Here are the tools I've fabricated. There might be $25 worth of parts to do all control arm and cradle bushings to replace the rubber. None of this will apply to poly.

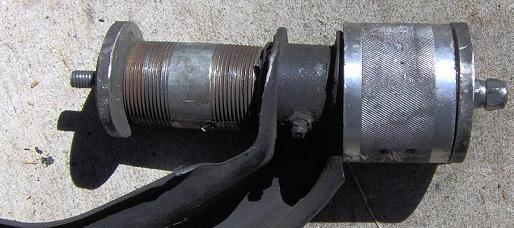

Below are the pieces I've collected to remove and install front/rear control arm and cradle bushings. The two knurled cylinders were custom made for me by a machinist buddy, but it wasn't necessary. There are pipe sections that do exactly the same thing. This is a top shot showing a cradle bushing in one sleeve. When removing the bushings you need a "receiver" sleeve to allow the bushing to pass into it while pressing on the other side.

Below is a side shot of the same tools. On the right is the pipe I use to put pressure on the bushing to push it out. Different sizes are needed for different bushings. It need to be no larger than the sleeve so it will pass into the control arm during the bushing removal..

Below is the tool installed to remove the bushing. What size pipes are needed only depend on which bushing you are removing.

You tighten the nuts on the end to put pressure on the bushing which tries to drive it into the receiver pipe. This pressure won't just pop the bushing out, but once you have it tightened as much as you can, hit the center of the bushing sleeve with an hammer and chisel or air chisel to bent it inward. This will collapse the sleeve and it will pop out. Quite satisfying actually when it pops.

Not shown is a small quarter circle I place between the loops to keep them from squeezing together. If you don't do this the bushing will hang up in the loops. You want to keep them somewhat parallel while removing and installing the bushing.

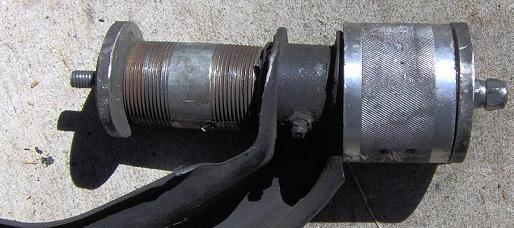

Below is the tool installed to press in the bushings. The sleeve on the left needs to fit over the rubber and press on the bushing's lip. I apply a thin coating of vaseline to the bushing to let it slide in. Tightening the nuts on each end will draw the busing into the loops. Often it won't seat completely so I tap lighty on the driving pipe and the bushing will slowly seat. Also, taping on the loop will assist in seating the bushing.

Once installed and flush with the arm loop I clean off the vaseline. No, the vaseline won't make the bushing pop out.

Again, not shown in the quarter circle between the loops to keep them parallel.

Tap in the inside of the bushing to check the tightness. The fit is a pinch on the sleeve by the arms.

Note: I've never had this problem with Fiero arms, but on G body arms the bushings will sometimes be loose. They feel tight, but you can pop them out with a light tap of a hammer. If that occurs, have the bushing tack-welded in three spots around the loop. The welds can be easily ground off if you need to replace the bushings in the future.

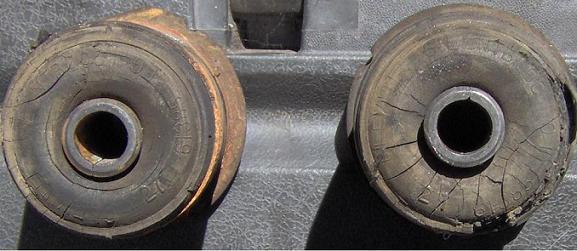

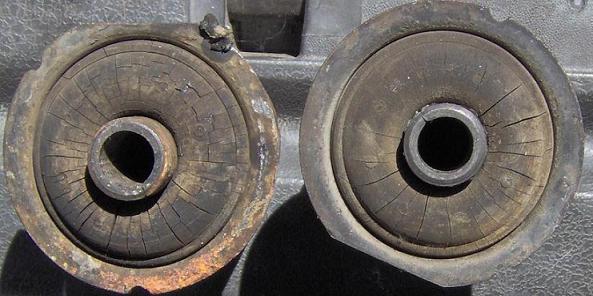

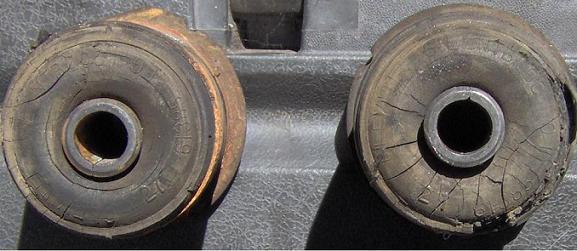

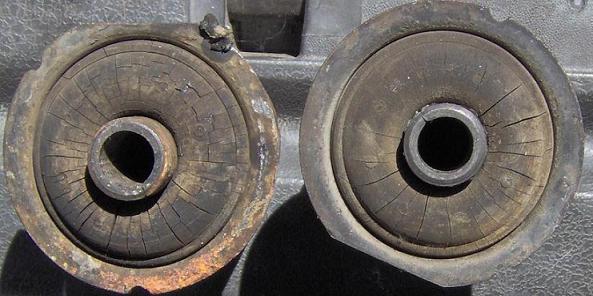

Below is one side of the cradle bushings I removed. Those are pretty shot. I installed poly but not by burning them out. Prothane has this problem of being off by .100" on the front bushings so I buy new rubber bushings, mill out the rubber, correct the poly bushing (mill off .100" of the inside of the lip) and press it into the sleeve. Then I install the bushings using the right combination of the pipes above. The rear cradle bushings are also .100" too thick so I correct that before installation too. Prothane gave me 10 sets of cradle bushings to play with on other cars but I never did hear from them if they corrected the error. Since I won't need any for a long time I haven't bought any to check.

A shot of the other side of the cradle bushings. Nice cracks.

A shot of the front trans mount. Notice the cracking and sagging.

A note: In the control arm pics above you can see the Herb Adams spherical bearings and the grease fitting. Since I installed my other arms with new rubber bushings and ball joints, I used my spherical bearing arms for this demo.

Yes, the arms work great with the spherical bearings but they are a bit too harsh for street use on rough roads. With poly cradle bushings they would have been brutal.

I think from these shots you get the idea on how to fabricate the special tools to remove and install all Fiero bushings.

Finally, I don't use poly in control arms so I won't be able to answer any poly control arm installation questions. This was intended for the rubber crowd. I'm more than happy to discuss rubber installation.

Terry

[This message has been edited by TK (edited 09-25-2005).]