So far everything that has been said is good

I would like to add a few notes.

About the heads…

If you want to learn, ask the machine shop if you can watch them do a head job and have them do it. because if you are going to have them do a valve job and have the heads checked you are wasting your time taking them apart.

But if you really must do it yourself…

When you take them apart and you’re keeping the valves and what not in order, take a centerpunch and put a mark on one of the heads and mark that corresponding box of parts so you’ll know which head to put the stuff back in to.

The tops of the valve stems may have spread out a bit so they don’t come through the guide. Use a fine file to get rid of the hump at a 45’ angle.

To clean the carbon and varnish off the valves use a bench grinder with a wire wheel.

Check the valve stems for wear or scratches

After the valves and heads are clean and everything is oil and grit free.

Put the valves in the heads and wiggle the valves they will probably all have a little slop, a tiny bit is ok, but if the valve can wiggle 2mm or more you need the guide either replaced or gnarled and honed. If this had to be done, the relationship of the guide and the valve seat will change slightly and a valve seat grind may be required.

I only suggest positive valve stem seals on the intake valves, some will disagree.

Cleaning the heads.

An air die grinder or angle grinder with a very small wire brush in the shape of a cup or all pointing forward like the pedals of a rose bud will clean in inside of the valve seats and the combustion chamber.

When finally assembling the head dip each valve stem in a cup of oil.

If you did a valve job, check stem height from the spring seat,

shims may be required.

Unless you have the expensive tools to do it yourself, a shop can do a better job.

Once it’s all back together take the heads to a machine shop and ask to have them “suck” tested.

This is a test to see if a vacuum can be created in the intake and exhaust ports, it shows if the valves are making a good seal at the seat. Anything below about 5 bar suggest a weak seal.

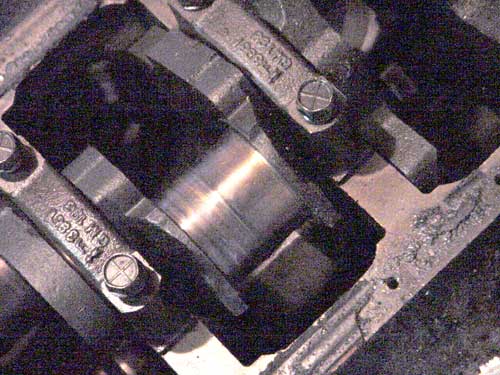

Have the rods checked, they may not be able to do it with the pistons on, and you will most likely damage at least one piston if you remove all 8. if you have them reconditioned they remove the bolts, grind the 4 flat spots so the rod and cap no longer make a circle when assembled it looks more like this (), then a new circle is ground so it’s perfect again.

Have the block cleaned, including the oil galleys, have cam bearings installed.

You might as well replace the freeze plugs yourself while you got the block out and clean right now. It’s cheap and easy, just ask for a freeze plug kit from an auto parts store, should come with oil and water galley plugs.

Chevy cams are known for going bad, get a new cam kit, this will also give you new lifters.

Once the engine is all back together minus the valve covers. Rotate the crank until you are at TDC on #1 on the compression stroke and don’t touch the crank again. Watch the rocker arms as your turning the crank, you are on the compression stroke when the intake valve was the last rocker to move. This will make timing simple when you drop in the distributor.

After the engine is complete the last part to put in being the distributor, put on an oil filter, fill it with oil and use an oil priming tool to run the oil pump with a drill.

I’ve seen two types of tools for this, one is a shaft that fits through a housing that looks like the bottom of the distributor case. And the other type is just a shaft.

If you get the type that is just a shaft, put some rags around the distributor opening on the intake, cause about 0.00001 of a second after the drill rpm drops down, the oil is gonna come up out of there like a fountain.

Rotate the crank shaft 360’ twice so your back at TDC on #1 and do your final valve adjustment to the fulcrum nuts.

Talk to your auto parts stores, and the machine shop.

They both can probably supply you with a kit that includes

Cam and lifters

Timing chain and gears

Freeze plugs

Rings

Bearings

Gaskets

The kit price should be a lot cheaper than buy each piece separately

(V8 Fiero's not allowed here, only V6 and 4 cil ). but 3800SC IS possible.

(V8 Fiero's not allowed here, only V6 and 4 cil ). but 3800SC IS possible.