|

| 48V automotive standard (Page 3/5) |

|

theogre

|

MAR 12, 04:27 PM

|

|

Important Note:

Any X battery needs More Volts to Charge.

Is Why "12v system" for cars and hell of a lot others have Alternator putting out 14-15 volts.

"36v" Lead Battery, actual battery at Full Charge is ~ 37.8v (2.1v x 18 cells), needs ~ 48v from the alt or whatever to charge.

LiIon etc is not different.

Example: Tools using 18/20v battery needs ~ 24v and maybe more from the charger but is much more complicated to charge right to have long live batteries.

Even ignoring BLM to level charging, at first a charger regulates volts then near full switches to constant current that can drive up the volts during charging.

But Again,

EV's and Hybrids can just have a "Tap" on the main battery that's closer to 48v because Charging Volts is calc'ed on the much bigger battery pack.

Why do EV etc need 48v... Just Because PW etc?

Not quite... EV's use Electric for AC, Heat, and More that love higher volts to run them a lot. Those could even get higher volts then 48v.

IOW Another Electric motor runs "AC" compressor for R134 or R1234yf. Often AC is a Heat Pump that get heat to cabin too because likely More efficient then just huge resistors. (Same problem w/ many Heat pumps at Home when have to run "backup" electric heat.)

|

|

|

cliffw

|

MAR 13, 10:27 AM

|

|

| quote | Originally posted by maryjane:

|

|

| quote | Originally posted by theogre:

|

|

Again, good information.

Let me research maryane's link before I don't burden y'all some more.

|

|

|

maryjane

|

MAR 13, 12:20 PM

|

|

| quote | Originally posted by theogre:

Important Note:

Any X battery needs More Volts to Charge.

Is Why "12v system" for cars and hell of a lot others have Alternator putting out 14-15 volts.

"36v" Lead Battery, actual battery at Full Charge is ~ 37.8v (2.1v x 18 cells), needs ~ 48v from the alt or whatever to charge.

LiIon etc is not different.

Example: Tools using 18/20v battery needs ~ 24v and maybe more from the charger but is much more complicated to charge right to have long live batteries.

|

|

Trying to charge a 12v car battery at 12v will give you a reading of 12v (or less) on the battery being charged, but very little current will flow from the charged battery. Basically, few electrons are being moved from plate to plate (and they will move slowly) and it's why it's so hard to 'jump' a dead car off with another battery on a car that isn't running. The electrons don't get bumped off their shells around the outer part of the nucleus on the plates and that's what current flow is.[This message has been edited by maryjane (edited 03-15-2023).]

|

|

|

cliffw

|

MAR 14, 09:25 AM

|

|

My next ignorant question.

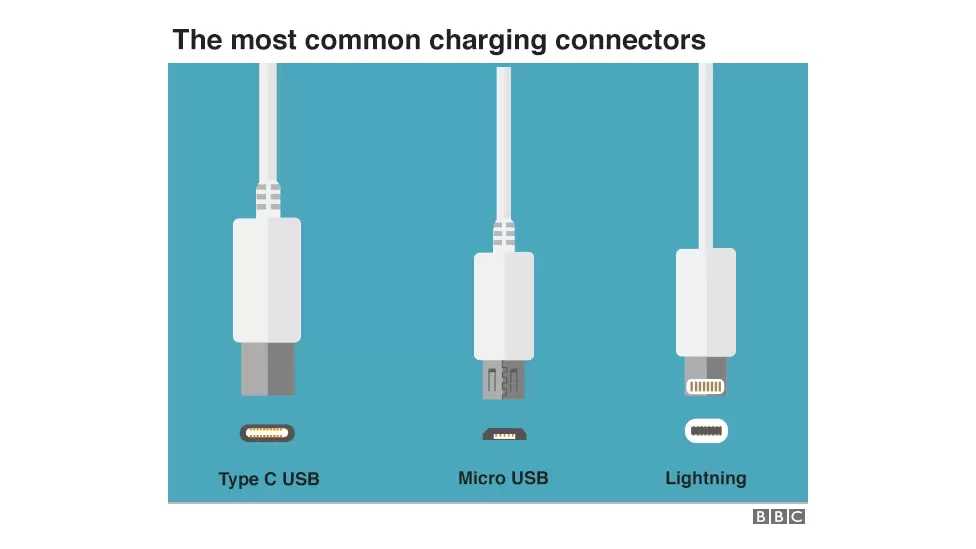

We have all of our phones, tablets, and other things which we charge with a USB cable. The out put connection is different per device.

Why ?

|

|

|

RWDPLZ

|

MAR 14, 10:19 AM

|

|

| quote | Originally posted by cliffw:

My next ignorant question.

We have all of our phones, tablets, and other things which we charge with a USB cable. The out put connection is different per device.

Why ?

|

|

Patents, trademarks, and licensing. Everyone wants to be the standard, and rake in the royalties, or use the cheapest standard they can get away with.

|

|

|

cliffw

|

MAR 15, 07:16 AM

|

|

| quote | Originally posted by RWDPLZ:

Patents, trademarks, and licensing. Everyone wants to be the standard, and rake in the royalties, or use the cheapest standard they can get away with. |

|

That makes a lot of sense.

How did the 120vAC plug become the standard ?

I thought trademarks or patents expired after seven years. Which is how we get generic drugs and other things.

|

|

|

maryjane

|

MAR 15, 08:47 AM

|

|

| quote | Originally posted by cliffw:

That makes a lot of sense.

How did the 120vAC plug become the standard ?

I thought trademarks or patents expired after seven years. Which is how we get generic drugs and other things. |

|

| quote | | Following the lead set by the lamp manufacturers in standardising lamp bases, a conference of the plug and receptacle manufacturers, including Hubbell, was arranged[when?] with a view to agreeing a standard configuration. It was a time of great expansion in the use of electrical appliances such as fans, heaters, and cookers, as well as portable devices such as hair curlers and irons, and the public wanted interchangeability. Hubbell's parallel pin configuration was preferred, but Hubbell rebelled against standardization, and refused to agree, asserting that it had common law rights in the dimensions of its line. The other conference members pressed on regardless, and agreed to standardize on Hubbell's parallel flat pin configuration and dimensions. Hubbell's court action only served to confirm the legality of their activities, to the great benefit of the U.S. public |

|

https://en.wikipedia.org/wi...er_plugs_and_sockets

The holes in each AC power plug... They are there only becuase the public has come to expect them there. There was a time (long past) when recptacles weren't spring tight with not much gripping force and the plug could fall out but that is no longer the case and the holes in the plug prongs no longer play any usefull purpose. Still, they've been around fo so long, that if given a choice, consumers will almost always chose one with the holes in them.

(The only possible reason you would need a plug with holes was if you live in a house with really old receptacles...1940s or older)

[This message has been edited by maryjane (edited 03-15-2023).]

|

|

|

theogre

|

MAR 15, 08:28 PM

|

|

In very short version...

The Holes are used by some manufacturers to Make the plugs. Holes are Index Points to anchor the metal into a mold etc to attach to whatever at the factory.

Wall and Many other sockets/outlet/etc Never use them to hold the plug. Not even parts made is 1920 to 50's do this.

Not even Hospital Grade and most other Industrial Grades never used them.

Big problem is if the socket use them to hold the plug then the plugs must have holes and exact same spot from hundreds to thousands of makers of each... Even is are from same brand... tolerance stacking can cause failures.

If a business required locking base and other plugs for Example Lock Out Tag Out or anti-tamper then have way more things to really lock them.

If a business required more anti vibration etc then have Push & Twist AKA Twist-locking connector sets for this. While many think 30a or higher, does make smaller 15a and 20a 120vac sets under ML and NEMA L numbers.

|

|

|

Patrick

|

MAR 15, 10:43 PM

|

|

| quote | Originally posted by cliffw:

We have all of our phones, tablets, and other things which we charge with a USB cable. The out put connection is different per device. Why ?

|

|

That'll be changing. Eventually, USB-C will be the universal standard.

European Union rules to force USB-C chargers for all phones

|

|

|

theogre

|

MAR 16, 12:49 AM

|

|

| quote | Originally posted by cliffw:

My next ignorant question.

We have all of our phones, tablets, and other things which we charge with a USB cable. The out put connection is different per device.

Why ? |

|

Simple because was Design for current USB protocol and plugs at the time. Design of X product is months to Years before actually made and sold.

Is why some USB3 things like External HD use USB3 A to Stacked B or SideBySide Mirco B so ports can handle high speed, get enough power or both.

While many "love" USB C... Has many problems and first is Size causing same problems w/ Mirco B and Mini B.

Publish Spec's often don't meet Real World use and wears out fast or just breaks. (Mini and Micro HDMI and Display Ports have similar issues when are actually used.)

Worse... Having a USB C plug often not = you get faster data transfer or more power. Example: Many things w/ C plugs still use USB2 for data and power.

Far Worse... High Power things not only get more amps but now get 9 to 20+ Volts thru that tiny USB C plug and cable. If the parts are damage at all then can fry the MoBo and more.

And That's with good parts from known brands. Many buy cheap knockoffs etc cause even more problems w/ USB, more so w/ C plugs.

Vs.

Big power plugs on laptops can break but often didn't fry MoBo etc. Bigger to handle by most users and harder to break. Or better Apple and some others magnet power connectors that "break away" w/o damage to anything.

Plus is why Dell and some others still offer Laptop Docks on some models like Dell Latitude. So Business users don't have to pull USB and many other plugs every day or more often. Dock connector and other things like guide parts so things align before the dock connector hits are made to last longer then most other plugs including USB ports.[This message has been edited by theogre (edited 03-16-2023).]

|

|

|

|