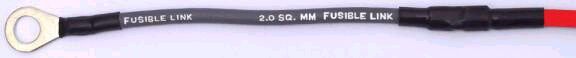

NEVER solder fuse links!!!!! This will change the value of the fuse. The link won't blow when it should.

They must be installed with good crimps and weather proofed. The best thing to use is the self sealing heat shrink tubing. It has an adhesive in it that melts when you shrink it. (You can get crimps with this already on them or use bare crimps and loose tubing.)

Yes, they do make fuses that could be used instead but I wouldn't do that. Especially in the extrememly wet area that is the Fiero engine bay.

Fuse links can be bad before they actually burn. The problem is water gets into them and starts corrosion. They can develope enough resistance to be a pain for quite awhile before they blow out. Once they corrode enough, you will do something that pulls some amps, like turn on the headlamps, and the link will fry off. This sort of failure is common when links are mounted to the starter or in any other wet area.

With the problem descibed above...

I would start by replacing both battery cables and the braided ground strap. Cables that look good often are not. Don't bother with an OHM meter... the wire is too heavy for that to be a useful test. I use ACDelco battery cables whenever I can. They give you enough thin wire to trim it to length so there are no splices in it. most other brands give you about 3 inches of thin wire.

Make sure the main junction under C500 is clean and tight.

Check all the connections on the alt and have the alt tested. You can have that done free at many parts stores and other places.

After that replace the main cable for the alt. This isn't as easy as it sounds. You have to use a high quality wire, preferably with high temperature insultion. Crimpling terminals reliably on large wire can be difficult by hand. I put the crimps onto the normal wire and solder them, leaving the one splice open for the fuse link. (Again, you musn't solder fuse links.) I then climp the fuse link in and cover with weather proof heat shrink.

Keep in mind you also have to crimp in the sense wire that goes from the side if the alt to the main wire. Most people crimp that wire into the big lug for the output stud with the main wire. Make sure you leave enough slack that you can unplug the side connector without undoing the main output post.