|

| Blooze Own: An F355 Six Speed N* Build Thread (Page 60/126) |

|

Bloozberry

|

DEC 07, 09:18 PM

|

|

Absolutely. The total amount of travel in jounce and rebound will be kept in check by the right spring choice, and by the springs and sway bar in roll. (I haven't shown how I plan to connect a sway bar yet but I'm working on linking it to the bell crank.) I alluded to it before, but you can use stiffer springs, or a bell crank with a greater than 1:1 ratio, or variable rate springs (wound tighter at one end), or any combination of all three to keep the suspension from travelling through it's full range. It can also be made to be softer at first and get progressively harder the more you roll or jounce as you mentioned would be desireable. Regardless, it's always better to have additional range available than it is to come up short against a bump stop. When that happens, you effectively lose all of your suspension dynamics and you may as well be driving a an ox cart... Haw Bright, haw!

Determining the optimal spring rates for road holding is done by using a formula such as the one found here: www.hypercoils.com/spring-rate-calculator/ as a starting point. This formula determines the best spring rate to keep your wheels in contact with irreguar road surfaces, though it may not give you a spring rate that's to your liking for suspension travel, nor the amount of squat you desire on acceleration. Like everything else, you must make compromises between many variables and choose the spring rate you need to satisfy mulitple objectives. I consciously chose 3" of travel so as not to artificially limit my options at this stage.

|

|

|

Dave E Bouy

|

DEC 19, 09:17 PM

|

|

| quote | Originally posted by Bloozberry:

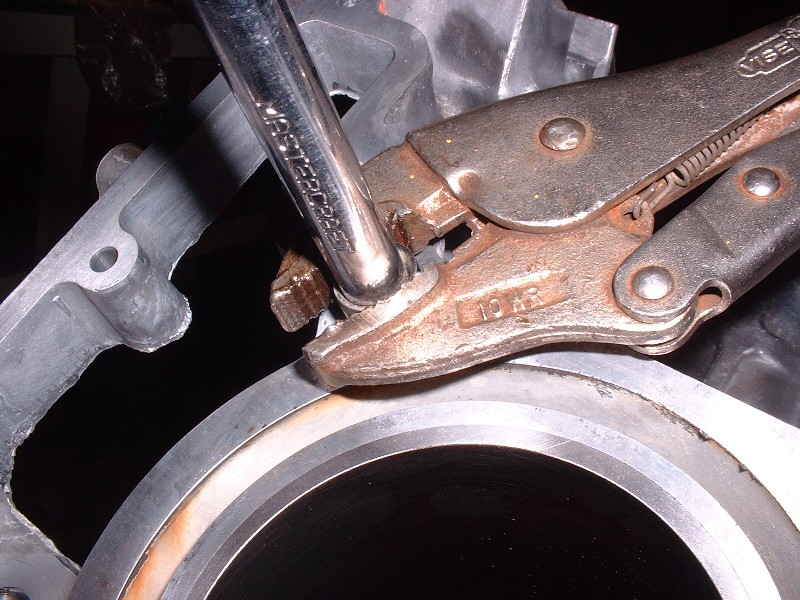

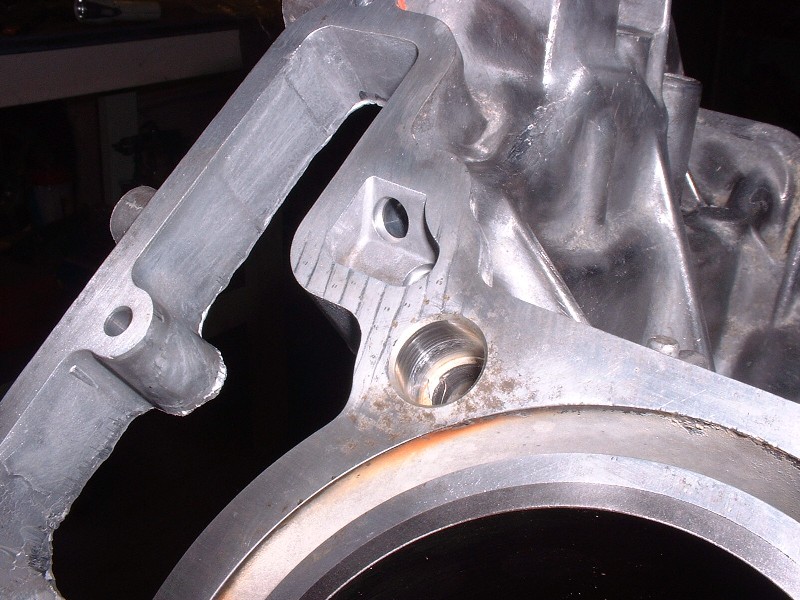

Next up was to remove the four steel head-alignment dowels on the deck surface. They’re swaged in the holes very tightly and are impossible to remove without ruining them. At first I thought they’d come out with a little gentle persuasion, but that gave way to more draconian measures. I’ve seen someone here on PFF remove them by welding a steel rod across the tops and twisting them out that way, but I found an easier method. I used Vise-grips to twist them out but found out that unless you push something into the hollow dowel, the Vise-grips will just deform it and slip rather suddenly. An extension for a 3/8” drive socket wrench fits just right. The extension prevents the dowel from collapsing and from there it was a simple matter of twisting and pulling at the same time. It still took a couple minutes per dowel though.

Here’s what they looked like after they came out. Definitely not reusable, and after a quick call to the local dealership, I found out that they wanted $17(!) for each one! And, to top things off, they are discontinued. There were still a few sets here and there across the good ol’ US of A, but I’m certain that shipping, brokerage fees, and taxes would have nearly doubled the price of these puppies. Luckily I have a friend with a metal lathe who turned some new ones for me for $20 labor.

|

|

I tried your method earlier tonight. I could get the dowels turning but I couldn't generate any lift. One dowel actually shredded under my visegrip and I guess I'll have to drill out the remains. For the other three I resorted to the steel rod welded across the dowel. It made for easier pulling. The heat may have helped too.

DF

edited to add Sorry to stray off topic here and now back to our regularly scheduled suspension redesign.[This message has been edited by Dave E Bouy (edited 12-19-2012).]

|

|

|

ArbinShire

|

DEC 22, 10:56 PM

|

|

|

Is this an actual build, or a theoretical build?

|

|

|

Bloozberry

|

DEC 23, 07:59 AM

|

|

|

Is this a silly question or a serious question? [This message has been edited by Bloozberry (edited 12-23-2012).]

|

|

|

m.mcc

|

DEC 27, 11:08 AM

|

|

Hello Mr. Blooze,

I joined the forum so I could thank you for sharing your research and scale drawings. I stumbled in here a few months ago through a google search and you have saved me untold hours of work on my project. I join the others who have expressed their appreciation for your hard work and generosity. You are a true craftsman and obviously a perfectionist. Thanks again.

Mike

|

|

|

Bloozberry

|

DEC 27, 04:43 PM

|

|

Thanks for the compliment Mike! And welcome to the Forum. The progress is slow and tedious at times, but kind words from complete strangers make it all worthwhile.

|

|

|

m.mcc

|

DEC 29, 02:45 AM

|

|

Thank you for the welcome, Mr. Blooze

When I found your build thread I was looking for information that would help me design a rear frame section using ’88 Fiero suspension pieces and to that end your drawings have been a God send especially since I don’t have a car to take measurements from.

I must admit that initially I didn’t spend much time reading about what you were doing. I just grabbed the pictures and ran but as I worked on my project I kept getting guilt pangs that I should at least thank you for your efforts, if not contribute to your favorite charity (or the car project  ) LOL. Well, since I posted the other night I’ve gone back and spent at least six hours reading and digesting what you are doing………and I’m developing a few questions. ) LOL. Well, since I posted the other night I’ve gone back and spent at least six hours reading and digesting what you are doing………and I’m developing a few questions.

A little background is in order. I’m NO suspension expert but I have built a lot of race cars, mainly oval track stock cars, and have worked through a lot of the same issues you are addressing. It’s been awhile since I started from scratch like you are doing, and a lot has changed, but I remember some of the basics and I’m seeing some things that I don’t understand. So how best to engage you on this? Do I post here, or contact you privately? I’m new to this forum and want to make sure that I’m adhering to accepted protocols.

Mike

|

|

|

Bloozberry

|

DEC 29, 08:12 AM

|

|

|

Please feel free to discuss your concerns and ask questions here in the thread Mike. I'm no expert either so input is always welcome. Constructive criticism is the mother of great design.

|

|

|

m.mcc

|

DEC 30, 10:35 PM

|

|

Blooze,

First off, I’d like to say how much I have enjoyed immersing myself in your build thread. Lots of good information and a lot of really smart and inquisitive contributors here as well. It’s been very thought provoking and fun.

What concerned me most as I began studying your suspension analysis was it seemed at first that you were basing your conclusions about camber gain/loss, roll center location changes, and roll steer fluctuations on measurements taken solely from static bump and rebound. That concerned me because I have found that these measurements are not always the same as those obtained from plotting the suspension pick up points during chassis roll.

As I proceeded through the thread I then saw where you later presented charts and graphs plotting the changes based on body roll. The effects of bump and rebound when driving through pot holes or in straight line braking and acceleration is an important consideration for sure but the effects caused by body roll are, by my way of thinking, a more important consideration. One thing on this before I move on to other thoughts: regarding the rear suspension, did you include the various Chapman strut upper mounting datum point movements during chassis roll in your analysis? Because of the roll center fluctuations inherent in the strut design these points are all over the map and because they are located a long distance from the roll center they move a lot for every degree of roll. This could be significant in your analysis. Perhaps I missed it, but I don’t recall seeing this on your drawings. If these were not included some of your findings might be skewed.

You have invited input and constructive criticism and I hope my comments will be received as such. I don’t want to be perceived as the stranger who shows up in your garage and tells you all you’re doing is wrong. That’s not my intent at all. There are really very few absolutes in building project cars, very few right and wrong ways, and the great thing is that every project is a combination of many disciplines applied with an individual’s own approach and style. In my mind, hot rodding is really an art form and a very personal expression. So my following thoughts and comments are presented as differences in style and in the spirit of “point, counterpoint”.

Okay, so here we go. You seem far more concerned than I would be with the suspension’s bad behavior at roll angles that I don’t think you’ll ever see and might not even be physically attainable with the components you are using. A big old Buick sedan driven into a sharp decreasing radius turn at 100 mph (er, 160 km/h  ) might see six degrees of roll but I doubt your car with its low center of gravity, wide stance, and stiff spring/bar package will ever see half of that even if it were to be track driven and I didn’t see that as part of your original design criteria anyway. I would be concerning myself with the suspensions behavior up to about 3 degrees and that’s about it. I would have little to no concern beyond that. With this in mind, most (but not all) of your scenarios fell within what I would consider to be generally acceptable limits within that roll range. Again, maybe not absolutely perfect for track use and not as desirable as say the GT40, but again the car is being built from a production car platform for road use. I think if you did this extensive analysis on even good handling production cars like BMW’s, Corvettes, etc you would find that even they have less than perfect behavior in the extremes of suspension movement. ) might see six degrees of roll but I doubt your car with its low center of gravity, wide stance, and stiff spring/bar package will ever see half of that even if it were to be track driven and I didn’t see that as part of your original design criteria anyway. I would be concerning myself with the suspensions behavior up to about 3 degrees and that’s about it. I would have little to no concern beyond that. With this in mind, most (but not all) of your scenarios fell within what I would consider to be generally acceptable limits within that roll range. Again, maybe not absolutely perfect for track use and not as desirable as say the GT40, but again the car is being built from a production car platform for road use. I think if you did this extensive analysis on even good handling production cars like BMW’s, Corvettes, etc you would find that even they have less than perfect behavior in the extremes of suspension movement.

Personally, in this application I would be more than fine with a camber curve of one degree (or even slightly more) per degree of body roll. The .7 to 1 of the GT40 is great but I don’t think you’d know the difference in this application. If you can get to .7 to 1 without a lot of hassle, fine. If not, get as close as you can without major modifications and call it good. Again, I don’t think you’ll even see three degrees of roll except under very rare circumstances. If you do, you’ll be looking for a revised spring/bar package no matter what the camber is doing. Another consideration is that radial tires actually like a little camber so there’s nothing wrong with a slight increase in static negative camber setting if you need it. I have little doubt that you could add another degree negative to static with negligible effect on tire wear or steering stability, although you might want to increase static toe-in ever so slightly if you do. That would be a seat of the pants trial and error adjustment. One last comment on camber. I do think you are correct in fixing the rear lower control link angle so it is level at static ride height.

I have been fooling around with this stuff for almost 40 years and I’ve grown increasingly skeptical about the conventional wisdom regarding the roll center, and by extension the roll axis, and the dynamic relationship they have with the CG and the various suspension components and, more specifically, the actual effect on weight transfer. Don’t get me wrong, we know that weight transfer occurs and we want to control it in a way that helps us. I’m just not so sure that a migrating roll center is that big a deal, especially in applications such as this. It’s an established fact that strut suspensions produce massive roll center movement. It’s also an established fact that there are a lot of very, very, good performance road cars that use struts on one or both ends and these cars don’t suffer from erratic handling. My friend’s WRX is a great example and the little Lotus that Colin Chapman first put these on was no slouch either.

We also know that dynamically the roll centers and roll axis are constantly moving around, as is the CG, so the moment arm is constantly changing in both length and I suspect also inclination. My personal theory is that the moment arm inclination relative to the force working against it at any given moment in time may be a factor-but I’ve not seen this discussed before so I could be all wet here.

I’m extremely intrigued with the force based roll center principles discussed by Bill Mitchell in the paper referenced by FieroWannaBe. I had not heard of this before but I have suspected that there was something else going on. Maybe this is it. I’ll have to find time to study this more. Thanks FieroWannaBe! Anyway, I’m of the opinion that in your application, or mine for that matter, that the roll center migration is worthy of note, and perhaps should be addressed within practical limits, but not enough to cause dramatic redesigns given the original project design criteria. If we were going F1 or Indycar racing it would be a different deal. Again, this is my opinion but I do also respect yours.

A quick mention here re: anti squat and dive. I agree with FieroWannaBe in that I don’t think you need to be overly concerned with it. Just design into whatever you end up with for rear suspension about the same as original factory and call it good. If you felt that you needed a little leeway just in case of axle tramp you could design in multiple forward trailing link mounting points (or provide for them). And leave the front alone. I don’t think dive will be an issue for you. I also agree with FieroWannaBe about roll axis and static rear roll center heights. Stick with about stock and you’ll be fine. You will probably do fine with a relative flat roll axis for the reasons he mentioned. As a side note, although I have met Herb Adams, and have actually bench raced with him at his shop/house many years ago, I have not read his book but your assessment of him is correct. His background has been primarily with front engine solid rear axle vehicles so you are correct in being cautious applying some of his recommendations to a mid-engine IRS car. Make no mistake, he is a very smart and accomplished engineer but some of what he is saying may not apply to what you are doing.

In summation, the areas that I personally watch closely in these types of projects are tire choice, camber curves that I may have messed up by lowering, brake bias, scrub radius if I’ve changed wheel offset, and especially roll steer. I try to keep the CG as low as I can (without tearing the car apart), the track widths wide, and let the tires do the rest.

Ok, I've prattled on long enough. So again, I applaud your project and sincerely thank you again for your incredibly unselfish sharing of your drawings and research. I plan to stop back by from time to time to see how you are progressing.

Best Regards (and Happy New Year!)

Mike

PS. Can you or one of your readers give me approximate dimensions for a stock '88 Fiero rear sway bar (eye to eye, arm length, and diameter)? I haven't been able to find one or reference for this information. I'd like to see what rate was stock and decide if that will work for me. That will give me a starting point if I need to make my own.

|

|

|

FieroWannaBe

|

DEC 31, 04:19 AM

|

|

| quote | [B]

PS. Can you or one of your readers give me approximate dimensions for a stock '88 Fiero rear sway bar (eye to eye, arm length, and diameter)? I haven't been able to find one or reference for this information. I'd like to see what rate was stock and decide if that will work for me. That will give me a starting point if I need to make my own. |

|

http://www.fiero.nl/forum/Forum4/HTML/043365.html

I would measure an 88 rear bar for you, but that's the only 88 rear suspension piece not sitting ok my garage floor right now, but R Runners pieces are top notch, and have about any range you need. I do have a low opinion of heavy rear bars in an open-diff RWD car though and there tendancy to pull up on the inside wheel.

I agree that expecting 6 degrees of role is an unreleastic expectation. But as a design engineer by trade, I feel to not take the time to analyze a system at all conditions, even the most extreme, is inviting critical errors into the system. One thing I would also see as a benifit to Blooze's analysis' would be the effect of bushing deflection, as it can be very significant. But is see no fault to design something to 10 tenths, perfection cannot be reached, but it can be approached, and the reward is knowing nothing was left on the table. If the suspension is capable of 3 inches of jounce and bump it can, somehow, achieve roll at those 3 inches.

|

|

|

|