|

| The White Bug (Page 4/46) |

|

pmbrunelle

|

MAR 27, 09:11 PM

|

|

Well, when I started the dream of having a turbo Fiero some 10-odd years ago, I bought myself an ebay turbo.

Since I plan on installing the turbo soon, I decided to do some last-minute checks:

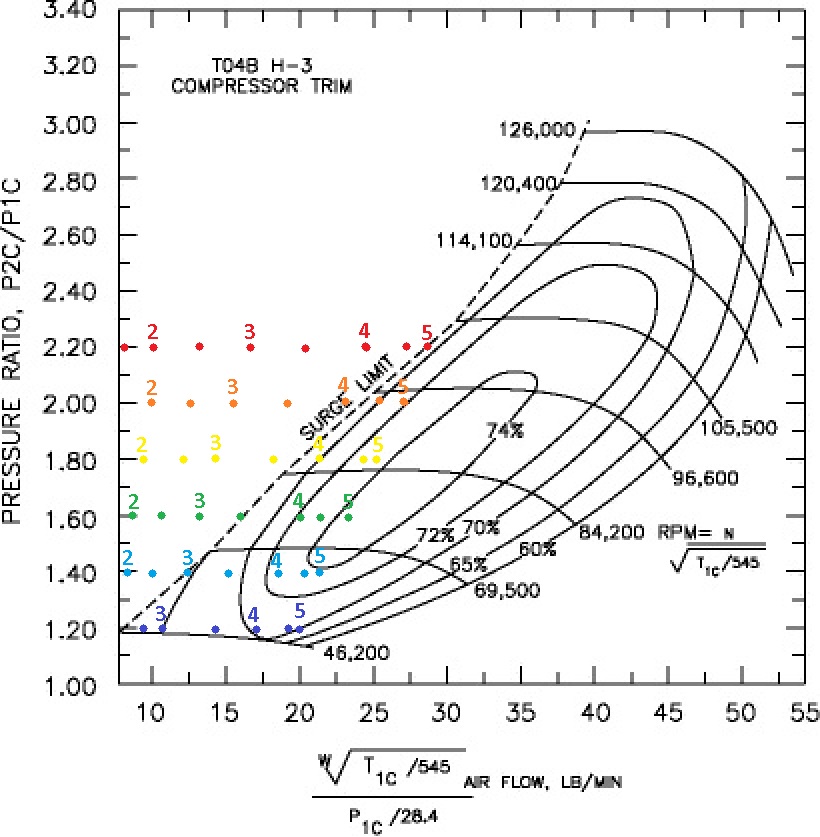

In this graph I am overlaying the engine's expected working points over the map of my compressor.

Basically, this turbo does not appear to fit whatsover with my engine. When I bought the turbo, I didn't know how to interpret a compressor map.

Now I'm investigating if I can just change compressor wheels (T04B S-trim or T04B V-trim), or maybe I want to change the entire turbo. To avoid throwing away too much hardware, I want to stay with an internally wastegated T3 turbine, and a compressor housing with a 2.75" inlet / 2" discharge. The Garrett GT3071R appears to be a good match, but I don't know if I want to spend for a whole new turbo. On the other hand, being too much of a cheapskate is expensive when things go wrong, so further study is required.

|

|

|

pmbrunelle

|

MAR 30, 01:05 AM

|

|

First "smoke test" of water injection system.

https://youtu.be/MJUYM5QOWno

So far, everything looks good!

Soon I'll pick what pressure regulator setting I want, and then I'll measure the flow for different duty cycles and different RPMs.

|

|

|

tiretread

|

APR 08, 03:16 PM

|

|

|

Threads like this make me feel entirely inadequate. I'm happy if I get my shoe laces done right. Amazing stuff.

|

|

|

Spadesluck

|

APR 08, 03:45 PM

|

|

| quote | Originally posted by pmbrunelle:

First "smoke test" of water injection system.

https://youtu.be/MJUYM5QOWno

So far, everything looks good!

Soon I'll pick what pressure regulator setting I want, and then I'll measure the flow for different duty cycles and different RPMs. |

|

I also think when everything is bolted up and running dripping will not be an issue as it is going to be sucked into the motor.

|

|

|

pmbrunelle

|

APR 09, 07:59 AM

|

|

My winter boots have zippers running up each side. That's how I stay focused enough to do car work

I tried blowing compressed air into the runner (an attempt to simulate a running engine) while it was spraying, and it didn't seem to have much effect on the dripping. These nozzles have a cone angle of about 70°; perhaps a narrower cone angle would be better.

Gasoline is injected at pretty much the same location, and it too does partially condense on the walls before being picked up by the airflow... This time delay of fuel lazing around in puddles of liquid before making it into the combustion chamber is why we need acceleration enrichment, or else you get a lean spot on throttle tip-in.

So, since water evaporates less readily than gasoline, I think I should expect similar or greater (water) puddling in the intake ports... and technically speaking, I should also use acceleration enrichment for the water injection, in order to deliver the requested amount of water into the combustion chamber.[This message has been edited by pmbrunelle (edited 04-09-2019).]

|

|

|

Spadesluck

|

APR 09, 12:27 PM

|

|

|

The water is really only going to be injected under acceleration correct? The chances of puddling I think is going to be very low because the motor is going to act like a vacuum cleaner at this point at sucking everything in.

|

|

|

pmbrunelle

|

APR 09, 08:58 PM

|

|

I'll only spray in high boost (whatever "high" turns out to be), in conditions where the 91 pump gas doesn't have enough octane to resist detonation.

I don't expect the turbo to spool off-idle either, so there will be some RPMs (maybe 3000) before the spray begins.

I ordered the turbo today, and as getting parts in Canada sometimes goes, I'll get it in a month. That gives me some time to work out the kinks with the water injection system, before I assemble the top end of the engine and fit the turbo.

I didn't want to spend too much for a turbo, but I didn't want a cheap knockoff that cannot be trusted, so I ordered a new Garrett-brand T04E 50 trim / Stage 3 .63 A/R journal bearing turbo. I already bought some intake and exhaust plumbing parts; this turbo is compatible with the hardware I already have.

In my research, I was really impressed with the Borg-Warner EFR line of turbos. To begin with the accessories, they have integrated wastegates and blow-off valves! That's a lot of installation headaches saved! Then, the compressor maps... they just work with a really wide range of pressures and airflows. The EFR turbos start at about twice what I spent for my journal-bearing Garrett. However, I'm sure they're worth every penny. For someone doing a more costly / high-end build than what I'm doing, that's what I'd suggest.

|

|

|

pmbrunelle

|

APR 21, 11:20 PM

|

|

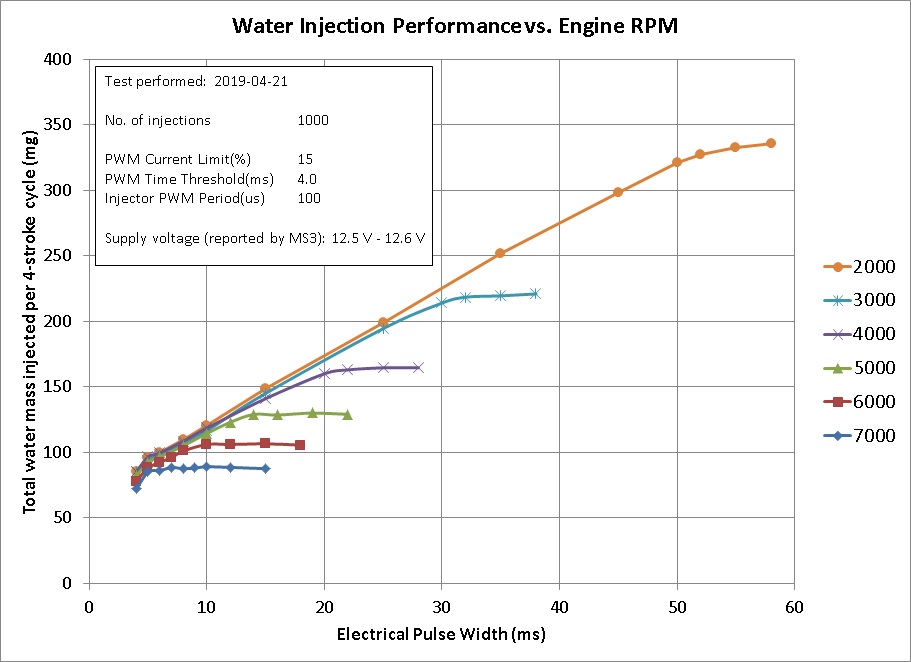

The water injection is coming along; I measured the amount of water sprayed as I varied the electrical pulse width. I'll use this information to help me set up / tune the MS3 once the car is up and running.

It takes about 4 ms for the solenoid to open; pulses shorter than that don't allow any water through.

At higher speeds, the solenoid valve (well, the entire system) isn't fast enough to allow for fine control; it's more of an on/off thing.

At lower speeds where the valve can be better-controlled, I'll be able to cut back on the water flow to avoid drowning the engine, and to reduce water consumption.

********************************************************************************

I have a small vibration problem to deal with; it appears that the pulsating flow from the water pump can cause a "water hammer" effect in the water lines and regulator. I'm going to try a length of soft hose to remedy the issue.[This message has been edited by pmbrunelle (edited 04-21-2019).]

|

|

|

pmbrunelle

|

APR 24, 09:10 PM

|

|

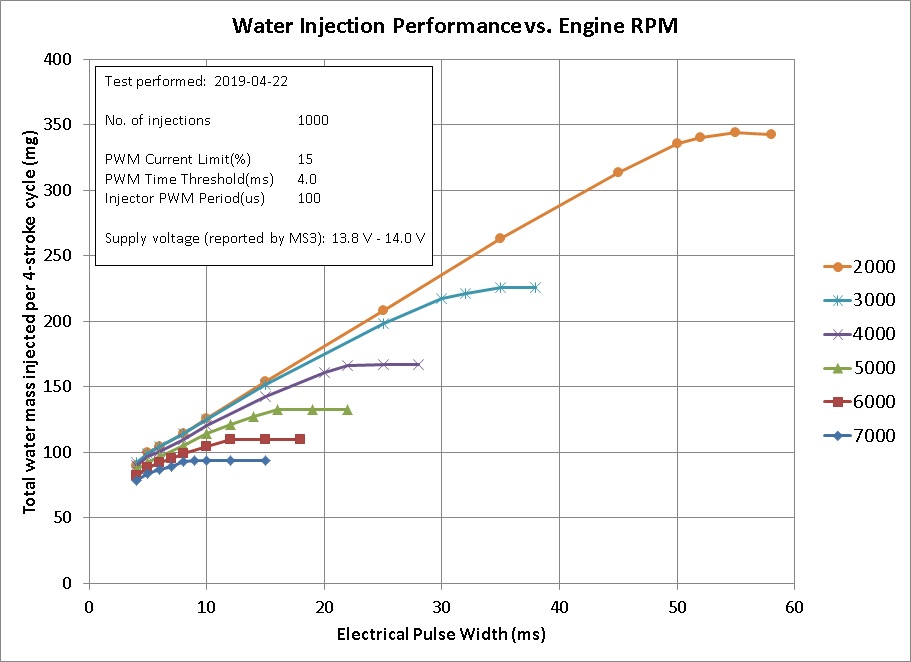

The following day, I re-did the curves, but while connected to the alternator of my truck, which was idling for the duration of the test.

I wanted to see the difference between running off a battery vs. an alternator.

With the greater voltage, the valve seems to snap open a bit faster.

The difference is most apparent in the high-RPM curves (6000 and 7000). These curves have more of a linear zone where the amount of water injected varies linearly with the pulse width.

Question for anyone with ideas... so I'll have to use studs to mount my new turbo to the T3 flange on the exhaust. I can't physically insert bolts into the holes on the turbine housing's flange.

The T3 flange on the exhaust has tapped through-holes. What is the proper way to install a stud so that it won't loosen? Anti-seize, special threadlocker? What kind of nut do I need?

|

|

|

pmbrunelle

|

MAY 15, 10:45 PM

|

|

I presently have an unbranded eBay blow-off valve with no specifications; like I did with the turbo, my goal is to rid this car of most of its iffy eBay parts.

So now, I'm shopping for a BOV.

Ideally, one that vents to atmosphere, rather than recirculating into the air filter can, for the simple reason of simplifying the plumbing.

I've been looking at the Turbosmart Vee Port Pro - Black:

http://www.turbosmartdirect...-Port-Pro-Black.html

What seems to be a common theme among BOV manufacturers is selection of a BOV spring based on your engine's idle vacuum. At idle, the spring should be strong enough to keep the BOV shut despite the vacuum trying to open it.

OK, but then what about during high-RPM closed-throttle deceleration? My Fiero engine which idles with 18 inHg of vacuum now goes up to 26 inHg of vacuum. I asked Turbosmart Tech Support about this, and they suggested that yes, the BOV may open during deceleration.

I don't know if I'm missing something, but it appears that atmospheric BOVs may allow the ingestion of unfiltered air

TiAL also has a BOV spring selection chart that is based on idle vacuum  (their tech support hasn't yet returned my inquiry) (their tech support hasn't yet returned my inquiry)

I could stick with the recirculating type BOV that sends the air back to the air filter can (sucking from the filter on decel would be OK too), but it's more fabrication work. I could also just stick a K&N filter on the outlet barb fitting of a recirculating BOV, but then that becomes an additional maintenance item.

If I go for a recirculating BOV, I'm considering the 1G DSM unit.[This message has been edited by pmbrunelle (edited 05-15-2019).]

|

|

|

|