|

| One cause of China's lack of shipping products lately? (Page 2/2) |

|

sourmash

|

OCT 23, 12:22 PM

|

|

|

pssst it's the new America.

|

|

|

maryjane

|

OCT 25, 12:41 PM

|

|

| quote | Originally posted by 2.5:

For sure I dont undrrstand why we cant get that straightened out either. |

|

See Rick's reply in one of the other threads which will explain part of the reason the supplylogistic train can't or isn't rapidly 'fixed'. But, labor (and the union) is only a portion of the problem.

Corporate Production (supply) vs Consumer (demand)

Once any production drops below demand, (with finite production capacity) there will be a shortfall of supply, but if production (supply) is steady enough to meet any increase in demand then all is well even if demand increases.

Logistics (shipping and recieving)

China makes 'stuff for coutries all over the world, not just for the USA. Some of their manufacturing capactiy was shut down or at least significantly decresed most of 2020 due to Covid. Once they got their nation back on reasonable footing, their production ramped back up. They have adequate shipping ports and handling facilities for container shipments but when the rest of the world began to exit lockdowns and demand picked back up, our import handling facilities are not adequate to handle the greatly increased amount of ships needing to be unloaded. Container ports are limited by the number of gantry cranes and dock facilites they have and no amount of new hires or personel will change that. by any significant measure. Even working 24/7, there is only so many containers they can unload in a single week. We do have ports on the gulf coast and East coast that could take on more shipping but the southerly run around either the Cape of Good Hope in Southern Africa or down around Cape Horn in South America would lead to longer trips, more costs and added costs to the consumers.

Once a port is back-logged, it takes a long time to catch up, just as it does with any logistics train, as ya have your normal deliveries plus the deliveries due to increased demand caused increases of supply.

We also, on the demand end, have a dire shortage of trucks and drivers. Adding to that, is an archaic network of rail freight assets.

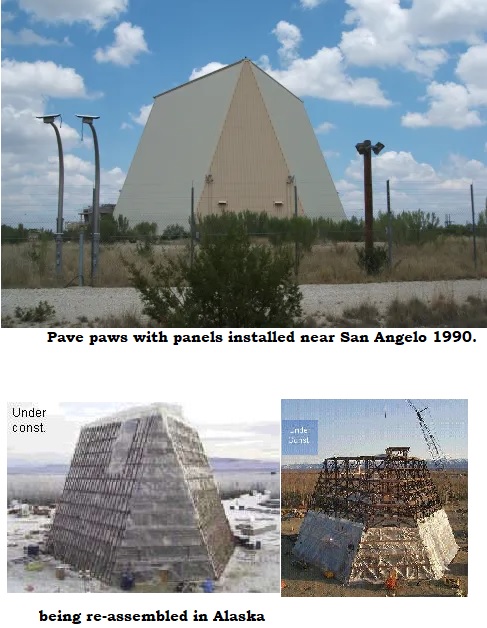

I saw a small example of what increased demand can cause to a business when I worked in a small precision machine shop in the mid-late 90s. Our bread and butter was making precision parts for machines at Johnson & Johnson's Ethicon division. We had 3-4 full time machinists, an owner/machinists, 3 good milling machines, 1 CNC machining center and one cnc lathe. We easily kept up with J&J's needs with only rare need for any overtime, but DoD USAF issued a requirement for local machine capacity to build replacement parts for a big radr array about 20 miles south of San Angeloat the tiny town of Eldorado. . Since we were the only real precisionmachine shop in the county, and fed law requires that local companies get the bidding priority, we had to submit a bid or lose any future work from the radar base and from the Goodfellow AFB. We did get the work (we were the only bidder that met their specifications) but shortly thereafter, USAF threw a wrench into the works. They were going to disassemble and move the entire array from West Texas to Alaska, and, significantly physically nlage the array and we were to make all the structural components needed to do the enlargement. Our task went from making a couple hundred parts to making thousands of the same parts overnight, PLUS our regular work for J&J.

J&J worked with us to some degree in postponing some of their work but we way overburdened with USAF work, then had to play catchup for a couple months with the J&J stuff after completing all the stainless and alum work for USAF and their Pavepaws array. 6 days/week, 12 hrs/day for about 3 months.

Another local company found themselves in the same predicament when they too submitted a bid to make the crating for shipping the disassembled array to Alaska. They had to work a lot of overtime to meet our production schedule plus take care of their normal customers. There was a LOT of blue collar overtime paid in San Angelo Tx that year.

Once you get behind, it is just difficult to catch up if there is limited facility infrastructure to meet increased demand and no amount of manpower can offset the need for heavy equipment and rolling stock.

|

|

|

Jake_Dragon

|

OCT 25, 12:53 PM

|

|

| quote | Originally posted by maryjane:

I saw a small example of what increased demand can cause to a business when I worked in a small precision machine shop in the mid-late 90s. Our bread and butter was making precision parts for machines at Johnson & Johnson's Ethicon division. We had 3-4 full time machinists, an owner/machinists, 3 good milling machines, 1 CNC machining center and one cnc lathe. We easily kept up with J&J's needs with only rare need for any overtime, but DoD USAF issued a requirement for local machine capacity to build replacement parts for a big radr array about 20 miles south of San Angeloat the tiny town of Eldorado. . Since we were the only real precisionmachine shop in the county, and fed law requires that local companies get the bidding priority, we had to submit a bid or lose any future work from the radar base and from the Goodfellow AFB. We did get the work (we were the only bidder that met their specifications) but shortly thereafter, USAF threw a wrench into the works. They were going to disassemble and move the entire array from West Texas to Alaska, and, significantly physically nlage the array and we were to make all the structural components needed to do the enlargement. Our task went from making a couple hundred parts to making thousands of the same parts overnight, PLUS our regular work for J&J.

J&J worked with us to some degree in postponing some of their work but we way overburdened with USAF work, then had to play catchup for a couple months with the J&J stuff after completing all the stainless and alum work for USAF and their Pavepaws array. 6 days/week, 12 hrs/day for about 3 months.

|

|

They changed the job after the company bid on it? I hope they paid well.

|

|

|

maryjane

|

OCT 25, 02:09 PM

|

|

They paid well enough for me to stay there another year and 6 months. Us machinists got a pretty good bonus when the owner's check came. Mine was $1500 on top of my wages. I do not know how much the company made on the deal. Beyond my paygrade.

Pave Paws replaced the old BMEW in Alaska.

It (PavePaws) has a 3000 mile range. When it was in Eldorado Tx, it 'looked' south and southeast. It now peers over toward China and the pole. Won't quite reach (according to unclassified released docs) to Beijing but it's close. 3900 miles from Clear Air Force Space facility to Beijing.

|

|

|

sourmash

|

OCT 25, 02:33 PM

|

|

When there's a labor crunch people get ideas that they can abuse the situation.

My last employer had a shortage of personnel when I went there (5-6 slots) and also when I left in 2018. The 3 stooges proofing people were so jealous of each other they couldn't agree on hires. Plus anyone who could perform decided the grass was greener elsewhere. Their immediate supervisor had terminal cancer and wasnt able to perform either. Two of the stooges wanted to be his replacement and were back stabbing.

They finally removed those 3 managers from the vetting process (they couldn't even agree on hiring their own, individual employees) but the brain drain had already happened. The main manager did finally succumb....no idea what it's like in these times for that group. I'm glad to not be there. "Corporate" sucks.[This message has been edited by sourmash (edited 10-25-2021).]

|

|

|

|