|

| The White Bug (Page 7/46) |

|

pmbrunelle

|

FEB 24, 08:55 PM

|

|

The engine wiring harness is complete, except for 5 wires that lead to future gauges up front. I have three Speedhut gauges that I'll be mounting in the rally gauge pod. They aren't strictly necessary for the engine's operation, so I may start driving the car before finishing up the gauges.

The wiring took about 4 months to do; way longer than I had expected.

Here is the MegaSquirt 3 computer:

Unlike its predecessor (MS2), this computer has two DB-37 connectors. My particular setup uses 44 of the 74 total pins.

Before covering up the harness with split loom and tape, I tested as many circuits as I could without actually running the engine. Any electrical problems would be easier to solve with the harness still just bundled together with tie-wraps. No problems were found.

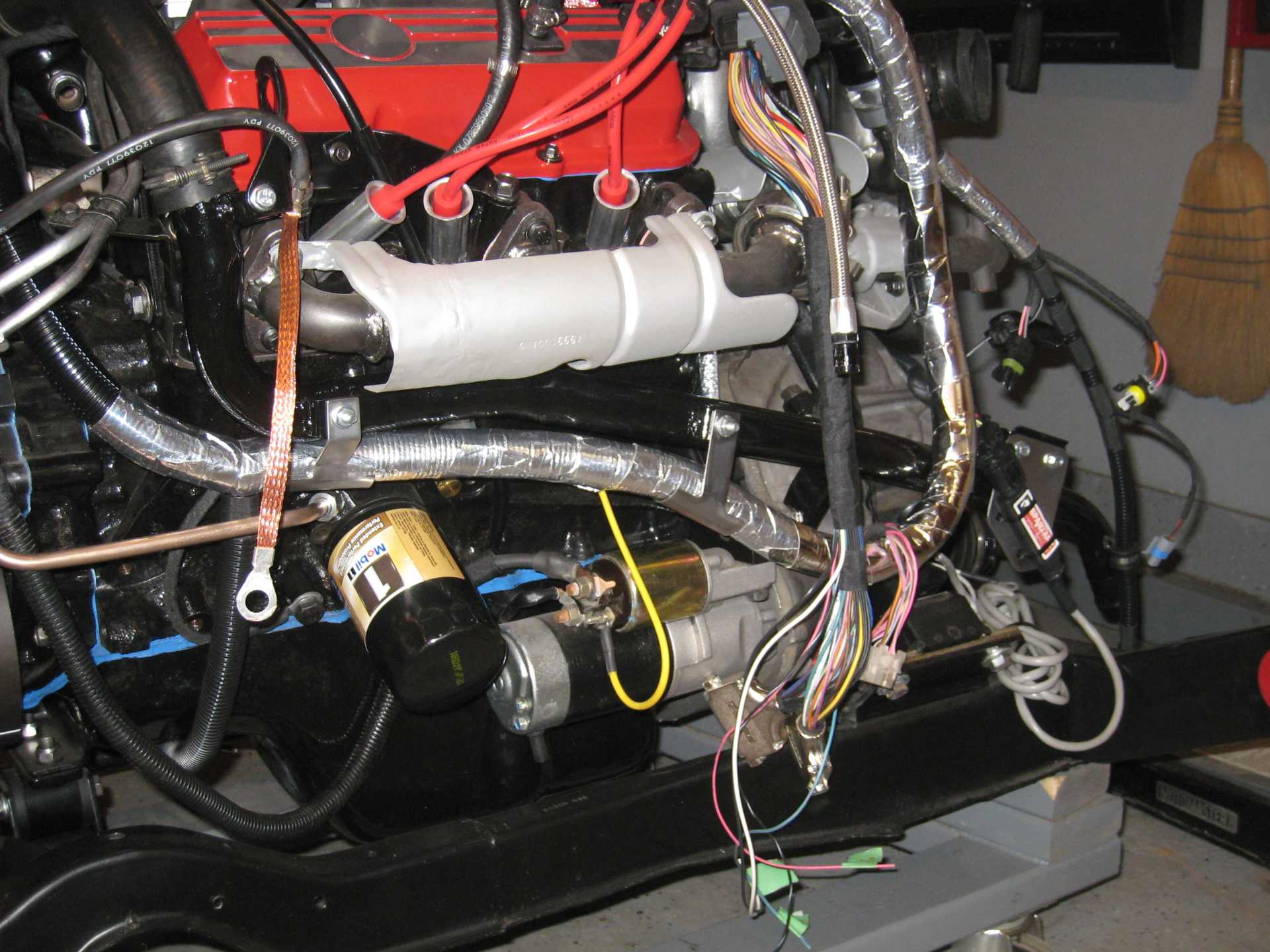

I made some brackets to support the harness in various locations. This is how the harness is supported by the engine coolant tube:

I thought it was important to keep the weight of the harness off the turbo oil supply line which runs underneath:

After painting the "half-pipe" brackets with POR-15 black, I taped the harness to the brackets.

|

|

|

ericjon262

|

MAR 28, 11:10 PM

|

|

I'm surprised I hadn't seen this yet. nice work.

in reference to your water injection, are you worried at all about heat soak reducing the effectiveness?

------------------

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

cognita semper

http://www.fiero.nl/forum/Forum2/HTML/119122.html

|

|

|

pmbrunelle

|

MAR 29, 01:27 PM

|

|

Most of the water won't get hot, since it's away from the engine heat in the tank. However, there is the "dead-end" of stagnant water in the IAC passage that could become heat-soaked if I just cruise around without ever entering boost.

A worst-case scenario would be that the engine heat causes the water in the IAC passage to completely evaporate, leaving the IAC passage empty. Then, when I hit boost, the engine will be without water for a half-second or so; the IAC passage must first be filled with water before the nozzles can spray.

The check valve springs in the nozzles *should* keep the water in the IAC passage pressurized to at least 35 psia; I think the pressure will raise the boiling point of the water enough to prevent boiling. I'm sure you know about this from your experience on steam-powered boats.

As a last resort, I could implement a software patch to trickle some small amount of water into the engine every X minutes (even out of boost), so the hot water in the IAC passage gets slowly replaced with fresh cool water. This is possible because the MegaSquirt source code is made available so end-users can customize their software; I can't imagine having a modded car with a closed-source ECU.

********************************************************************************

So what's the difference between injecting hot vs. cold liquid water into the engine?

Well liquid water droplets are sprayed from the nozzles, and liquid water is sucked into the cylinder during the intake stroke.

During the compression stroke (or maybe start of power stroke?), the temperature will increase to a point that the liquid water will boil into steam. As the liquid water boils into steam, the water will absorb heat energy from its surroundings equal to its latent heat of vaporisation. The heat of vaporisation is much more than the difference between hot vs. cold liquid water, so I don't think there would be much difference in terms of cooling the contents of the cylinder.

Of course, this analysis was supposing that the anti-detonant effect of water is due to cooling. However, we know that anti-detonant effects are possible due to other (chemical?) reasons... as we see with the addition of tetraethyl lead to fuel.

Maybe water has an anti-detonant effect due to some mechanism other than cooling; I don't know.

An interesting test would be to run the engine with chilled dry air; cold enough so that the in-cylinder temperature is the same as with water injection. If the results are the same, then we conclude that water injection works by the cooling effect. If the results are different, despite the same temperatures, then we conclude that the water molecules have some other anti-detonant effect.[This message has been edited by pmbrunelle (edited 03-29-2020).]

|

|

|

ericjon262

|

MAR 29, 02:27 PM

|

|

| quote | Originally posted by pmbrunelle:

Most of the water won't get hot, since it's away from the engine heat in the tank. However, there is the "dead-end" of stagnant water in the IAC passage that could become heat-soaked if I just cruise around without ever entering boost.

A worst-case scenario would be that the engine heat causes the water in the IAC passage to completely evaporate, leaving the IAC passage empty. Then, when I hit boost, the engine will be without water for a half-second or so; the IAC passage must first be filled with water before the nozzles can spray.

The check valve springs in the nozzles *should* keep the water in the IAC passage pressurized to at least 35 psia; I think the pressure will raise the boiling point of the water enough to prevent boiling. I'm sure you know about this from your experience on steam-powered boats.

As a last resort, I could implement a software patch to trickle some small amount of water into the engine every X minutes (even out of boost), so the hot water in the IAC passage gets slowly replaced with fresh cool water. This is possible because the MegaSquirt source code is made available so end-users can customize their software; I can't imagine having a modded car with a closed-source ECU.

********************************************************************************

So what's the difference between injecting hot vs. cold liquid water into the engine?

Well liquid water droplets are sprayed from the nozzles, and liquid water is sucked into the cylinder during the intake stroke.

During the compression stroke (or maybe start of power stroke?), the temperature will increase to a point that the liquid water will boil into steam. As the liquid water boils into steam, the water will absorb heat energy from its surroundings equal to its latent heat of vaporisation. The heat of vaporisation is much more than the difference between hot vs. cold liquid water, so I don't think there would be much difference in terms of cooling the contents of the cylinder.

Of course, this analysis was supposing that the anti-detonant effect of water is due to cooling. However, we know that anti-detonant effects are possible due to other (chemical?) reasons... as we see with the addition of tetraethyl lead to fuel.

Maybe water has an anti-detonant effect due to some mechanism other than cooling; I don't know.

An interesting test would be to run the engine with chilled dry air; cold enough so that the in-cylinder temperature is the same as with water injection. If the results are the same, then we conclude that water injection works by the cooling effect. If the results are different, despite the same temperatures, then we conclude that the water molecules have some other anti-detonant effect.

|

|

boiling wasn't the big concern, but you are right about latent heat, it is a very significant amount of energy, without any change in temperature. I know it's been in use since the 1930's at least, in fighter planes (I almost said jets... lol!) it would be an interesting test to see, but probably a fairly difficult one to accomplish. I'm considering water/meth for my car until I can find or build a suitable a2w intercooler for my configuration.

My only other concern I would have, would be valve failure, if the check valve in one of the nozzles fails, there will be almost no way to detect it except for changes in performance. It may be worthwhile to plumb a pressure transducer to the IAC passage so that you have that indication available, if you have another available analog input on the MS3x

The MS stuff is awesome, unfortunately for me, I know almost nothing about computer code, so I can't make as much use of it as others can. ------------------

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

cognita semper

http://www.fiero.nl/forum/Forum2/HTML/119122.html

|

|

|

longjonsilver

|

MAR 29, 02:32 PM

|

|

Absolutely amazing build. Glad to have met you about this time last year. i could tell by the way you talked that you must be some kind of automotive engineer. This stuff is way over my head. You're going to enjoy your car.

jon------------------

Astronomy says we will find a coded signal from outer space. Then we'll KNOW that life exists there, for coded signals aren't by chance.

Biology says there are coded genetic signals in every cell, but we KNOW that no intelligence created life.

I'm the original owner of a white ' 84 2M4 purchased Dec 10, 1983 from Pontiac. Always garaged, no rust, 4-wheel drifts are fun!

|

|

|

pmbrunelle

|

MAR 30, 01:33 AM

|

|

| quote | Originally posted by ericjon262:

My only other concern I would have, would be valve failure, if the check valve in one of the nozzles fails, there will be almost no way to detect it except for changes in performance. It may be worthwhile to plumb a pressure transducer to the IAC passage so that you have that indication available, if you have another available analog input on the MS3x

|

|

To detect if the water in the IAC passage boiled off due to check valve failure, I could do a test at idle:

1. Open the water solenoid.

2. See how long it takes for the engine to cough and stumble.

3. If the engine stumbles right after opening the solenoid valve, then the IAC passage is full of water.

4. If there's a time delay between opening the solenoid and the stumble, that means the IAC passage was empty.

But yes, in general, I'm putting a lot of faith in an assembly that I can't easily inspect. The water manifold / nozzles are perhaps the most risky part of this Fiero project.

Nevertheless, I enjoy the risk and uncertainty... that's what makes the project interesting and challenging. I didn't want to follow a well-proven recipe.

I'll probably pull the intake in a year or two to check the nozzle spray patterns... could be earlier if I blow up the engine.

| quote | Originally posted by ericjon262:

The MS stuff is awesome, unfortunately for me, I know almost nothing about computer code, so I can't make as much use of it as others can.

|

|

I remember that once upon a time, you were welding with a flux core unit. Now you have graduated to TIG. You improved your skills/knowledge, in conjunction with your personal projects. Similarly, if you want to add basic programming to your skill set, your MS is there and ready for you...

The MS3 code probably has around 100 kloc (kilolines of code) for the entire project... obviously a beginner shouldn't attempt to rewrite an entire engine management software on his own. However, with beginner-level programming skills, you can make meaningful changes with 100 loc modifications, or even 10 loc.

********************************************************************************

| quote | Originally posted by longjonsilver:

Absolutely amazing build. Glad to have met you about this time last year. i could tell by the way you talked that you must be some kind of automotive engineer. This stuff is way over my head. You're going to enjoy your car.

jon

|

|

I'm glad I met you too... now when we correspond online, we know the face behind the keyboard.

As far as my automotive job goes... I still have it for the moment, but the economic situation is delicate. I may be forced to transition over to some other field...

********************************************************************************

The powertrain is in the engine bay, for real now:

I just need to fix up the brakes (they were rusty, leaking fluid, and the parking brake didn't work) before starting the engine for the first time and driving the car.

I may or may not install the decklid for the first start. I'm thinking that no decklid would enhance access to the engine bay if I need to deal with an engine bay fire, for instance.

|

|

|

ericjon262

|

MAR 30, 01:53 AM

|

|

I don't even remember my last time running flux core! LOL. I could definitely learn it, right now, I don't feel like I have the time to devote to it, I have lots of engineering projects I'm working on, and adding coding to the list would ensure that none of them get done!

I wasn't necessarily meaning the water boiling off, more just leaking into the intake, that being said, only a small amount could leak from the manifold, and it's probably not enough to matter anyways.

Man, that engine looks good in there. I really like the effort you put into making the whole assembly appear to be a stock unit, if someone didn't know a Fiero didn't come stock like that, they would assume it did. ------------------

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

cognita semper

http://www.fiero.nl/forum/Forum2/HTML/119122.html

|

|

|

pmbrunelle

|

APR 25, 11:24 PM

|

|

I fired up the engine today!

There was a bit of farting around with getting the engine to actually start; I believe this was due to the ECU not being tuned whatsoever for this engine.

Once the engine caught, I brought it up to 2000~2500 RPM. I used my laptop computer to adjust the AFR to about 14 so that the engine could smoothly complete the 1/2 hour break-in period for the flat-tappet camshaft.

No funny noises, no leaks, no smoke beyond the initial burning-off of paint and oil. I noticed that the exhaust components changed colour. The exhaust pipe coming out of the turbine outlet took on a straw colour.

After letting the engine cool off from the break-in, I went for a drive around the neighborhood:

https://www.youtube.com/watch?v=oxFyXg5_rVE

For a first drive, I find it went well:

The transmission and clutch work like they're supposed to.

Exhaust noise is a bit loud, but it's within the range of a tuner car. However, it's not a terribly pleasing sound.

The engine saw a bit of boost: I briefly hit 125 kPa absolute of manifold pressure (says my dad who was riding shotgun with the laptop)

Some issues were uncovered:

The engine seems to run a bit hot; this could be related to the low compression ratio. I might need to get a fancy 3-row radiator.

ECU loses synchronization with the crankshaft above ~3000 RPM. Not sure if it's a hardware or software problem.

Overall, I'm quite happy with how things went today.

Of course, before this can become a reliable driver, I still have a bunch more work to do

|

|

|

La fiera

|

APR 27, 08:20 PM

|

|

Good job Patrick!!! Very impressed awesome work buddy, Keep it up! That set up will be like a Rally turbo set up.

Rei Moloon[This message has been edited by La fiera (edited 04-27-2020).]

|

|

|

pmbrunelle

|

APR 27, 11:58 PM

|

|

I'll be sure to give updates as this engine grows up!

This evening, with a warmed-up engine, I focused on getting the car driveable in the idle to 3000 RPM range, for calm neighborhood driving. Learning to crawl before ripping through the gears.

Some observations:

This engine needs a lot more idle airflow than a stock 2.8; I'll need to adjust the idle screw on the throttle body to give the engine the air it needs.

While cruising around in the 10-25 mph range, in 1st, 2nd, or 3rd gear with the throttle barely pressed, the engine would start bucking, oscillating in unison with the windup/backlash of the drivetrain. Making sure the fuel tables were smooth and setting the AFR to 12.5 suppressed the bucking tendency to an acceptable level. For now, I'm OK with that. Later on when the rest of the tune is sorted out, I'll look into leaning out this low-speed cruise.[This message has been edited by pmbrunelle (edited 04-28-2020).]

|

|

|

|