|

| The Turbo Super Duty Build. (Page 50/63) |

|

FastIndyFiero

|

FEB 20, 05:16 PM

|

|

|

Wow, looks nice. Does that intake look like a production unit, or custom? I'll try emailing you again, can you PM me the bounce error you're getting? My email seems to be working okay on my end.

|

|

|

FastIndyFiero

|

MAR 07, 02:00 PM

|

|

Started on the aluminum proto exhaust flange. Couldn't get it quite finished yet.

[This message has been edited by FastIndyFiero (edited 03-07-2009).]

|

|

|

Stubby79

|

MAR 07, 05:33 PM

|

|

| quote | Originally posted by Blowd:

May as well put up a photo of the head. I got some of the shelf dust off of it.

|

|

Man, that thing's got balls!

.

.

.

...I mean it! 4 of 'em!

.

.

.

...sorry, had to say it.

|

|

|

sardonyx247

|

MAR 20, 12:55 AM

|

|

|

|

FastIndyFiero

|

MAR 22, 10:10 PM

|

|

| quote | Originally posted by sardonyx247:

hey fast indy, your Indy fast yet?

j/k

If I was closer I swear I would go there and finish it for you.

get er done

I want to see that thing smoke every thing on the road.

|

|

Hehe...Donate 5-6 thou and I'd have it done in a month

Aluminum test flange is done, will know fitment tomorrow. It's .500" thick, has a .25" recess so the transitions can be nested inside the flange and welded inside and out. I'll probably also leave a little more material radially around the port, just for a little extra stiffness and space for the weld.

Also planning on cutting (on the CNC machine) a 2 piece mandrel for forming the transitions from oval to round, hoping to do that this week.

|

|

|

FastIndyFiero

|

MAR 24, 03:36 PM

|

|

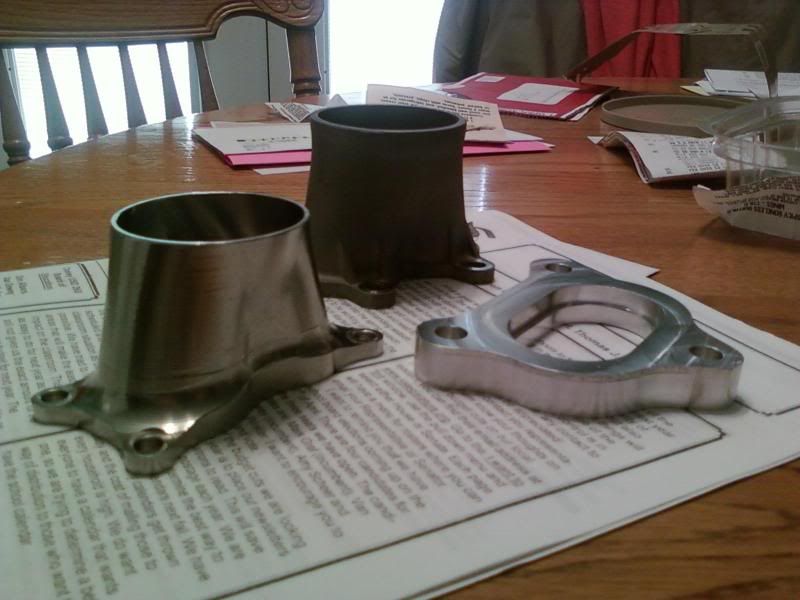

As shown not very clearly by the crappy cellphone pics, it fits pretty good!

|

|

|

Blowd

|

APR 06, 11:04 AM

|

|

Port alignment looks nice (I jus luv lookin down those ports). So that's probably gonna take a pretty good notch on the water pump, but will definitely make for a trouble free header.

Keep us posted.

|

|

|

FastIndyFiero

|

APR 17, 05:09 PM

|

|

I was recently thinking about becoming a little more ambitious with the exhaust flange project. Because I am already investing a fair amount of time in cutting these flanges out myself, I started thinking about reverting back to my original plan from several years ago and doing the entire transition in a single billet. Because I don't have my own NDI/X-ray inspection quality control department, minimizing welds is one of my top priorities in the design of my exhaust system. With an addition of a couple of machining operations, I could eliminate having to cut out a mandrel and form the transitions by hand and having them welded onto the flange.

This got me thinking about what F1 does. Unfortunately, I wasn't able to find any kind of good information or even closeup pictures of the parts that I was looking for, but what I WAS able to find was a seller on eBay clearing out old CART/IRL exhaust parts. I figured this may be more useful to my turbocharged application anyway (though I won't succumb to claiming that my level of build or tune even approaches that of an IRL engine). So, just because I was curious, I wound up with three flanges; two from successive generations of late 90's Mercedes Ilmor engine, and a flange from a Chevy Aurora engine. The Aurora flange is billet Inconel while the Mercedes flanges are cast stainless or Inconel, I'm not sure which. These confirmed my sneaking suspicion that a one-piece transition could be a suitable solution to the problem of transitioning from the port to the round tube, and looked fairly similar to what I had already worked up in CATIA. On to the pics.

These are obviously no-expense-spared pieces, with the Mercedes flange even sporting webbing bracing the flange mounting points. Both transitions sport a very sharp knife edge where the ports merge, though something I'm not concerned about because my ports merge inside the head, not far past the bowl. Also evident is the relatively thin flange at the base, both measure around .15" thick where the bolt face would be. This was somewhat suprising to me, though I suspect I can't build a flange that thin because of the Cossie's 3-bolt flange versus the 4-bolt IRL parts. More later.

|

|

|

KurtAKX

|

APR 25, 02:01 PM

|

|

Am I missing something? Aluminum exhaust flanges- they must just be for mockup, right?

Inconel is definitely a much better choice for turbo exhaust system temperature considerations. Your exhaust will be hotter than the melting temp of aluminum!

|

|

|

FastIndyFiero

|

APR 27, 12:17 PM

|

|

| quote | Originally posted by KurtAKX:

Am I missing something? Aluminum exhaust flanges- they must just be for mockup, right?

Inconel is definitely a much better choice for turbo exhaust system temperature considerations. Your exhaust will be hotter than the melting temp of aluminum! |

|

Yes...Just for mockup/test run of my CNC code. The flange that you see in 6061 there will be replicated in 321 Stainless. Austenitic stainless can be somewhat difficult to machine unless the toolpaths are just right (it work hardens very quickly, so making shallow or redudant cuts will cause very fast tool wear, or breakage).

In terms of cost and lack of availabilty (and difficulty in machining), Inconel is orders above even 321SS. I don't even want to consider what the same 1/2 x 5 x 36" plate that ran $100 in 321SS would be in Inconel. On the other hand, doing 1-piece transitions (instead of just flanges) in 321 is not completely outside of the realm of possibility, but again, the hunk of 2" x 4" x 24" hunk of SS that it would take wouldn't be cheap.

So for the moment I'm split on it.

|

|

|

|