Here we go AGAIN

Remove the long screws (there were only three in both mine???) They are an odd size..6.5mm think..my screwdriver adaptor fitted perfectly!!

Then remove the mounting plate. Next you have to prise apart the black plastic body..it isnīt too hard, but take care!!

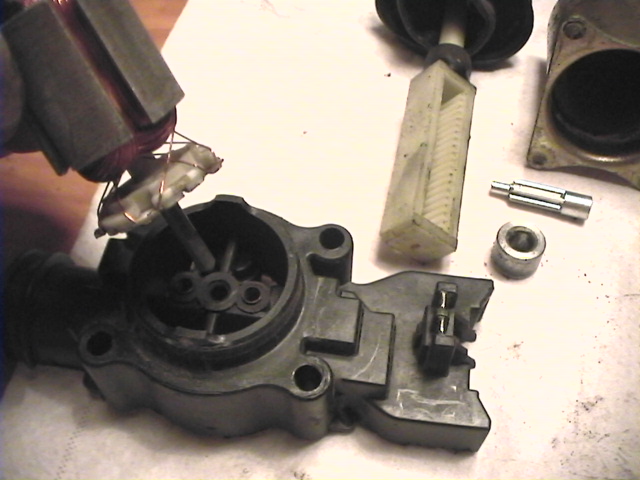

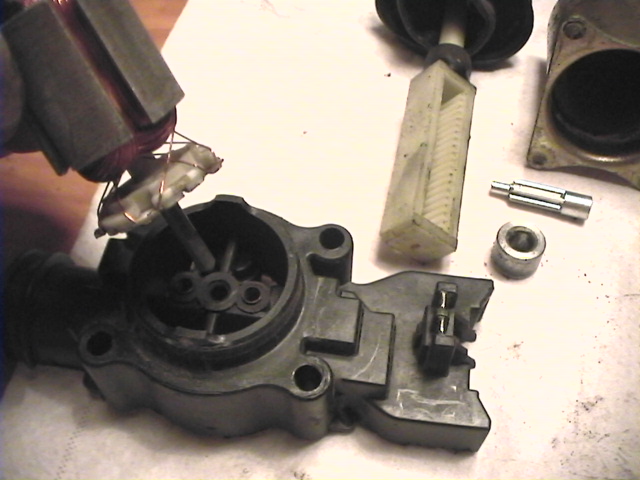

You can now remove the drive shaft with the nylon gear, and the bearing/guide that keeps the shaft in place against the motor drive gear.

Then, there is a black plastic 'plate' that covers the contacts and brush tubes.You have to carefully prise that up..again be gentle, and it will pop out!

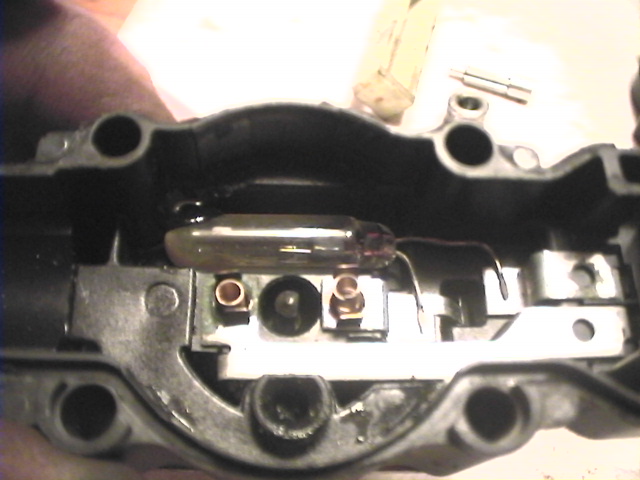

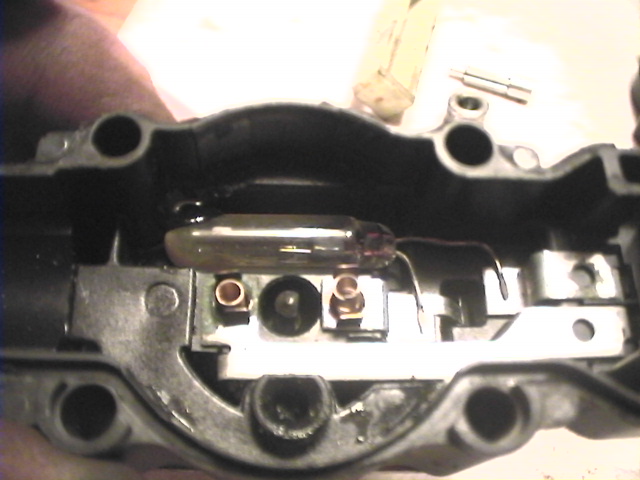

Once that is removed, you can remove the metal gear from the motor spindle. You can then see the metal strips that lead from the connector to the brush tubes, and a glass tube that houses a bi- metal strip that is an anti-overload mechanism.

You can use a meter to check continuity from the connector contacts to the brushes.

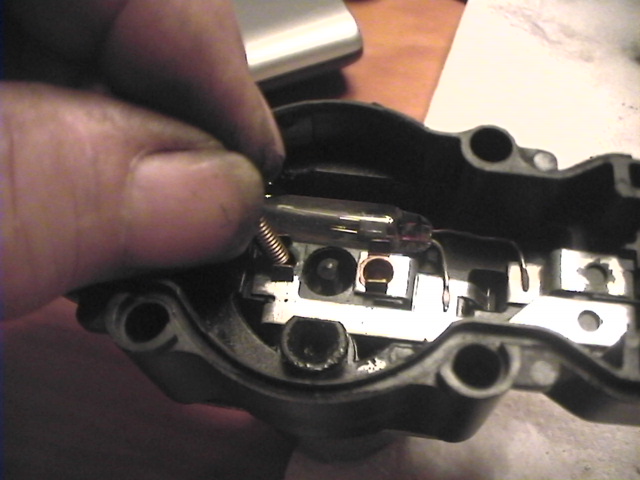

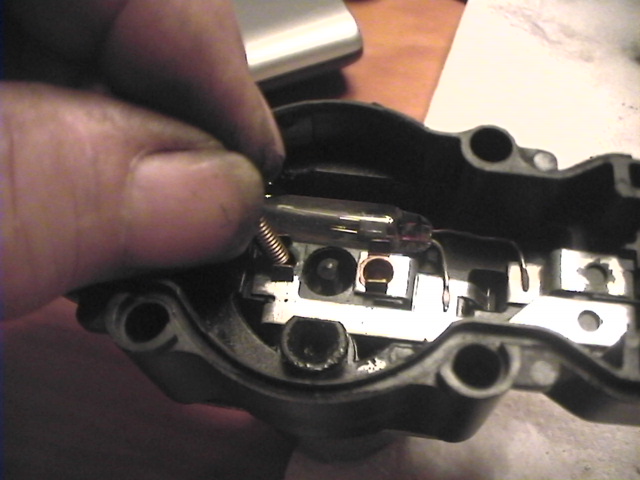

Next, you have to VERY CAREFULLY prise up the two little flaps that retain the brush springs and brushes. They are quite fragile, so be careful!! If they do break off, as one of mine did, you can solder it back into place.Then the springs and brushes can be lifted out..

Now turn the body over, and prise the motor cover up from the body. It is compression fitted to a lip on the body, but comes off quite easily. The commutator will spring out too, because of the magnets.

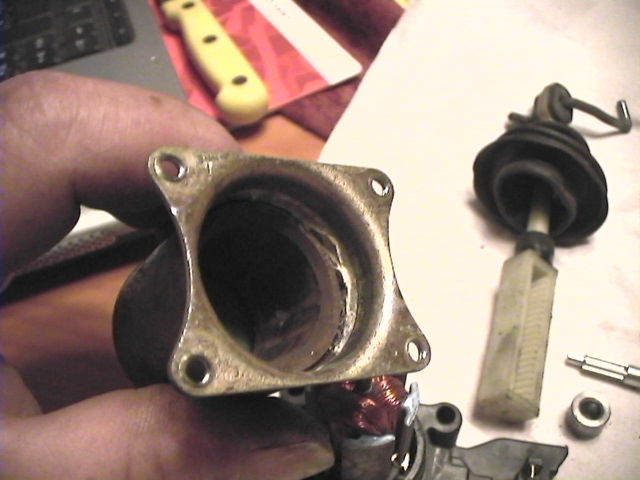

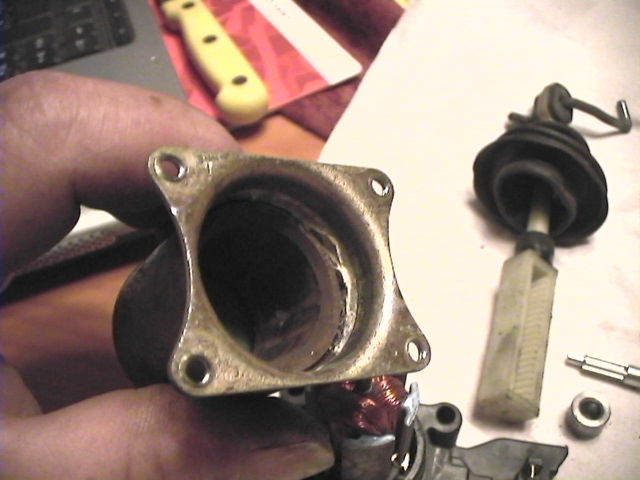

Once it was all apart, I emery clothed the rust off the winding faces, and the inside of the magnets inside the motor shell. I also cleaned out all the old grease from the shaft spigot, and put some fresh white grease in the bearing in the cover top. I also cleaned up the copper contact plates with fine steel wool, removing all the tracks and dirt. My brushes were fine, so I cleaned them up whilst they were out. I also checked all the windings on the armature, and they were good too. So now, to put it all back together was, obviously the same process in reverse

Put the armature into its guide hole, replace the cover, ensuring the spigot of the armature is in the right place!!

. Turn it all over, and drop the brushes into their tubes, and then the springs. Next you have to be very careful bending the retaining tabs back over the springs. Replace the black plastic plate, etc, and then bolt it all back together. Hopefully, it will work!!

Nick

So as I have taken a deposit on the sale of the car, I thought I would try to repair them . I established there was power getting to them, and so I took them off, and disassembled them. This was very hit-and-miss, becuse I had never taken one apart before

So as I have taken a deposit on the sale of the car, I thought I would try to repair them . I established there was power getting to them, and so I took them off, and disassembled them. This was very hit-and-miss, becuse I had never taken one apart before