|

| LS4 / F40 swap - fieroguru (Page 179/216) |

|

ericjon262

|

FEB 20, 09:58 PM

|

|

Nice! I made the first cut on mine yesterday, I think it is probably fairly recognizable around here! I ended up with the Crossfire Pro, and a Hypertherm Powermax 85. need to work on getting everything a bit more dialed, but it works. Thanks for your help and advice!

------------------

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

cognita semper

|

|

|

fieroguru

|

FEB 21, 08:52 PM

|

|

| quote | Originally posted by ericjon262:

Nice! I made the first cut on mine yesterday, I think it is probably fairly recognizable around here! I ended up with the Crossfire Pro, and a Hypertherm Powermax 85. need to work on getting everything a bit more dialed, but it works. Thanks for your help and advice!

|

|

Congrats! The Pro and Powermax 85 will be a nice setup!

Once you get it dialed in and master the drawing/conversion to cut files, it will be a game changer.

It is one of my favorite tools now.

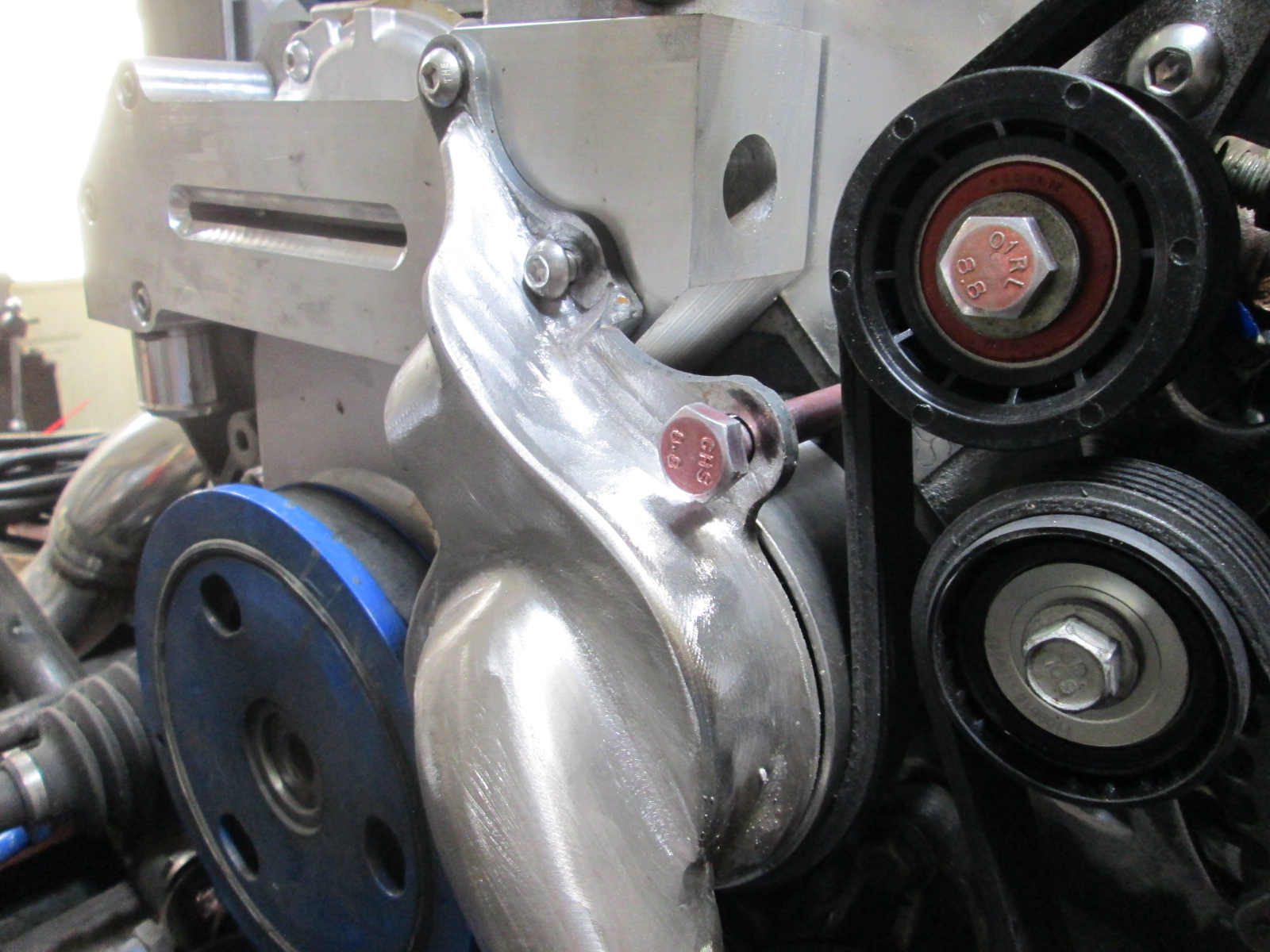

It is great to have drawings of parts, move them around in cad, make a cut file, and assemble the parts. Reworked the AC brackets to make room for the water pump (and the bracket to mount the water pump) in an hour or two this weekend. It is really making me change how I think about mount and bracket design.

|

|

|

fieroguru

|

FEB 24, 08:23 PM

|

|

|

|

Spadesluck

|

MAR 13, 04:58 PM

|

|

|

Very nice. I have a miller 255 that does it all. Will be getting the tig setup probably this summer.

|

|

|

ericjon262

|

MAR 13, 08:13 PM

|

|

| quote | Originally posted by fieroguru:

Finally pulled the trigger on a new tig machine. I have been super pleased with my Lincoln Promig 175 (2007), so I am sticking with Lincoln for the tig as well. Not sure when it will arrive.

https://www.harrisweldingsu...-for-a-limited-time/

|

|

when I started reading this, I was almost worried you would say "Diversion 165/180", I had one for a while, and it worked, but it wasn't working at what the $3000 price tag should have bought. I've heard really good things about the Lincoln Square wave machines! I recently bought a Primeweld Tig 225 to replace my broken Diversion, having the ability to adjust bias and frequency is a game changer on aluminum!------------------

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

cognita semper

|

|

|

fieroguru

|

APR 17, 06:19 PM

|

|

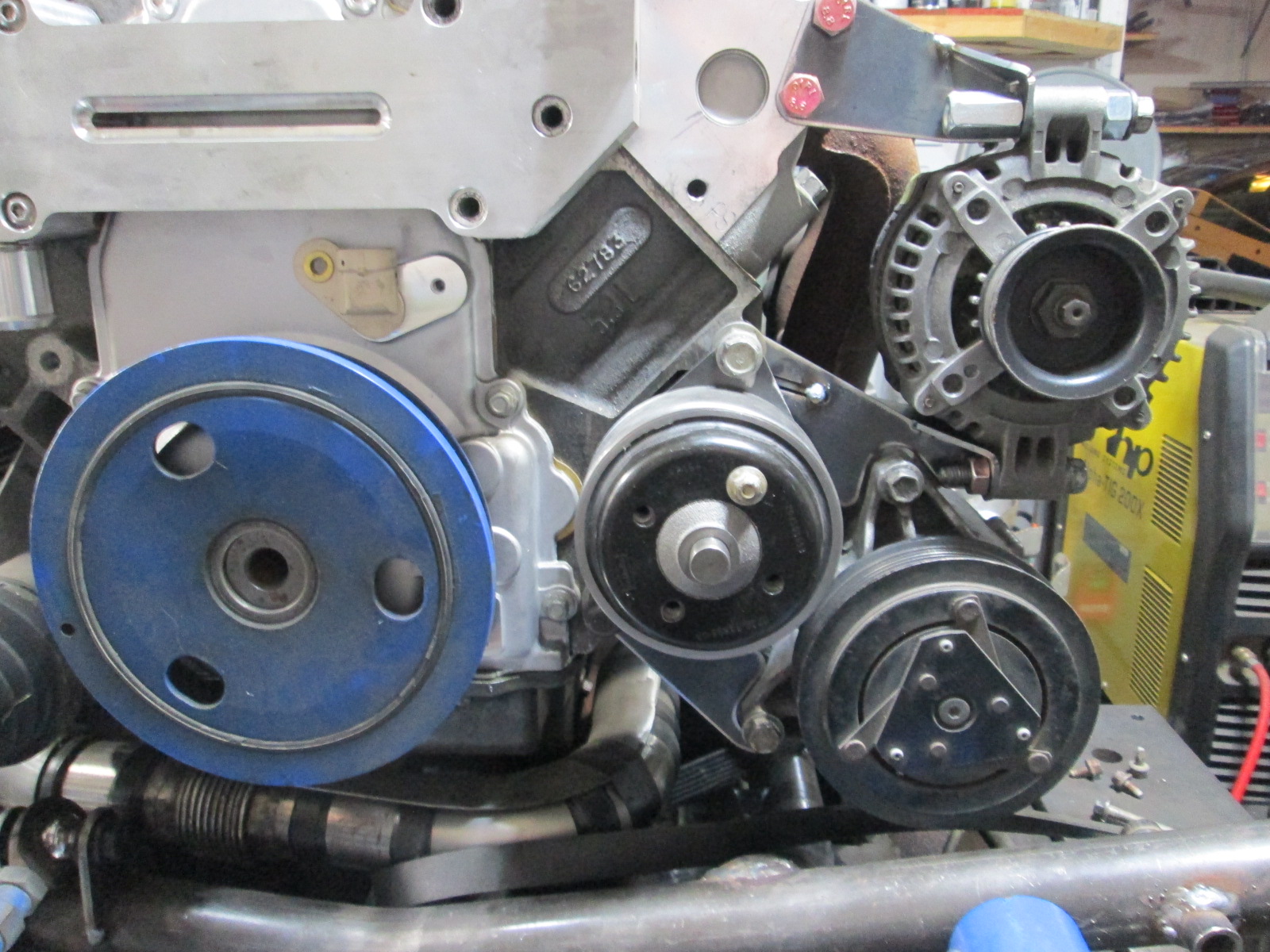

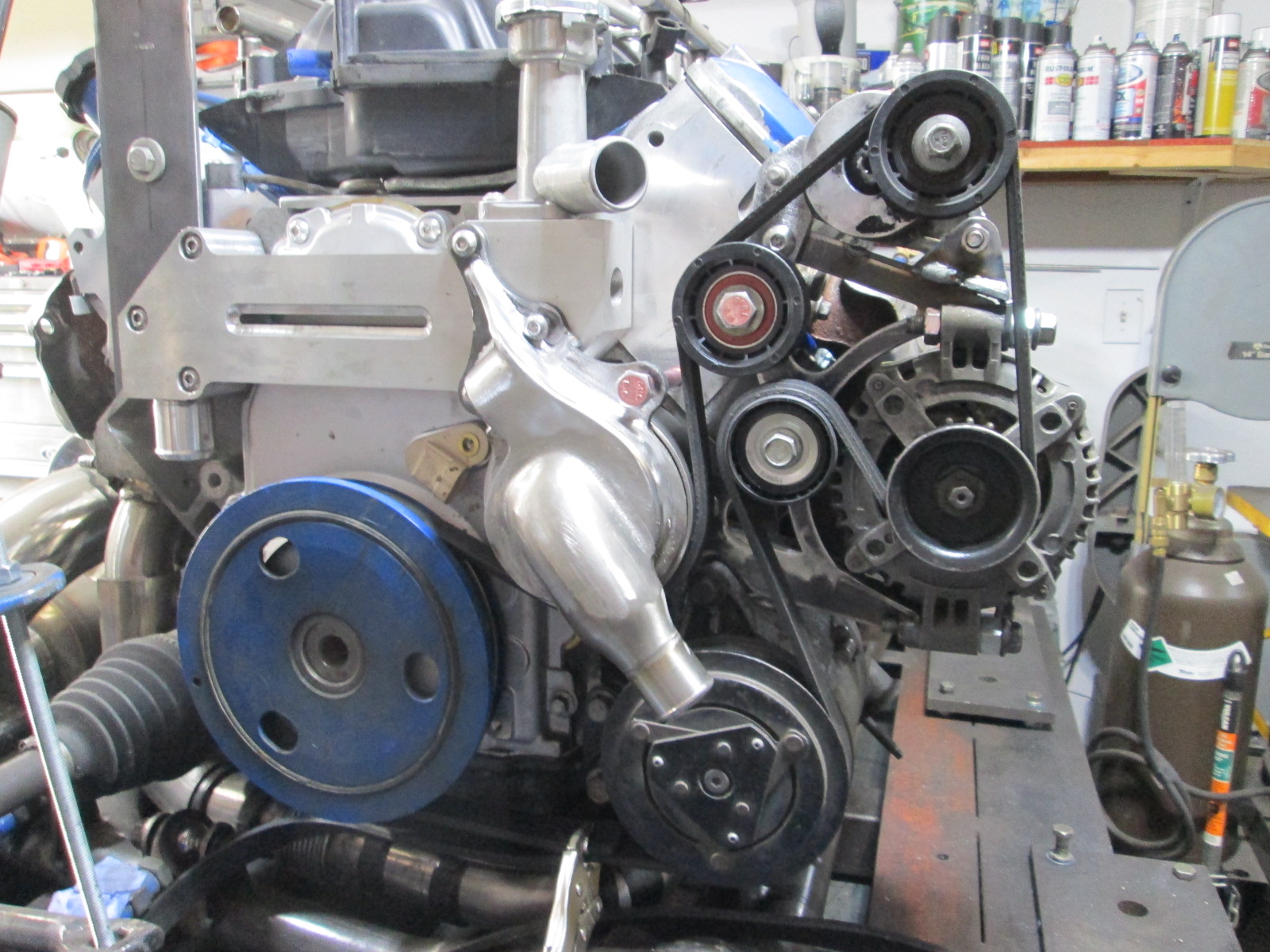

It is really hard to believe that I have been working on my LS water manifold since late 2017 (4.5 years). The manifold was the easier part, but the goal was always to have a mechanical water pump version for my car. This has probably been one of my most challenging swap tasks to date, as there is just not that much space to work within. I also kept myself restricted to the LS4 Alternator and AC compressor, which just added another layer of complexity with the Alternator mounting bosses. Lots of attempts, lots of scrapped metal and parts, and $$$ spent, but I finally figured it out and fabricated a workable mechanical water pump solution!

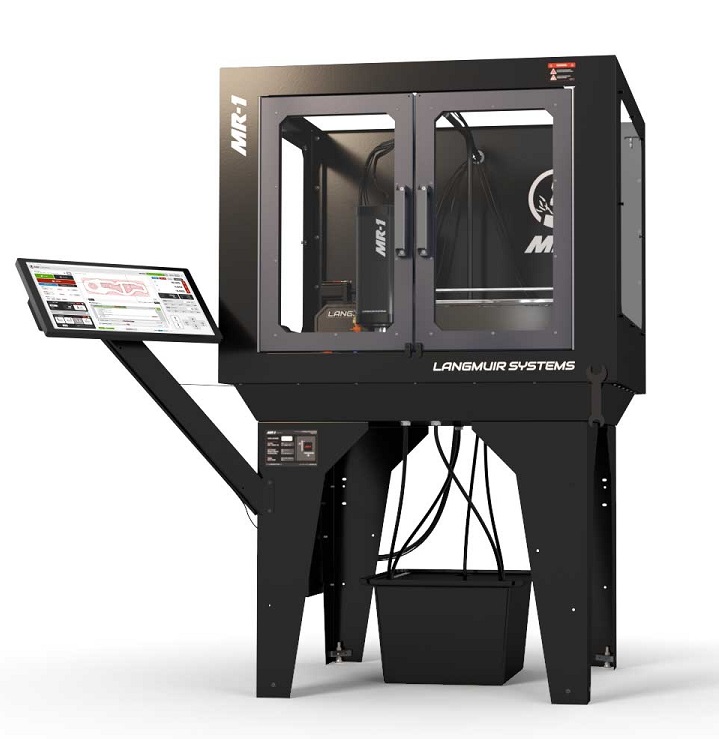

I am going to pull the trigger on the Langmuir MR-1 CNC Mill. It is 3.4 HP 220V single phase, has 22.8" x 21.8" x 6" machine travel, room for a 33" x 31" work piece, and a 48" x 55" footprint (with the enclosure) in the shop. I plan to get most of the options including the flood coolant, enclosure, 2 vices, some tooling, and tooling setting sensors, but will not get the touchscreen PC or the threading tooling (SAE and I would need metric).

https://www.langmuirsystems.com/mr1

This mill should be a good compromise between cost, capabilities, and shop space requirements. It should be large enough and capable of making just about any custom Fiero parts I could dream up...[This message has been edited by fieroguru (edited 04-17-2022).]

|

|

|

Bob2112

|

APR 17, 10:05 PM

|

|

I will happily buy that manifold to help you recover the cost of the mill.

|

|

|

Trinten

|

APR 17, 10:55 PM

|

|

Yeah, I think I see the number of rose-tinted glasses folks pinging FieroGuru with ideas and questions are going to go up quite a bit. ... I may or may not be one of those people.

FieroGuru, at this rate you're going to need to hire someone part time to help you keep up with your Fiero side hustle.

|

|

|

fieroguru

|

APR 27, 08:01 PM

|

|

Yesterday was the pre-launch for the Langmuir MR-1. It opened at 3 PM Central and I placed my order/deposit at 4:30. Originally they were estimating the lead-times to start late August/early September, but my order is estimated to ship in the middle of December...

I am fine with the lead-time as it will let me get the wiring upgrades to the garage complete as well as give me time to reconfigure all the equipment to make the needed space.

|

|

|

V8Steve

|

APR 28, 09:09 PM

|

|

|

Awesome, keep up the good work! ------------------

88GT 355 CI, AED HO 750 Double Pumper, AFR milled 180, Dyno'd at 427 HP, 360 WHP, F40 6-Spd

anderson@gdsconsulting.com

|

|

|

|