|

| LS4 / F40 swap - fieroguru (Page 199/216) |

|

Trinten

|

JUN 13, 10:49 PM

|

|

I am pretty sure I saw Shawn's Fiero (that one pictured) at the 40th! Or... someone has one in the same color, engine swap, and repurposed grating for the 'grill' of the hood window. lol

It's cool you're running into other Fiero folks that you know.

Congrats on the good mileage so far!!

|

|

|

Sage

|

JUN 14, 12:47 PM

|

|

| quote | Originally posted by fieroguru:

Tedd, we came up I-71 from Louisville, so didn't go past Marietta.

|

|

Enjoy!

HAGO!

|

|

|

fieroguru

|

JUN 14, 08:19 PM

|

|

|

|

fieroguru

|

JUN 23, 03:20 PM

|

|

Here is one of the professional photos of Marty and I rolling into one of the HRPT venues:

Since returning from the HRPT, I have mostly just been driving the car to work and back. Best tank when I did another mileage run was 27 mph, and the daily commute with some tuning runs have been around 20 mpg.

Been slowly working on the minor things the HRPT helped identify. I figured out the issue with the corrupted tunes... operator error. I was disabling the DTC for when I failed the MAF to run speed density. The E40 ECM has to set the DTC to run 100% speed density, and that is what I was running to dial in the VE tables. Once I stopped trying to set P0103 to report no error, the tuning has been much more predictable.

1. Installed shorter/softer bump stops. On the tour we bottomed out the front about 5-6 times on typical public roads. Here is the clearance to the trimmed down bump stops. It was less then this with the car loaded with 2 people and gear for 6 days.

Here is the trimmed bump stop, the new one, and a stock one. To install this one does require drilling out the bump stop hole to 3/8".

2. Very happy with the amplifier and its performance, so finished up the trim plate to hide all the wires. Given the irregular shape of the opening, I made the first one out of card board, then 2 test plates in 16ga before making the final one.

3. The shifter pleather boot was severely worn and peeling. Picked up another VW shifter, drilled/tapped for M16x1.5mm and installed it. This is also a general over view pic of the interior with the steering wheel, relocated gauges, and the 2DIN radio/NAV unit. The 2DIN head unit will be getting replaced for several reasons, the main one being the touch screen is a little flakey and makes loading map routes challenging.

4. Installed new 105/hr @ 43.5 psi injectors. I had been running decapped injectors that flowed about 85 lb/hr @ 58 psi and suspect they were causing some of the idle quality issues with their flow performance no longer patching the specs in the calibration. These new ones come with all the injector specs to change in the tune and should allow the idle to be more consistent. These are also about the largest ones I can install in the E40 without doing a full scale of all air flow tables within the calibration.

5. Fixed the O-ring leak around the base of the F40 shifter on the transmission.

6. Removed and wrapped the warm air intake. Mainly as a test to see if it will lower the normal IAT temps when cruising and driving around time as the engine bay gets quite hot - probably 165 degrees+. Normal IAT temps during cruise on an 80 degree day are about 115 degrees, in town it climbs to ab out 125 degrees, and when in stop and go traffic they go up to 145 degrees. The issue is the engine bay is probably about 165 degrees. Under these conditions, the air is flowing slowly through the tubing and picking up the heat. At WOT, the air flow will increase, so there will be less time in the pipe to raise or lower the temps.

7. Not done yet, but I am also working to relocate my air filter about 6" closer to the rear wheel to get it further from the engine bay and help draw in the coolest air possible. The needed 45 degree 4" tube will be in on Monday.

|

|

|

dskebo

|

JUN 25, 01:06 AM

|

|

|

So you are running speed density which means the mass airflow doesn't work where it's at correct? You are using it simply as an intake temp meter correct? I have my air filter in front of my left rear tire behind the plastic inner liner , works really well. On another note out of all those pics of Fieros yours is by far the best looking.

|

|

|

fieroguru

|

JUN 25, 07:13 AM

|

|

| quote | Originally posted by dskebo:

So you are running speed density which means the mass airflow doesn't work where it's at correct? You are using it simply as an intake temp meter correct? I have my air filter in front of my left rear tire behind the plastic inner liner , works really well. On another note out of all those pics of Fieros yours is by far the best looking. |

|

I have driven the car in both formats 100% MAF and 100% VE, it is all part of the process.

To tune Speed Density, you need to turn off the MAF. To tune MAF, you need to turn off Speed Density.

I will switch back to running 100% MAF for a while to dial it in. Once both are tuned +/- 1%, then I can choose to run 100% Speed Density, 100% MAF, or Dynamic with a mixture of them both.

The only current issue with the MAF is that I will likely max it out based on the limits of the hard coded limits of the ECM without doing an airflow scale to the tune.

|

|

|

fieroguru

|

JUN 26, 07:02 PM

|

|

Almost done with the filter relocation.

It used to be right off the compressor housing, now it is under the driver side frame rail and more into the wheel well.

It barely fits between the frame rail, the transmission, the tripot, the sway bar, the lateral link, and the rear cradle vertical mount. I will likely loosen up the front cradle bolts, remove the rear cradle bolts, and rotate the cradle down so I can better install the clamps and maximize clearance in the area. I might try to add a shield to the top to help ensure the engine bay air has a hard time getting to the filter inlet.

Should be back driving the car this weekend and can run some logs to see if the IATs stay lower during extended idling and while running down the interstate.

|

|

|

Will

|

JUN 26, 07:45 PM

|

|

|

|

fieroguru

|

JUL 04, 09:40 PM

|

|

Filter relocation is complete and the Fiero is back together and driving!

It was sprinkling most of the day, but I was able to get a few tuning runs in.

Planning to drive it to work on Friday and all next week.

|

|

|

fieroguru

|

JUL 14, 09:34 PM

|

|

Largely just been driving the car to work and back and having fun with it. I had to look back at a picture of the cluster from the 4 years it was off the road: 239,289. It is now at: 242,086 so the new swap has logged 2,797 miles with 1100 of them on the HRPT.

Speed Density tune is really close now, and I did 3 WOT runs in that configuration. I have switched back to 100% MAF and did some tuning on it. I will keep it MAF only for a couple of weeks for my daily commute and tuning runs. Once that is done, then back to closed loop dynamic.

Still on a mission to reduce IAT temps. The next area of focus were the heat shields around the turbo turbine housing. So the car went on jacks stands, and the cradle was rocked back to gain the needed access.

Muffler system out. It is pretty obvious that it has been hot. Some of my tuning runs the EGT reaches 1400 degrees, but quickly drops back down when I get out of it. You can also see where I had previously heat wrapped the tail pipe that is closest to the air filter. You can also see the passenger side tip is rarely used. The cutout opens under boost, so it hasn't seen as many sustained heat runs as the driver side has.

Turbo with the stainless steel heat shields:

Heat shields removed and next to turbo blanket. The turbo blanket is from Funk Motorsports in the UK. It is about 3 times thicker than the cheap ebay/amazon turbo blankets (and more than 3 times more expensive). You can also see the heat shields had started to discolor, but not near as much as the exhaust pipe.

Turbo blanket installed:

Also went ahead and wrapped the 3.5" muffler, the 3 1/2" down pipe to the 3" Y and to the 3" muffler. The body of the 3" muffler doesn't get that hot, so I left it natural. The new heat wrap is darker because it is still wet. I soaked it in water before wrapping.

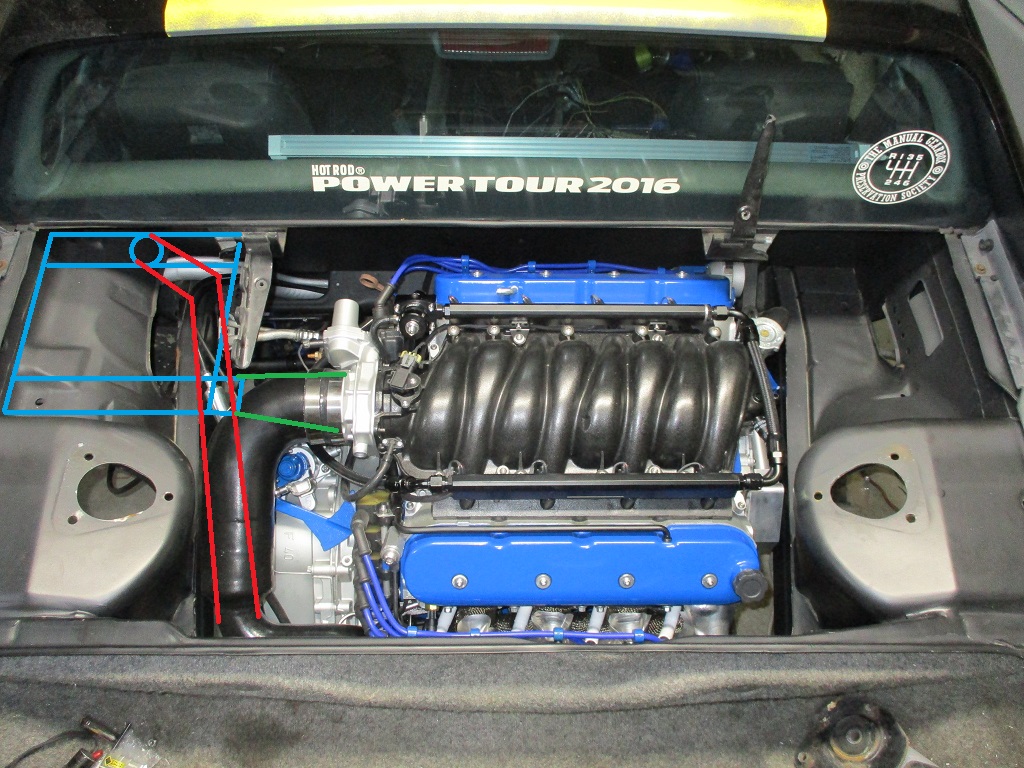

Also picked up a cheap intercooler. The hose nipples need to be cut off and repositioned. Once they are cut off, it will be 15x12x4 and should fit under the driver side decklid vent. Once it is there, I will add a fan plus seal the intercooler from the engine bay. If this works out, I will likely drop the $$$ on a real intercooler core and have it fabricated.

This is the general concept that was discussed several pages back.

|

|

|

|