|

| LS4 / F40 swap - fieroguru (Page 178/210) |

|

Trinten

|

NOV 07, 06:53 PM

|

|

Cool!

I hadn't read about the Volvo EHPS unit. I had only found the slightly older Toyota Spyder MR2 unit!

It actually looks very similar, too. I might have to try to chase one of these down as an emergency future-replacement part.

Your knuckles are looking awesome too!

|

|

|

fieroguru

|

DEC 05, 07:12 PM

|

|

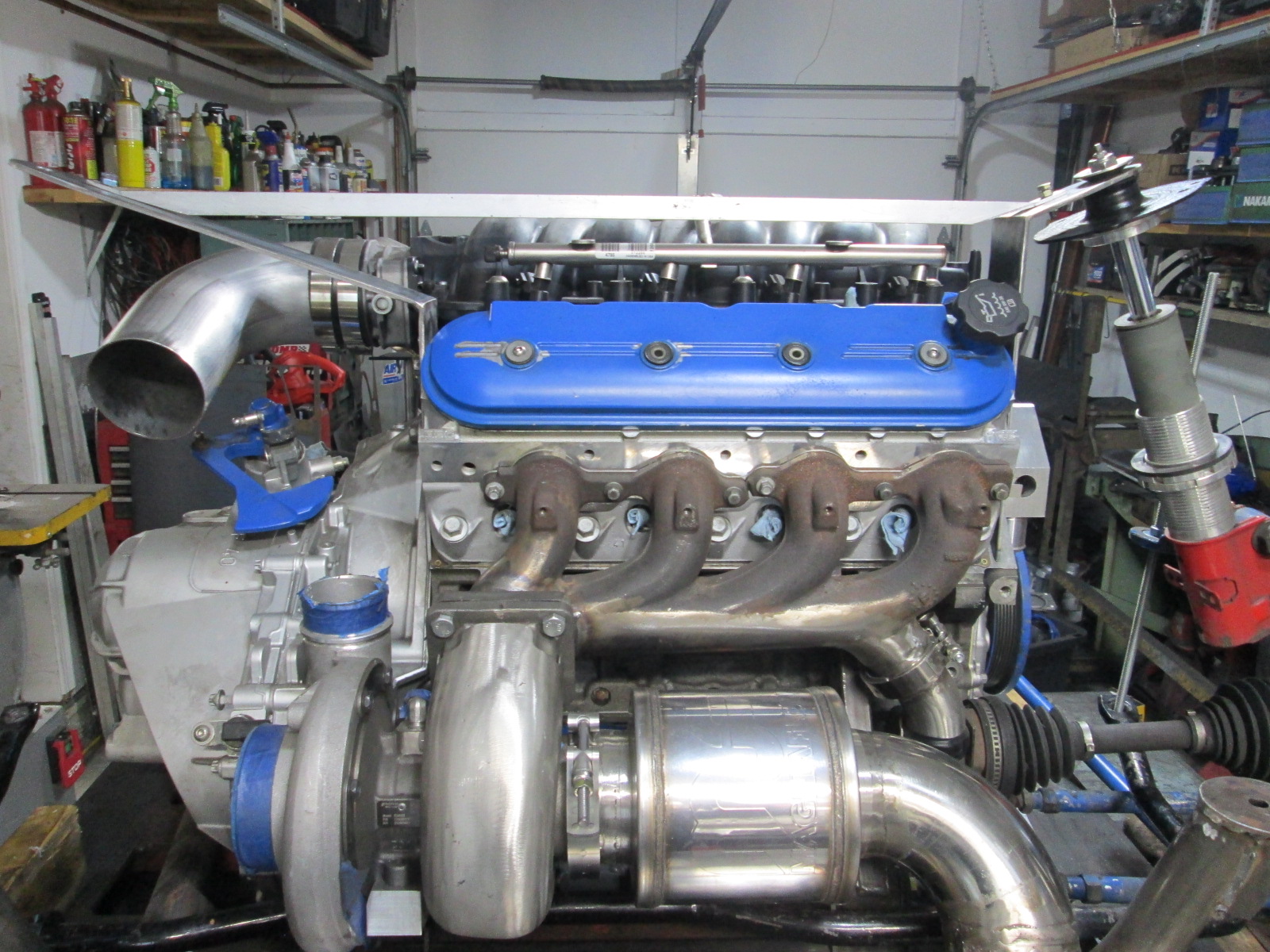

With the temps starting to drop and wanting to get the engine back in the work bay and out of the car for winter to finish everything, I diverted my efforts to the items I need to finalize at this stage of the drivetrain test fit.

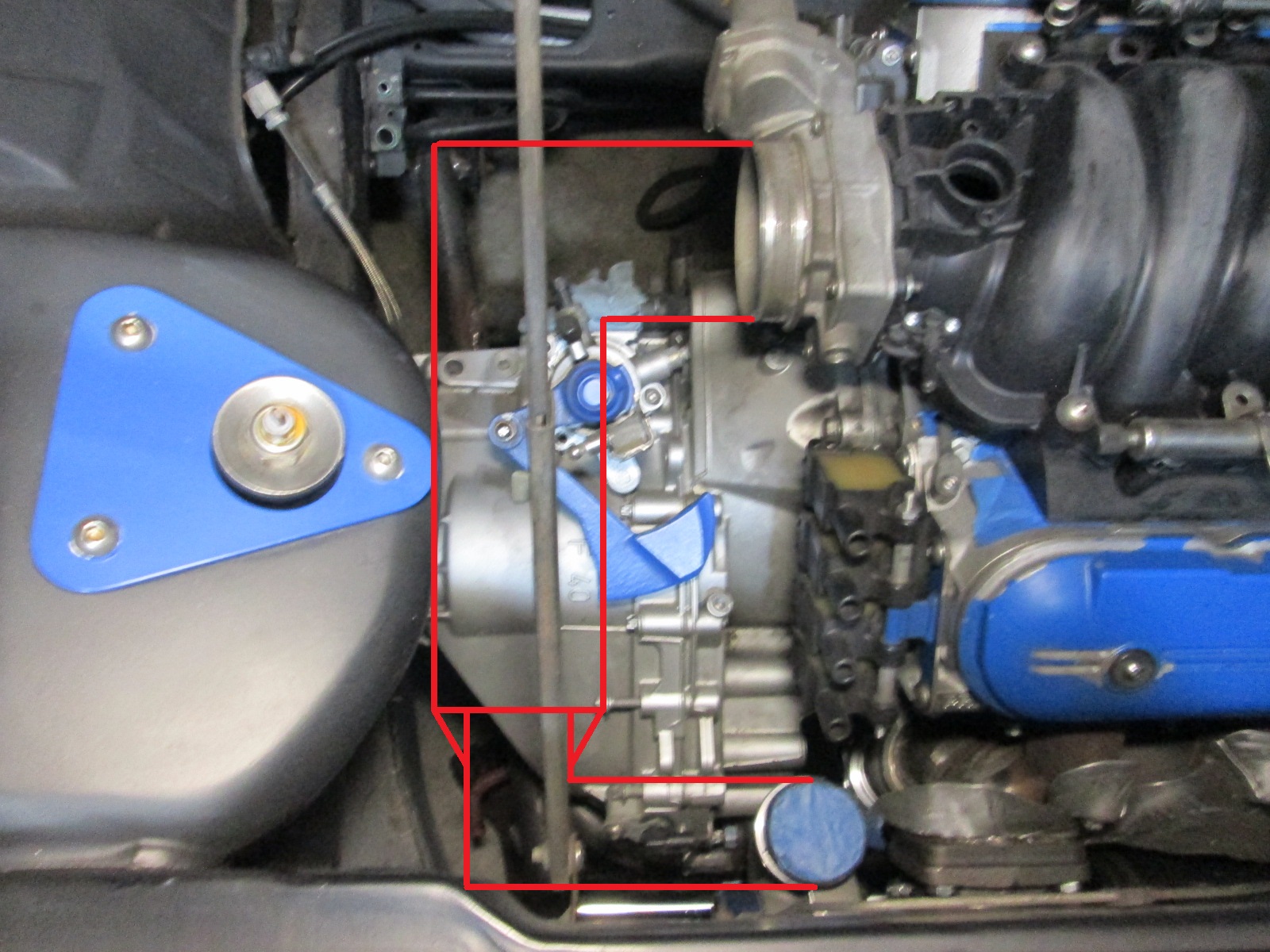

Cold side... took some measurements and ordered some additional bends. It will be 2 1/2" out of the turbo, two 90s to offset the tube close to the strut tower, 2.5" to 4" transition, LS7 MAF, 90 turn before entering the throttle body and into the intake. Here is a very crude paint representation:

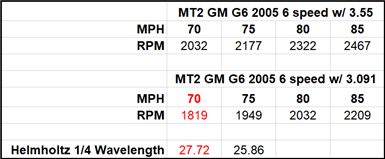

Also worked some more on the exhaust... When the car had the 3.55 final drive, it didn't have any noticeable resonance when cruising in 6th at 70 mph. When I swapped to the 3.091 final drive, the car was noticeably louder at 70 mph due to resonance and it dropped off as the car got to 80 mph. Since i am going with 3" exhaust, resonance will be worse, so I want to use a helmholtz 1/4 wavelength resonator and have used my prior observations of resonance rpm to help narrow down the expected length needed.

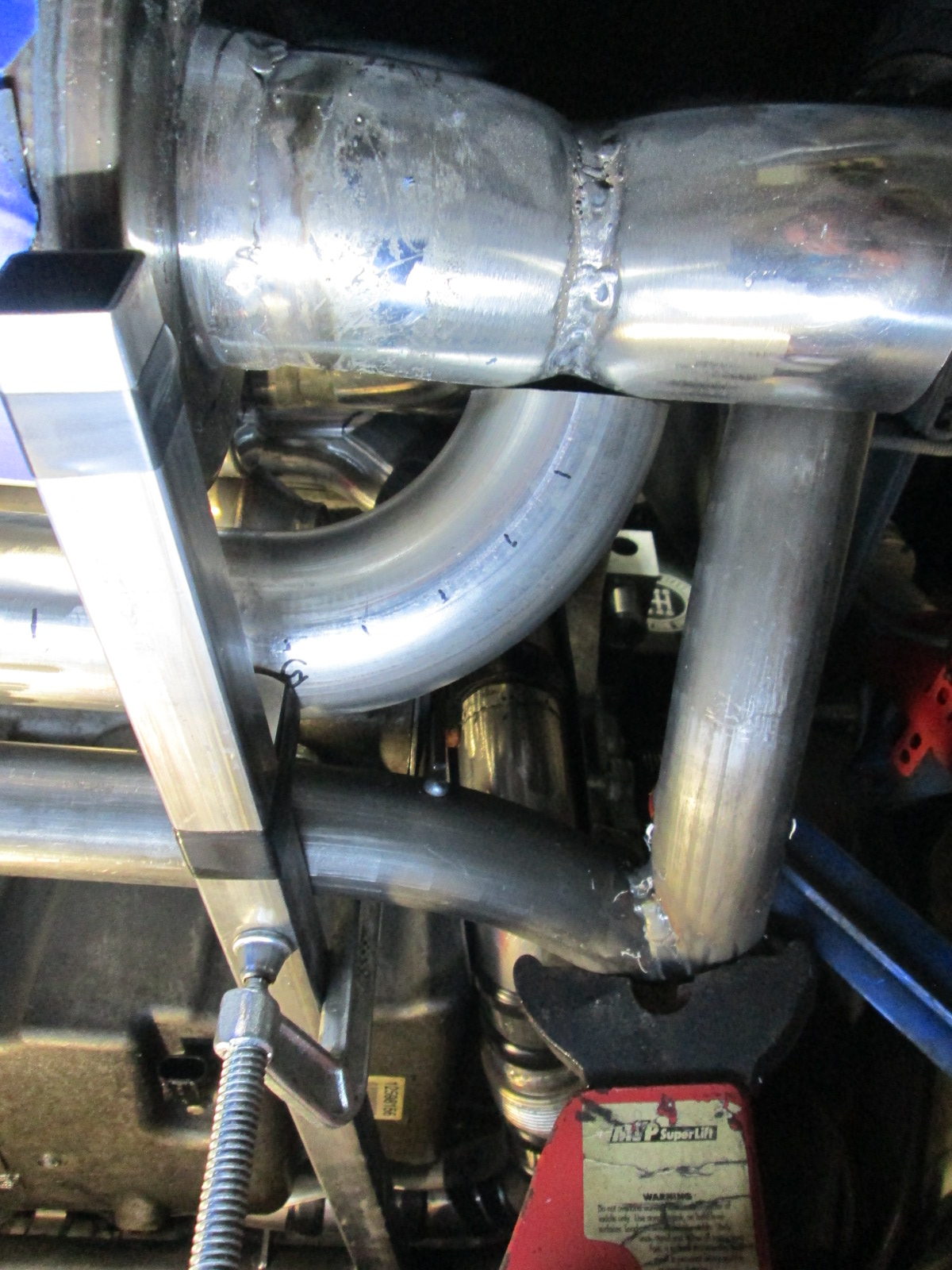

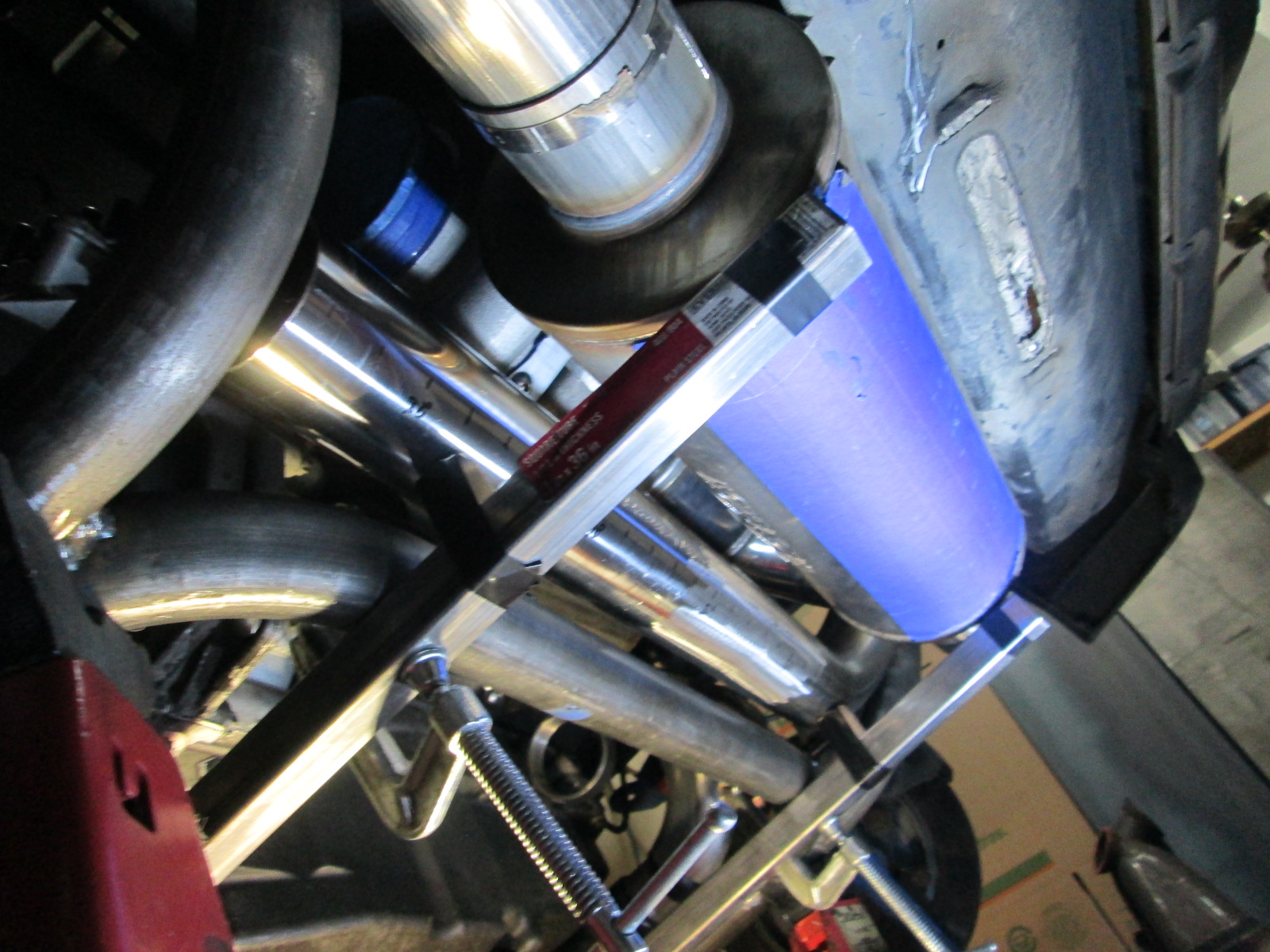

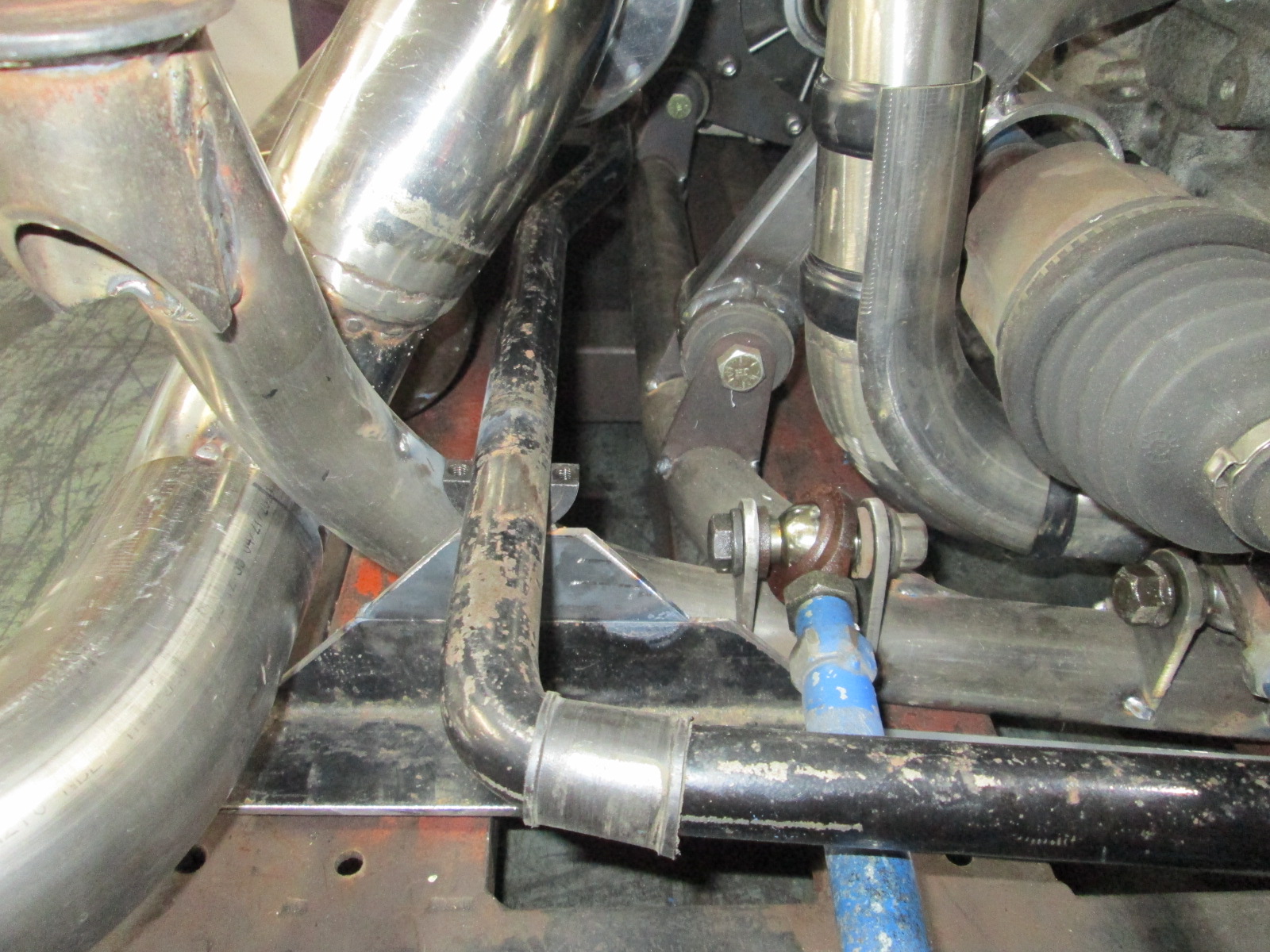

I had talked about using the cutout on the passenger exhaust tube to act as a resonator, but there is just too much pipe to fit in that area. Instead, I will route it parallel to the muffler between the muffler and cradle rail. Here it is setting in place. It is about 27 3/8" in length, which should work. It will come off the exhaust at the Y section where the 3.5" splits to dual 3" exhaust tubes.

Now that the resonator plan was in place, I could started installing the cutout on the passenger side exhaust. The picture below shows the DS and PS exhaust pipes with the PS pipe having the cutout assembly. Still some final fitment and trimming needed, but things are starting to come together.

|

|

|

Will

|

DEC 05, 07:40 PM

|

|

|

The turbo will definitely have something to say about the resonance as well.

|

|

|

fieroguru

|

DEC 11, 07:45 PM

|

|

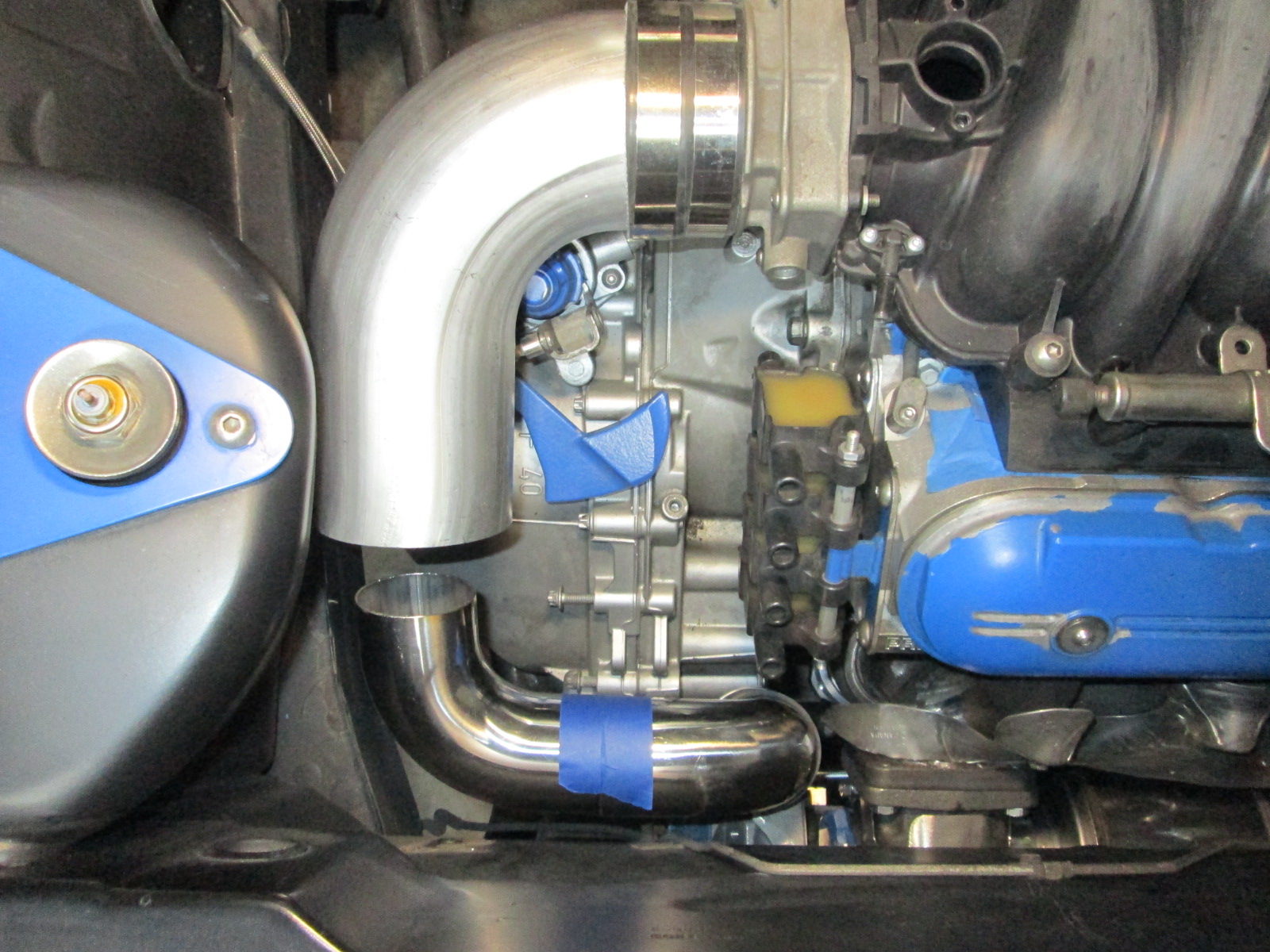

Mocking up the cold side. I think I will trim the hose barb off the turbo outlet and use a V-band setup on that end. This will allow me to lower the 2.5" side about 1.5 to 2", increase the incline angle from the turbo and throttle body tube and maximize the length of the 4" section.

This is mocked up enough to know 4" section will clear the strut tower (especially when angled down some more, so the rest of it can be finished on the stand.

|

|

|

fieroguru

|

DEC 24, 05:17 PM

|

|

I had a few hours today to accomplish more with the exhaust.

While I have always used the stock megaphone tips, they are only dual 2" tubes and would be a restriction for the 3" tail pipes. I found these stainless tips made from a 2.5" Y with dual 3" tips.

Cut the inlet off, oval the 3" tail pipe and some welding and it looks like this:

I think they will work well for a shockish look.

|

|

|

fieroguru

|

JAN 03, 05:24 PM

|

|

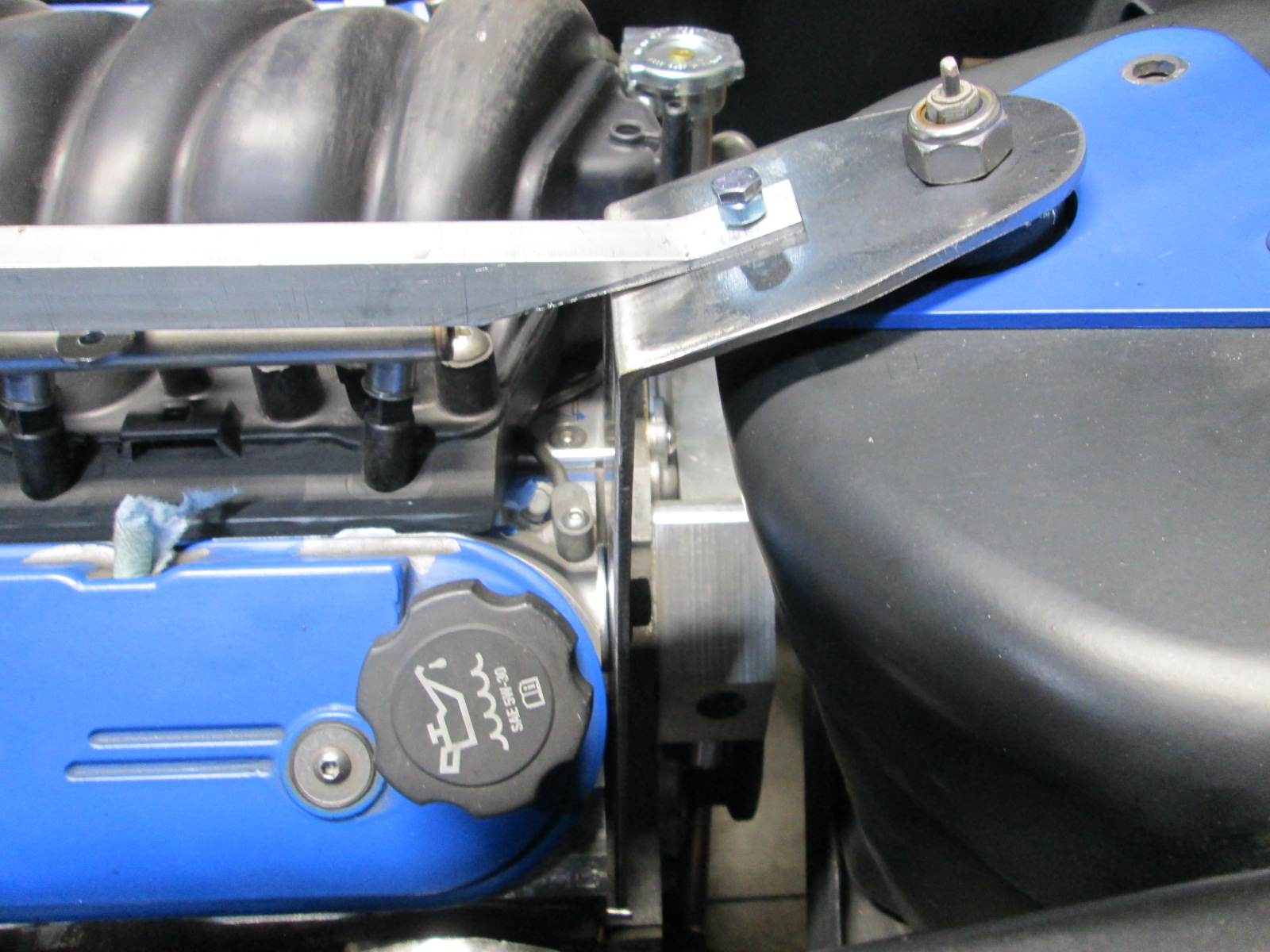

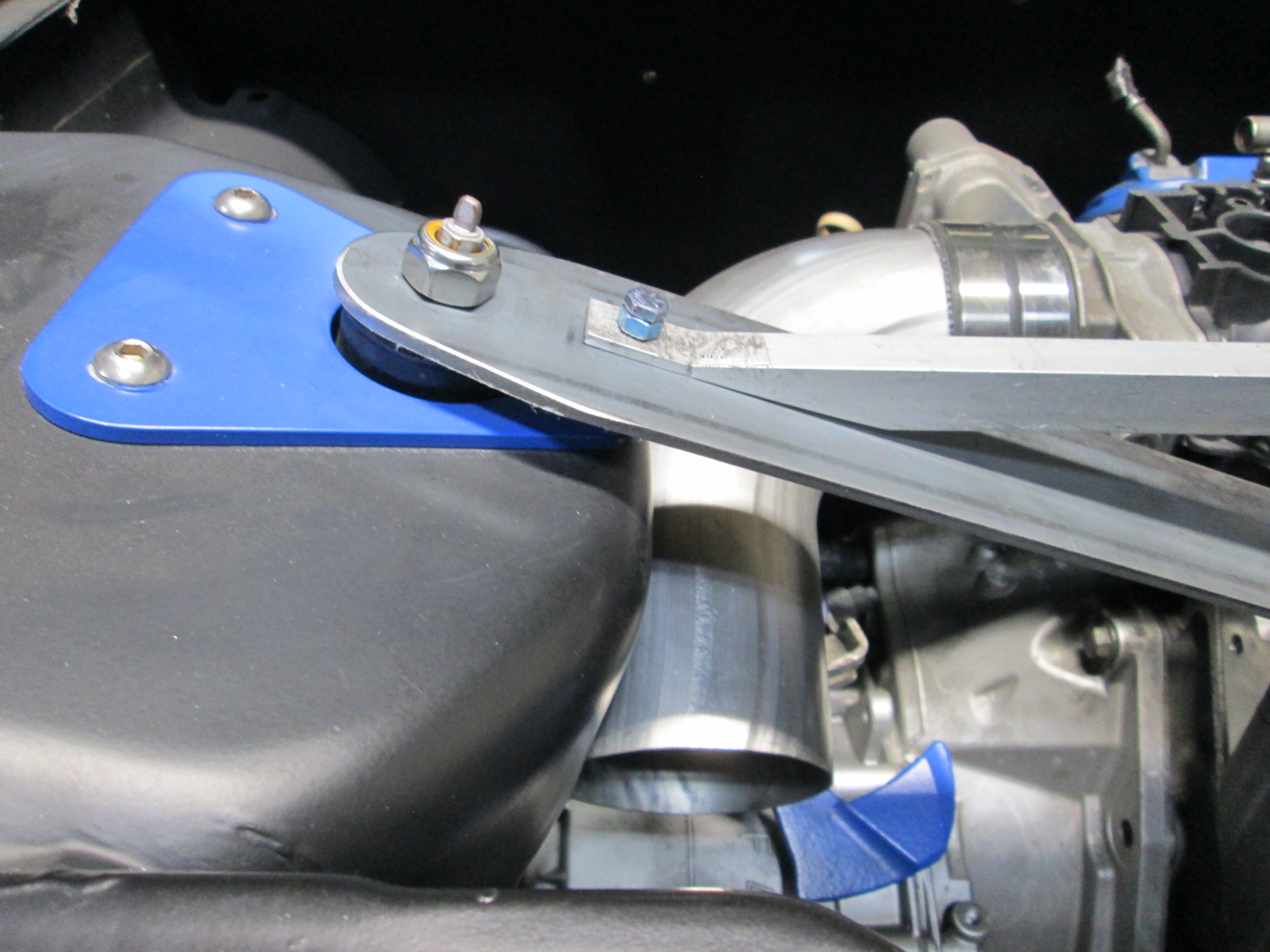

While the engine was in the chassis, I wanted to pickup the top of the struts so I could play around with sway bar placement.

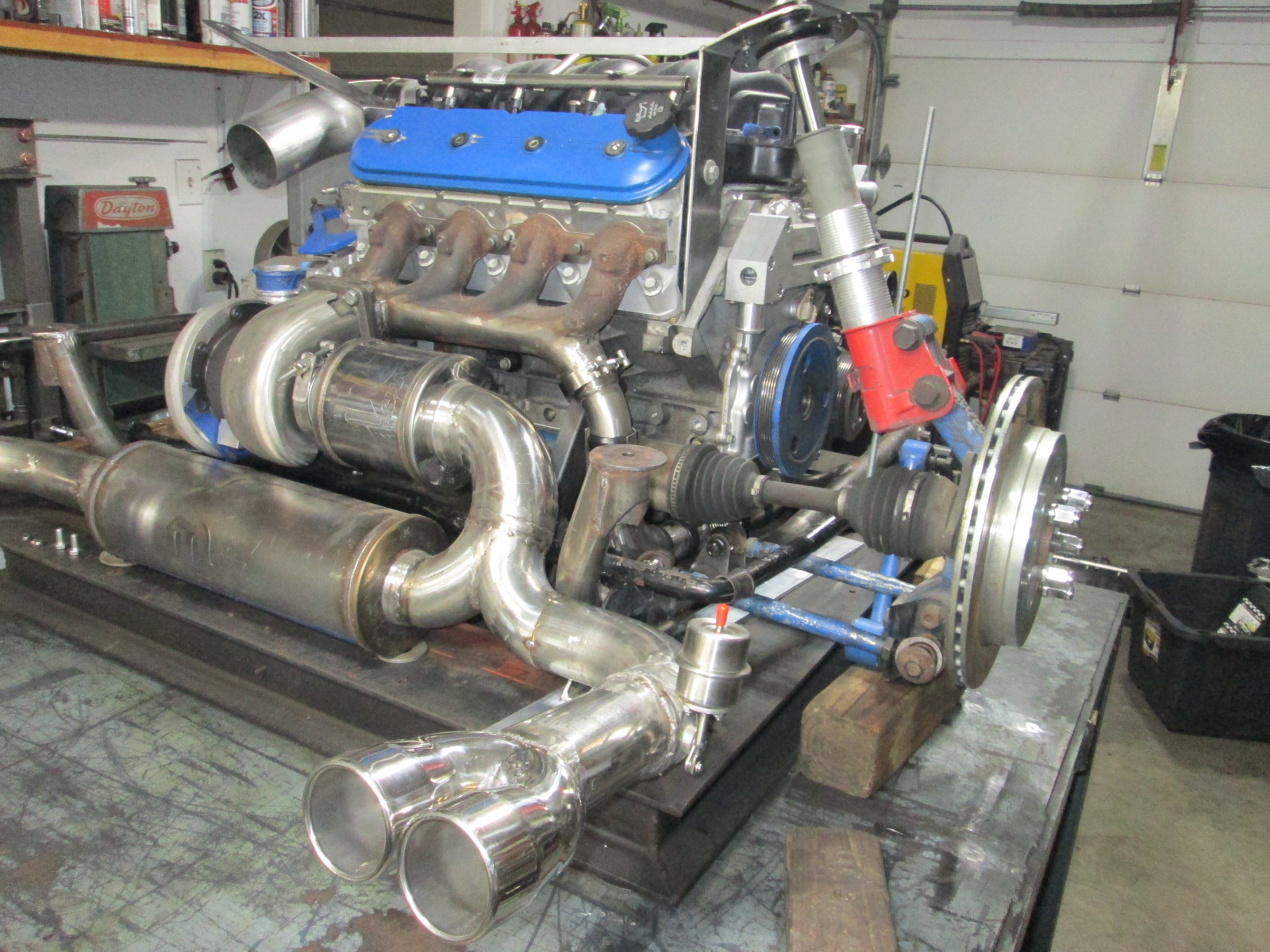

After those strut location brackets were done, it was time to put the drivetrain back on the table:

Here you can see the passenger side exhaust made with the vacuum activated cutout, as well as the suspension mockup at ride height.

Since the turbo clearance required the tubular cradle for clearance to the rear crossmember, and the stock sway bar mounts above the rear crossmemeber, the turbo also requires the sway bar to be relocated several inches lower. This puts it too low to continue to go over the axle, so it was flipped over and positioned under the axle, but over the lateral links, which makes for a tight fit... but it does fit with adequate clearance for full compression and full droop!

For the swaybar test fit, I quickly fabbed up a bracket to hold it in position. I will make another for the other side to fine tune the placement as well as verify with the driver side as well (it has a shorter axle, so geometry will be slightly different and will likely be the side the ultimately sets the final position and overall length of the end lengths.

At full compression, the bar clears the lateral link and axle.

Here is the clearance between the sway bar and compressor housing:

|

|

|

Skybax

|

JAN 05, 11:12 PM

|

|

|

|

Trinten

|

JAN 06, 05:46 PM

|

|

So most of the time your exhaust will be going through the left side, which has an additional muffler, which will make things nice and quiet. When you jump on it, the cut-out will open up to make sure you don't have a exhaust choke. I get that. Your vacuum cut out, how will that work? Will it function off vacuum from the engine, or will you have a separate vacuum pump and a switch to operate?

Sorry if you posted that elsewhere already and I missed it.

|

|

|

fieroguru

|

JAN 06, 08:27 PM

|

|

I am not convinced on the drivers side actually being quiet... but I have tried to maximize the length of unrestricted muffling. I don't think I will be able to drive it to work daily. Neighbors probably won't like hearing it pull out of the driveway at 4:30 am.

There will be a vacuum reservoir by the cutout which will be maintained by engine vacuum when not in boost.

A 12v dc mac valve will be used to apply vacuum to open the cutout on demand - it is spring loaded closed for 90% of the time.

I could use a pressure switch for condition based activation, but I think it would be really cool to have a go baby go button on the shifter!

|

|

|

fieroguru

|

FEB 20, 09:47 PM

|

|

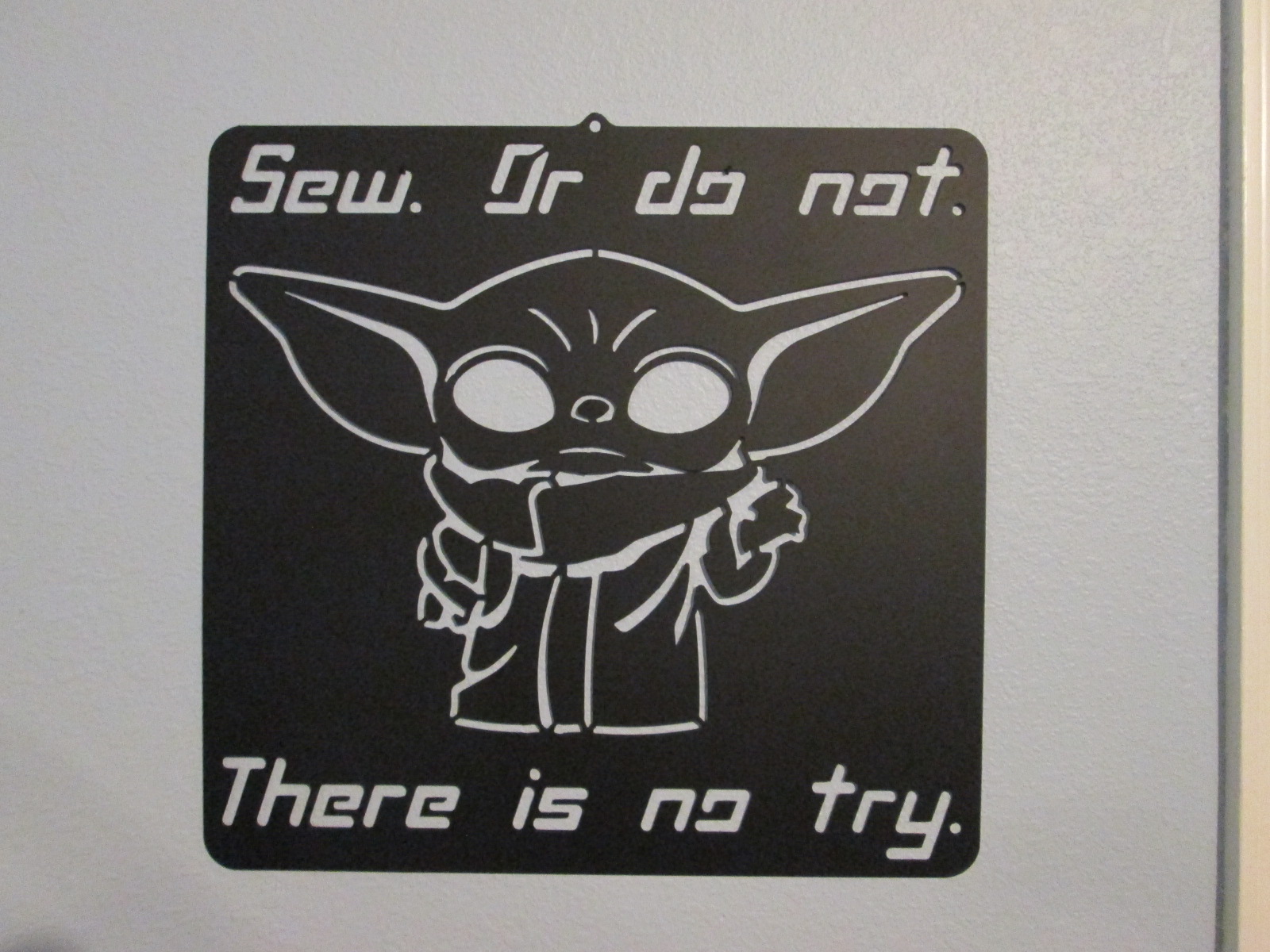

Used the plasma table to make something nice for Sara. It is about 22" x 22', took 5 solid minutes of cutting and about 500+ lines of g-code. Definitively the most complicated part I have cut so far:

Here was my inspiration:

|

|

|

|