|

| Bringing a 88 Fiero Back to Life with a LFX Swap (Page 1/15) |

|

MikesFirstFiero

|

JUL 27, 02:16 AM

|

|

I and my wife moved back to the US after spending 12 years in Malaysia, I was an elevator controls designer over there. I finally decided to retire and do nothing too serious. Well that lasted for about a year and then we bought a house and I had three car garage and one car. So I setup a garage wood shop and built drawers for cabinets, a headboard, a kids rocking horse, chairs and cutting boards. Life was OK but not too complicated. Then a good friend called me and said he knew of a 1988 Fiero that was originally a 2M4, now swapped to a 2.8 with an A/T, but it did not run. And it's been sitting for ten years mostly in a garage. It's only $1K and the car is "complete" meaning all the parts are there, good or not, has 20 year old tires and flaking paint. On the good side it has a factory shop manual and it's red.

Photos taken after I swapped out the original 14" for 16"

Having always admired the Fiero, I bit on the deal. My friend even trailered it over from Seattle to North Idaho where I live. Getting it running was slow and frustrating since I knew squat about GM cars in general and Fireos in particular. But it's a car, so how bad can it be?

Lets see, I replaced

Battery, which was located in the rear trunk

Fuel Pump, all the rubber parts were melted

Rebuilt all 4 calipers

New 16" wheels and tires

Plugs, Wires, Oil pressure switch/sender

Idle Air

Throttle Position Sensor

Coolant Temp Sensor

Heater Hoses

Front Shocks

Rear Struts

Poly bushings all around

New Front Hubs from Dickman

New Cat converter, one of the main things wrong with the engine

Added a resonator since the Ocelot exhaust was too loud for myears

New distributor - More on that to come

New radio with display & ApplePlay

Reversing camera (on license plate)

Alternator, twice. Thanks for AutoZone's lifetime guarantee.

Finally it wants to run. Set the timing and it idles well. Goose the throttle and it dies and won't start. Timing has gone to hell. Reset it and next start it dies. Turns out the reluctor wheel on the old distributor was loose, the press-fitting had failed. One new Taiwan-made distributor and it began to come to life and ran pretty well once I chased down some vacuum leaks. If ever there was a system doomed to fail it is the 2.8 vacuum hose system. Particularly when it is 30 years old.

It ran well enough to take to Seattle and didn't fail me but it was irritating with 65 MPH being 3900 RPM. And not very economical getting 20 MPG. My wife's 3.5L Venza gets 25 MPG on the same trip but going 75 MPH. So I decided to begina restoration and improvement project. First was the change to Corvette C4 rear discs all around using the stock calipers. That worked out quite well after reading Pennock's looking for answers. I made brackets from 3/8" steel and it gave much more stopping power with the same pedal pressure.

Emboldened by that success I decided to do two things. First I hated the manual steering effort and the rack was so worn it was like tilling a sailboat. More Pennocks reading I decided to go with a 90's Camaro rack and a power steering pump from a MR2 Spyder. The rack took some trimming on the tie rods, as did the tie rod ends. I had to make a new driver side bracket to hold the new rack. The biggest issue was the new hydraulic hoses on the rack were too high and interfered with the spare tub. Who needs a spare? trimming the bottom off gave the clearance to alllow the hoses to fit for the pump too. While I was digging around the front I decided to relocate the battery from the rear trunk to the front using V8 Archie's battery holder. The power steering pump was difficult to find and I ended up getting a rebuilt one from SoCal for $600. Wiring it in was simple. Did not hookup the VSS output but it works well none the less. It detects when you load the pump by turning the wheel and increases the pressure all by itself. This is a neat setup with tank, pump and controller in one compact unit.

I never liked the stance of the car and decided to lower the front end using Dickman's 1" lowering ball joints. They clear the 16" wheels after trimming the lower A-Arm since it hits the Vette rotors. It would hit the stock rotors too for that matter. Does it handle better? Don't know but I like the look now.

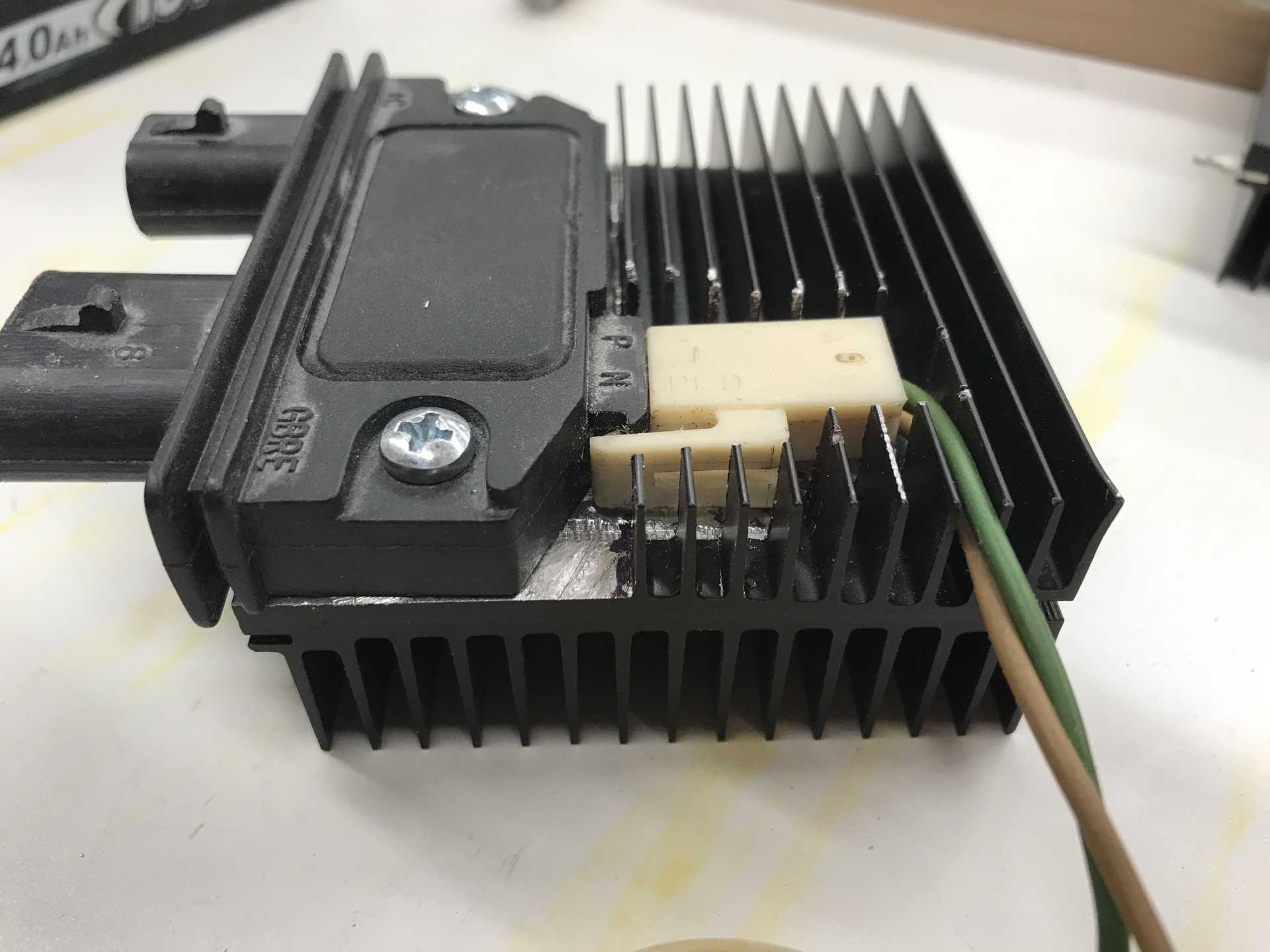

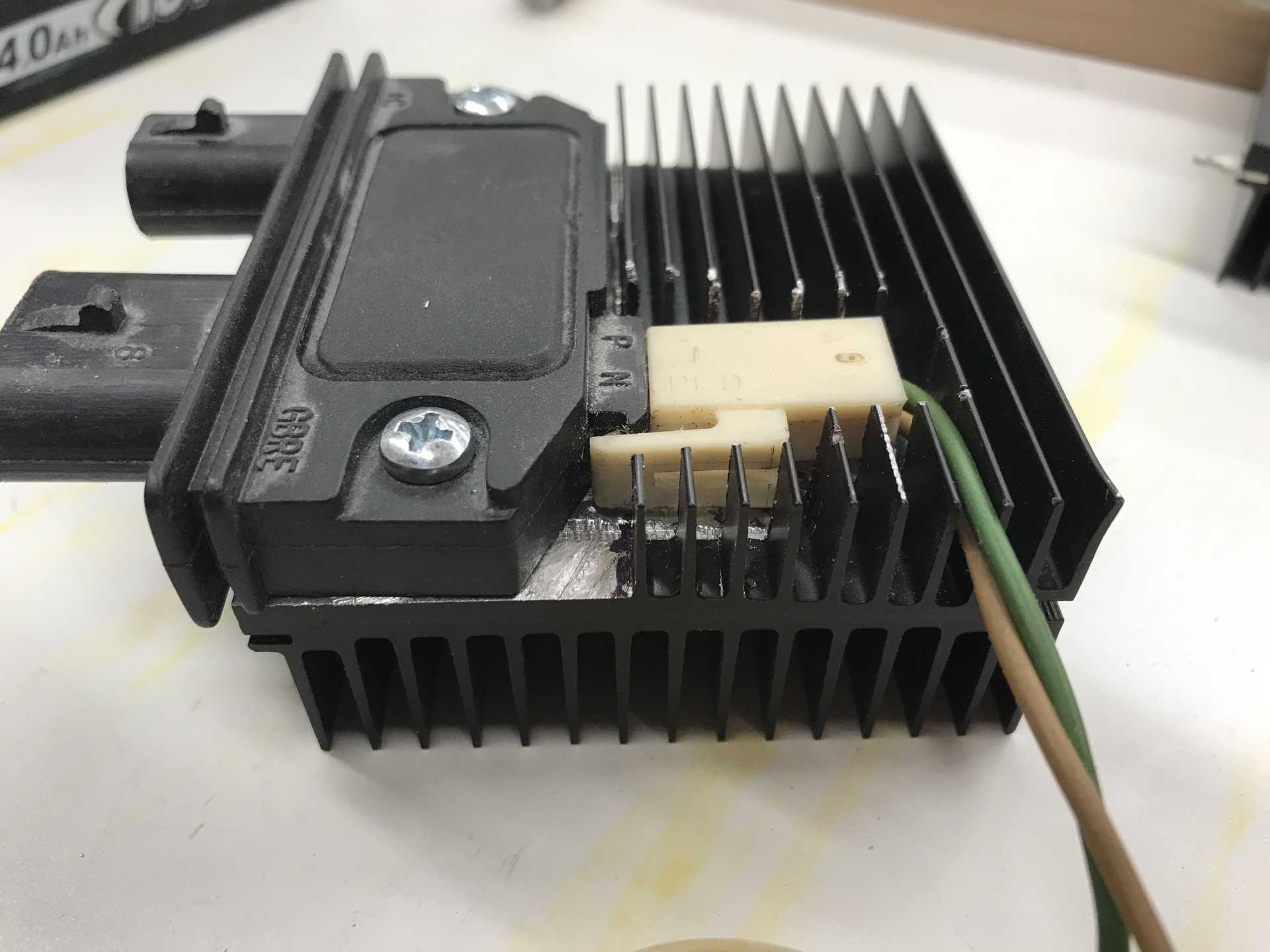

Now the troubles started. The engine had a chronic ever-so-often misfire. Then it would simply die when running and also misfire at high RPM. Probably the ignition module (one year old now). Replaced it and found the mounting of the old module to the distributor had uneven heat sink compound causing it to overheat. Problem solved so I thought. Not really, I got out my temperature meter and found the module runs about 120F when on the heat sink. Then when the engine was good and hot I measured the temp of the heatsink (which is mounted to the cast iron intake manifold) it runs about 150-160F. Not a very good heat sink, more like a heat source. So I remote located the module on a good heat sink and the temperatures dropped to 110-115F. Problem solved ? No it died again after all my attempts. Then the real problem was discovered. The connector to the reluctor coil was worn on one pin and it would actually lose contact with the pin on the module. Instant stoppage. When it cooled down it might make contact and run normally - or not. Fifteen minutes with a pair of needle nose pliers and the contact was good again.

That stupid white connector looked good but I found the problem by accident. I plugged in the connector to the module and caught only one pin. I noticed there was no contact friction and that was the problem. The advice to change the coil every now and then is good. Not because the coil goes bad but because the connector can become loose. If you have patience it can be bent back into proper shape. But eventually it will relax again and fail.

A note on remote module. Do Not ground the heatsink directly to the chassis. Put the heat sink on insulating washers and ground it ONLY to the distributor as follows. The wires on the coil will need to be extended and must be 2 conductor stranded shielded wire #24 - #22. The shield must connect to the distributor and to your new heat sink. The signals on this cable are very low and the shield isolates the internal low voltage from all the other electrical noise in the engine bay. The shield also provides the only ground path between the remote module and the distributor.

By this time I was fed up with the old engine, old transmission (which locked up it's clutch when hot) and started to hunt for a modern engine & transmission to do a swap. Fixing the problems on the old engine would still give me a slow car with poor fuel economy. Having a car with a 200 mile range sucks. The hunt led to two solutions, either a 3.2L VW VR-6 with a auto-shift manual transmission or a GM LFX with a 6T70 would do the job. The VR6 is physically smaller and produces 270 or so HP and having a paddle shifted manual is lots of fun, my Alfa 147 in Malaysia had one and it was great. The LFX is larger as is the 6T70, but much more available and less costly. The engine is lively and the transmission can be manually shifted.

That decided it, I'd go with the LFX. Digging into the details I found that you need a lot more than the engine & transmission. So I eventually found a totaled 2018 Impala at an IAA auction. It took three weeks to win it since the insurance company did not want to sell it at the price people were willing to pay. The third time it went up for sale the same thing started to happen and the seller finally dropped his reserve. I snapped it up with a bid of $1525. Then you add the auction fees. The final cost was $2250. Plus the $200 to become a bidder. But I literally had a complete running car. For some reason the auction listed it as not running. Strange since it simply needed a good battery charge to run. While IAA isn't inexpensive they do treat customers well and try to accurately describe the cars they sell. Not all IAA sites allow ondinary folks to place bids, but in Washington state they do.

Next: You bought an Impala, Now What?[This message has been edited by MikesFirstFiero (edited 02-04-2024).]

|

|

|

Daryl M

|

JUL 27, 03:11 AM

|

|

| quote | Originally posted by MikesFirstFiero:

I and my wife moved back to the US after spending 12 years in Malaysia, I was an elevator controls designer over there. I finally decided to retire and do nothing too serious. Well that lasted for about a year and then we bought a house and I had three car garage and one car. So I setup a garage wood shop and built drawers for cabinets, a headboard, a kids rocking horse, chairs and cutting boards. Life was OK but not too complicated. Then a good friend called me and said he knew of a 1988 Fiero that was originally a 2M4, now swapped to a 2.8 with an A/T, but it did not run. And it's been sitting for ten years mostly in a garage. It's only $1K and the car is "complete" meaning all the parts are there, good or not, has 20 year old tires and flaking paint. On the good side it has a factory shop manual and it's red.

Having always admired the Fiero I bit on the deal. My friend even trailered it over from Seattle the North Idaho where I live. Getting it running was slow and frustrating since I knew squat about GM cars in general and Fireos in particular. But it's a car, so how bad can it be?

Lets see, I replaced

Battery, which was located in the rear trunk

Fuel Pump, all the rubber parts were melted

Rebuilt all 4 calipers

New 16" wheels and tires

Plugs, Wires, Oil pressure switch/sender

Idle Air

Throttle Position Sensor

Coolant Temp Sensor

Heater Hoses

Front Shocks

Rear Struts

Poly bushings all around

New Front Hubs from Dickman

New Cat converter, one of the main things wrong with the engine

Added a resonator since the Ocelot exhaust was too loud for myears

New distributor - More on that to come

New radio with display & ApplePlay

Reversing camera (on license plate)

Alternator, twice. Thanks for AutoZone's lifetime guarantee.

Finally it wants to run. Set the timing and it idles well. Goose the throttle and it dies and won't start. Timing has gone to hell. Reset it and next start it dies. Turns out the reluctor wheel on the old distributor was loose, the press-fitting had failed. One new Taiwan-made distributor and it began to come to life and ran pretty well once I chased down some vacuum leaks. If ever there was a system doomed to fail it is the 2.8 vacuum hose system. Particularly when it is 30 years old.

It ran well enough to take to Seattle and didn't fail me but it was irritating with 65 MPH being 3900 RPM. And not very economical getting 20 MPG. My wife's 3.5L Venza gets 25 MPG on the same trip but going 75 MPH. So I decided to begin restoration and improvement project. First was the change to Corvette C4 rear discs using the stock calipers. That worked out quite well after reading Pennock's looking for answers. I made brackets from 3/8" steel and it gave much more stopping power with the same pedal pressure.

Emboldened by that success I decided to do two things. First I hated the manual steering effort and the rack was so worn it was like tilling a sailboat. More Pennocks reading I decided to go with a 90's Camaro rack and a pwer steering pump from a MR2 Spyder. The rack took some trimming on the tie rods, as did the tie rod ends. I had to make a new driver side bracket to hold the new rack. The biggest issue was the new hydraulic hoses on the rack were too high and interfered with the spare tub. Who needs a spare? trimming the bottom off gave the clearance to alllow the hoses to fit for the pump too. While I was digging around the front I decided to relocate the battery from the rear trunk to the front using V8 Archies battery holder. The power steering pump was difficult to find and I ended up getting a rebuilt one from SoCal for $600. Wiring it in was simple. did not hookup the VSS output but it works well none the less. It ddetects when you load the pump by turning and increases the pressure all by itself. This is a neat setup with tank, pump and controller in one compact unit.

I never liked the stance of the car and decided to lower the front end using Dickman's 1" lowering ball joints. They clear the 16" wheels after trimming the lower A-Arm since it hits the Vette rotors. It would hit the stock rotors too for that matter. Does it handle better? Don't know but I like the look now.

Now the troubles started. The engine had a chronic ever-so-often misfire. Then it would simply die when running and also misfire at high RPM. Probably the ignition module (one year old now). Replaced it and found the mounting of the old module to the distributor had uneven heat sink compound causing it to overheat. Problem solved so I thought. Not really, I got out my temperature meter and found the module runs about 120F when on the heat sink. Then when the engine was good and hot I measured the temp of the heatsink (which is mounted to the cast iron intake manifold) it runs about 150-160F. Not a very good heat sink, more like a heat source. So I remote located the module on a good heat sink and the temperatures dropped to 110-115F. Problem solved ? No it died again after all my attemtpts. Then the real problem was discovered. The connector to the reluctor coil was worn on one pin and it would actually lose contact with the pin on the module. Instant stoppage. When it cooled down it might make contact and run normally - or not. Fifteen minutes with a pair of needle nose pliers and the contact was good again.

That stupid white connector looked good but I found the problem by accident. I plugged in the connector to the module and caught only one pin. I noticed there was no contact friction and that was the problem. The advice to change the coil every now and then is good. Not because the coil goes bad but because the connector can become loose. If you have patience it can be bent back into proper shape. But eventually it will relax again and fail.

A note on remote module. Do Not ground the heatsink directly to the chassis. Put the heat sink on insulating washers and ground it ONLY to the distributor as follows. The wires on the coil will need to be extended and must be 2 conductor stranded shielded wire #24 - #22. The shield must connect to the distributor and to your new heat sink. The signals on this cable are very low and the shield isolates the internal low voltage from all the other electrical noise in the engine bay. The shield also provides the only ground path between the remote module and the distributor.

By this time I was fed up with the old engine, old transmission (which locked up it's clutch when hot) and started to hunt for a modern engine & transmission to do a swap. Fixing the problems on the old engine would still give me a slow car with poor fuel economy. Having a car with a 200 mile range sucks. The hunt led to two solutions, either a 3.2L VW VR-6 with a auto-shift manual transmission or a GM LFX with a 6T70 would do the job. The VR6 is physically smaller and produces 270 or so HP and having a paddle shifted manual is lots of fun, my Alfa 147 in Malaysia had one and it was great. The LFX is larger as is the 6T70 too but much more available and less costly. The engine is lively and the transmission can be manually shifted.

That decided it, I'd go with the LFX. Digging into the details I found that you need a lot more than the engine & transmission. So I eventually found a totaled 2018 Impala at an IAA auction. It took three weeks to win it since the insurance company did not want to sell it at the price people were willing to pay. The third time it went up for sale the same thing started to happen and the seller finally dropped his reserve. I snapped it up with a bid of $1525. Then you add the auction fees. The final cost was $2250. Plus the $200 to become a bidder. But I literally had a complete running car. For some reason the auction listed it as not running. Strange since it simply needed a good battery charge to run. While IAA isn't inexpensive they do treat customers well and try to accurately describe the cars they sell. Not all IAA sites allow ondinary folks to place bids, but in Washington they do.

Next: You bought an Impala, Now What? |

|

Your story sounds familiar, but my Impala was a 2013. I considered using the automatic, but decided that the cradle mods were more than I wanted to tackle. I went with the Saab F40. Good luck on your project.

|

|

|

Dennis LaGrua

|

JUL 27, 06:49 AM

|

|

|

Having completed several 3800SC swaps and one 4.9L ; the LFX Fiero engine swap would be a harder swap to do but IMO one of the best. While other swaps have a history to them and you can find swap parts, its not so with the LFX. But being all aluminum, having a very light weight, using more modern technology and offering 300 HP in stock trim is very attractive. I wish my GT had this engine. Good luck on the swap. With your level of skill, I am sure that you will complete it, and hopefully provide some info on how it was done. ------------------

" THE BLACK PARALYZER" -87GT 3800SC Series III engine, custom ZZP /Frozen Boost Intercooler setup, 3.4" Pulley, Northstar TB, LS1 MAF, 3" Spintech/Hedman Exhaust, P-log Manifold, Autolite 104's, MSD wires, Custom CAI, 4T65eHD w. custom axles, Champion Radiator, S10 Brake Booster, HP Tuners VCM Suite.

"THE COLUSSUS"

87GT - ALL OUT 3.4L Turbocharged engine, Garrett Hybrid Turbo, MSD ign., modified TH125H

" ON THE LOOSE WITHOUT THE JUICE "

|

|

|

MikesFirstFiero

|

JUL 27, 10:13 AM

|

|

Thanks for the reply, I'd better finish it by November or my wife will kill me.

Being "light" seems is relative. When I move it around on the hoist it sure seems really heavy.

Sometimes I feel like a Pioneer which is defined as "A Person with Arrows in their Back". Without Pennocks this would be extremely difficult.

|

|

|

Blacktree

|

JUL 27, 10:58 AM

|

|

|

I think the LFX weighs about the same as the old 2.8 V6. The transmission will be heavier, though.

|

|

|

Raydar

|

JUL 27, 11:02 AM

|

|

I wish you luck with your project. Several of these in the works, now.

I'm curious as to how the 6T75 will fit. One of the other builders described a bunch of work that was going to be required, in order to make it fit, and went with an F40, instead. Some of the newer GM automatics (and even some of the older ones, but using updated electronic controls) are quite good.

|

|

|

MikesFirstFiero

|

JUL 27, 11:28 AM

|

|

|

I thought of the 6T75 since it is significantly stronger internally. But finding a LFX with 6T75 was a problem. From what I read it is the same external size as the 6T70

|

|

|

Dennis LaGrua

|

JUL 27, 11:59 AM

|

|

| quote | Originally posted by MikesFirstFiero:

I thought of the 6T75 since it is significantly stronger internally. But finding a LFX with 6T75 was a problem. From what I read it is the same external size as the 6T70 |

|

My school of thought is to use the transmission that was designed for the powertrain. In this case its the 6T45 designed for 300 ft lbs of torque. That is pretty strong. I see swaps where just about any engine including the SBC is bolted to the Getrag. You know that's not going to last. Being a former drag racer years back we always used modified autos but today's automatics are very strong. I know little about the LFX swap except that they have been done in Miatas and trucks but it appears that using the autos on a Fiero application may require cradle modification depending on what unit is used. . While there appear to be a number of LFX Fiero swaps in the works, I don't believe that any are on the road as yet.

Word to the wise though, GM had a recall on this engine due to timing chain and bearing failures. A 2019 GM Recall document can be found online

------------------

" THE BLACK PARALYZER" -87GT 3800SC Series III engine, custom ZZP /Frozen Boost Intercooler setup, 3.4" Pulley, Northstar TB, LS1 MAF, 3" Spintech/Hedman Exhaust, P-log Manifold, Autolite 104's, MSD wires, Custom CAI, 4T65eHD w. custom axles, Champion Radiator, S10 Brake Booster, HP Tuners VCM Suite.

"THE COLUSSUS"

87GT - ALL OUT 3.4L Turbocharged engine, Garrett Hybrid Turbo, MSD ign., modified TH125H

" ON THE LOOSE WITHOUT THE JUICE " [This message has been edited by Dennis LaGrua (edited 07-27-2021).]

|

|

|

Will

|

JUL 27, 12:08 PM

|

|

| quote | Originally posted by MikesFirstFiero:

I thought of the 6T75 since it is significantly stronger internally. But finding a LFX with 6T75 was a problem. From what I read it is the same external size as the 6T70 |

|

The Cadillac XTS-V even had a 6T80

It was AWD and would have to be converted for Fiero use... I think that's just a matter of unbolting the T-case and possibly swapping the diff carrier.

|

|

|

Will

|

JUL 27, 12:16 PM

|

|

| quote | Originally posted by Dennis LaGrua:

My school of thought is to use the transmission that was designed for the powertrain. In this case its the 6T45 designed for 300 ft lbs of torque. |

|

Not sure where you got that info, but GM used the 6T70 with LFX. 6T45 would be a downgrade.

|

|

|

|