|

| The White Bug (Page 5/42) |

|

pmbrunelle

|

MAY 16, 07:42 PM

|

|

TiAL acknowledged that yes, the BOV will open during overrun.

However, they maintained that positive pressure will be maintained upstream of the throttle body whenever the BOV opens... I guess because the turbo is spinning anytime the engine is running. So normally, dirt should not come in; it should be blown out.

They did suggest that if I was driving in a very dusty/dirty environment, then a conservative approach would be to use their recirculating BOV, either with a small air filter on it, or routed back to the airbox.

|

|

|

Spadesluck

|

MAY 17, 11:34 AM

|

|

|

I have never given much thought to a BOV ingesting during deceleration not have I seen any talk about it. Most just talk about the springs rates for opening and closing during desired operations. I myself would not be overly concerned about it. I would be most concerned for the BOV working properly during let off so I do not hurt the motor.

|

|

|

pmbrunelle

|

JUN 09, 10:19 PM

|

|

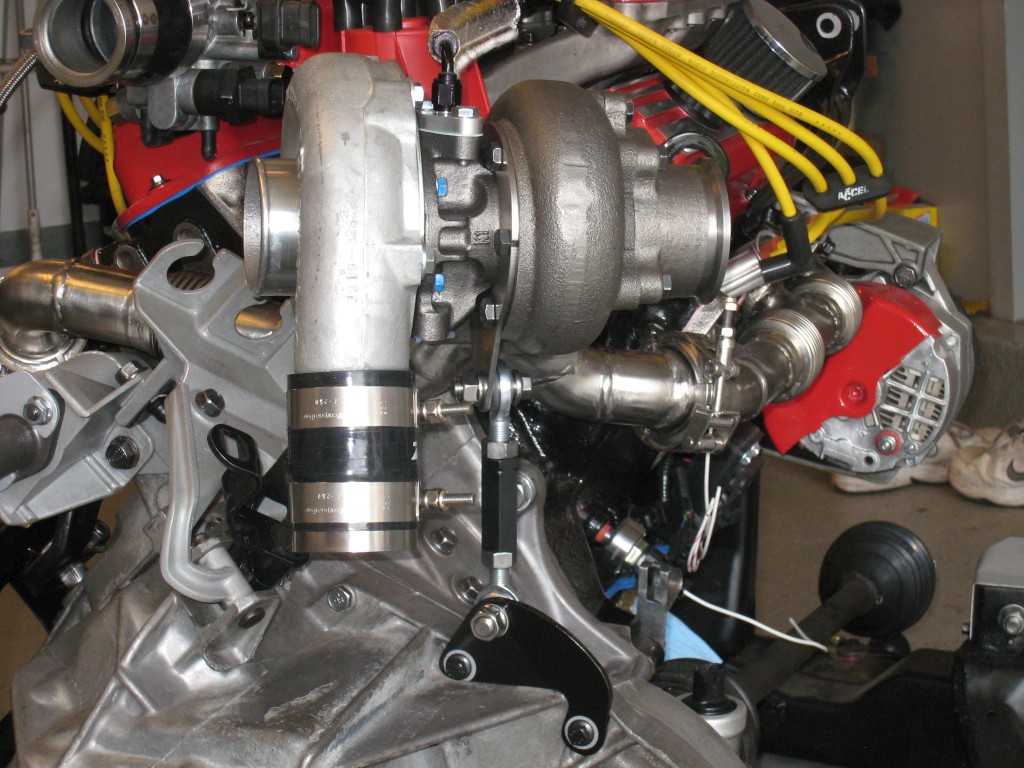

I finished the exhaust up to the turbine inlet. I am using the stock log manifolds, but with bellows in between the ports. With the bellows, each segment of the exhaust can grow independently as they get hot, without developing undue stress.

The same reasoning applies to the bellows in the crossover pipe.

The bellows fit underneath the stock front manifold heat shield, provided that I hammered the AC compressor clearance bump flat. Since I don't have AC, no problem there.

I'm using the Volkswagen exhaust port gaskets. They have a stainless steel exterior; looks like they won't blow out.

The compressor housing is quite close to the shift cables, but I should still be able to install/uninstall them. I successfully tested this theory with the engine+cradle in the car, as if I were doing it for real.

The shift cables come really close to the crossover pipe; I'll have to come up with some sort of heat shield, in addition to the insulating sleeves that come on the Rodney Dickman cables.

Right now the turbo is supported only by the exhaust. An additional support to hold the turbo's weight is presently in the works.

|

|

|

La fiera

|

JUN 28, 10:02 PM

|

|

| quote | Originally posted by pmbrunelle:

I finished the exhaust up to the turbine inlet. I am using the stock log manifolds, but with bellows in between the ports. With the bellows, each segment of the exhaust can grow independently as they get hot, without developing undue stress.

The same reasoning applies to the bellows in the crossover pipe.

The bellows fit underneath the stock front manifold heat shield, provided that I hammered the AC compressor clearance bump flat. Since I don't have AC, no problem there.

I'm using the Volkswagen exhaust port gaskets. They have a stainless steel exterior; looks like they won't blow out.

The compressor housing is quite close to the shift cables, but I should still be able to install/uninstall them. I successfully tested this theory with the engine+cradle in the car, as if I were doing it for real.

The shift cables come really close to the crossover pipe; I'll have to come up with some sort of heat shield, in addition to the insulating sleeves that come on the Rodney Dickman cables.

Right now the turbo is supported only by the exhaust. An additional support to hold the turbo's weight is presently in the works.

|

|

Nice set up! When is it going to be ready?!

|

|

|

pmbrunelle

|

JUN 28, 11:58 PM

|

|

Hopefully I'll be able to take the car for a spin a few times sometime before it snows, around November.

I've done a good amount of the work so far; I see the light at the end of the tunnel.

I try to think a few steps ahead, so that I have the right parts/supplies already on hand when I need them.

I've been thinking about the first startup, and how I should use motor oil with ZDDP or other magical ingredients to reduce the risk of wiping a cam lobe in the first half-hour of life.

So far, I have identified Redline-brand oil as a candidate:

https://www.redlineoil.com/15w40-diesel-motor-oil

I can buy this locally.

It says "WITH EXTRA ZDDP FOR WEAR CONTROL" right on the bottle.

Previously, I used 15W-40 Shell Rotella T in my Fiero, but as time goes on, I'm not even sure if that's good oil anymore.

Canadian Tire has this fake zinc stuff:

https://www.canadiantire.ca...ditive-0380268p.html

However, the Hy-per Lube doesn't have the reputation of ZDDP, so I don't feel like betting my engine on it.[This message has been edited by pmbrunelle (edited 06-29-2019).]

|

|

|

Dennis LaGrua

|

JUN 29, 09:05 AM

|

|

|

Very Impressive build, neat, clean and well put together. Your knowledge of automotive electronics is also a cut above the rest. The engine should really run nice. ------------------

" THE BLACK PARALYZER" -87GT 3800SC Series III engine, custom ZZP /Frozen Boost Intercooler setup, 3.4" Pulley, Northstar TB, LS1 MAF, 3" Spintech/Hedman Exhaust, P-log Manifold, Autolite 104's, MSD wires, Custom CAI, 4T65eHD w. custom axles, Champion Radiator, S10 Brake Booster, HP Tuners VCM Suite.

"THE COLUSSUS"

87GT - ALL OUT 3.4L Turbocharged engine, Garrett Hybrid Turbo, MSD ign., modified TH125H

" ON THE LOOSE WITHOUT THE JUICE "

|

|

|

Frenchrafe

|

JUN 29, 11:42 AM

|

|

Like Denis said: Very impressive build!

I had been tempted to do up my old 2.8 into a turbo setup, rather like that Fiero that lives in Norway I belive.

Good on you to do such a well thought out 60° V6 turbo build!

Rafe

PS : Thanks for the tip in using bellows on the exhaust manifold logs - I'll be doing this the next time when mine crack again!------------------

'87 Fiero GT. 3800 turbo. Sticky tyres. Driven hard!

|

|

|

pmbrunelle

|

JUN 29, 08:38 PM

|

|

| quote | Originally posted by Dennis LaGrua:

Your knowledge of automotive electronics is also a cut above the rest. |

|

I work in the design of automotive electronics, so that may clarify things...

| quote | Originally posted by Frenchrafe:

PS : Thanks for the tip in using bellows on the exhaust manifold logs - I'll be doing this the next time when mine crack again! |

|

I think it's a good idea, but I'll only know for sure once I have some miles on the car![This message has been edited by pmbrunelle (edited 06-29-2019).]

|

|

|

pmbrunelle

|

JUN 30, 04:29 PM

|

|

Here the turbo support is installed. Its function is to support the weight of the turbo, to take the weight off the crossover pipe.

I'm using a RH-LH pair of 7/16"-20 rod ends threaded into a hex rod. Since the crossover pipe sags by 0.008" under the weight of the turbo, I simply crank up the rod-end assembly to raise the turbo's position by 0.008". The idea is to put the crossover pipe into its "zero-stress" position.

I was inspired by seeing many 80s turbo Formula 1 engines having this kind of setup.

Honda RA166E: https://upload.wikimedia.or..._Collection_Hall.jpg

Renault EF4: https://upload.wikimedia.or...n_Player_Special.jpg

TAG-Porsche: https://upload.wikimedia.or...t_Porsche_Museum.jpg

However, it's not because this design is found on race cars that it's suitable for a street car. I guess I'll see what happens.

|

|

|

Will

|

JUL 01, 09:48 AM

|

|

|

That does look like a fun setup. Do you have your plate laser or water-jet cut?

|

|

|

|