| | | quote | Originally posted by Blacktree:

Looks like you nailed it. The problem is, when you switch to the hydraulic lifters, that's going to change. But it should be close enough. |

|

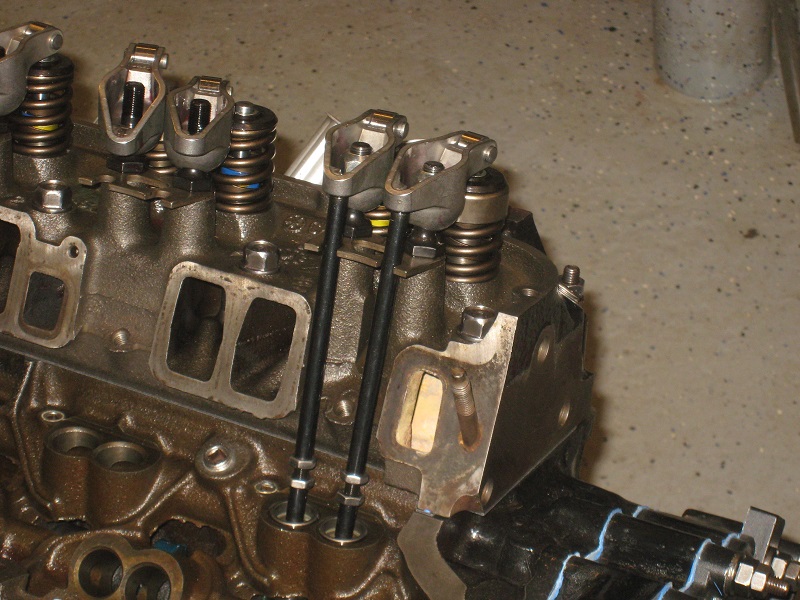

Good to know that it looks OK by your eye.

Actually, figuring out the pushrod I need with the hydraulic lifter is pretty simple once I have it figured for the solid lifter.

Throwing out

random numbers here as an example:

Solid lifter height (pushrod cup to bottom face): 1.200"

Hydraulic lifter height (pushrod cup to bottom face, with plunger preloaded 0.040"): 1.100"

Pushrod length needed for solid lifter (determined by trial and error): 6.158"

Pushrod length needed for hydraulic lifter:

The hydraulic lifter is 1.200" - 1.100" = 0.100" shorter than the solid lifter.

Therefore, to make up for the shorter height of the hydraulic lifter, the pushrod should be lengthened by 0.100".

Pushrod length for hydraulic lifter: 6.158" + 0.100" = 6.258"

Again, these were random numbers. I just chose them to explain the general procedure for adjusting a pushrod's length depending on the lifter used.

| | | quote | Originally posted by olejoedad:

You can set this up using hydraulic lifters. Initial valve lash settings sink the plunger in the lifter to midpoint of plunger travel. Oil pressure when engine is running provides extra " cushion" at high RPM. When rotating the engine by hand to set up initial positioning, hydraulic lifters work just fine..... |

|

When turning over the engine by hand, the valve won't start opening until the plunger has bottomed out in the lifter. So you won't see as much valve lift as when the engine is running.

| | | quote | Originally posted by viperine:

You can also disassemble a lifter and insert washers inside of it to simulate lifter height at full pumped up (running) value.

This is the method I used to determine pushrod length on my 406 sbc build. It's been a while and I am sort of fuzzy on how I pulled it off, but i do know I only needed to use one spare lifter for the whole process. |

|

I actually started doing that with the least-worn of my old lifters; it was a bunch of fooling around though. Then, when I tried to weld the plunger to the lifter body, I was having a hard time welding the plunger without damaging/affecting the pushrod cup.

So buying a pair of $3 solid lifters seemed like a no-brainer.

Obviously, the method

can be made to work.