Good news, surgery on the Fiero went well today, have to admit it was a little unsettling, short summary for future members that run across this...

- Replaced the master and slave using

Rodney's quality replacements.

- Installed new pedal bushings and new grease when I removed pedal to verify it wasn't bent. Adjusted banjo so pedal is freely at the top of the stroke, but not maxed out, you want about 1/16" to 1/8" of play at the initial onset of the pedal throw.

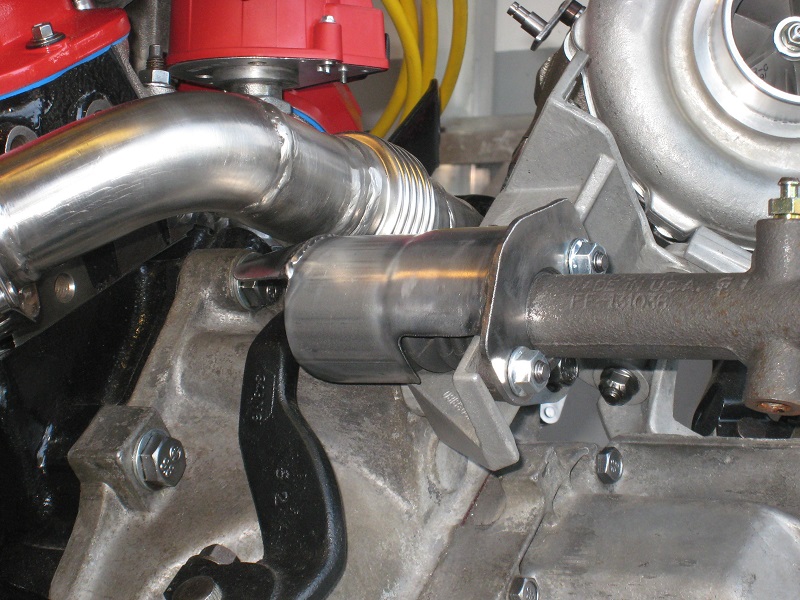

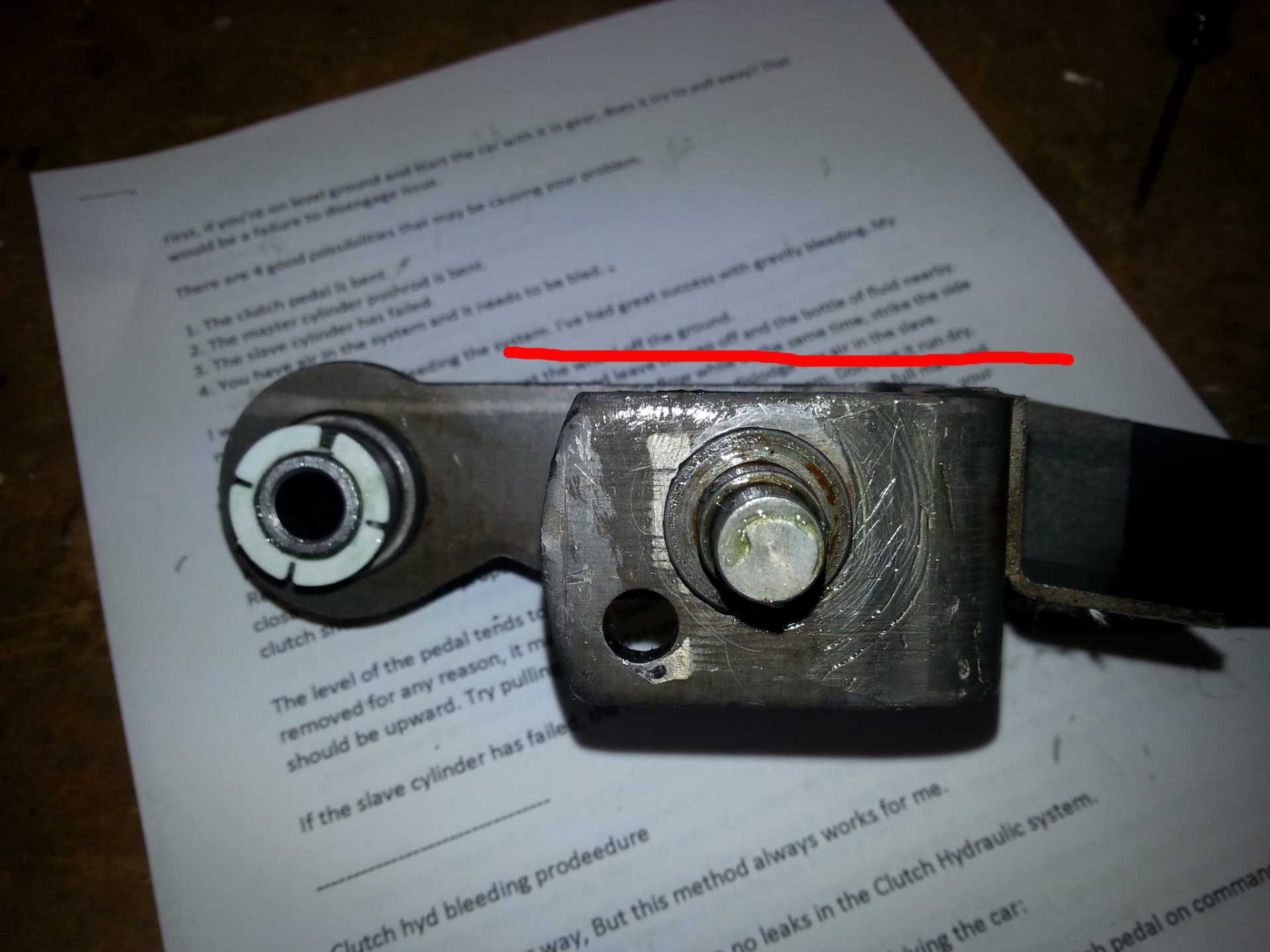

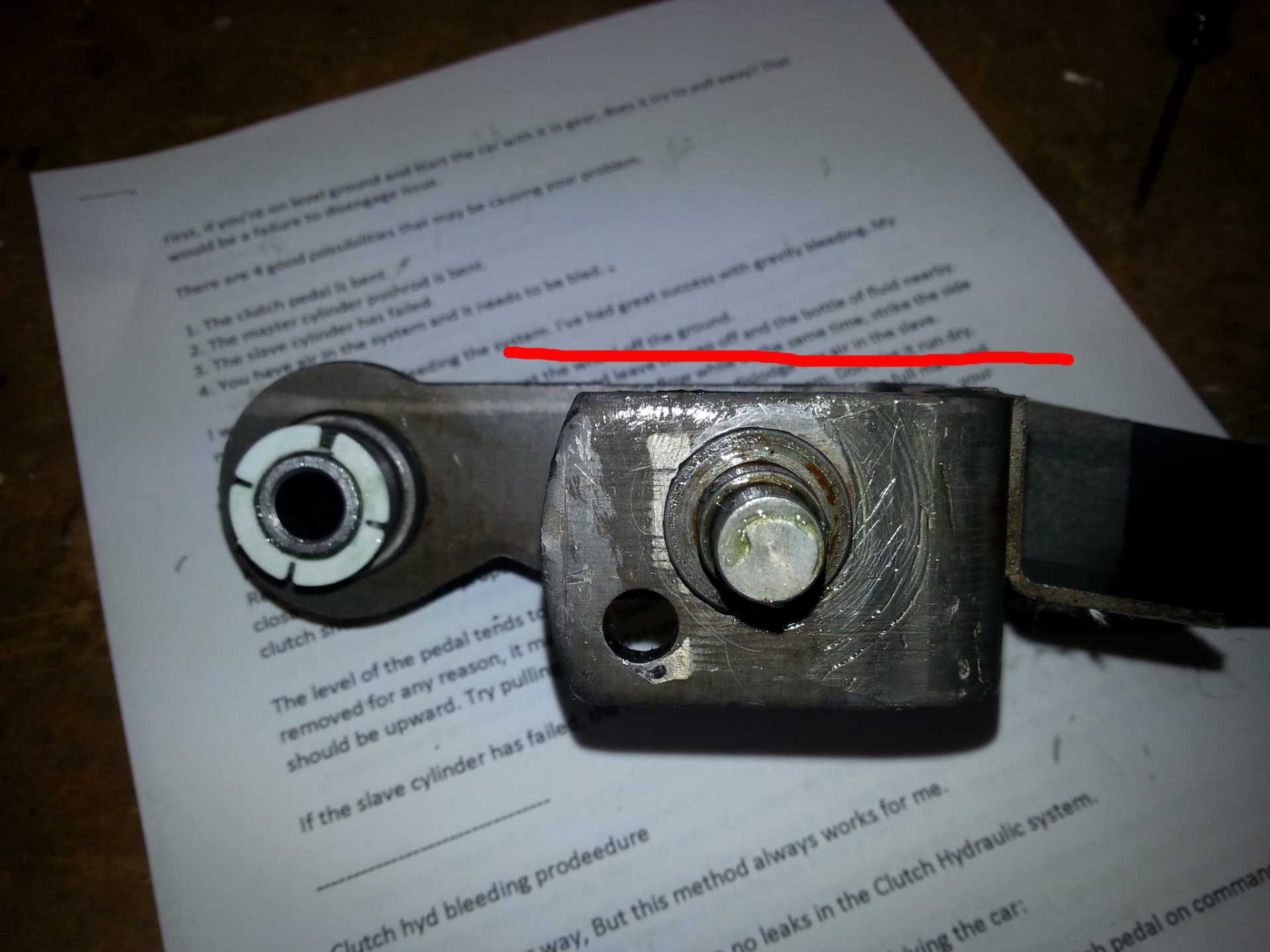

- After installing everything the aluminum slave bracket on this 1986 V6 broke off. I just learned in this thread that is common and

Rodney offers a steel replacement bracket, once again thanks Rodney!

- Upon removing original bracket again I discovered 2 things... The bracket was already cracked/broken 50% at the top bolt because you can see the recent clean break, and also see the other crack was dirty, so it was cracked years ago and flexing all this time. Secondly, the hole for the lower bolt (in aluminum trans case) that holds the bracket on had boogered threads. I wasn't comfortable with that considering all the pressure/stress put onto the bracket in that direction when operating the clutch, so I decided a drill & tap was the best solution.

- Had to use a right-angle drill because you can't fit a regular drill down in that area.The original bolt was 10x1.5x25 so I went with a 12x1.5x30 to utilize all of the 1" thread depth in the hole. I placed a vacuum cleaner nossle next to the hole with paper towel and reversed duck tape to simulate a dental assistant while I was drilling and tapping.

- I also had to slightly enlarge the sides of the lower square hole in the new Rodney steel bracket so the new larger 12mm bolt fit through and had wiggle room.

- Decided to leave that one tab on the heat shield disconnected and bent the tab up (the one toward the rear of the car), this allows you to bolt the slave to the bracket, then bolt the bracket to the car, then lower the heat shield, and last attach the other slave bolt with heat shield tab inserted. The heat shield is still plenty secure connected with the one tab and bolted on the engine (you can leave that engine bolt connected the entire time and just move the heat shield out of your way). As mentioned by somebody above, you want to install the heat shield tab on the back side of the bracket where the nut goes onto the stud, not in-between the slave and bracket.

- Bolted everything up and visually verified everything operated smoothly before going for test drive, looked like I'm getting over 1" of throw. The test drive was perfect, but the pedal felt like a completely different car, but I guess that is no surprise because everything IS different so it SHOULD feel different. (hydraulics, banjo, non-flexing bracket, etc) It will probabbly take me a day to get used to the revised clutch operation stiffness and release point.

I'm ready for the weekend...

[This message has been edited by Skybax (edited 08-04-2021).]