|

| A 3.4 DOHC Build then... F40 Turbo (Page 25/57) |

|

Fierobsessed

|

JUL 06, 07:21 AM

|

|

I don't remember off the top, but that OSE 12P looks fascinating... more digging for me to do now!

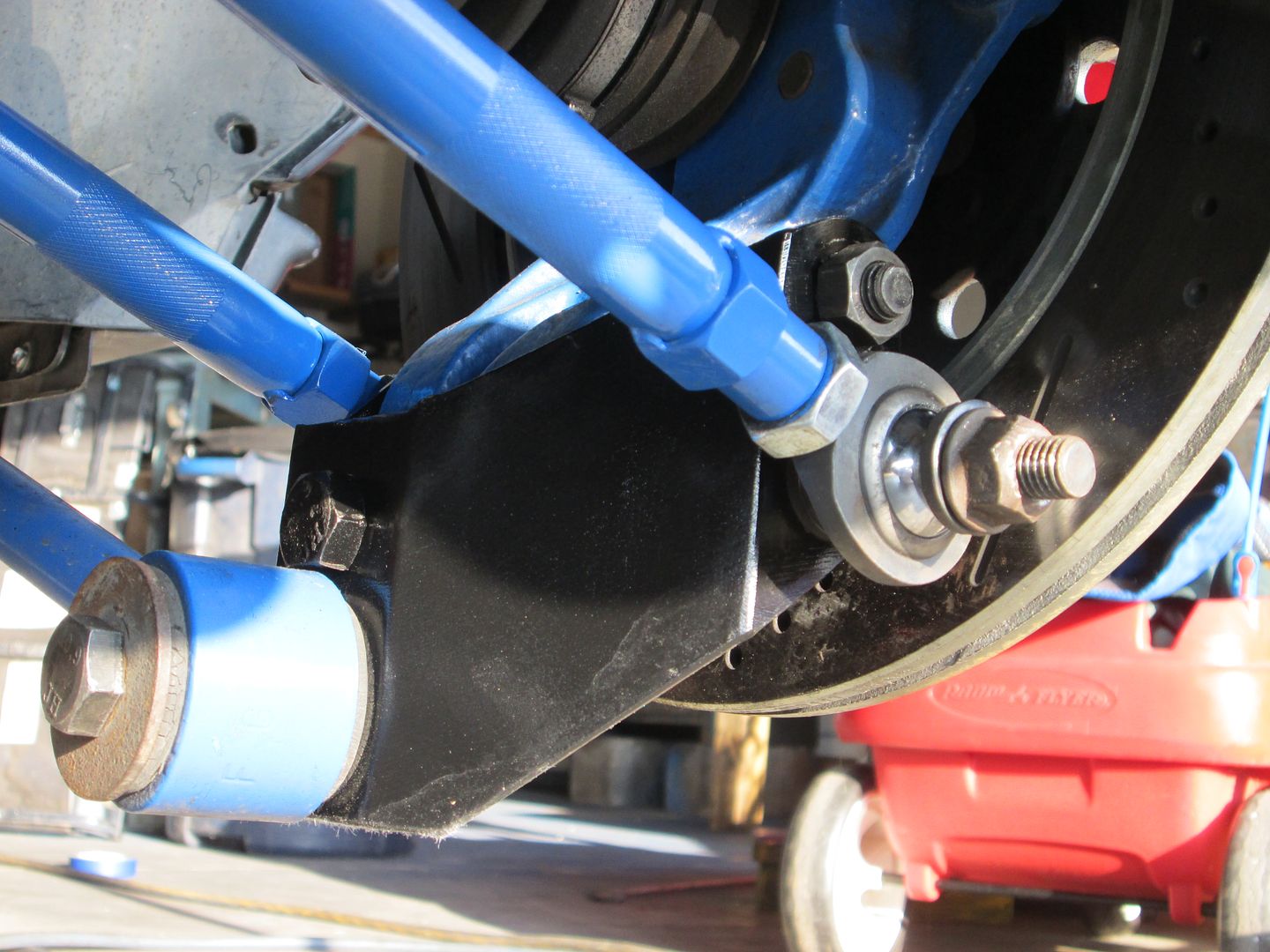

Today, I started on the rear suspension, got a bunch of work done on it!

When I put the engine in originally, I went ahead and put in prothane bushings. I think I didn't grease them enough, they always squeaked. So this time, I'm going to make a couple of modifications to the bushings, then add some zerk fittings where applicable.

I started with a 1' long piece of delrin 2.5" In diameter, Cut It down to size, then bored a hole in it, then sliced it into little washers with a parting tool.

Then I took each bushing and cut off the flanges off of each of them. What I am left with is a hybrid, delrin/polyurethane bushing.

Then, I got busy making a ton more of these.

For the adjustable Toe link, I did something a little special. 88's have a problem when the rubber deteriorates on the toe links, or when poly is installed, the metal sleeve slides down the bushing and eventually comes in contact with the cradle, and/or the upright, and starts to saw into them. So I made a cup shaped delrin bushing that will prevent that from happening again, by ensuring that the sleeve can't slip off the poly.

Then I got really busy with the sandblaster and blasted clean the uprights and the links.

I also ordered a new pair of wheel bearings. I had an unusual, and unfortunate mishap with one of them just before I pulled the engine for this project. See here for details.

http://www.fiero.nl/forum/Forum2/HTML/125790.html

Needless to say, I went for a set of bearings that weren't just cheap replacements. I specified Timken's... at nearly 4x the cost of the cheapest ones I could find.

No kidding, you can get a PAIR of new "513011K" rear Fiero wheel bearings to your door for $40 on eBay. Shipping included. But you have been warned...

Another task, back to the fuel lines. Since I decided to go all Nylon and Quick disconnect on my fuel lines, I ordered a few parts to make this happen

Dorman parts:

I also ordered 10' of 3/8" and 5/16" nylon fuel hose too. I'll post more details when I actually do the fuel lines themselves

And, I received my Stainless scrubbers that I will be using as a coalescent inside the air/oil separator. I ordered 12, thinking I'd need 3 or so. Nope, one was plenty. These are nice because I can be reasonably assured that I will not need to worry about pieces coming off and going down into the oil pan.

Yep, one's plenty.

I'm still a bit concerned about the mounting location for this piece though. It looks like the spot that I have slated for it might be a bit more crowded then I initially thought. It's looking like it might go in the wheel well where the old air intake and water separator were. There just isn't any space left inside the engine bay. I've truly packed every possible space with every piece of needed equipment. It's insanity I tell you!

The only thing that is holding me up right now, is the clutch pressure plate. Hopefully Spec will pull through and I'll have that soon. Then, I can actually start finalizing my setup, and actually tightening down some more bolts.

Once I get this suspension done, and the clutch installed. I'll really need to focus long and hard on getting the heat shielding done. It seems like the crossover is such an inconvenience. It's near the air intake, The turbo compressor, the throttle body and it's wiring, the CTS, the intercooler and plumbing. So it seems that the solution is to really concentrate on shielding the crossover from everything really, or build heat shields for every one of these items. Either or both of these solutions must be considered.

|

|

|

Joseph Upson

|

JUL 06, 08:03 AM

|

|

|

Autospeed still expressed some concern with the possibility of some steel shards coming loose over time when they performed this catch can modification, I'm not sure what they did but I think they installed a piece of screen over the drain and vent hole to make sure it didn't happen. I've been running a standard cheap ebay catch can with the see through level hose on the side for months now, with a vent to the inlet air pipe to the turbo to help suck the vent gasses through. The inlet port from the valve cover has about a 3" tube connected internally directing the vent gasses to the bottom of the catch can to help separate oil before venting out the top. So far I have yet to see any oil register in the level tube. I run 15W50 Mobil 1 so that may be helping keep the oil mist to a minimum.

|

|

|

Fierobsessed

|

JUL 09, 11:17 PM

|

|

I think a screen is a good idea too. Why not?

Got my wheel bearings and fuel hoses in today.

The fuel hoses are 10' rolls of 5/16" and 3/8" Nylon fuel hose. I'm actually a really big fan of the plastic fuel hoses with quick disconnects. This allows for flexability, small packaging, and if protected correctly, infinite lifespan. Just all around easier to deal with. It's not all that expensive either. A novice can just go to Autozone, pick up a Dorman 800-229 and 800-230 a 3/8" and 5/16" compression fittings, put those on the tank, then make up the plastic lines that will plug into practically any swap.

Like I was saying in my last post, I sprung some extra $$$ for the Timken bearings. I could have spend $40 on a pair of brand new pieces of junk. But I still think at 4X the price, they really aren't even all that expensive.

Old Duralast bearing on the left, new Timken on the right.

You can see right away that the wheel flange is WAY thicker. Good. I don't ever want that to fall apart on me again. Also, it looks like the outer bearing area between the wheel flange and mounting flange is also MUCH heavier. Perhaps a larger bearing lives in there then normal???

I can say though, that the crappy Duralast bearing looked exactly the same as the OEM bearings. Physically indistinguishable from OEM. But you can see that with the Timken, they at least made an effort at improving the bearing, even though they are competing against some slash-throat pricing.

I am still waiting on a pressure plate. Hope it comes in soon! It's really stalling this whole project, and worse, my motivation.

In the meantime, I've been painting the cleaned suspension parts and getting a few more supplies together. I need very little more then the pressure plate to finish this whole project. I still need to make a pair of mount brackets for the FMHE, and start running some lines front to back.

|

|

|

zkhennings

|

JUL 10, 03:36 PM

|

|

|

Where did you get the delrin? That is such a good idea, I want my suspension to be able to move easier!

|

|

|

Will

|

JUL 11, 12:05 AM

|

|

| quote | Originally posted by Fierobsessed:

Today, I started on the rear suspension, got a bunch of work done on it!

When I put the engine in originally, I went ahead and put in prothane bushings. I think I didn't grease them enough, they always squeaked. So this time, I'm going to make a couple of modifications to the bushings, then add some zerk fittings where applicable.

I started with a 1' long piece of delrin 2.5" In diameter, Cut It down to size, then bored a hole in it, then sliced it into little washers with a parting tool.

Then I took each bushing and cut off the flanges off of each of them. What I am left with is a hybrid, delrin/polyurethane bushing.

http://images.fieroforum.com/2012/IMG_1958.JPG

Then, I got busy making a ton more of these.

http://images.fieroforum.com/2012/IMG_1959.JPG

For the adjustable Toe link, I did something a little special. 88's have a problem when the rubber deteriorates on the toe links, or when poly is installed, the metal sleeve slides down the bushing and eventually comes in contact with the cradle, and/or the upright, and starts to saw into them. So I made a cup shaped delrin bushing that will prevent that from happening again, by ensuring that the sleeve can't slip off the poly.

http://images.fieroforum.com/2012/IMG_1960.JPG

Then I got really busy with the sandblaster and blasted clean the uprights and the links.

http://images.fieroforum.com/2012/IMG_1961.JPG

|

|

| quote | Originally posted by zkhennings:

Where did you get the delrin? That is such a good idea, I want my suspension to be able to move easier! |

|

Just go to rod ends in the lateral links. Urethane is for suckas and has all the problems you noted and then some. Stop wasting time trying to fix something that should be trashed and go with what GM should have put in those links in the first place.

http://realfierotech.com/ph...p?f=3&t=2573&start=0

There are a few threads on it on this forum as well. I think FieroGuru has found rod ends with integral sleeves that help significantly.

|

|

|

Fierobsessed

|

JUL 12, 04:19 PM

|

|

|

Thanks Will. I'm seriously looking into that now. Just so long as they are durable, and greasable, I'm totally cool with using them. I will be driving this car a buttload once It's up and running. So the links have to be very durable, if not lifetime parts. I honestly hate poly, I have to fix a serious issue in the front end where the poly siezed to both the inner and outer sleeves, and worked the sleeve out of the control arm. it's a crap sandwich up there. There is no way I would ever put poly back in unless I can reliably grease it externally. That was my current intention. But... A good and durable heim setup I'd be all over. Bushing compliance be damned! So, it looks like I'll be doing a little research and perhaps some shopping.

|

|

|

fieroguru

|

JUL 12, 04:29 PM

|

|

Here are the ones I am using, chromoly, teflon lined, non-greasable:

http://www.fiero.nl/forum/Forum2/HTML/120882.html

| quote |

QA1 PCYM Series rod ends feature a 2-piece chromoly steel design and a heat-treated, black oxide coated body for corrosion resistance. The ball is heat-treated as well with a precision-ground, hard chrome plated finish. The ball is specially designed for high misalignment applications. QA1 PCM Series rod ends are built to last.

|

|

I would not suggest greasing them. All it does is give something for the dirt/grit to stick to and wear them out faster. I am up to about 3K miles on my setup with lots of driving in the rain and they are still tight.

I did bore out some large nuts and tacked them to the tubes so I had a good method to tighten them.

[This message has been edited by fieroguru (edited 07-12-2013).]

|

|

|

Will

|

JUL 14, 05:29 PM

|

|

| quote | Originally posted by Fierobsessed:

Thanks Will. I'm seriously looking into that now. Just so long as they are durable, and greasable, I'm totally cool with using them. I will be driving this car a buttload once It's up and running. So the links have to be very durable, if not lifetime parts. I honestly hate poly, I have to fix a serious issue in the front end where the poly siezed to both the inner and outer sleeves, and worked the sleeve out of the control arm. it's a crap sandwich up there. There is no way I would ever put poly back in unless I can reliably grease it externally. That was my current intention. But... A good and durable heim setup I'd be all over. Bushing compliance be damned! So, it looks like I'll be doing a little research and perhaps some shopping. |

|

I know it's counter-intuitive, but greasable rod-ends are contra-indicated.

Just get high quality (minimum $25 each) steel on steel and seal them with sealing washers and rod-end boots.

|

|

|

Fierobsessed

|

JUL 14, 07:28 PM

|

|

|

My thinking is that we are dealing with is something similar to a tie rod end. They grease and seal those, and they have lube grooves in them to promote grease flow. That's what OEM uses, and it lasts a really long time, but usually winds up needing to be changed out once in a cars life. So I'm a bit weary of metal on metal with no lube. What I think I'll do, unless I am convinced through more research otherwise, is get a higher end grease-able setup; Grease it and run it. If it all goes tits up, I'll get new joints and run them dry. Not like its difficult to replace joints anyway, but it is a pricey experiment in durability. I'm doing some serious research in the meantime. Overall, I like the idea though. They are pretty, and they should make up for some of the shortcomings of the Fiero's old design. It's also got me thinking about making my own custom press-in Front A-arm Joints, since the poly up there has been quite troublesome. And, I have the resources to make it happen. I'll let you guys know what I wind up deciding to do.

|

|

|

Will

|

JUL 15, 11:17 AM

|

|

| quote | Originally posted by Fierobsessed:

Overall, I like the idea though. They are pretty, and they should make up for some of the shortcomings of the Fiero's old design. It's also got me thinking about making my own custom press-in Front A-arm Joints, since the poly up there has been quite troublesome. |

|

I'm designing weld-in spherical bearing sleeve that will work on '84-'87 rear arms and '84-'88 front arms. I'll be glad to share the design with you.

|

|

|

|