|

| The Turbo Super Duty Build. (Page 41/63) |

|

FastIndyFiero

|

OCT 02, 06:09 PM

|

|

| quote | Originally posted by darkhorizon:

Assuming it flows in the same ballpark to what a dohc head can flow, 600 horsepower is not at all far off. The only problem i see is the fact you will need to run MORE than 30psi of boost.

I think an hx40 or hx55 holset would do this for you. They live at 30psi, and can even go higher without to much efficiency loss. |

|

Peak flow is almost 280CFM for my 2v head, not fantastic, but it's no slouch. I'm also not sure why you think I will need to run more than 30 psi. I already have a Garrett GT3776, 76mm compressor wheel, HX55 is slightly smaller at 72mm.

I almost forgot to add, also, that this is computed with 110 octane, and icewater in the IC. Obviously on pump gas it would be much less. I have no idea if I could hit 800HP, if I'm going to try I'm probably going to need another set of injectors. Historically this program has been very accurate...Only one way to find out

(I think the "one way to find out" is MORE MONEY)

|

|

|

darkhorizon

|

OCT 02, 08:27 PM

|

|

the moltron #65's that you can get and still run high imped, will limit you to 400-500 horsepower anyway, just go all out and get the 1500CC injectors and call it a day. (about 150# injectors lol)

|

|

|

86FieroCentPa

|

OCT 02, 09:51 PM

|

|

Im sorry I dont have anything productive to add to this thread. Other than I have been following it for awhile, and I think that this motor will be amazing.....But this 800HP stuff just reminded me. You're lucky that your thread didnt fall to these dogs....

http://www.fiero.nl/forum/Forum2/HTML/086397.html

|

|

|

FastIndyFiero

|

OCT 24, 10:38 AM

|

|

|

|

FastIndyFiero

|

NOV 07, 07:28 PM

|

|

Been getting bored again...Also following yet another lead on camshafts....

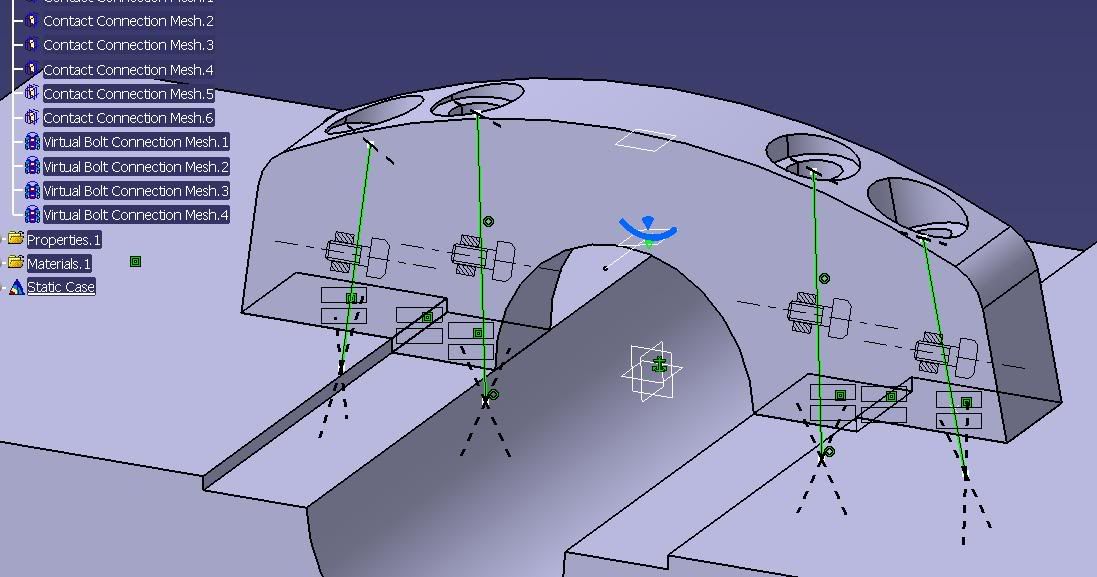

So I've been designing a new 4-bolt splayed cap (again). My cap girdle got me thinking about how thermal expansion affects cap and bearing deformation, and the results are pretty amazing. I've been testing various cap geometries to try to get the least deformation at the crank-cap interface. The standard cap geometry used by most vehicles does some interesting things when heated to 200*F. I don't have any pics of the test results yet, but here's one design I've gone through:

Nate

|

|

|

RandomTask

|

NOV 07, 07:33 PM

|

|

|

|

Mr.PBody

|

NOV 07, 09:57 PM

|

|

|

As of today in what state is the motor in? Are you nearing completion? I have been following this thread forever!

|

|

|

KurtAKX

|

NOV 08, 12:33 AM

|

|

| quote | Originally posted by Mr.PBody:

As of today in what state is the motor in? Are you nearing completion? I have been following this thread forever! |

|

I bet its farther from assembled than it was at this time last year

|

|

|

FastIndyFiero

|

NOV 08, 04:12 PM

|

|

Heh, I think it actually might be LESS assembled than this time last year. At this point, all I need is some deciding factor to either use the Cossie stuff or the Pontiac stuff I already have. It seems like I've come 10 miles, and the long block is only about 1 inch away from being done (and done right too) if I use the Pontiac head. Lack of parts might end up nixing the Cosworth gear, but it's always been what I really wanted to try. The geometry of the Cossie head allows me to make optimizations with the intake and exhaust system that I wasn't able to do with the Pontiac head, and I think in a street environment the Cossie would probably be more reliable.

Anyway, the State of the Motor Address, by item (using Pontiac SD parts):

BLOCK - Needs to be plateau honed .002" and a couple oil holes on the deck plugged.

Crank/Rods/Pistons - Done

Head - Coated, P&P'd, Flowed, needs to be reassembled

Intake - Done

Oil Pan - Need one

Valve train - Need pushrods

Exhaust - Need to go through a few more header designs, it's a PITA

Clutch/Trans - Need to determine gear ratios => Trans => Trans spacer and spline for 3 disc 5.5" clutch

Engine management - Ehhhh......Haven't decided how done I am on this yet. (VEMS? MS-II? Big $tuff 3?)

This is your State of the Motor

|

|

|

FastIndyFiero

|

NOV 08, 04:18 PM

|

|

Forgot pics from my FEA results...

Because of where I constrained the mock engine block, the displacement of the cap is shifted on the scale. I'm EXTREMELY happy with how this design has turned out, there is VERY little deformation of the cap bearing surface (around .00004" variation) when thermal and bolt-tightening loads are applied. The stock SD main cap was around .002" at the top of the cap bearing surface.

|

|

|

|