|

| The Turbo Super Duty Build. (Page 54/63) |

|

FastIndyFiero

|

JUL 06, 01:16 PM

|

|

| quote | Originally posted by pontiacjeff:

Wow, tried to read thru but had to jump to the end... I am in the parts acquisition process to build a SD4 16V turbo engine myself. Please keep those CNC coordinates so I can buy some flanges form you! I'll check in when my parts arrive here. I have to ask if you have any spare bottom end stuff, rods, pistons, crank, block? |

|

I always save all of my models. What I can make depends on how much spare time I have, but I can always send you the CAD data. Any competent shop with a CNC machine would have no trouble knocking these out. I don't have any spare bottom end stuff, but if you keep looking I'm sure you'll find something. Just do a daily search on eBay and it will pop up.

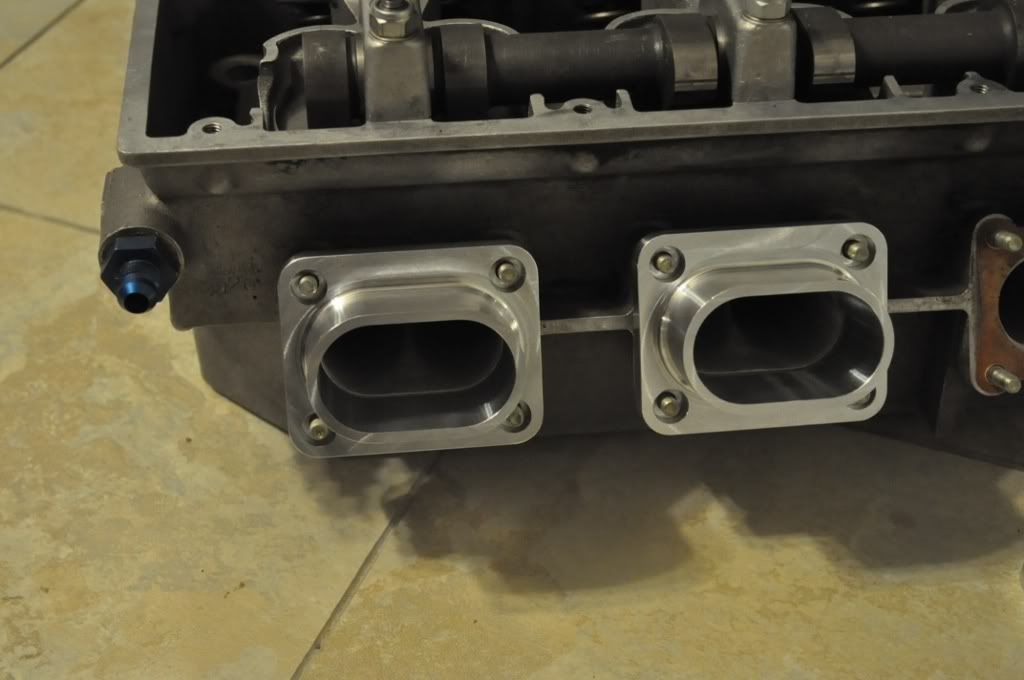

Finished a prototype intake flange today:

|

|

|

FastIndyFiero

|

JUL 06, 06:21 PM

|

|

The bolts are stand-ins, they're too long. The proper bolts will ride inside of the counterbores. The new flange ID is .010-.020" smaller than the port on the head, but there's plenty of material to take it out to a ported match. I'm pretty happy with how it looks, just have to make 4 more now out of a proper weldable aluminum alloy.

|

|

|

HausFiero

|

AUG 05, 01:38 AM

|

|

|

This project is awesome. How much hp are u guessing the finished product will put out?

|

|

|

FastIndyFiero

|

AUG 13, 01:45 AM

|

|

| quote | Originally posted by HausFiero:

This project is awesome. How much hp are u guessing the finished product will put out? |

|

Hopefully bunches. Over 800 is what I'm shooting for.

Progress has been slow the last little bit. Been working on my other project:

http://www.flickr.com/photo...01614/in/photostream

|

|

|

ghost187x

|

AUG 16, 06:28 PM

|

|

|

|

pontiacjeff

|

AUG 24, 01:03 PM

|

|

|

I am ready for a set of intake and exhaust flanges. About to unpack 5 boxes of Cosworth stuff. Only lacking a 2.7L 3.25" crank. I'll send a pm to follow up.

|

|

|

fierosound

|

AUG 31, 10:40 AM

|

|

|

|

30+mpg

|

FEB 19, 07:09 AM

|

|

|

Hmm, no running engine yet? 6+ years and counting. I think you've passed SmooothGT for the longest unfinished thread.

|

|

|

FastIndyFiero

|

FEB 26, 05:23 PM

|

|

Haha. There's no beating Smoooooth.

Progress!

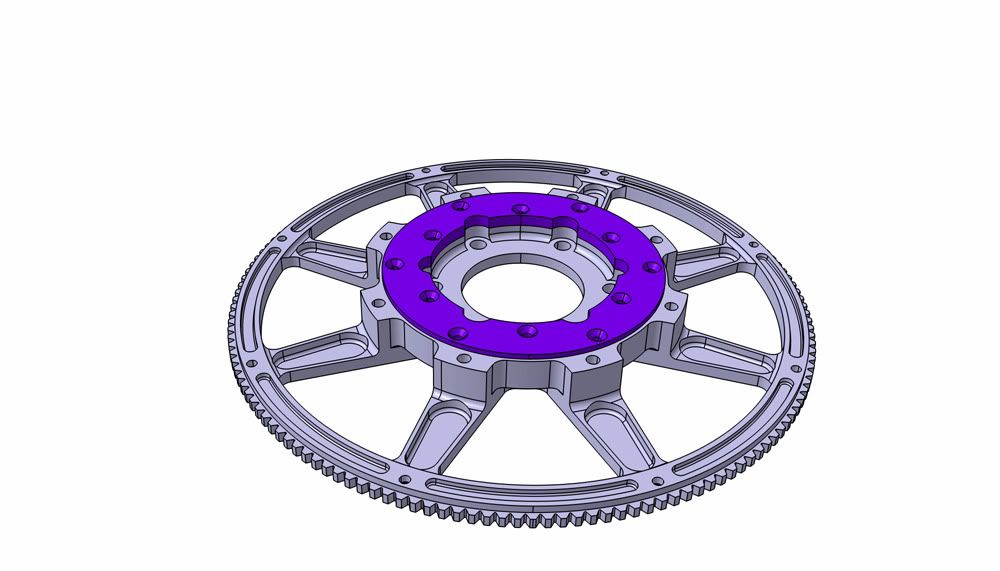

Made this set for Alan Samura.

|

|

|

FastIndyFiero

|

JUN 07, 03:13 PM

|

|

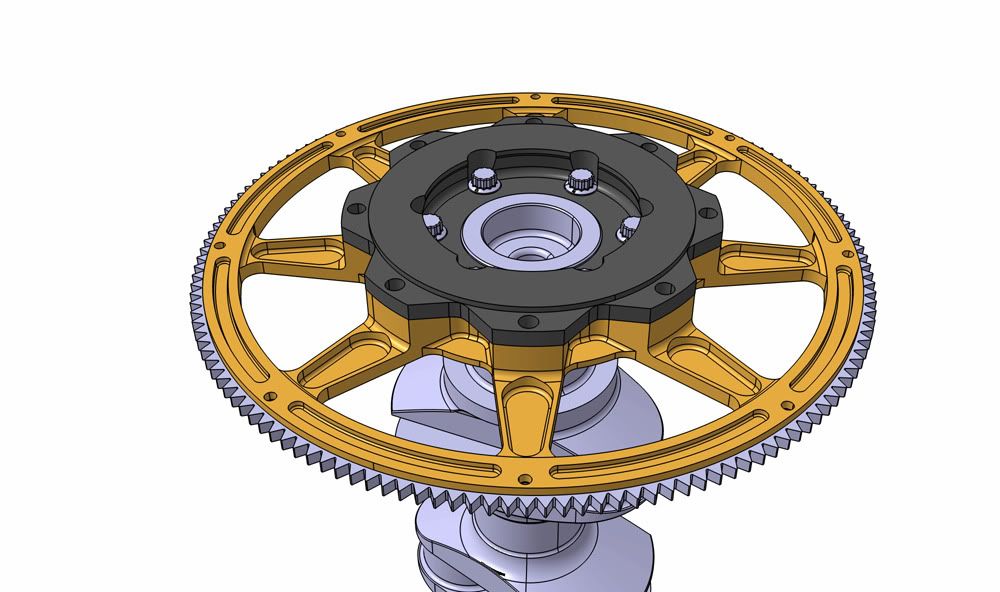

So I've been working on the flywheel situation. For the last several years I had contemplated running a reverse-mount starter through the tranny bellhousing and in conjunction with a reduced diameter flexplate. I'm still not sure what tranny I'll be running, so I've decided to bite the bullet and just set up with the stock starter position / iron duke ring gear.

I still have an issue caused by the large SBC crank pattern messing with the friction insert. I've analyzed this to death, saved weight everywhere I can, and I think the result is looking very good. Total weight is almost 3.5lbs with ring gear. Inertia for the assembly is about 50lb-in^2. Total including a Tilton Carbon-Carbon 5.5" would be 8.1lbs and 74lb-in^2, a savings of.....alot.

However, I did a little re-evaluation of objectives and I examined the alternate route of retaining the mini steel flywheel, and basically just making a flex plate. The weight for the assembly isn't much worse (4.6 vs 3.5lbs) and the inertia is only moderately higher (61 vs 52 lb-in^2). What's pushing me towards this is that I don't need to mess with a friction surface, it can take thrust loads from the TOB more easily, and if I mess up the flywheel I can toss it and get a new one for around $100-150, which is about the same as most friction surfaces. If I go to a bellhousing mount starter I can just toss the flexplate in the garbage. Right now I'm wondering if the inertia will be too low and my non-racedriver skills won't be able to hack it with nearly instantaneous throttle response. The crank will only add about 70 in-lb2 of inertia. I'm looking at a total rotating inertia 60-90% smaller than a typical V8.

|

|

|