|

| LS4 / F40 swap - fieroguru (Page 153/197) |

|

Will

|

APR 15, 10:00 PM

|

|

| quote | Originally posted by fieroguru:

My plan has always been to run a 1 way clutch in the drive shaft to the front diff. With the smaller front tires, the front will always over run (rotate faster than) the rear. When there is zero slip at the rears, the front just spin as normal w/o any power applied (they are effectively being pushed faster than the engagement RPM of the power). When the rears do slip (on hot dry pavement), and try to rotate faster than the fronts, the 1 way clutch will engage and send power to the front wheels. The fronts will then try to put an end to the wheel spin while helping to pull the car in the right general direction. One the rear slip subsides, then the fronts go back to their free wheeling... that at least is the thought/theory... Simple 100% mechanical AWD on demand w/o the typical binding in parking lot maneuvers. |

|

Sounds like that's going to have pretty harsh engagement. Are you expecting that actual spin or only slip at the rear will engage the front? Engaging on slip will be gentler/smoother, but you'll have to have the speeds closely enough matched that differential tire wear front to rear over the life of the tires may cause an issue.

|

|

|

fieroguru

|

APR 16, 09:25 PM

|

|

|

With my current wheel/tire sizes it would only take about an inch or two of slip to match rotation front rear and start transitioning power, so the rears can't really get away to much before the fronts will come into play. With early engagement, some good rubber mounting of the front diff and possible rubber isolation within the driveshaft, transition of power shouldn't be too harsh.

|

|

|

fieroguru

|

MAY 09, 05:16 PM

|

|

Last few weeks have been super busy... but I finally have a free weekend to focus on the LS4/F40...

With the HRPT being delayed until late August, I am back focused on installing the turbo. Put the mockup engine/transmission/cradle on the fixture. Used the drivetrain support brackets to properly locate the engine/transmission to the cradle, fabbed up some temporary solid mounts so I could test fit the turbo manifold/turbo to my chassis and verify clearance to the trunk.

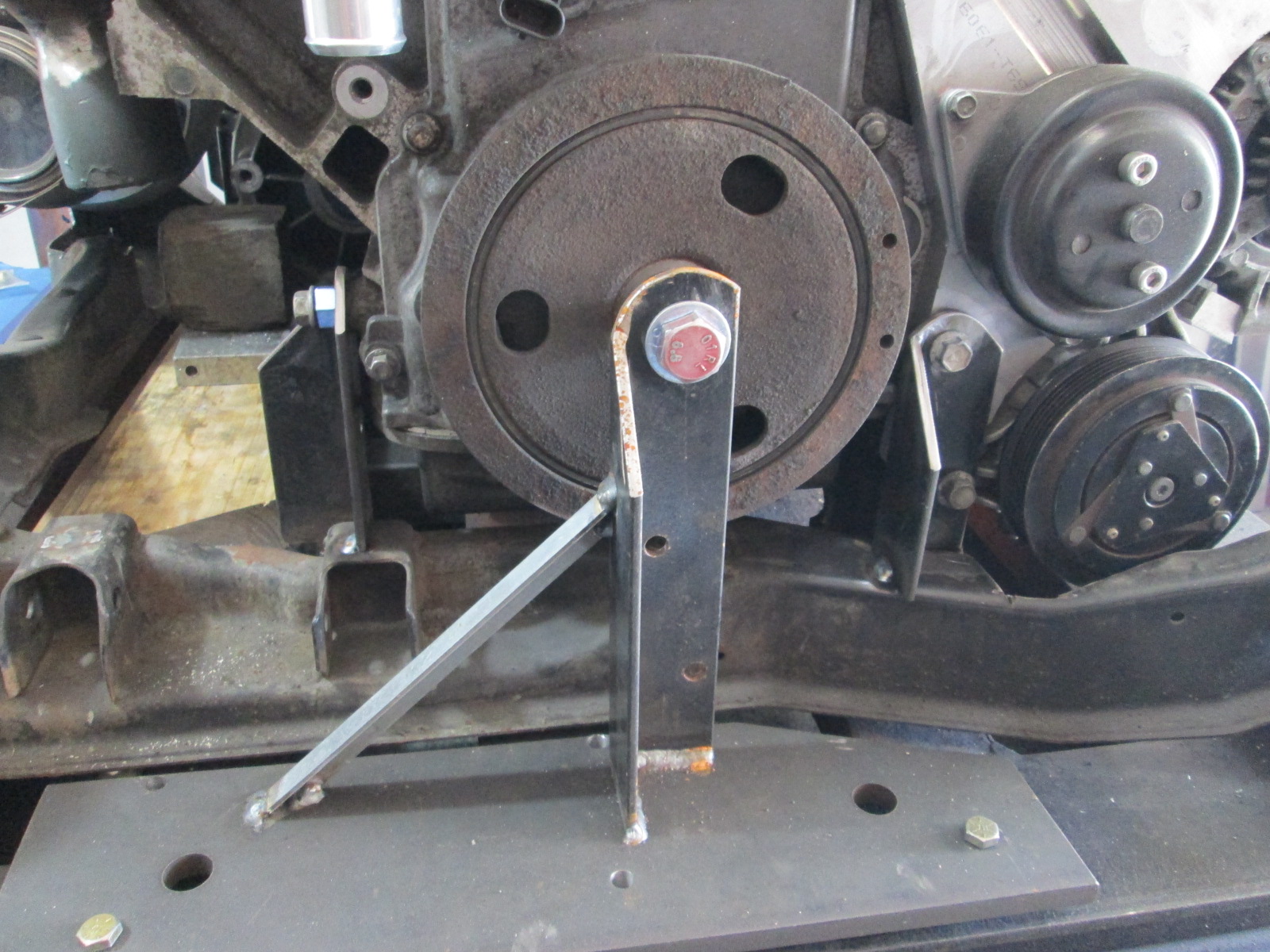

Here is are the engine side solid mounts (just for locating):

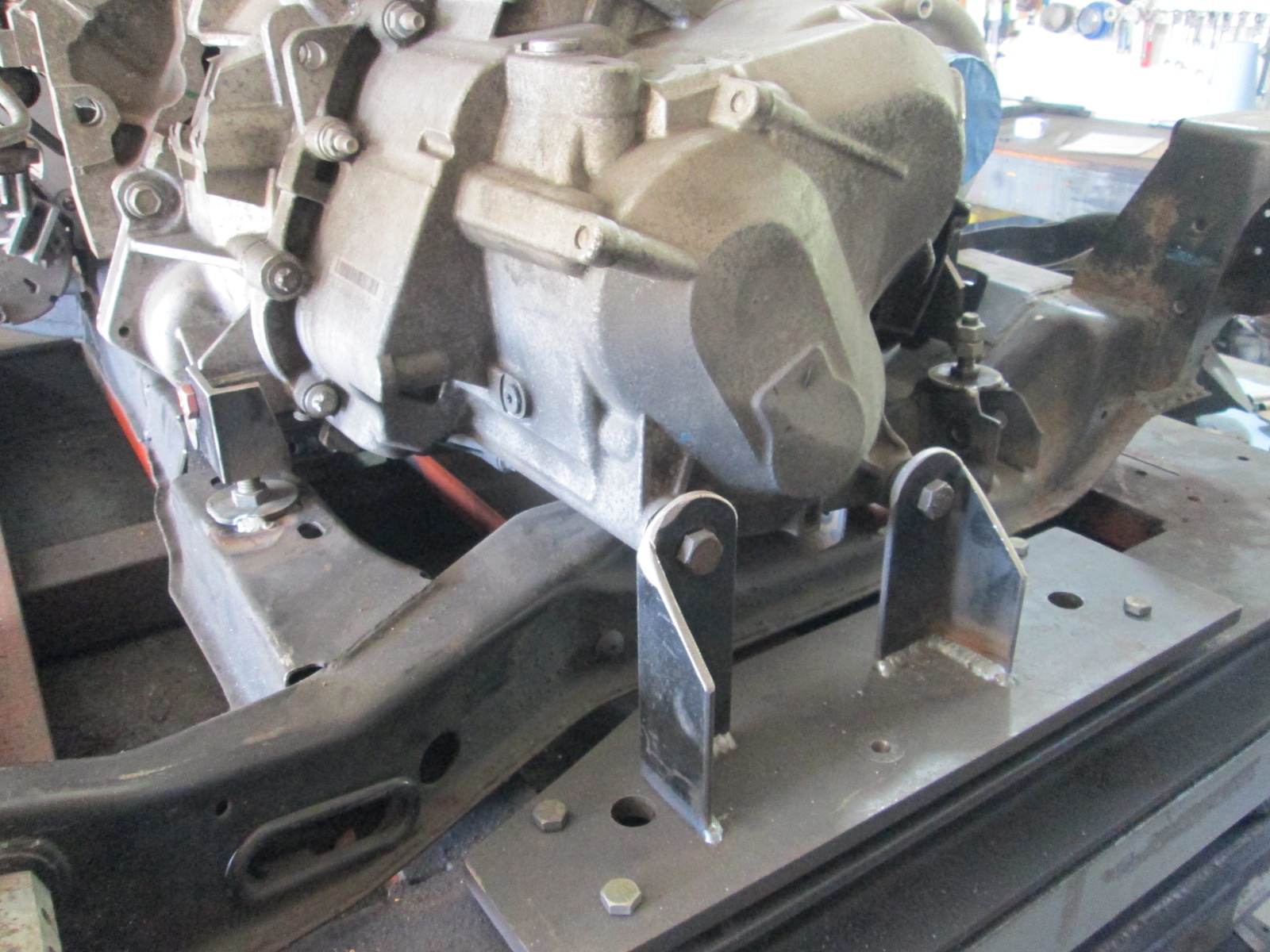

Here are the transmission side solid mounts (just for locating):

Turbo:

Engine in car. Turbo clears the stock trunk and is quite hidden!

I think it is time to commit to this turbo placement and fully weld on the flange.

|

|

|

Trinten

|

MAY 09, 10:40 PM

|

|

|

Will you build up the inside and outside of the trunk with a lot of heat insulation/shielding? I thought turbos get pretty hot, I could imagine the carpet in the trunk melting/catching fire.

|

|

|

ericjon262

|

MAY 10, 01:46 AM

|

|

| quote | Originally posted by Trinten:

Will you build up the inside and outside of the trunk with a lot of heat insulation/shielding? I thought turbos get pretty hot, I could imagine the carpet in the trunk melting/catching fire. |

|

I was thinking the same thing.------------------

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

cognita semper

http://www.fiero.nl/forum/Forum2/HTML/119122.html

|

|

|

fieroguru

|

MAY 10, 09:12 AM

|

|

Metal heat shields with an air gap work wonders.

There will be a stainless heat shield around the exhaust scroll and a heat shield riveted to the truck wall with an air gap as well. This will provide 2 shields and 3 air gaps of separation from the turbo scroll and the truck wall.

The top of the truck manifold will have the OEM heat shield installed as well.[This message has been edited by fieroguru (edited 05-10-2020).]

|

|

|

Will

|

MAY 10, 11:19 AM

|

|

|

I've heard turbo blankets actually work better than discrete heat shields.

|

|

|

qwikgta

|

MAY 10, 05:03 PM

|

|

with this new setup, are your running lower on the cradle? did you always need to cut into the cradle for the A/C? Seems like your setup is lower than the previous one. Older pics don't show the cradle cut up at the A/C location.

Rob

|

|

|

fieroguru

|

MAY 10, 07:41 PM

|

|

| quote | Originally posted by Will:

I've heard turbo blankets actually work better than discrete heat shields. |

|

That is an option as well.

I was planning to get a 3 1/2" donut and cut/trim/modify a close fitting heat shield around the scroll.

| quote | Originally posted by qwikgta:

with this new setup, are your running lower on the cradle? did you always need to cut into the cradle for the A/C? Seems like your setup is lower than the previous one. Older pics don't show the cradle cut up at the A/C location.

|

|

The engine is at the same elevation if not a smidge higher. The issue is the alternator... it is a monumental pain to mount. My goal is for as many parts to be aluminum vs. welded steel brackets. The old setup had the alternator bracket wrap around the top and bottom of the A/C compressor, which allowed the A/C compressor to be higher. With the aluminum mount solution, the A/C compressor has to be lower to make room for the lower alternator bracket.

Don't fret about the trimmed cradle... it isn't staying. This car will be getting a tubular rear cradle. Partially to save weight that is being added with the turbo, partially to make the rear sway bar fit (needs to be mounted lower) as the turbo is in the way for the stock location. I should pick up the material for the cradle later this week.

The plant is down the week of Memorial day, so hopefully I can make some good progress that week (and in the weeks leading up to it).[This message has been edited by fieroguru (edited 05-10-2020).]

|

|

|

fieroguru

|

MAY 10, 07:57 PM

|

|

|

|