|

| LS4 / F40 Swap #2 - fieroguru (Page 1/21) |

|

fieroguru

|

AUG 03, 08:55 AM

|

|

My first LS4/F40 swap was built just for me and I went all out with a lot of performance parts and custom touches to make it truly unique (only thing left LS4 is the long block). So a couple of weeks ago, I purchased an 06 LS4 from an Impala SS to do another LS4/F40 swap. With this swap, I have several different goals I would like to pursue:

1. Do the swap in a manner in which others could copy.

2. Explore the benefit of modifying the stock LS4 intake and rear exhaust manifold vs. replacement.

3. Learn about the Gen 3 E40 ecm (compared to the E67) and see if DoD/AFM will work w/o the BCM on a Gen 3 engine.

4. Have quick access to a LS4/F40 for parts development (like the flywheel and starter bracket) - allows me to keep driving my LS4/F40 Fiero.

A few ground rules for the swap...

1. Only LS4 components will be used. I would like to dyno the car with it 100% stock, then start swapping out the stock parts with modified ones one-by-one to see how much the LS4 can be improved by modifying its own parts.

2. Keep things simple so others can copy.

3. Custom parts will be kept to a minimum.

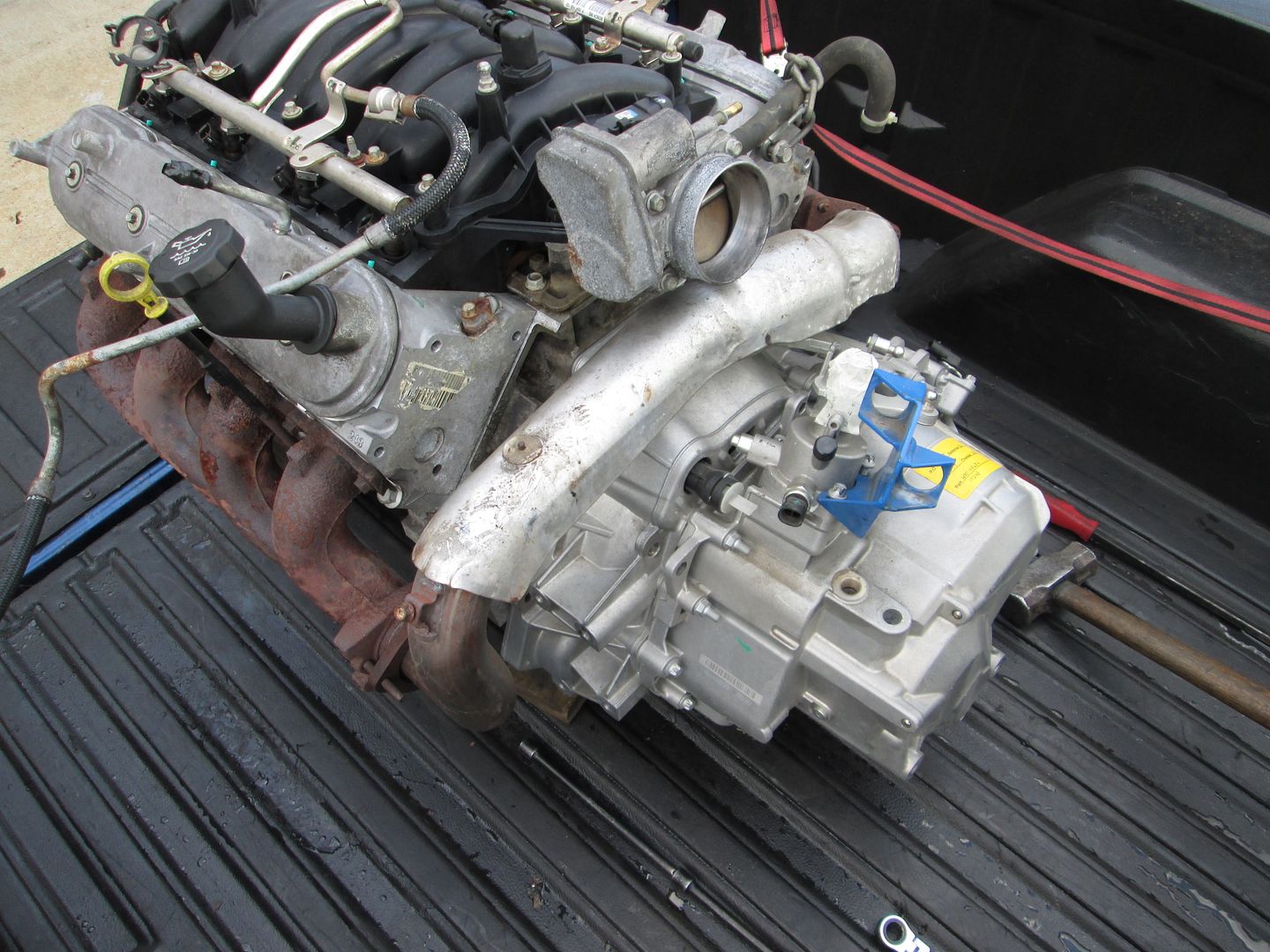

This engine was a complete drop out, but I tore it down to just the engine so I could clean it. After its first trip to the car wash (still needs more cleaning):

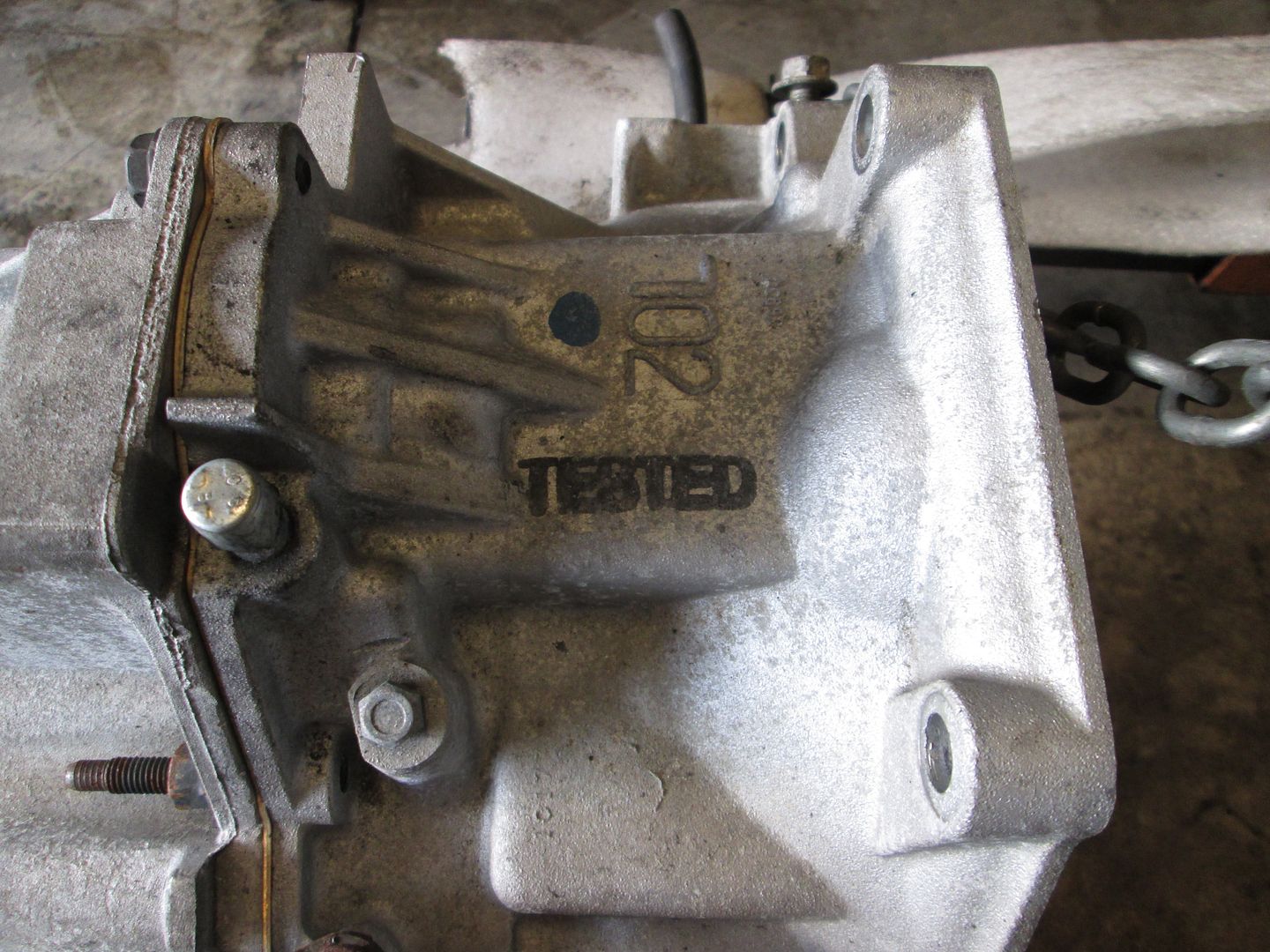

This engine also came with a GM replacement transmission. I need to power up the ECM to get to the VIN # and find out when it was replaced. The engine supposedly has 92K on it, so the replacement trans should have much less than that. I still haven't decided if I will sell this off to recoupe part of the purchase price of the engine, or if I will keep it and use it in the LS4/4T65e-hd swap I am doing as well. Until I make the final decision, I will use this transmission to make a better (more precise) starter location fixture.

The areas I consider a restriction on the LS4 is the Intake and Rear Exhaust Manifold.

The intake had significant notch in it to clear the OPSU. This significantly reduces the diameter of the intake neck opening and likely costs hp:

Here is my proposed mod... enlarge the neck so it has a uniform diameter for its entire length.

The LS4 front manifold is quite good with each port dumping into the main log section. This main log is 2.3" OD and many people use this manifold for turbo LS applications.

The rear manifold is where the significant restriction is. In this portion there are 5 cylinders of exhaust flowing through a 1.8 x 2.7 OD ellipse. Which is about 14% smaller than the main log on the front manifold & there is 1 more cylinder pushing through it.

The main log for the other 2 cylinders on the rear manifold is also about 16% smaller than the front one after 2 cylinders.

The proposed mod is to cut open the rear manifold and add some sections of pipe to enlarge the exhaust passages for both sides of the rear manifold:

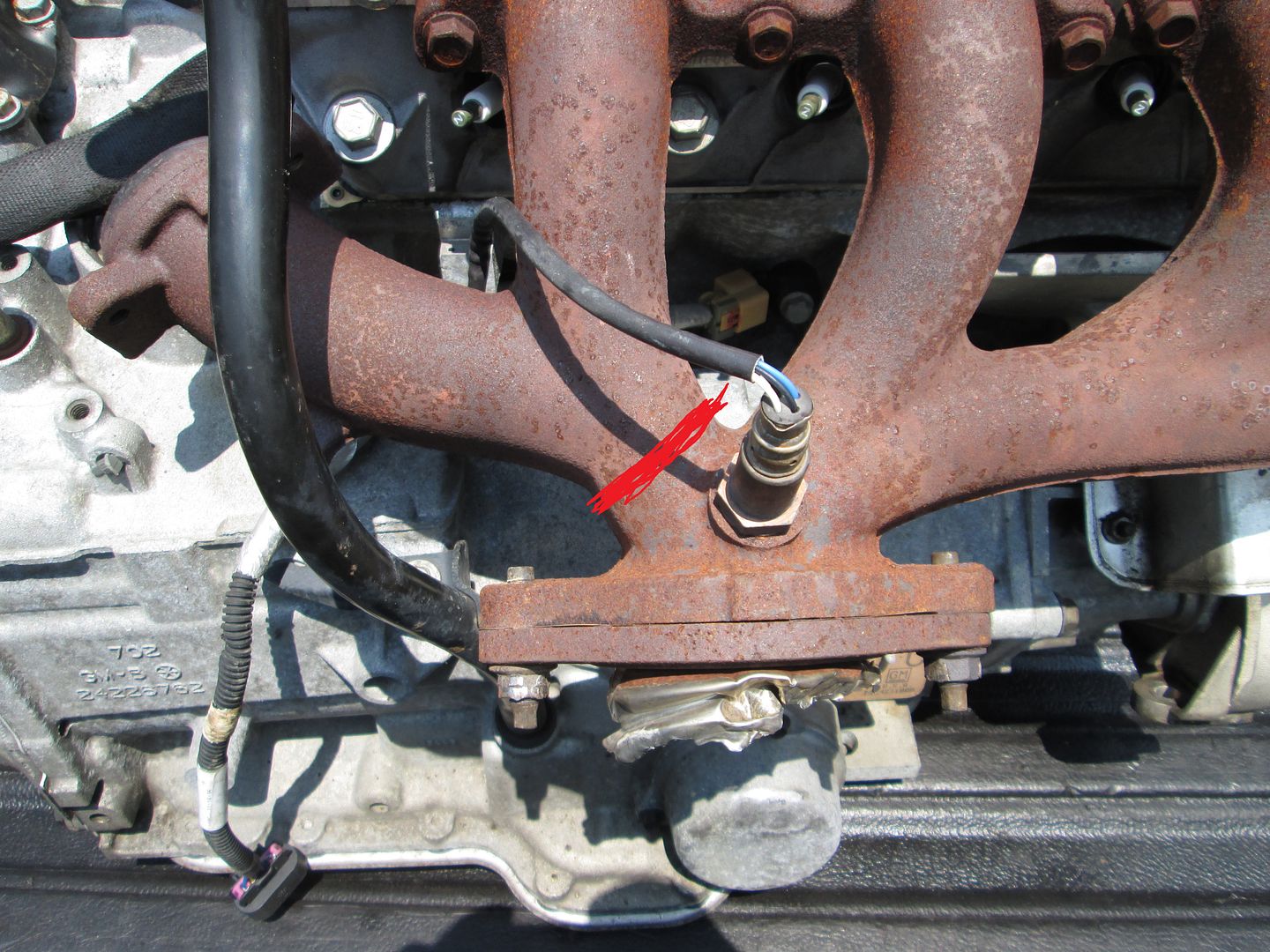

One of the first things I wanted to verify was if the F40 would clear the stock exhaust crossover. So while the engine was in the back of the truck, I installed the F40 and the crossover to see. In 1st (can't even get to Rev) there is interference between the counter weight on the shift arm and the heat shield.

Removing a section of the heat shield might help with 1st gear, but I doubt it would fix Reverse. So I will likely modify the counter weight. Right now I am thinking about scoring it on the top side and bending it down to it will clear, then weld up the scored opening. This would allow it to keeps its general shape/weigh, but fix the clearance issue as well.

I don't have a chassis for this swap at the moment, so the LS4/4T65e-hd swap will take priority. This swap will be progressing as the same time, but likely at a slower pace.

------------------

Website: fieroguruperformance.com

Products: 88 13" Brake Kit, 88 12" Brake Kit, 88 Lateral Link Relocation, 84-87 Machined Front Hubs, Custom Machining

Engine Swaps:

LS4/F40, HSR/SBC/F23, Pro-Flo/383/Getrag, 4.3CPI/4T60, Ramjet SBC/Getrag, 4.9/Isuzu, Carb SBC/Isuzu, 4.5/Isuzu[This message has been edited by fieroguru (edited 06-25-2016).]

|

|

|

Lunatic

|

AUG 03, 09:03 AM

|

|

|

Another excellent build as always and we'll all be following along. Quick question, is it that the LS4 is easier to obtain than the LS1 or LS2? Or is this just your preferred engine of choice?

|

|

|

fieroguru

|

AUG 03, 09:34 AM

|

|

| quote | Originally posted by Lunatic:

Quick question, is it that the LS4 is easier to obtain than the LS1 or LS2? Or is this just your preferred engine of choice? |

|

The LS4 has the GM Metric bolt pattern which does 2 things.

1. Allows them to bolt to Fiero transmissions w/o and adapter plate (but you have to fab up a starter mount).

2. Keeps used prices quite low vs. the other aluminum block LS(x) engines. Since they don't have the SBC bellhousing pattern, they are of little use to most hotrodders, so demand and prices are quite low. You can buy a LS4 engine for 1-4K cheaper than the LS1/LS2 engines.

My LS4/F40 car dyno'd at 382 wph (~ 430 fwhp), so they can be built up to surpass the "stock" power levels of the stock LS1/LS2 and get very close to the stock LS3.

|

|

|

lateFormula

|

AUG 03, 10:52 AM

|

|

Guru, here's another possible solution for the small diameter region on the rear manifold:

|

|

|

dobey

|

AUG 03, 05:30 PM

|

|

Hey guru. I'm curious about the interference with the counter weight there, as I'll be using a crossover pipe on my car, though I'll be building a custom exhaust for it. Can you give a measurement from the top of the counter weight, to the bottom of the LS2 throttle body (since I'll be using the LS2 as well, and I'm not sure if the bottom is lower than the LS4 TB or not) on your finished car?

My current plan is to have that section of the crossover be 2.25" OD. I'm not sure what the stock crossover diameter is with/without the heat shield either.

I'm curious if I could make it fit.

|

|

|

fieroguru

|

AUG 03, 06:33 PM

|

|

| quote | Originally posted by lateFormula:

Guru, here's another possible solution for the small diameter region on the rear manifold:

|

|

That's and option, but I am pretty sure mine would flow better. Having two opposing exhaust streams is rarely good for flow. With mine they remain angled toward the exit which helps both sides flow into the exit.

| quote | Originally posted by dobey:

Can you give a measurement from the top of the counter weight, to the bottom of the LS2 throttle body (since I'll be using the LS2 as well, and I'm not sure if the bottom is lower than the LS4 TB or not) on your finished car?

|

|

Stock LS4 crossover OD is 2.1", but the point of interference is more on the heat shield around the expansion joint section which is wider.

With the shifter in R (highest possible position) there is only 3" of vertical clearance between the counterweight and the bottom of the LS2 TB. They are offset from each other some so the maximum clearance is 4 1/8" if the pipe passed through them at an angle.

Just an FYI, most guys with intake swaps have to angle their TB's for clearance to the Doug Thourley Headers (and probably the eBay knockoffs).

About that counter weight mod... there is only about 1/4" between the counter weight and the transmission case in 5th gear, so not much room to push it down. I might just have to trim the point enough so it will clear and weld back on the part on the outer edge (or just leave it off and see what happens).

[This message has been edited by fieroguru (edited 08-03-2014).]

|

|

|

dobey

|

AUG 03, 09:12 PM

|

|

| quote | Originally posted by fieroguru:

Stock LS4 crossover OD is 2.1", but the point of interference is more on the heat shield around the expansion joint section which is wider.

With the shifter in R (highest possible position) there is only 3" of vertical clearance between the counterweight and the bottom of the LS2 TB. They are offset from each other some so the maximum clearance is 4 1/8" if the pipe passed through them at an angle.

Just an FYI, most guys with intake swaps have to angle their TB's for clearance to the Doug Thourley Headers (and probably the eBay knockoffs).

About that counter weight mod... there is only about 1/4" between the counter weight and the transmission case in 5th gear, so not much room to push it down. I might just have to trim the point enough so it will clear and weld back on the part on the outer edge (or just leave it off and see what happens).

|

|

Thanks! I don't think I'll have a problem getting the crossover pipe at an angle. And I'll be using v-bands to connect it all together, so I won't have to worry about the big ugly 2-bolt flanges interfering with things.

As for the counter weight, does it clear if you remove the heat shield? Maybe the crossover could be ceramic coated or something to keep the heat in, rather than using the shield? Might be an option if it gives enough clearance.

|

|

|

fieroguru

|

AUG 05, 06:38 AM

|

|

The final drawing for the flywheel was sent to the machine shop yesterday for quoting. The last one I had was 2-3 years ago and I added 3 bolt holes to the backside so I can use tabs to ensure the ring gear stays put (never had any issue with mine being press fit only), but almost all available aluminum flywheels have these tabs, so I added them.

It will be 1-2 weeks for the quote to be returned. Once i have it, I will approve production of the first flywheel so I can verify the machining program and tolerances. I will also start a thread in the Mall for those interested in getting in on the first batch. All I will be looking for is a number of people ready to buy so I can size the first run appropriately. No one will pay or send $$$ until I have the flywheels in hand and ready to ship.

I have also asked the machine shop about having some made with different crankshaft bore/bolt patterns for the 60* V6 and the N* applications. The main questions is if I order say 10 flywheels, and have some of each version made, do I still get the volume discount for the 10 flywheels.

|

|

|

iluvsd619

|

AUG 09, 02:00 AM

|

|

|

Awesome! Thanks for doing this! Ill be watching!

|

|

|

fieroguru

|

AUG 09, 10:10 AM

|

|

Just been in the parts gathering stage for this swap (work on the accessory drive in the LS4/4T65e-hd thread).

The connectors for the fiero clutch line and HTOB are in, just need tested.

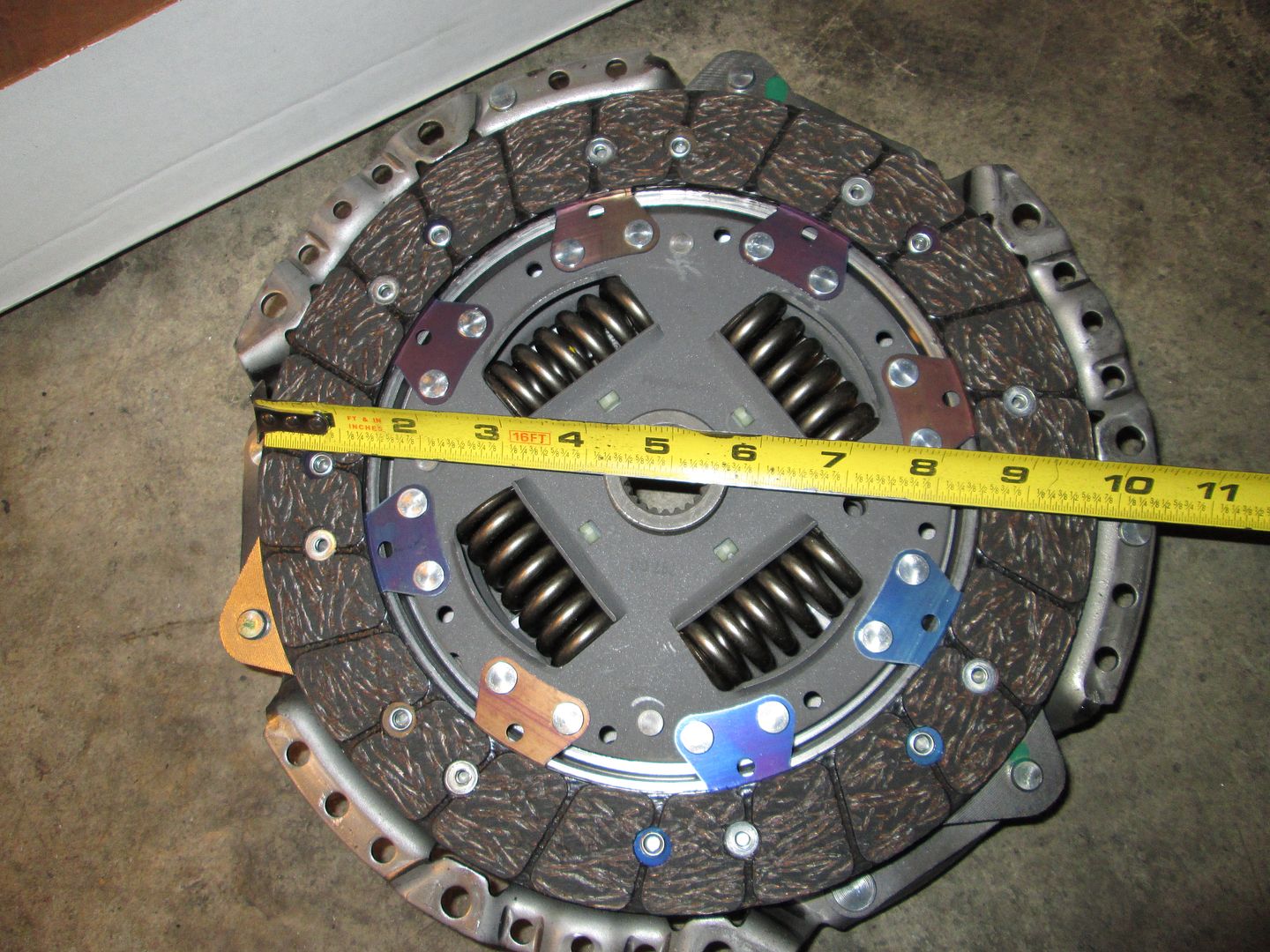

Also have the wear strip and ring gear for the flywheel:

And a stock clutch for use to verify the machining on the flywheel when its ready. This one was about $100 and the Spec Stage 4+ is a $575 flywheel. As part of this swap, I might install a lower level clutch since to see if I can find one that holds the power, but isn't as expensive.

|

|

|

|