|

| LS4 / F40 swap - fieroguru (Page 114/216) |

|

Danyel

|

FEB 13, 01:10 PM

|

|

Guru I fully understand the R&D that goes into making a new product safe and reliable and I also know that just like you I do long hours of work to make an new item available to members. It was NEVER my intent to piss you off I just wanted the damn 13in kit and you did not have them available ..... yep I did go the wrong way to get a set and at first was NOT my intent to making em available until I got dozens of PMs askng me when will they be available to buy..... If you decide to start the production on them then GOOD for you. I would buy a hardware kit in a heart beat but you arent makin them available... I will make my own based on YOUR design because they are EXACTLY what I need .... I repeat NEVER WAS IT TO PISS YOU OFF OR STEAL YOUR DESIGN....

this is my last comment in you wonderful F40 thread in which I also own one of those trannys ... and lookin forward to reading more on your developments ..... hope you will understand my point of view in desperately wanting a13in kit....and do apologize for any grief given....

greatest regards

Danyel------------------

Black Widow Build Thread 2007 - 2014 Tylers Toy

My Low Profile Buckets for sale My LED Sidemarkers for sale

|

|

|

Neils88

|

FEB 13, 09:03 PM

|

|

Just remember....stealing the idea of a single person is plagiarism.....stealing the ideas of many people is research....

|

|

|

RCR

|

FEB 14, 06:02 PM

|

|

Honored to be mentioned with the likes of Fieroguru, even if incorrectly. I'm all about DIY, not making a profit, but I'm not here to reproduce other's work when it affects there life, that's one reason I never mentioned the rotors used in his kit. I hope for the good of our "club" that Fieroguru can find it in himself, the time, and the worth, to bring his parts back to our market. To anyone that wants to copy it for whatever reason, you do have to live with yourself.

Peace out, all...

Bob

|

|

|

fieroguru

|

MAR 13, 07:29 PM

|

|

For the past many weeks, I have been putting my garage back together with benches, shelves, tools, and as well as pulling out my inventory. While this garage is larger than my old one, the wife wants to actually use it to park her car inside in the winter, so my focus has been to maximize the use of the available space. I also had 220V wired into both bays for the compressor, welder, vertical mill, and band saw.

I also like bright work areas, so the garage got a super simple lighting upgrade. Since the fixtures were single bulb ceramic and rated for a lot more than 100W, I found some 200W bulbs that put out over 3500 lumens. So for about $12 the main garage bay is very bright! Many of the after pic where shot at night with the doors down.

I do still need to add some additional lighting over the mill.

From this:

To this:

The other bay:

Storage areas between the beam and the back wall:

[This message has been edited by fieroguru (edited 03-13-2016).]

|

|

|

Jfrost

|

MAR 14, 05:38 PM

|

|

|

That's a garage to be envious of, nice work!

|

|

|

fieroguru

|

MAR 18, 07:48 PM

|

|

The wife took the girls back to KY this weekend to visit some friends, so I have the run of the garage this weekend to knock out some customer orders as well as do some upgrades on my Fiero.

My goal this summer is to do more autocrossing with the local car club, so upgrades to the springs, wheels, and tires are all in order.

I had been running some cut down Chrysler cirrus springs (moog 7634) with something around a 360 lb/in range as installed... but I want something stiffer. So I am following Fierobsessed's lead and using the Moog 639 springs. I cut them down to 8 3/4" free length and should have a rate around 575 lb-in.

Springs went in w/o issue and front the first trip around the block, I think they will do the trick! The Koni's in front are set to full stiff, but I really need to get them revalved for the higher spring rate... maybe later this summer.

For the rear, I order 425 lb/in springs for my coilovers, but they haven't arrived yet...

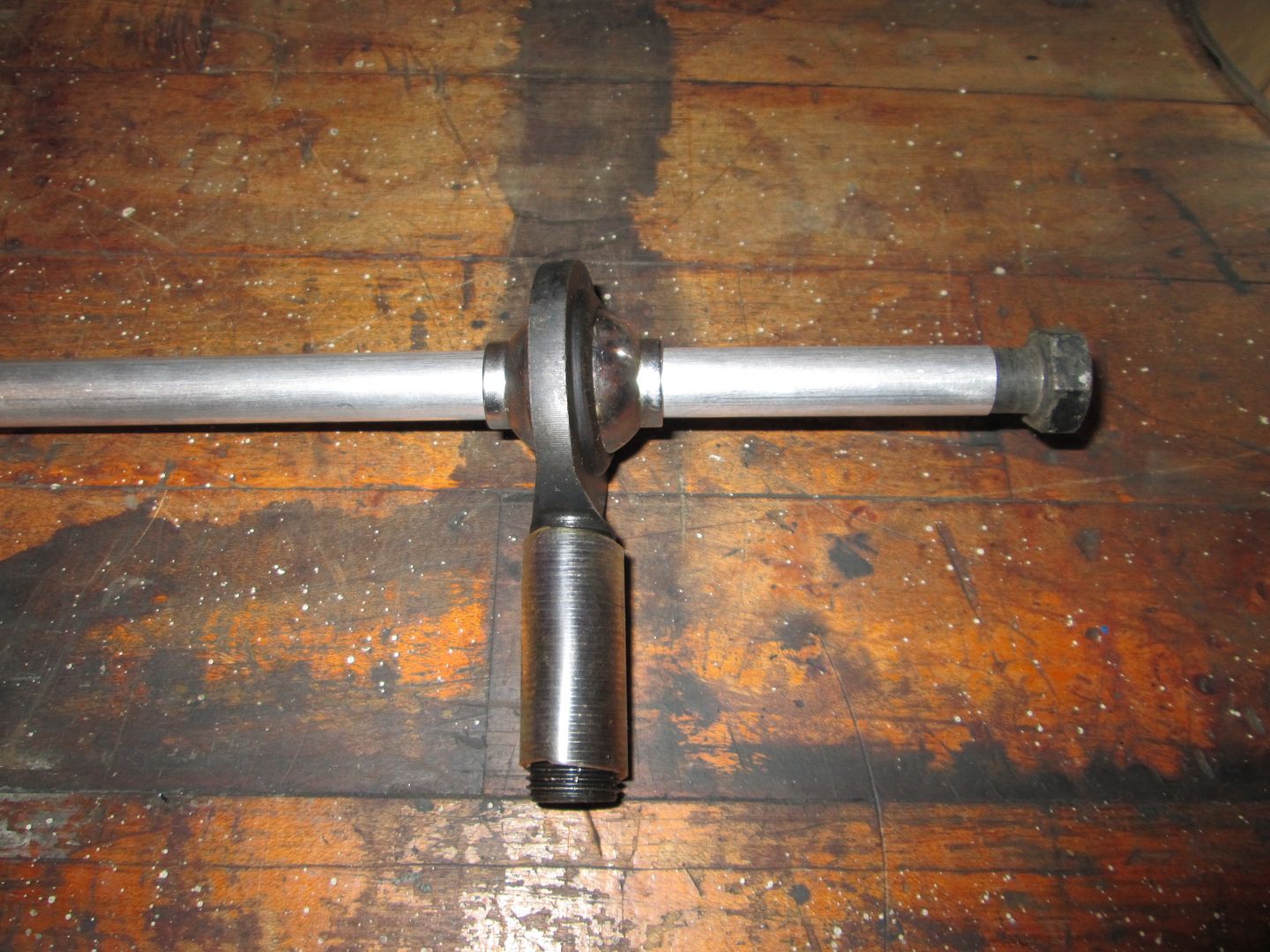

On the rear as well, the rod ends for the lateral links have worn after 3 years and 20+K miles, so I ordered a new set. Since these are 1/2" ID and the mounting bolts are M12, there is about 0.032" of slop between the bolt and the rod end. To close up the gap, I found some aluminum sleeve material that has 0.016" wall thickness and 1/2" OD from McMaster.com (7237K39) for $4.55 + shipping.

The sleeve slides into the rod end and allows the M12 bolt to pass through it too!

Using a tubing cutter with the bolt inside the tube to support it, I was able to cut the 8 sleeves (4 are installed in the pic below):

Saturday I am planning to swap in the new rod ends...

|

|

|

fieroguru

|

MAR 19, 05:22 PM

|

|

|

|

fieroguru

|

MAR 20, 03:28 PM

|

|

Today, I swapped out the fan relay. The fan relay set a DTC. Lucky for me my daily commute has less than 3 miles of non-interstate at each end, plus the cooling system is overkill. So I drove it for several days w/o the fan working w/o it ever even getting to 200 degrees. With a new relay, the fan is back working, so I drove it around town for about an hour running to get more stuff for the garage.

The LS4/F40 swap has been bullet proof reliable for the past 3 years with the exception of 2 items.

1: Getrag Select Cable used as a Shift Cable - broke the cable twice - redesigned the bracket to use a stock Isuzu Shift cable - been working great for 2+ years, so it is no longer a concern.

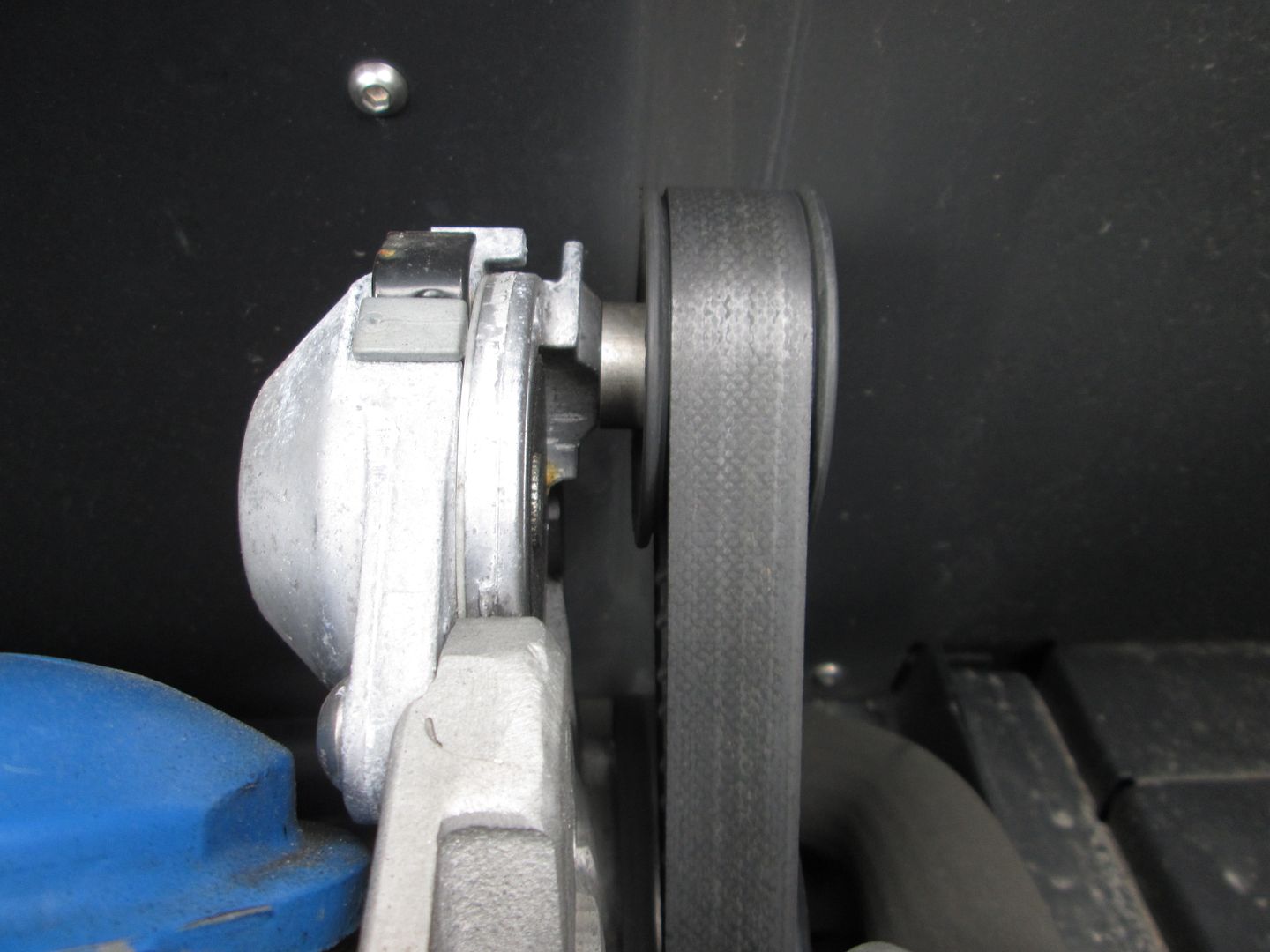

2: Belt tensioner - I have broke this tensioner twice, once while sitting in the driveway, the other while driving on the interstate. The "issue" is I added a spacer to shift the pulley further from the tensioner body. This extra spacer length is overstressing the the pulley bracket leading to a premature failure at some point...

Stock pulley spacing:

My setup:

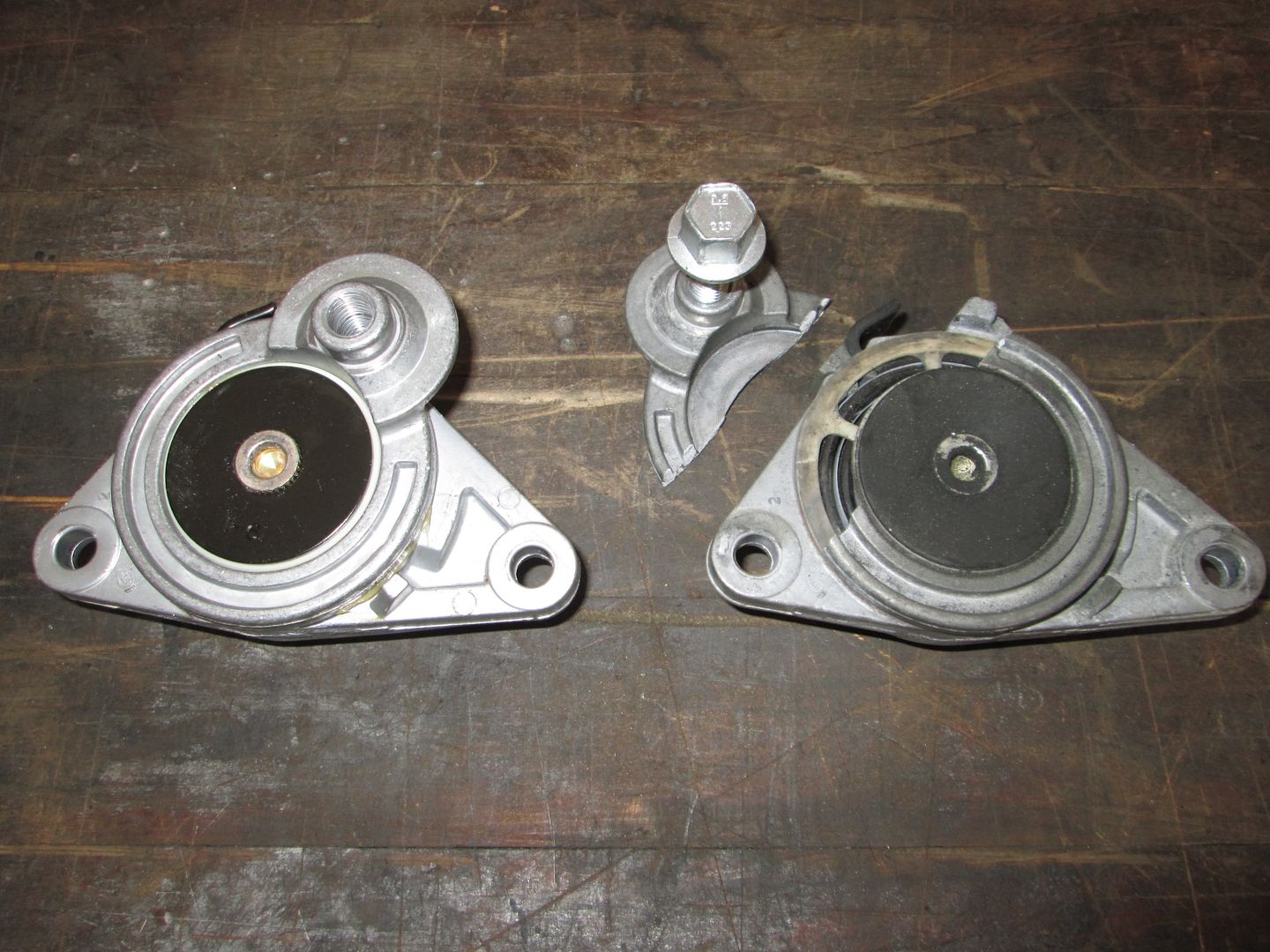

The eventual result:

There isn't much material in the bracket... which is part of the problem:

So one of my next projects is to disassemble a new tensioner and make a new pulley bracket for it with a significant amount more material thickness. Once that is done, it shouldn't break again.

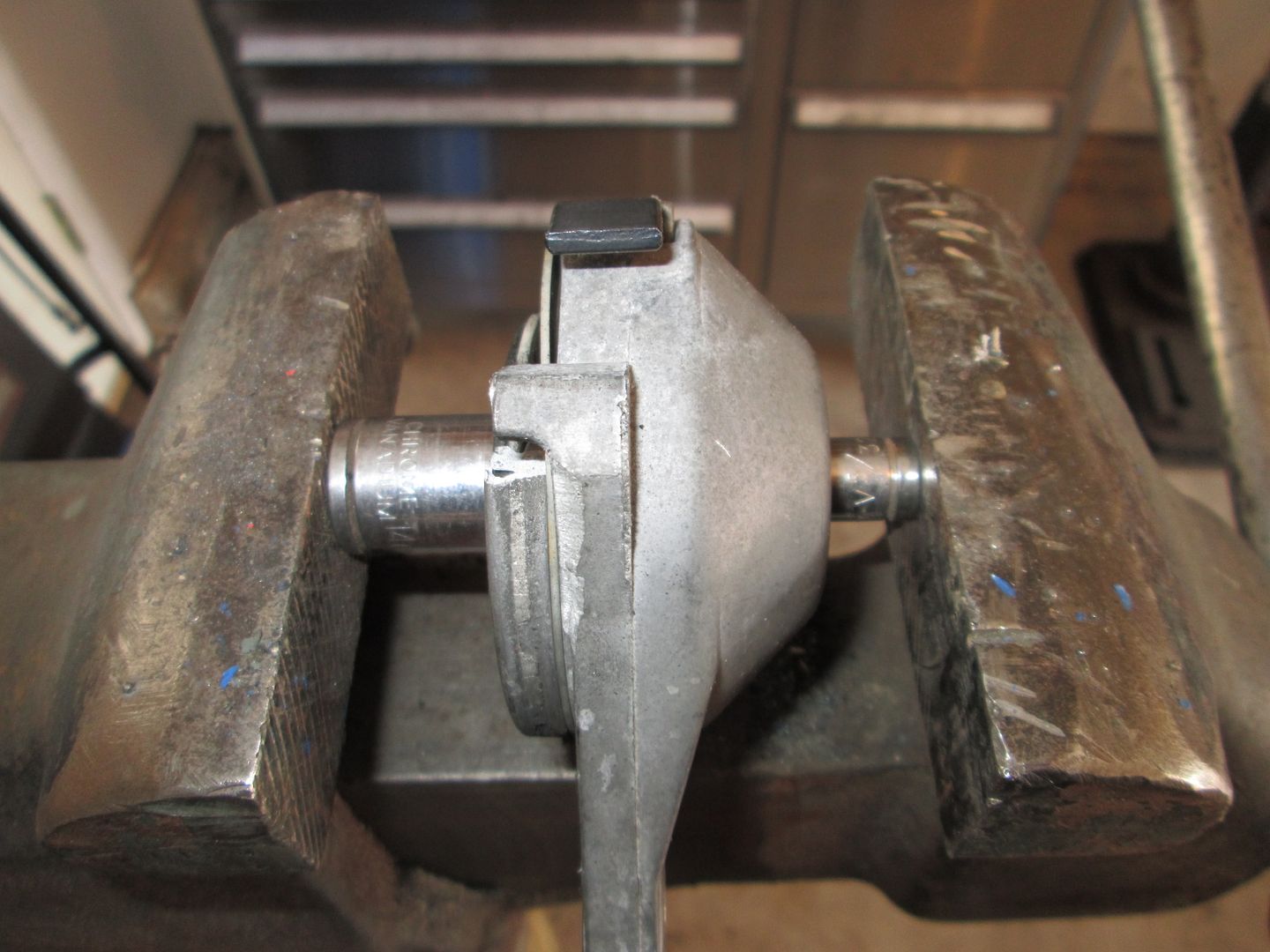

The tensioner is just pressed together, so with some properly sized sockets and a vice, it comes right apart:

Here is the part than needs to be remade:

A 2x3x12 bar of 6061 aluminum has been ordered and will be here in a few days![This message has been edited by fieroguru (edited 03-20-2016).]

|

|

|

85-308

|

MAR 21, 08:09 PM

|

|

hi Guru!

Nice to see you are back at it! Garage looks great; I will have to go back and get caught up.

I assume at some point you will get back into production of parts for the LS4 and F40... If it is in recent posts then I will find it.

Better weather and a lot of things out of the way means I am getting back at it, too.

GP

|

|

|

mrstan

|

MAR 28, 10:30 PM

|

|

|

Do you have instructions for that Kent Moore J-36419 tool for castor / camber? I have a pair, but wanted to see if you had advice or instructions for use? Any pointers for this tool?

|

|

|

|