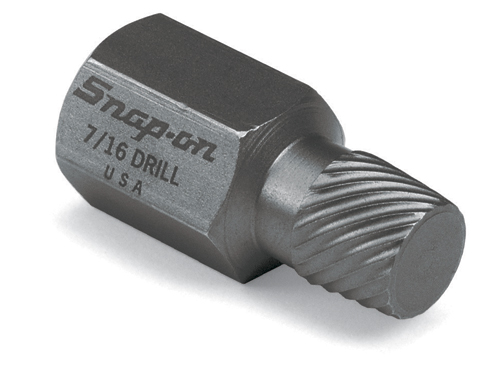

Man, the cylinder deck dowel pins in my N* engine were in real tight. In past rebuilds, I've been able to grab one with a pair of Vise-Grips, and "walk" them out of the hole. Not these. I tried inserting a bolt into the center hollow section to keep from crushing it, grab the pin with a pair of Vise-Grips, and pry the 'Grips up with a couple prybars. No luck. Then I drilled 1/4" holes through the sides of each pin and inserted a 1/4" rod and welded it in place.

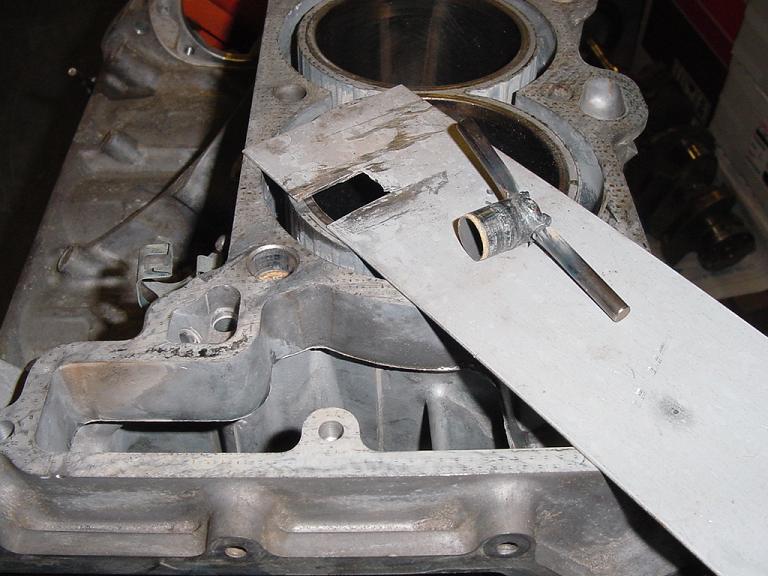

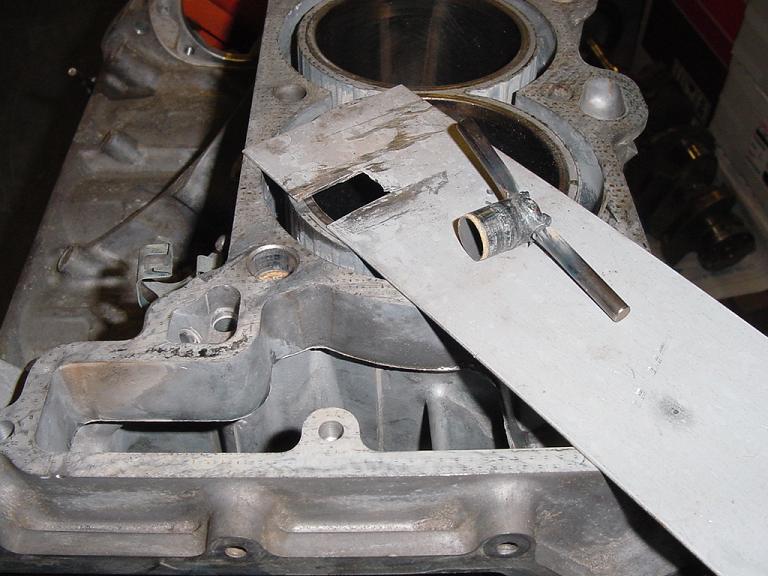

Then I positioned two metal wedges (a single steel and a single stainless steel wedges were all I had on hand) under the 1/4" rod, and atop a 1/16" thick aluminum sheet, with the wedges pointed in opposite directions on either side of the pin.

Then I alternately beat each wedge until the pin was free.

I've never seen dowel pins that were so tough to get out. I hope this info may help someone else out there.

[This message has been edited by WAWUZAT (edited 04-15-2007).]