|

| The White Bug (Page 9/46) |

|

ericjon262

|

APR 29, 06:39 PM

|

|

| quote | Originally posted by Will:

Crankshaft in a lathe... |

|

Probably the easiest way to test it if he has a spare. The VR sensor should be magnetic, maybe it has a weak pull and is, for lack of a better term, floating and not providing a clean signal to the converter.

I assume you're able to log the signal while the engine is running, does one signal appear longer than the others? can MS display in that kind of resolution?

Edit:

The LX9 3500 uses a hall effect sensor in the stock 3.1/3.4/3100/3400 position, it requires +12V, but would also allow you to eliminate your converter box.

here's the pinout for the 3500 sensor.

Edit again: I haven't confirmed the 3500 sensor works in the early block, but it's probably worth a try.

------------------

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

cognita semper

http://www.fiero.nl/forum/Forum2/HTML/119122.html[This message has been edited by ericjon262 (edited 04-29-2020).]

|

|

|

pmbrunelle

|

APR 29, 10:12 PM

|

|

A (normal) lathe won't turn fast enough to spin a crankshaft to its redline.

I think I would be able to do something with a computer soundcard and a step-up audio transformer to simulate a VR sensor signal. Not as good as a true end-to-end test, but it would be inexpensive!

********************************************************************************

I was too anxious to troubleshoot things, so I jumped ahead and started working on solutions:

I switched to the optoisolated input on the MS, and I removed the low-pass "Dave" capacitor to remove any possible time-smearing that could merge two notches into one.

After doing this, I still lost sync at 3k RPM.

Then, I removed the crank sensor bolt, and I pulled away the sensor from the engine block by a smidgen. This also increased the sensor to notched wheel gap by the same smidgen.

Bam, I was able to rev to 4k RPM without a hiccup. Since the engine was cold, I didn't want to rev it any higher, and I didn't have the time before supper to let the car warm up.

With magnetic sensors like this, you want a small gap to maximize the signal level. However, when the gap is too small, in addition to seeing the teeth, you also see the imperfections much more. So the best signal-to-noise ratio will exist at some certain distance; not the closest gap possible.

I suspect that these imperfections are confusing the MAX9924, and that the ideal gap with the MAX9924 is greater than with the DIS brick.

Closed black-boxes such as the MAX9924 are the manager's dream... you can just buy a pre-built solution, and nobody needs to spend time developing an in-house solution. It's all good, until you have problems... you end up wasting time trying to reverse-engineer the black box and guessing at what it's going to do. An in-house solution on the other hand, intimately understood by people in-house, is far easier to understand and debug. In this case, I fell victim to the manager/outsourcing syndrome.

In this case, I will probably test different shims to space the sensor away from the machined mounting pad on the engine block... I'm hopeful that I can find a working solution this way.

********************************************************************************

My understanding is that the MS tooth interrupt is edge-triggered, and only by rising or falling edges (the user chooses which edge is the most accurate reference edge). So ONLY the reference edges are logged.

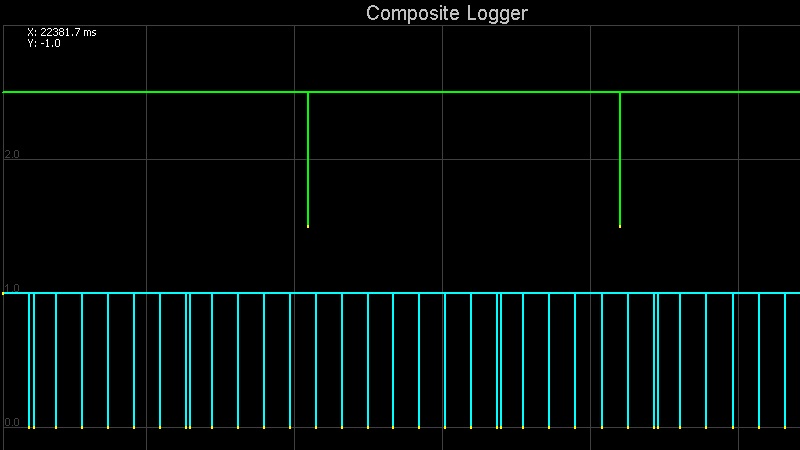

Here is an example showing a missing double-notch:

The dizzy (cam) sensor is represented by the green trace; we only see every other edge in the log. In reality, it is a square wave with approximately a 50-50 duty cycle.

********************************************************************************

I studied the possibility of using a 3500 crank sensor.

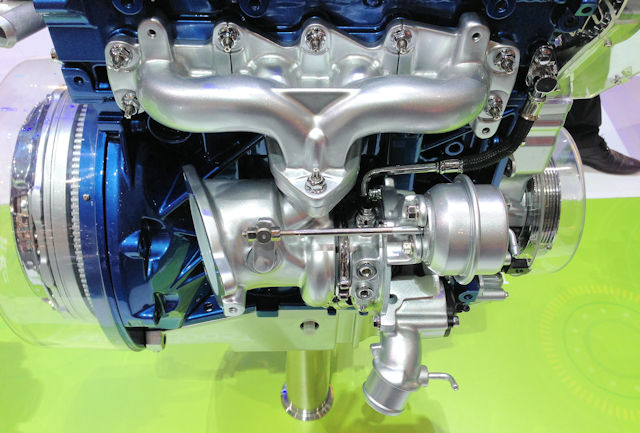

Here are pics from my evaluation:

https://www.fieromontreal.c...86.msg33228#msg33228

The early and late sensors interface with the engine block in the same manner.

However, the reluctor wheels are of a very different design:

Early: smaller major diameter, flux through the concentrator depends on presence/absence of a notch.

Late: larger major diameter. magnetic flux is directed forwards or rearwards, and the sensor detects this.

So, using an early crankshaft, I have to use an early sensor. I did not study the possibility of using a non-GM sensor with the GM block/crank.

I liked the idea of a 3-wire interface to the ECU, with a robust digital link. Since my sensor didn't do this, I did the converter box instead.[This message has been edited by pmbrunelle (edited 04-29-2020).]

|

|

|

ericjon262

|

APR 29, 10:39 PM

|

|

Glad to see you appear to have it working again, or at least a path forward.

thats an interesting note on the sensor comparisons.

there is a possible 3rd option, the 3900 uses a 58x wheel, and is machined into the crank much like the 2.8/3.1/3.4 reluctor. it may be a drop in for the early sensor, and have the correct standoff and orientation. I would look into it just because it would allow me to remove an additional interface that can fail, but I understand if you want to run what you have as well. ------------------

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

cognita semper

http://www.fiero.nl/forum/Forum2/HTML/119122.html

|

|

|

pmbrunelle

|

MAY 02, 11:41 PM

|

|

I shimmed the crank sensor with a 0.035" washer; there is still the occasional sync loss at high RPM/acceleration, but it's much better. I'll try another shim later on.

I also decided to check the timing with a strobe lamp; it was 17° retarded compared to the MS3's commanded timing. I applied a 17° global offset in the MS3 to make the commanded and measured timing values match each other. This made the car run a bunch better, including reducing its overheating tendency.

With a 4 psi wastegate actuator spring setting, the wastegate doesn't seem to have the capacity to divert enough exhaust gas around the turbine. The boost increases linearly to 8-9 psi near redline. To solve this issue, I'll probably just install the 10 psi spring kit in the actuator. With a higher boost pressure setting, less wastegate flow will be required.

It is typical for issues to arise on new engine setups... after 100 km so far, some of the exhaust manifold bolts loosened. Some fell out while driving. I was using regular ARP bolts with the included flat washers. I don't know if the Volkswagen gaskets compressed; perhaps I should have retightened the bolts daily during the initial settling period. I'm not yet sure how I want to address this issue.

Perhaps serrated-head bolts would help? Claude thinks that a stud+nut arrangement might be better.

|

|

|

Will

|

MAY 03, 12:02 AM

|

|

I haven't played with the VW gaskets.

I reommend these: https://www.globalindustria...NT26vXYvYqjf7XiY_93V GUA5epBEaAjiNEALw_wcB

They'll help, but won't fix the problem.

Get some ARP Stainless bolts and regularly retorque them. You might also want to try longer bolts and spacers in order to improve the stiffness ratio of the joint.

Also might try spot-facing the surface of the flange that the bolt head seats against.

|

|

|

La fiera

|

MAY 03, 08:40 AM

|

|

Glad to hear the car is running much better now Patrick! As far as the bolts loosening I believe

is becasue the metal's different expansion rates, the head and the manifold.

And now is more pronounced becasue of the flex pipes in between.

I've never had that problem and I always use stronger bolts and the stock gaskets but I do use red Loctite.

I put some loctite on the threads and let it dry, then I screw them in and over torque them a bit and that's it.

I hope you find a solution for it!

|

|

|

claude dalpe

|

MAY 03, 09:44 AM

|

|

| quote | Originally posted by pmbrunelle:

I shimmed the crank sensor with a 0.035" washer; there is still the occasional sync loss at high RPM/acceleration, but it's much better. I'll try another shim later on.

Perhaps serrated-head bolts would help? Claude thinks that a stud+nut arrangement might be better. |

|

I don't think it's a good idea to further distance the crank sensor from another 35 ".

Because the crank sensor is a magnet and it has a distance limit to be respected for a good reading, 35 "(Your original distance) + 35" + 35 "= it's too much for the magnet.

Most turbo engines or supercharger manifolds are assembled with studs and nuts, it's the same idea when you assemble engine heads with ARP nut studs

|

|

|

Will

|

MAY 03, 10:00 AM

|

|

| quote | Originally posted by La fiera:

And now is more pronounced becasue of the flex pipes in between.

|

|

The flex couplings are supposed to make it less pronounced.

| quote | Originally posted by claude dalpe:

Most turbo engines or supercharger manifolds are assembled with studs and nuts, it's the same idea when you assemble engine heads with ARP nut studs

|

|

OEMs use studs for ease of assembly during production.

Studs do not have any magic in them.

Using spacers to make the exhaust bolts longer improves the stiffness ratio of the bolted joint... that may help significantly.

I've been using stainless bolts and torquing them to 15-18 ftlbs with anti-seize. I have pretty good luck, but a couple of problem children that don't like to play nice.[This message has been edited by Will (edited 05-03-2020).]

|

|

|

fieroguru

|

MAY 03, 11:01 AM

|

|

| quote | Originally posted by pmbrunelle:

after 100 km so far, some of the exhaust manifold bolts loosened. Some fell out while driving. I was using regular ARP bolts with the included flat washers. I don't know if the Volkswagen gaskets compressed; perhaps I should have retightened the bolts daily during the initial settling period. I'm not yet sure how I want to address this issue.

|

|

There are exhaust bolts available either drilled for safety wire or tear drop locks. Both will prevent the bolts from walking out. However, if the root of the issue is the gasket relaxing at temp (copper is known for this), then you will need to retorque a couple of times... which likely will fix the issue w/o needing to use wire or other positive locks.

|

|

|

claude dalpe

|

MAY 03, 11:31 AM

|

|

| quote | Originally posted by pmbrunelle:

I shimmed the crank sensor with a 0.035" washer; there is still the occasional sync loss at high RPM/acceleration, but it's much better. I'll try another shim later on.

I also decided to check the timing with a strobe lamp; it was 17° retarded compared to the MS3's commanded timing. I applied a 17° global offset in the MS3 to make the commanded and measured timing values match each other. This made the car run a bunch better, including reducing its overheating tendency.

With a 4 psi wastegate actuator spring setting, the wastegate doesn't seem to have the capacity to divert enough exhaust gas around the turbine. The boost increases linearly to 8-9 psi near redline. To solve this issue, I'll probably just install the 10 psi spring kit in the actuator. With a higher boost pressure setting, less wastegate flow will be required.

It is typical for issues to arise on new engine setups... after 100 km so far, some of the exhaust manifold bolts loosened. Some fell out while driving. I was using regular ARP bolts with the included flat washers. I don't know if the Volkswagen gaskets compressed; perhaps I should have retightened the bolts daily during the initial settling period. I'm not yet sure how I want to address this issue.

Perhaps serrated-head bolts would help? Claude thinks that a stud+nut arrangement might be better. |

|

What I see on this image of the manifold (lower in the link) is that it is on the side where there are no flex pipes between the turbo and this end of the manifold and after this part of the manifold there is a flex, + it is the bolt from the top which is missing so it is the weight of the turbo which moves this part of the manifold which does not have the rest of the 2 other cylinders on the manifold to prevent it from pivoting.

https://www.fieromontreal.c...=3886.0;attach=13127

|

|

|

|