Hello, everyone!

I'm working on an engine swap, and I'm nearing the finish line.

My next big issue is that the machine shop put what appears to be the temperature sensor in the head and the coolant plug for the head in the wrong spots. I went to remove the coolant plug (I have a set of plumbing coolant plug wrenches), and it wouldn't budget. I cranked on it with the breaker bar, and then tried the breaker bar. I'm afraid to put heat on it.

But, does anyone have suggestions for how to remove this coolant plug from the head?

Alternatively, I may just rewire the plug for the sensor and route it back to the front of the engine. The one issue with this is that the coolant pipe runs right past it and it looks to be in the way.

Let me know your thoughts.

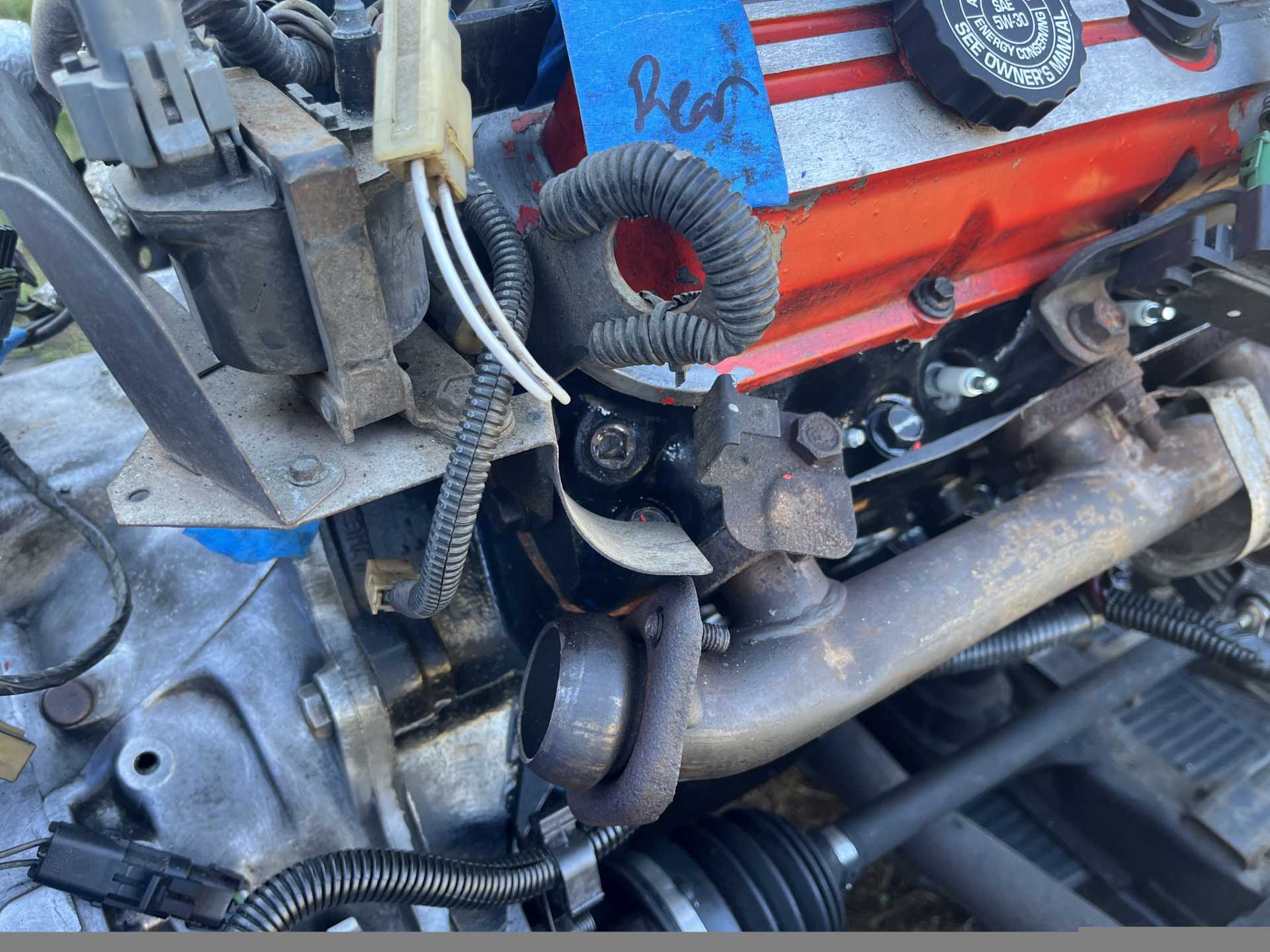

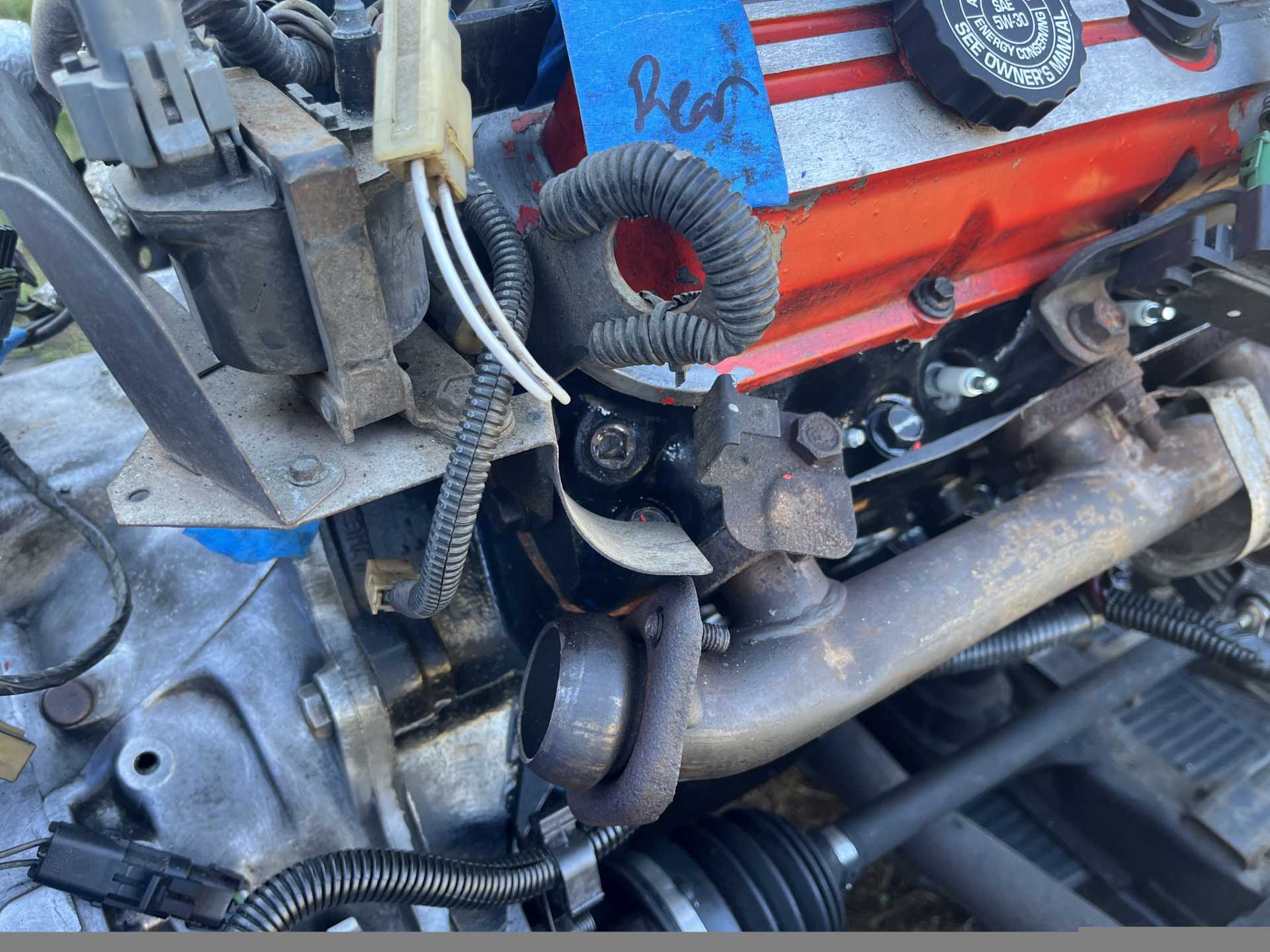

The plug in question:

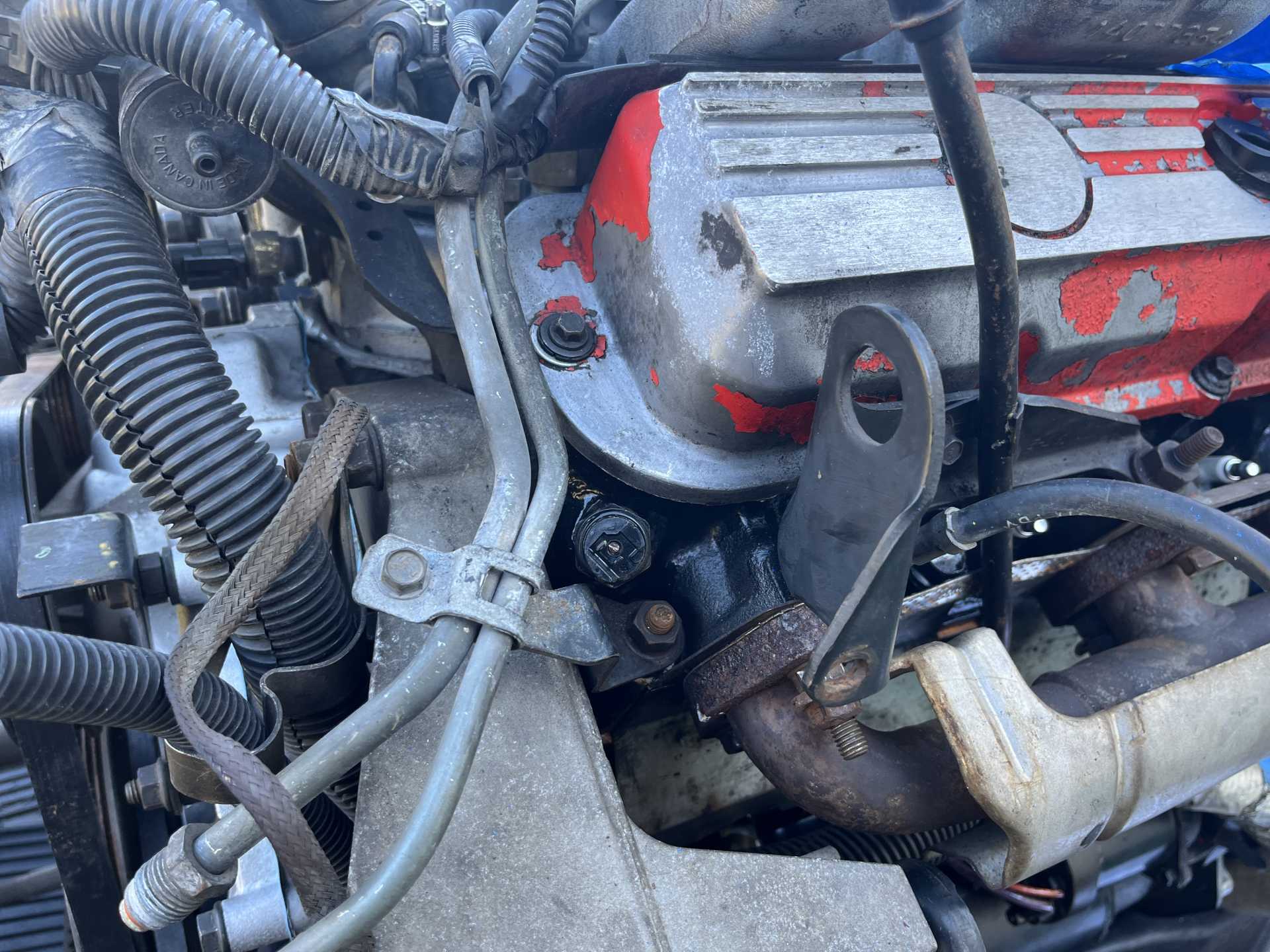

The sensor:

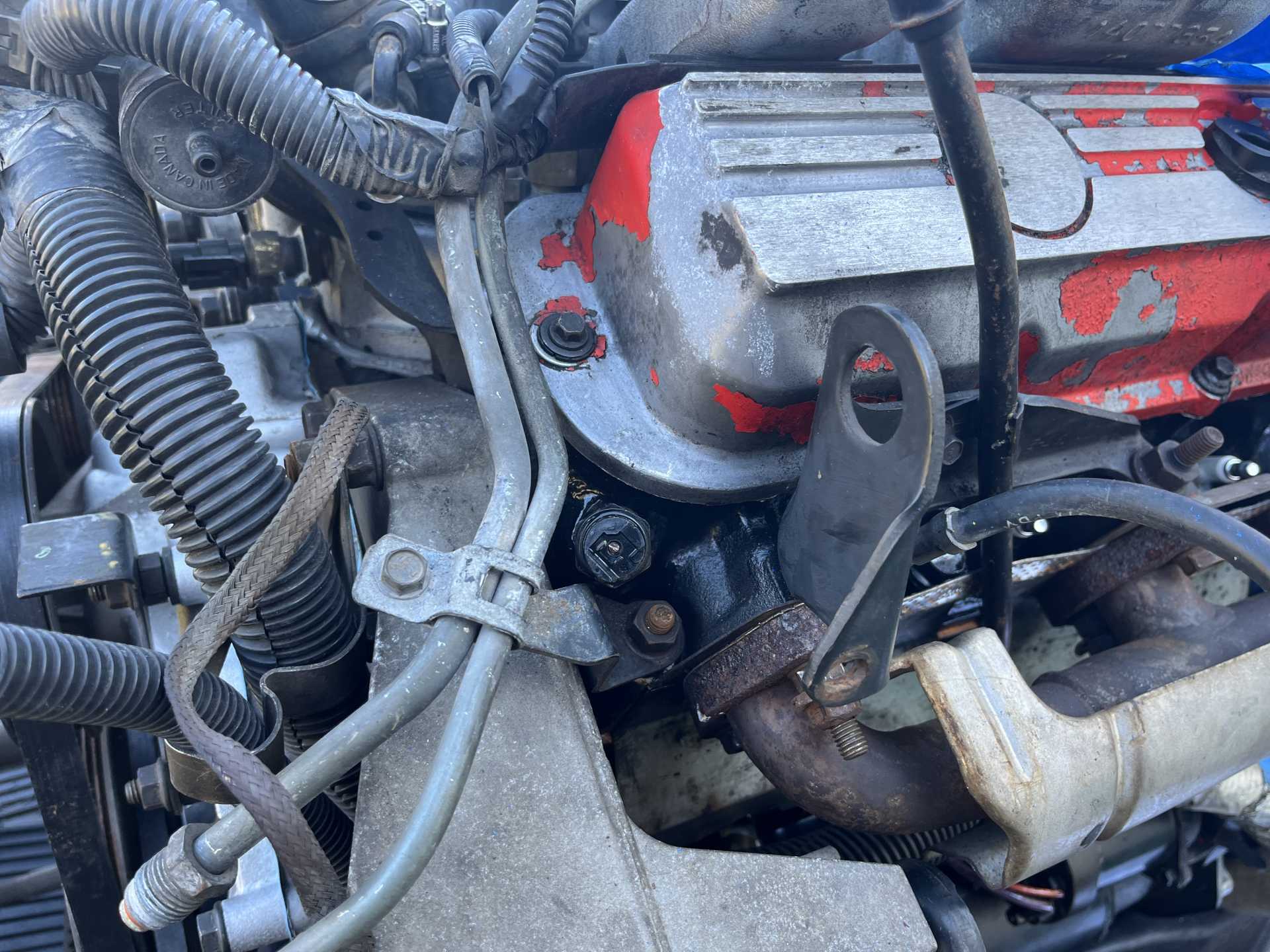

The coolant pipe that impacts the sensor: