|

| 2nd Gen Headlight Pin Replacement (Page 2/6) |

|

Fierology

|

JUL 07, 03:28 PM

|

|

| quote | Originally posted by lateFormula:

With all due respect Ogre, those pins act as a clutch. There is no mechanism by which those pins can "shear", unless they completely break down and turn to dust which is what they naturally do over time. Next time you need to rebuild one of these headlight motors, buy a set of Rodney's pins, and before you install them, grind 1mm off of their length. Reassemble the motor and you will find that the motor cannot lift the headlight assembly because the large gear cannot transmit it's rotational energy to the steel plate that is fastened to the output shaft. Those pins act as a clutch and will provide slippage if the motor is overloaded. The headlight drive assembly of large gear, delrin/nylon pins, and output shaft are controlled to have a specific spacing (preload) between the components by the shim washers that are used in the housing.

|

|

Does the Delrin impede the slippage? It seems you are saying that it allows the motors to function as originally intended. Is this true? Thanks.

|

|

|

theogre

|

JUL 08, 01:37 AM

|

|

| quote | Originally posted by Fierology:

If I understand what delrin is like, it seems to be a harder, tougher material than the original. ... I'm asking this question concerning proper material before I put the parts in lest the Ogre's theory is correct and it strips the gears. |

|

Tough? Delrin is use to Make gears etc. Most anything made in Nylon, can be made in Delrin.

http://plastics.dupont.com/...as/delrin/H76836.pdf

http://plastics.dupont.com/..._Prod_Prop_11_06.pdf

Strip? Yes but usually Not right away. Can take a few years to strip the gears if the system works.

Rodney etc is trying to make dowels/pins that last... I don't blame anyone.

And I have Delrin dowels

I've taken apart 1 motor last week because has stuck down... (7/1/13. Too hot/wet to mess w/ other side) The replacement Delrin dowels look new after years of use but the gear was waiting to break because the dowels won't absorb enough shock. Lucky I found this before gear broke because Gen2 uses all ~3/4 of the teeth. I was able to rotate the gear so stall points at another set of teeth. (Edit: Changing stall point then you run thru the damage area.) {Stalled point is the motor stalled at end of travel.}

| | CLICK FOR FULL SIZE |

Now I've got to search at junk yards looking for good gears...

New Dowels source? Don't know. Right now I'm still using my Delrin parts. It took years to slow, I have some time...

Just use new gears... Aftermarket/"Restoration" gears have a bad rep but is cheap if i can't find OE ones.

Just use Metal gears... Might solve gear failure but not save output shaft if the dowels are too hard. Hard dowels + metal gear then next weak part fails, likely output shaft.

and Metal gears Cost... $40-60 + shipping for 1 gear.

http://www.ecklerscorvette....r-kit-1988-1996.html

http://rodneydickman.com/ca...h=32&products_id=257

For the rest...

Just buy what the Internet says is good... No Thanks. Reexamined the "Internet Wheel" is often a good thing.

Several vendors sell, even use, Delrin and other hard plastics. (I think Eckler's change/altered their dowels/pins... For 1, now their hollow.)

In designing Gen2 system, GM gave the pins a graceful way to fail and easy to fix. Anyone whine about OE dowel spec should try fixing Gen1 that loves to nickle and dime you to death. Bumpers bad, Gears bad, 1 to all relays are dead, limit switch is toast, etc, etc, etc... Worse, Gen1 is very good at killing you battery.

Repairing the dowels every few years is a pain (I can do it and I only have one hand that works.) but better that then fixing gears or messing to pin the output shaft pieces back together. (Output shaft problems use PFF etc search...)

You blame Delrin? Any pin harder then OE part can cause this damage.

Is it possible that other things can contribute to this? Old age of Gen2 parts likely won't help but adding new Delrin pins then old part will fail faster then "normal."

(Edit for a short version)

(9/15 Edit to fix image)[This message has been edited by theogre (edited 09-23-2015).]

|

|

|

Fierology

|

JUL 11, 10:31 PM

|

|

Thanks, Ogre. I'll mull it over.

Michael

|

|

|

trotterlg

|

JUL 11, 11:48 PM

|

|

|

A shear pin should shear if sometnhing else goes wrong with the system. If it shears when nothing else is wrong then the shear pin is too weak. The pin should let go just before something else more expensive fails, if your pin has sheared and nothing else is wrong then the pin was not strong enough. Larry

|

|

|

Fierology

|

JUL 12, 05:41 PM

|

|

I believe it just deteriorated after almost 30 years of use, not necessarily from excess stress.

-Michael

|

|

|

theogre

|

SEP 23, 03:00 PM

|

|

update...

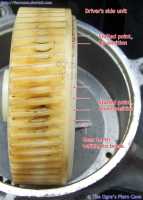

I made this "cut away" view today to show how the dowels get a beating each time the motor is on. (I took pictures to make this at same as gear above but lost track of them.)

| | CLICK FOR FULL SIZE |

Notice the dowels make a very small amount of contact on the output shaft. That point gets all the load from the gear side of them.

Over time, the OE dowels will deform way before they fail and turn to dust.

Grinding to dust is more accurate. The flat sides of gear opening and shape of output part acts as a mortar and pestle (wikiHow) and just grind the dowels to dust and stops working at all. You might find bigger pieces but most are "stuck" in more open areas and doesn't make the unit to operate or may make it work sometimes.

W/o the dowels, the gear just spins around the metal part.

|

|

|

Rodney

|

SEP 23, 06:27 PM

|

|

You might take note that some do sell these pins for less. The reason probably is they are probably cast injection molded plastic (hopefully Delrin). Years ago you could buy these at auto stores and they were turned Delrin. Now they are cast Delrin which has a lot shorter service life than the (turned from Delrin rod) Delrin torque pins. Mine are turned Delrin.

This idea was introduced (I believe) by Ford many, many years ago for electric window motors. The pins are there for a reason.

------------------

Rodney Dickman

Fiero Parts And Acc's Web Page:

All new web page!:www.rodneydickman.com

Rodney Dickman's Fiero accessories

7604 Treeview Drive

Caledonia, WI 53108

Phone/Fax (262) 835-9575[This message has been edited by Rodney (edited 09-23-2015).]

|

|

|

fierofool

|

SEP 23, 08:09 PM

|

|

i work mostly with generation 1 motors. They work similarly but still dis similarly. They also use bump stops and in both motors, the bump stop do absorb shock. In the case of Gen 2, the module turns off the motor when it locks up. Generation 1 uses breaker points.

I've experimented with various materials for bump stops. Maple and plastic dowels, threaded rod, and other materials. I've seen motors filled with RTV and J & B Weld and even threaded nuts, too. In the case of the maple dowels, they began to splinter. The plastic dowels, and threaded rod were too hard and I started to see the same result Ogre illustrates. Some of the aftermarket dowels were too soft and caused the Gen. 1 motors to continue to cycle.

I eventually stumbled upon a very low mileage set of motors that had a perfect set of original bump stops. I've since acquired two more sets, one set of which has bumpstops of the green material, but they've not been tested. I also have a set of 20,000 mile Generation 2 motors that were stored inside when the car was totaled. Someday I'll have them tested.

Generation 1 original bumpstops

_1.JPG)

I had my former partner's machine shop do a Rockwell Hardness test. I then searched various materials until I found one that closely matched. Finding that product was the difficult part, but I finally succeeded. Some of my motors have been out there for at least 7 years. Either they're still working as they should,  or they broke and the customer doesn't want to deal with me again, or they broke and the customer doesn't want to deal with me again,  but I like to think they're still working. but I like to think they're still working.

Edit to add:

The Generation 2 shaft shown in the center of Ogre's picture will simply continue to turn when the bumpstops crumble. At that point, no further damage can be done to the inside workings of the motor. The Generation 1 motor is a prime example of what can happen if bumpstops are used that are too hard. The metal drive plate in this Generation 1 gear holds the bumpstops captive underneath it. There are 4 fingers, one on either corner that keep the bump stops from coming out. They exert force against the bumpstops when the motor suddenly stops. When the bumpstops crumble, those steel fingers then start to slam against the hard plastic ribs of the gears. Either the gear teeth strip or the metal fingers break off. Luckily, it's usually the softer plastic gear teeth, but I've seen a broken metal plate.

_3.JPG) [This message has been edited by fierofool (edited 09-23-2015).]

|

|

|

Rodney

|

SEP 24, 10:32 AM

|

|

| quote | Originally posted by fierofool:

Generation 1 original bumpstops

_1.JPG)

|

|

I have one set of these black rubber bump stops. I believe I got them from a headlight motor that has the plastic intermediate gear. I think these are certainly very rare. Most had the green bump stops and the metal intermediate gear. I still have a few of these NOS green bump stops. When I bought all the left over 84-86 headlight motor obsolete parts from the original manufacturer that made the 84-86 headlight motors they sent me only green bump stops.

Years ago I had many more OEM plastic gears than I had green bump stops. So I thought for a long time on what I could use to replace the green bump stops. One day I thought of using rubber O ring material. That seems to work fine. The FS should thank me as they copied my O ring idea and now also sell these bump stops made out of rubber O ring material. ------------------

Rodney Dickman

Fiero Parts And Acc's Web Page:

All new web page!:www.rodneydickman.com

Rodney Dickman's Fiero accessories

7604 Treeview Drive

Caledonia, WI 53108

Phone/Fax (262) 835-9575

|

|

|

fierofool

|

SEP 24, 11:36 AM

|

|

|

The durometer of TFS bump stops seems to be a little softer than yours. I've never had problems with yours compressing the way theirs does. I had given some thought to having a mold made and then casting these in polyurethane but my former partner was killed in a plane crash and the machine shop closed up. Never got around to it after that. [This message has been edited by fierofool (edited 09-24-2015).]

|

|

|

|