|

| Trinten's SBC/F23 build - The work has begun! (Page 59/76) |

|

Trinten

|

MAR 15, 08:54 PM

|

|

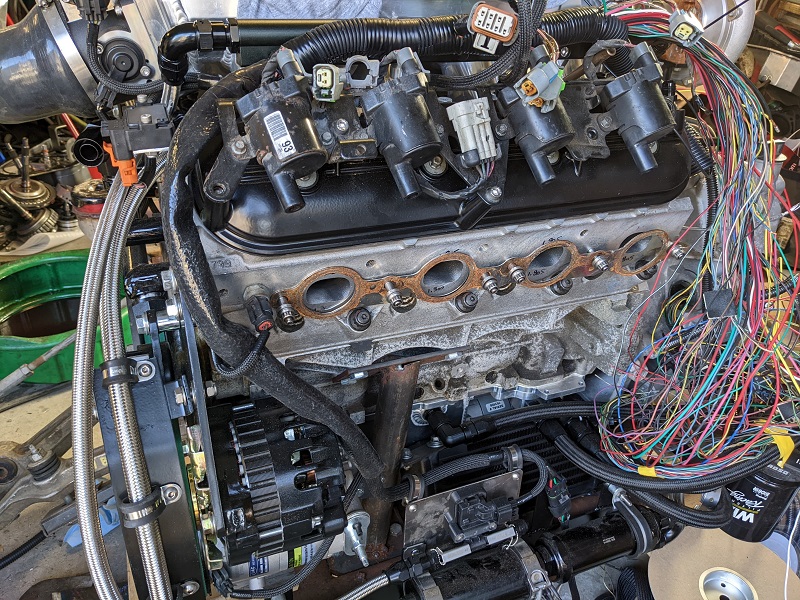

Mike has finished welding up all the exhaust stuff. I didn't get a picture after he put on the wastegate connection. But once everything gets back from Jet Hot, I'll put up more pictures.

Currently all the pieces are on their way to the Colorado facility for their 2500 coating. They couldn't do it in their local facility because the application method is different.

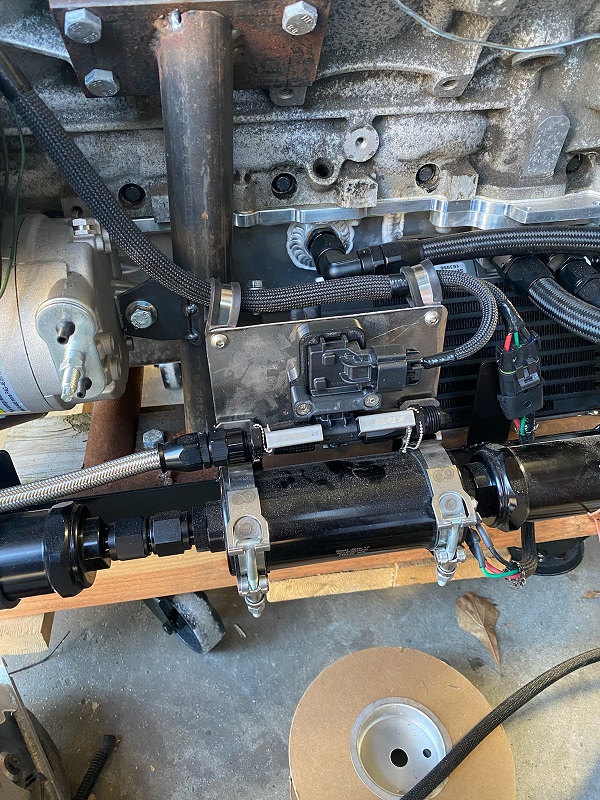

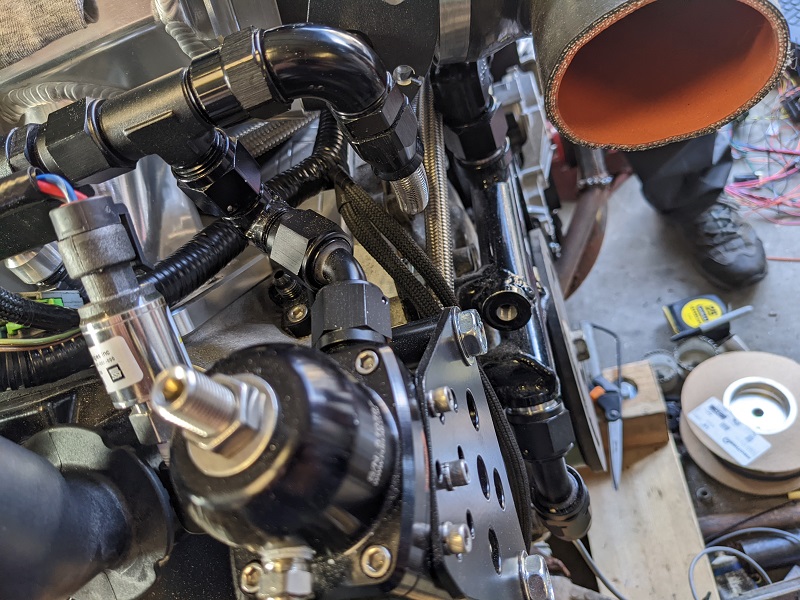

With that on it's way (and about a month turn around time, plus shipping time), Mike has gotten back to the engine harness. He is still working on the prototype one, using the original harness as much as possible.

He is still putting all of the many... many feet of high temp wire loom to work, to make things look as slick as possible, since this will likely be the one in the car for Carlisle.

That last pic is of a mounting bracket he made for the P-clamps to keep the wiring neat.

We talked about doing the wiring in the hyper-hidden slick way that FieroGuru does (and got me top marks when I had that setup at AutoFair in a car judgement stuff).

Mike doesn't want to go that route, so in case anything needs to be fixed or replaced, it'll be easier to troubleshoot and, well, fix or replace it!

There's still a lot to do. This weekend we plan on using the plasma cutter to finish cleaning up the cuts from when we took out the strut towers, take out the dog bone bracket, and start cleaning up the bulkhead.

[This message has been edited by Trinten (edited 03-26-2023).]

|

|

|

Will

|

MAR 21, 07:07 PM

|

|

| quote | Originally posted by Trinten:

We talked about doing the wiring in the hyper-hidden slick way that FieroGuru does (and got me top marks when I had that setup at AutoFair in a car judgement stuff).

Mike doesn't want to go that route, so in case anything needs to be fixed or replaced, it'll be easier to troubleshoot and, well, fix or replace it!

|

|

After building things that are in orbit and seeing plenty of aircraft wiring harnesses, I have to say I appreciate an visible and obviously obsessed-on harness over a tuck job. A tuck is certainly a lot of work, but boils down to repeatedly asking the question "Where can I hide this?" Serious harness workmanship is, well, serious, and should be shown off. NASA harness requirements are informed by millions of dollars of testing, inspection, and yes, failures and losses as well.

I'd rather see a harness presented such that it's painfully obvious to everyone that the builder really knew his **** than... not see a harness at all.[This message has been edited by Will (edited 03-21-2022).]

|

|

|

Trinten

|

MAR 21, 07:42 PM

|

|

Thanks Will

I really hope you can make it to Carlisle. I've told Mike about your work on your build, I think you guys would have some awesome conversations that I would not understand.

I still need to get the pictures off of my phone, but this weekend we did not get to doing the engine compartment as planned. The day was spent on doing wiring work, and we ran out of Deutsch pins. So I ordered like... 80 of them from Summit in the size Mike told me to get, and got those going to his place by 2 day air. He wants to finish getting the engine harness plugged into the bulkhead connector before the weekend.

Currently having an issue with getting the custom axles manufactured in a timely manner. G-Force says they are at least 10 weeks out, maybe longer due to supply issues. DSS (who I was reluctant to contact due to another member recently having an issue) hasn't gotten back to me at all. I did hear from another company called CVJ who says they do have 4340 bar in stock. Though for custom axles there is a lot of 'you send us this or that', and they make the bar to your specs, assembly it with the other parts you supply, and send them to you. So I'm making sure I understand their process exactly and may go with them unless I turn up multiple reasons why I shouldn't use them.

Jet Hot confirmed they received my materials today, so I paid that invoice. They currently expect to ship it back to me on April 25th.

|

|

|

Will

|

MAR 22, 07:39 AM

|

|

| quote | Originally posted by Trinten:

Thanks Will

I really hope you can make it to Carlisle. I've told Mike about your work on your build, I think you guys would have some awesome conversations that I would not understand.

I still need to get the pictures off of my phone, but this weekend we did not get to doing the engine compartment as planned. The day was spent on doing wiring work, and we ran out of Deutsch pins. So I ordered like... 80 of them from Summit in the size Mike told me to get, and got those going to his place by 2 day air. He wants to finish getting the engine harness plugged into the bulkhead connector before the weekend.

Currently having an issue with getting the custom axles manufactured in a timely manner. G-Force says they are at least 10 weeks out, maybe longer due to supply issues. DSS (who I was reluctant to contact due to another member recently having an issue) hasn't gotten back to me at all. I did hear from another company called CVJ who says they do have 4340 bar in stock. Though for custom axles there is a lot of 'you send us this or that', and they make the bar to your specs, assembly it with the other parts you supply, and send them to you. So I'm making sure I understand their process exactly and may go with them unless I turn up multiple reasons why I shouldn't use them.

Jet Hot confirmed they received my materials today, so I paid that invoice. They currently expect to ship it back to me on April 25th. |

|

You're Welcome!

Ehh... my car's ugly and will still be ugly right after I get it running. I expect that after I get it running there will be a shakedown period as well. I'm going to take it to a very reputable tuner to have the tune smoothed. Since I don't have the car running yet, I haven't reached out to schedule, but I'm sure he has a back log as well.

I haven't dealt with DSS myself, but their custom axle service that just requires a flange-to-flange distance sounds good on paper. ...As long as you have inner and outer flanges. You have Corvette hub carriers, so you should be able to order DSS Corvette hub flanges. There are still a very few of the GM racing 4T65 output flanges in the supply chain. I have a pair, and may still have the info to get you to the guy that has more.[This message has been edited by Will (edited 03-22-2022).]

|

|

|

Trinten

|

MAR 22, 08:27 AM

|

|

| quote | Originally posted by Will:

I haven't dealt with DSS myself, but their custom axle service that just requires a flange-to-flange distance sounds good on paper. ...As long as you have inner and outer flanges. You have Corvette hub carriers, so you should be able to order DSS Corvette hub flanges. There are still a very few of the GM racing 4T65 output flanges in the supply chain. I have a pair, and may still have the info to get you to the guy that has more.

|

|

Yes, I have a set of the corvette axles, though we did cut them to bolt the outer stub into the wheel hub so the wheels would stay on securely.

So the output flange is the housing for the inner tripod? The 4T65 uses the same size and spline count that (some) 4T80s and the C5 vette differential used?

If yes, then that's awesome and I'd be glad to try to get a pair of them.

GForce also makes billet flanges (they call them stubs - or I'm confusing the part you're talking about with a different part). Though their outer one may only come in a beefier 33 spline, which would mean buy another new set of wheel hubs.

And hey, my car is going to be ugly as sin too. I'll keep my fingers crossed that your tuning and shakedown goes smoothly.

|

|

|

Will

|

MAR 22, 08:42 AM

|

|

These are the hub flanges or drive flanges. They go into the hubs.

DSS 33 spline:

https://driveshaftshop.com/...e-930-cv-1595613401/

DSS 30 spline:

https://driveshaftshop.com/...08mm-porsche-930-cv/

These are the output flanges. They'd go into the transmission

https://www.realfierotech.c...php?p=153658#p153658

| quote |

Hmmm.... What are these?

|

|

They fit the 4T65E-HD, but if swapped left for right, they also work with a Getrag or F23 and intermediate shaft.

I *think* the 4T80E uses the same inner CV joints as the 4T65E-HD, so these should work with your 4T80E. If you have both the output flanges and hub flanges, then just measure between them and send the measurements to DSS (or GForce?) and they'll build you a set of axles to connect the flanges.[This message has been edited by Will (edited 03-22-2022).]

|

|

|

Trinten

|

MAR 22, 09:49 AM

|

|

I pulled up a 2002 Monte Carlo.

The spline count on what they call the inboard side (which on their site is the side closest to the transmission/differential because the inboard fitting is listed as female, and that lines up with the test axle I bought) is 34 splines

The 4T80 that I have and the C5 Vette are 41 splines.

Some earlier 4T80s, such as the 1995 Deville, had 35 splines.[This message has been edited by Trinten (edited 03-22-2022).]

|

|

|

Will

|

MAR 22, 02:21 PM

|

|

|

|

Trinten

|

MAR 22, 03:27 PM

|

|

It's okay! It's always good to explore new options!

GForce will sell their billet drive and output flanges separately, and will cut the splines either to the stock or to other sizes.

I've made progress during lunch today and finding someone who has 300M bar stock handy and has a 4-5 week turn around time for cutting them to the length and spline count I want.

The thing I'm struggling with now is finding measurements and drawing information on the CV joints I wanted to buy (or even info on the stock CV Joints), so I can figure out if they'll fit/bolt into the Vette's drive flange.

So far, most of my searches for "C5 Vette" "CV joint" turns up complete replacement axles.

I think this weekend, after we take measurements, I'll need to disassemble the drive flange and take a bunch of measurements and pictures of the CV joint that is in there.

I suppose it's possible that the Corvette guys are only shredding splines in wheel hubs and output flanges, and the CV Joints themselves are holding up just fine.

|

|

|

Trinten

|

MAR 22, 09:18 PM

|

|

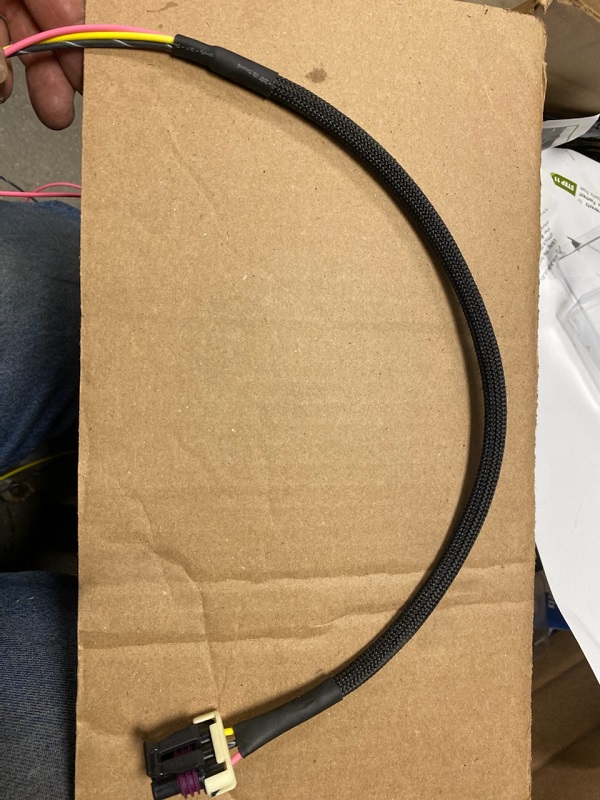

Okay, so some pictures!

As I mentioned earlier today in another post, Mike has been working on the engine harness, but we had to stop because we ran out of pins!

I also repalced the blower motor for the HVAC, vacuuming out the air box and cleaning the cage while I was at it. When I got done Mike looked at it and said "It looks brand new!" and I said "thanks, no sense putting a dirty part in there, especially if it's pushing air into the car." and he said "Too bad no one will ever see it."

That wasn't meant as a knock, it's a little bit of an inside joke, he has done a lot of things that are really clever or very precise, that we both know that no one will ever see.

So for this prototype, we are using what we can out of the loom that I bought, but in a few spots Mike used the more traditional split loom, usually because I didn't have all the sizes of wire loom we needed.

I also bought some very high end thermal protection sleeving that goes on over the normal loom. It's meant to be a little baggy. Mike used the cool self-fusing tape I bought to close off the ends of it.

Lastly, he did a quick test fit of the LS4 A/C hose to make sure it would clear everthing.

After he held it up and saw it would clear the fuel system and his brackets, he gave me a good natured eff-u, again cursing my 'luck' with how well stuff has worked out on this car, and commenting about how the smallest customization on his Grand National always lead to a domino effect of additional changes.

I just turned it around and complimented him on his craftsmanship and fore thought.

I also shot FieroGuru a question about the spread bar reinforcements for the decklid hinges he made for me (I lost them), thankfully it's an off the shelf piece, he told me the dimensions I needed, so need to get some of that.

Also found an interesting article today - https://www.rcnmag.com/tech/exotic-axles

For those that don't want to read it, basically a guy was building a kit car and wanted to find axles without getting custom ones made. He went to O'Reilly and they had a full catalog of A1 Cardone parts, laid out with columns like the oil filter lookup books are, and was able to find axles that were off the shelf and fit his kit car, despite the output flange and drive flange being from different cars.

This doesn't seem to exist online (outside of the typical make/model searches), so I sent Cardone an email asking them where I can download or buy such a catalog.

If I can find some off the shelf axles to use as daily drivers until I get my heavy duty axles, I'll do that. Plus gives me a spare set![This message has been edited by Trinten (edited 03-26-2023).]

|

|

|

|