Here is what and HOW i did it on my swap... this is cut right out of my swap post thread!!

-------

Well first of i sat for some time trying to figure out the best way to mount the alternator... I already had the top bolt figured out, and the spacing too (15 10mm washers) so it was now that i had to figure out how to tie in the other mount on alternator (in front) and the back bolt too (for support)

I decided that for the front i would chop up the stock alternator brackets... They are as they would be stock on the alternator...

Taking the angle off and the bar leaves you with this...

Now the best i can i will try to explain how i did this.

NOTE--- DO NOT cut anything before reading WHOLE post.. hehe, not that you would anyways but im telling you ABOUT where to cut stuff... you will have to cut it for yourself so that you get the proper location on your 'Nator

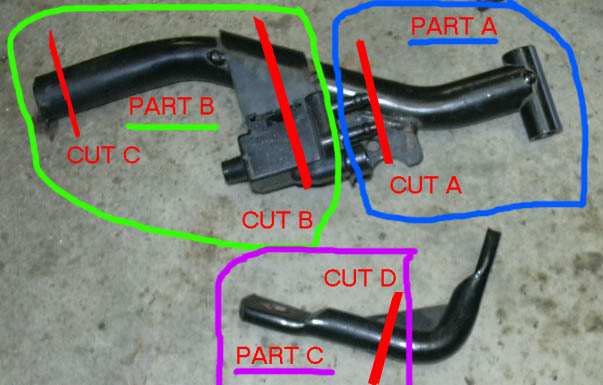

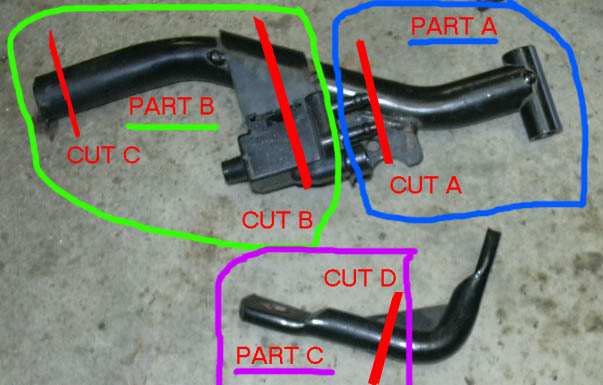

Below is a pic of how i cut everything up to make the parts i needed. There is allot going on in the pic so i will explain it out, sorry i have no in process shots but Mikee the action shot guy is not around cause gas is Thirty Billion Dollars a drop.. hehe!!

First off i took the large tube bracket and cut off ALL the other brackets on it, the sylonoid bracket and the U shaped steel piece near "CUT A". Normally the side near "CUT A" bolts to the blower, NOT anymore!!

Circled in GREEN and labeled as PART A is the new BOTTOM BRACKET. This will bolt to the hole in the bottom of the alternator (in back) and be welded to the super thick engine mount.

I then made the rest of the cuts on that tube (CUT B and C) to leave me with PART B. This will become the rear mount. However, after making the cuts you will not have any good way to bolt it to the alternator SOOOO... You take the other bracket piece and cut it at CUT D to make PART C.

Well the Lower Mount (PART A) is already done so lets forget that for now and move onto the REAR mount... It now will begin to read like assembly instructions for some back yard play set...

After cutting Part B out, which you need to do at CUT B and C (c - because there is a nut welded in the end of tube) you will then take PART C and make a cut at CUT D. Cut the angle OFF of PART C leaving behind just round stock with a flattened end with hole. NOW basically PART C just slides in the end of PART B.... make sure you put it in the end of PART B near where you made CUT C.

This will get welded in place but NOT YET because you need to make sure it all lines up right before tacking together.

If you have the alternator properly spaced, I checked and RE-checked the belt travel and alignment. Should be perfect.....ish.

I basically have the top bolt in the block and through the long "wing" of the alternator. I then rotated it up so that it was close to the manifold heat sheild but DIDNT touch it. Also not so low that the belt hits anything (like itself at the water pump pulley which is close squeeze).

Then all you do is measure from center of bottom bolt hole to the engine mount to get length for PART A... now you know where to cut it at CUT A.

To get the length for PART B just measure from bolt hole in back of the alternator to the mount and subtract about an inch or so so that you have some room for PART C to stick out (flat spot with hole is there for a reason).

At this point with you would have everything cut to length... I bolted on PART A and then pushed it against engine mount to make sure it fit right and i had good angle on alternator (not to close to sheild and not to low for belt path). Then if all is well just TACK weld it GOOD into place. Remove alternator CAREFULLY and weld PART A to the mount.

I then put the alternator BACK ON and bolted it all down snug and checked fit and belt again...

Now you can figure out PART B... I bolted PART C to the alternator then slid PART B over top of it and lined it up where i wanted it on the engine mount... Did some looking around and clearence checks (dont want to block off ANY access to your engine mount bolts or it will never come off) LOL! Now just tack weld PART C to PART B. Remove the tacked assembly and weld it GOOD and SOLID! I then put the assembly BACK on the alternator, checked alignment onto the engine mount and tacked it to the mount NICE and STURDY....

Remove the alternator once again and weld the piss outta that tube to the engine mount...

TA-DA thats it... hard core solid mounting.

Here are some pics and short descriptions of the setup...

Here i am testing the position of the bottom mount... The bend goes towards the FRONT and so does the SHORT end of the tube where bolt goes...

Here is the bottom mount welded into place...

MORE TO COME SOON... Just wait for the post!!

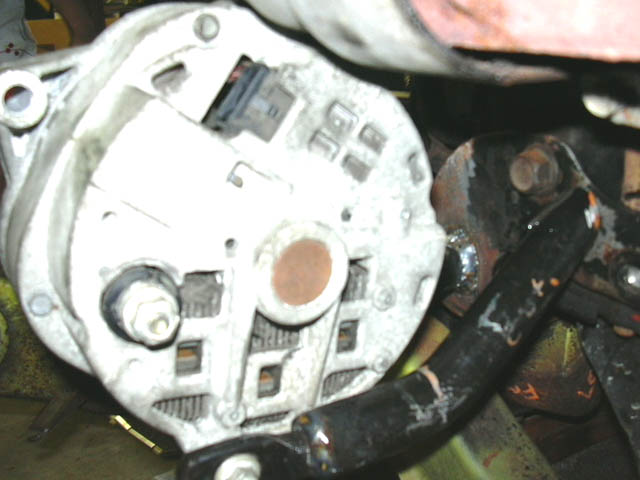

I dont have any pics of the back mount as a seperate PART B and PART C but here you can get the idea of how its fitted together... here i am lining up the location on the engine mount...

Here is a BAD SHOT but it shows about how you have to watch where you put back mount... there be bolts to dodge hehe!!