Removing the factory brake combination valve and replacing it with a Wilwood Combination Proportioning Valve (Part Number 260-11179) was more complicated than I expected so I thought I’d document the war here. Note that I have Corvette C4 rotors and calipers front and rear in my 1987 GT.

The needed various connections are as follows:

Master Cylinder Front brake – SAE 9/16”-18 inverted flare (female)

Master cylinder rear brake – SAE 1/2"-20 inverted flare (female)

Brake line front right brake – DIN 10 mm-1.0 bubble flare (male)

Brake line front left brake – DIN 10 mm-1.0 bubble flare (male)

Brake line rear single line for both brakes – DIN 14 mm-1.5 bubble flare (male) (#%$*!)

Wilwood proportioning valve, all brake fittings – SAE 3/8-24 inverted flare

Wilwood proportioning valve, front brake light switch port – 1/8-27 NPT

A big problem is that GM used a rare 14mm bubble flare connector to the rear brake line. A union for this connector is virtually unavailable. The common bubble flare fittings are 10mm and 12mm.

Adding to this complication, there is no room to cut and reflare the rear brake line in the front compartment. Adding to this addition, the brake line is thick hard steel, so is impossible to flare without using heat, and there is no room for that. There is more: the rear brake line itself is 6mm NOT 1/4 inch (6.3mm) which means most flaring tools can’t flare 6 mm anyway.

Even though GM used both metric and SAE brake line fittings for the brakes, material for all the other connections are readily available so as long as you can double flare (“inverted flare”) and bubble flare (“DIN flare”). Connecting everything else is easy.

If I were to do it again, I would rip out the factory rear brake line from the front trunk all the way to the right rear of the car and replace it with handmade one using that easy-to-bend-and-flare nickel/copper brake line. A new tee fitting would be needed at the back with three 10mm bubble flare ports. The end in the front trunk could go directly to the proportioning valve using SAE 3/8 inch-24 double flare fitting.

The way I did it, after two weeks of banging my head on a wall, was to pirate the factory tee fitting from the back of a wrecked Fiero. It has two 10mm bubble flare fittings and one 14mm bubble flare fitting. I bought a plug for one of the 10mm fittings, hooked the 14mm fitting to that cursed rear brake line in the front trunk and flared a 3/16 inch tubing with a 10mm nut and a bubble flare for the other port. That, I hooked up to the proportioning valve back brake port with an SAE 3/8-24 inverted flare nut.

The good news is that I can appropriately proportion the brakes (I can selectively lock the rear or the front based on the proportioning valve setting). For my car's configuration, backing the proportioning valve 5 rotations off of "full rear pressure" causes the front brakes to lock and the rear wheels to still keep rolling but nearing their threshold.

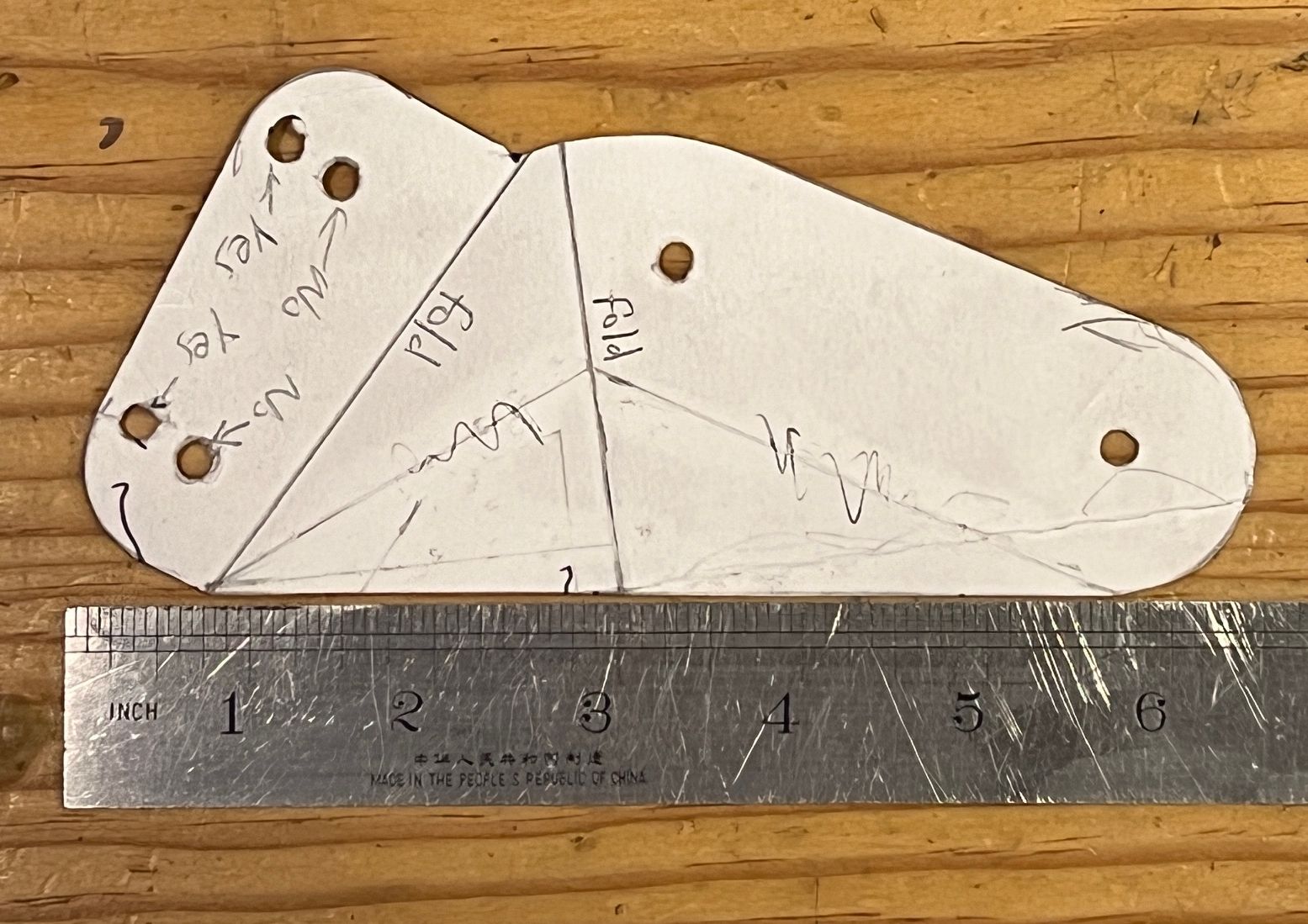

Here are photos: