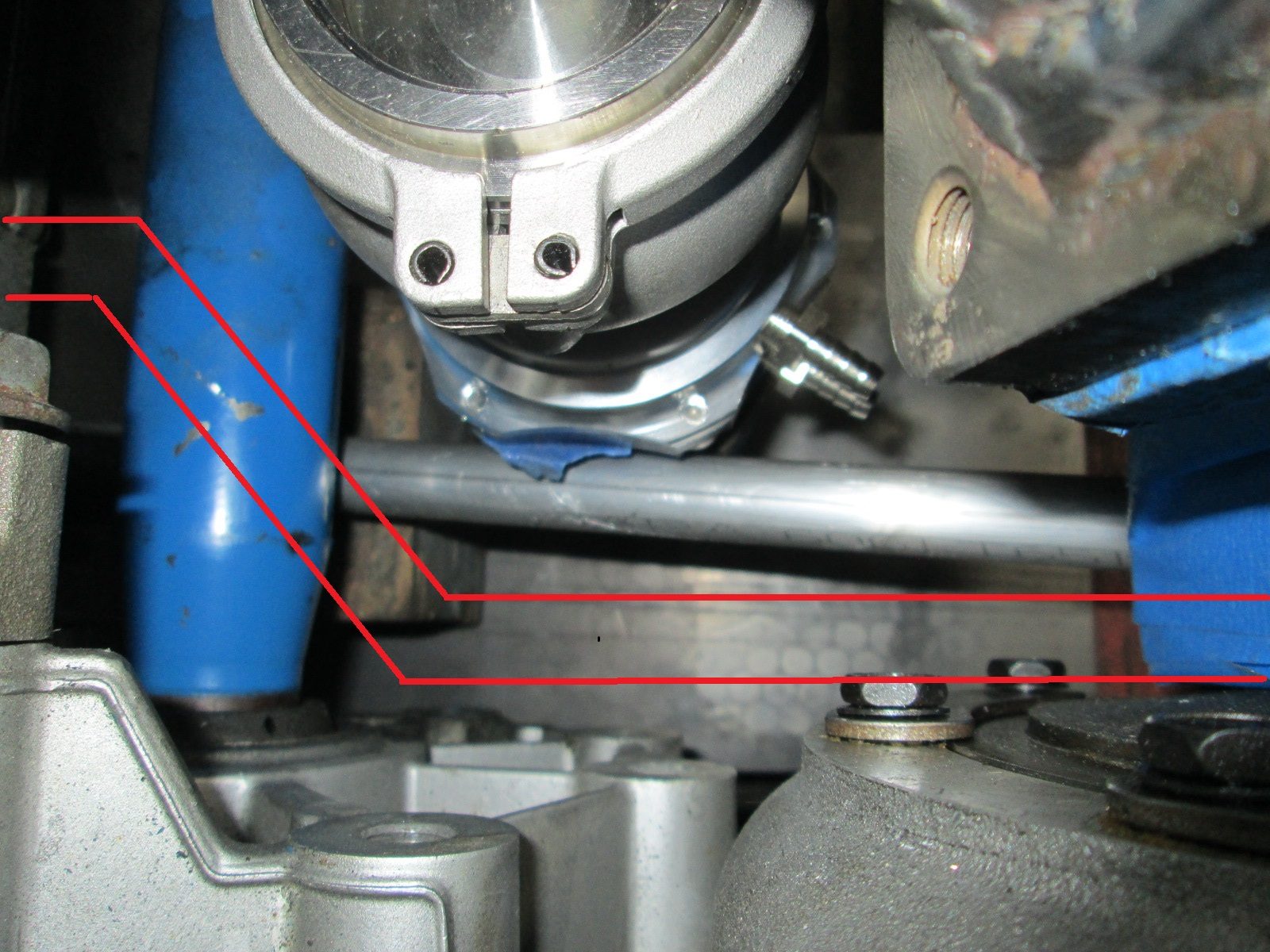

As I was exploring options, I determined the oil drain tube needs resolved first as it and the waste gate want to occupy the same space. I used some 3/4" tube to show the available drop as well as the needed path to the back corner of the oil pan and under the intermediate shaft.

I went ahead and ordered some 3/4" stainless tube and fittings for the oil line. My plan is to make a couple of gradual bends to route the drain around the wastegate as it goes to the oil pan. This will allow me to place the wastegate as close to the end of the manifold as originally planned. This is the general route, but all the bends will be very gradual.

|

|

|

fieroguru

|

MAY 24, 09:17 PM

|

|

My day job has the plant closed for 1 week due to low volume (so I took 4 days vacation), all current Fieroguru Performance orders are complete and shipped, the mower is fixed and the lawn mowed... so now the LS4/F40 Turbo will get some much needed focus for the next week. Turbo manifold, hot side piping, cradle & mounts are the primary goals.

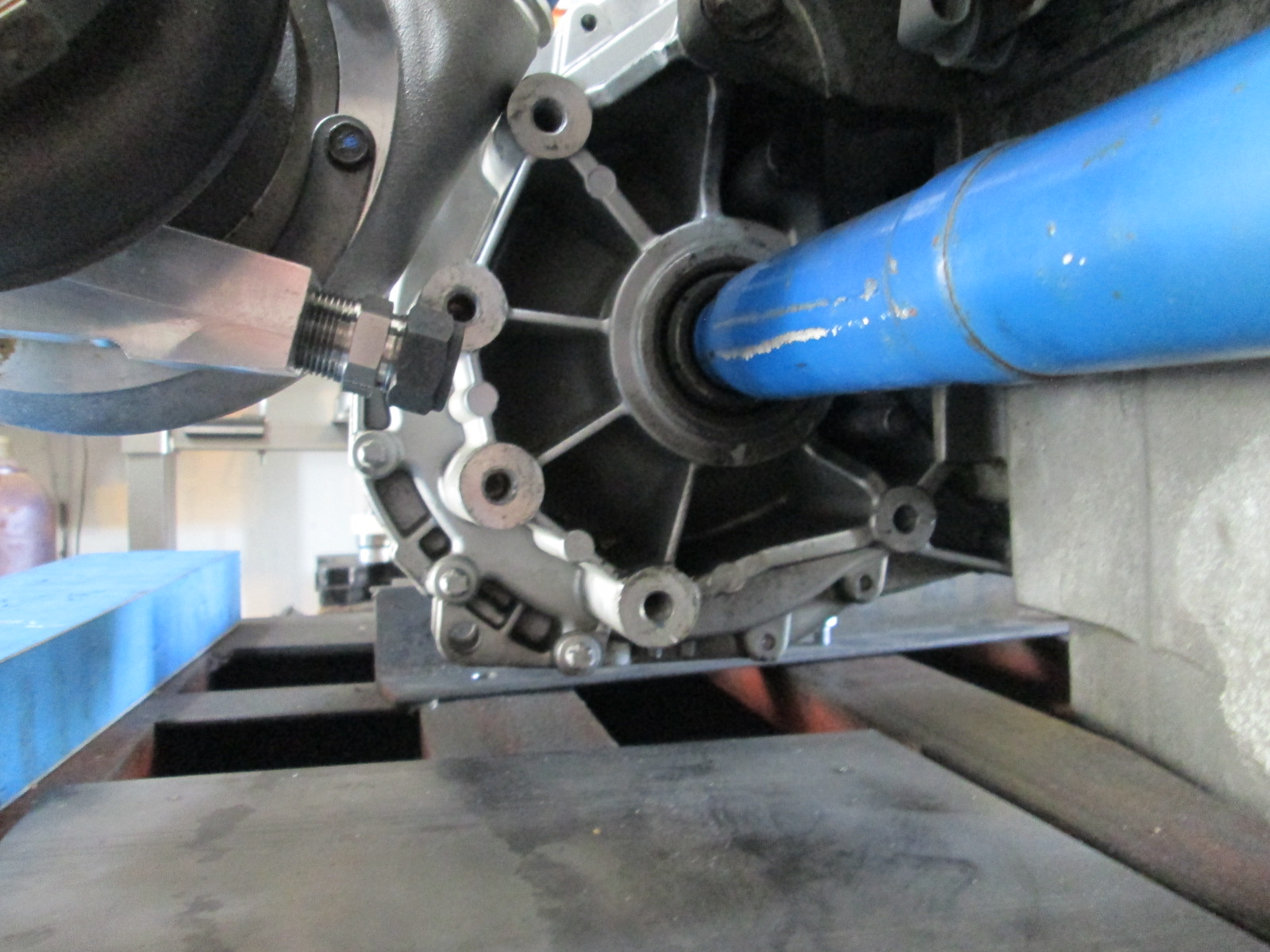

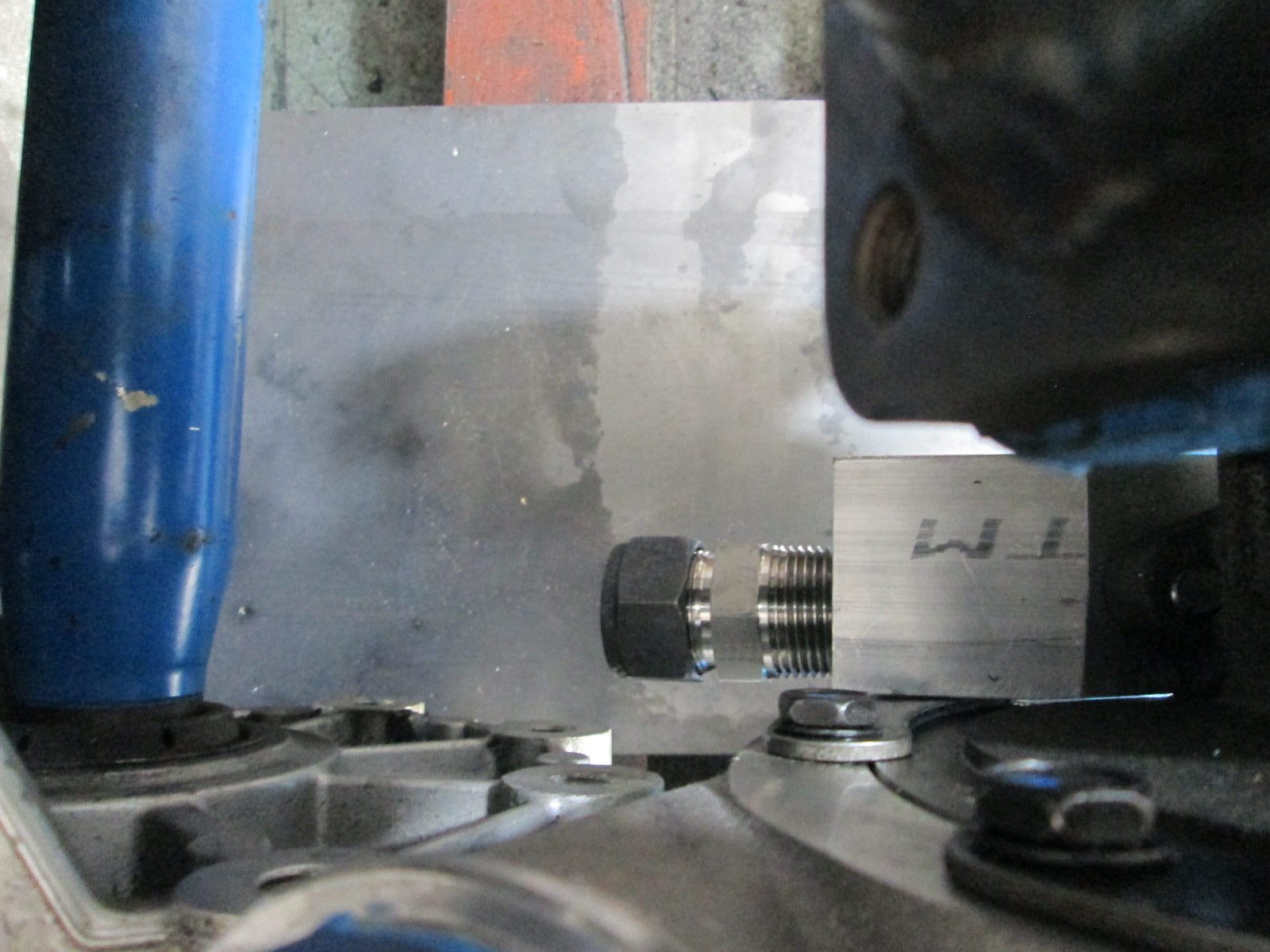

I messed with the oil return from the turbo today. I decided to make an aluminum block to accept the 3/4" tube fitting (3/4" OD, 0.040" wall) so it could be as high as possible. This will give me a little larger than 5/8" ID with a smooth wall @ 12o slope to the oil pan, which should work fine. The oil inlet has a built in orifice (about 0.040"), so the drain is much, much larger.

I will be removing about 3/8" to 1/2" length from the block to pull the fitting back closer to the turbo. Once I have everything figured out, I will likely make a prettier one, but that will be a little later. I want to get to the stage where I can bend up the line and route it to the oil pan so I can finalize the wastegate placement and weld the fitting on the manifold.

|

|

|

Will

|

MAY 24, 10:07 PM

|

|

|

Where's the "transfer case" going to go?

|

|

|

fieroguru

|

MAY 25, 08:13 AM

|

|

The AWD conversion is a couple years off, so I am taking the path of least resistance to get the car running with the turbo this summer.

When I design and machine the awd case, I will move the wastegate and try to route the oil drain through the new AWD case. Worst case I switch to a scavenge pump.

I want to be driving and enjoying the Fiero with 500+ whp while I work on those issues. The car has already been out of service for far too long...

|

|

|

|