|

| Duke sensor questions, IAT and O2 Sensor (Page 2/2) |

|

Patrick

|

MAY 30, 01:01 AM

|

|

I found a great couple of posts by Bloozberry in the following thread from 2010. Thankfully, the images have survived!

Location of ECM? ground on block of 88 V6

| quote | Originally posted by Bloozberry:

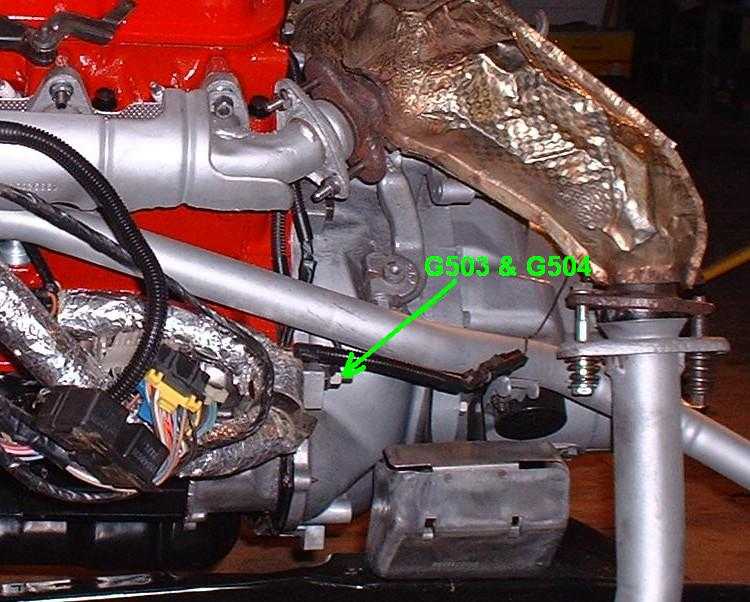

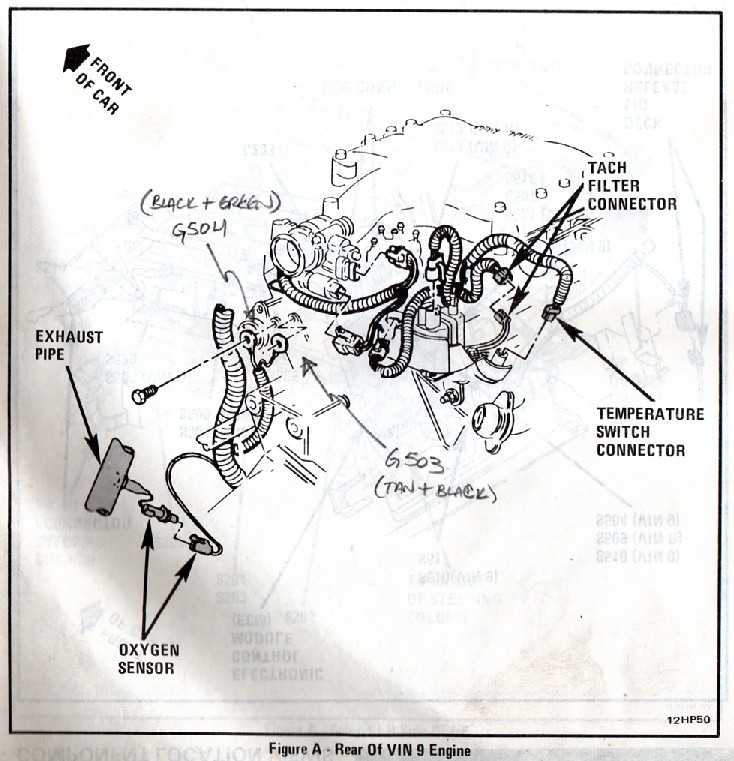

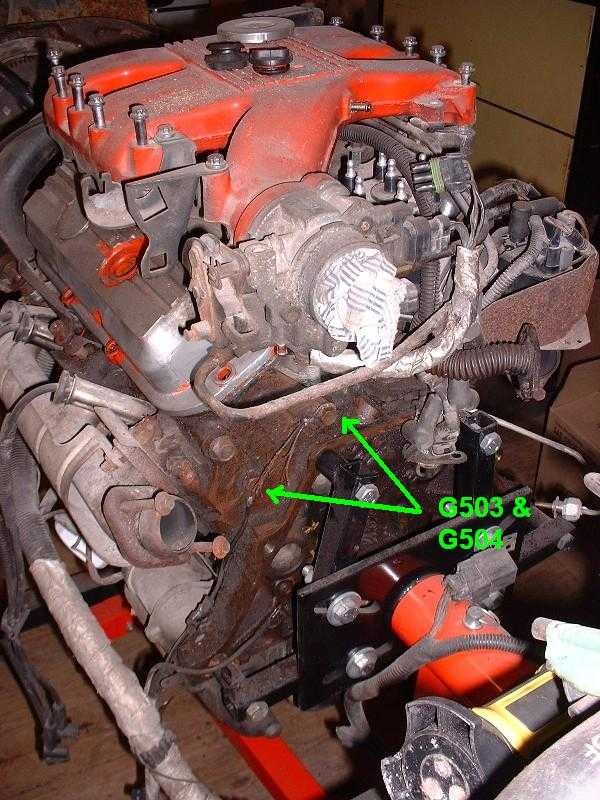

There are also two pairs of sensor grounds (G503 and G504) that come from the ECM and attach to two separate bellhousing studs in that area. One pair has a dark green wire and a black wire, and the other pair has a tan wire and a black wire. Both pairs terminate in a huge eyelets.

OK, here's what the service manual says, but like I said, I had to insert the titles and furthermore, not all G503 and G504's are located where the book shows since some are on the bellhousing as mentioned before.

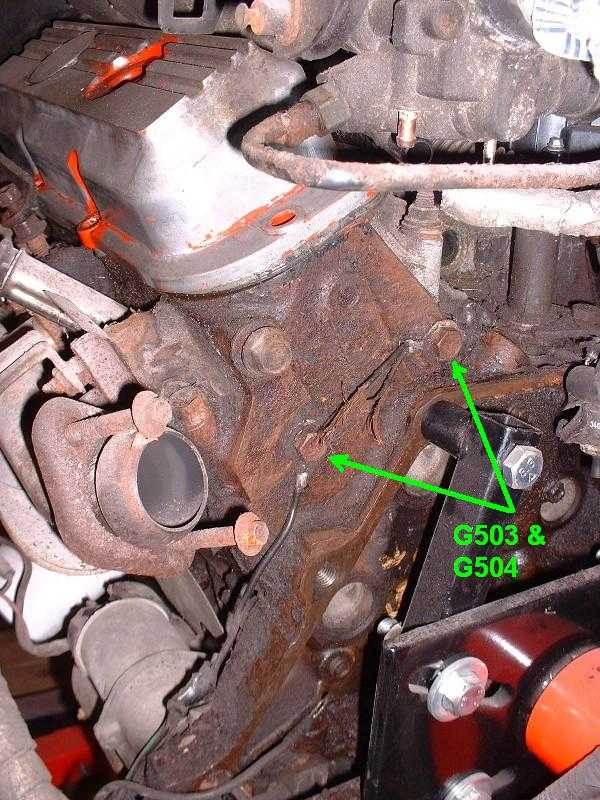

Here's what I found on my spare '88 engine... interestingly, they're both located where the manual says they should be... and they've been broken and repaired by the previous owner so that all four wires are soldered onto a single larger black ground wire and then attached to the lower of the two head locations.

Here's a close-up (... I warned you it was a cruddier engine!  ) )

|

|

|

|

|

Jason88Notchie

|

MAY 30, 07:13 AM

|

|

|

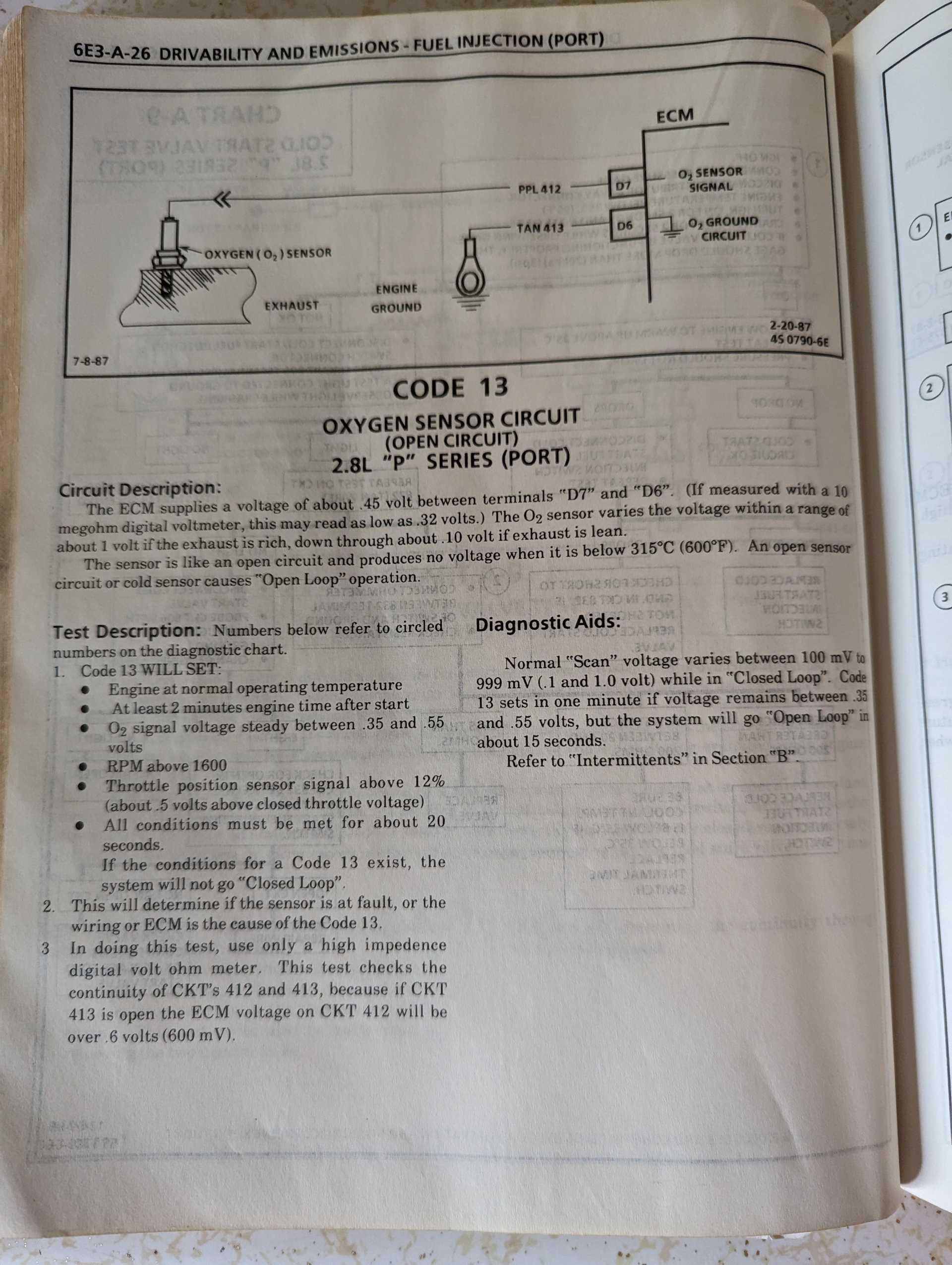

This thread may help explain a bit on how the O2 sensor circuit works. For 88 V6, but should be the same.

|

|

|

82-T/A [At Work]

|

MAY 30, 07:55 AM

|

|

Ok, so it seems like everyone is basically saying the same thing... that the 1-wire oxygen sensor grounds through the exhaust manifold... but of course, it "connects" to the tan wire ground going to the ECM (via the engine's metalurgy).

I'll just say that, other than the benefits of a heated and direct-ground O2 sensor... the biggest take-away from all of this for me has been it just proves how important it is for the engine to be properly grounded since half the components work directly off engine ground... the least of which are the spark plugs / ignition system. I mean... I don't need to be self deprecating here, but even with my education, and the ~20 years tooling in the parking lot and garage on cars... the obvious importance of engine block grounding to the chassis and the battery can be sometimes lost. It explains of course WHY the negative battery terminal connects directly to the block outright. But really emphasizes the need for the ECM's ground terminals to also be equally grounded.

| quote | Originally posted by theogre:

Your Idle issue Is Not the O2 sensor "getting cold" & does Not need a Heated O2.

"1 wire" O2 sensor Does Not "get cold" @ idle on nearly all vehicle using them. More so on the Duke that has it ~5 Inches from the Exhaust ports that will make the O2 reach operation temp of > 600°F In Seconds from when the engine starts. That even in the Winter as reported by ECM scanners. If a Duke needs > 1 to 2 minute absolute max w/ engine start from very cold to see O2 Ready then have wiring problems, bad O2 sensor or bad ECM.

"1 wire" O2 sensors actually have 2 wire, Yes Two wires, but 1 is a Fake "Ground" to the block. Heated "3 wire" setup is the same for O2 sensor part.

Others have 4 wires, 2 heat, 2 O2

|

|

Thanks Ogre. Just to be clear, the car doesn't have an idle issue. It was idling really well when we started tearing it down. The prior owner, or I should say the long-term owner who had it before me, he was a master mechanic in his own right. Many Fiero members would be proud. He saved all his old sensors, wrote right on the box when they were removed, whether they were still working, and he troubleshooted everything. The thing ran great... but ultimately we decided to tear the car apart because it had over 200k miles on the Iron Duke (appears to all be original), and everything was coated in a 2" thick film of oil. The whole point of me going through this was to teach my daughter auto mechanics too... and give her some pride in ownership. She's already telling me she wants to baby the car when she starts driving it (she gets her license next month).

I'd thought about the proximity of the O2 sensor to the exhaust ports... seems like this would make a bigger difference on the V6 since it's in the Y-pipe. But from everything I've read, a heated O2 can help maintain consistent temperatures and will reduce the time required for the car to be clattering at 2k rpms on start-up.

I'm also going with the newer ThermAC shield that's on the 87+ engines rather than the 84-86 one... gets the heat from the manifold rather than the downpipe.

[This message has been edited by 82-T/A [At Work] (edited 05-30-2024).]

|

|

|

theogre

|

MAY 30, 07:00 PM

|

|

87+ Dukes Do Not have a Thermac & OE E-manifolds don't have a stove. Because 700 series TBI doesn't need the Thermac.

When E-manifolds on 87+ dukes have the stove already been replace @ least 1 time, often more the 1 time, & just left the stove on the replacement part.

Dukes don't need or want a heated O2. You solve Nothing by installing one & eat more power too..

Very likely 2 wire O2 won't help.

All the ECM cares is O2 sensor crosses line in the middle being rich or lean in X time. If not then set DTC 44 45 or both over time.

If having a old slow O2 is because they wear out after 30,000 miles but often does "work" even @ 100,000 miles. Main problems w/ slow O2...

1. You can't tell looked @ stream data from the ECM including "faster/better" ECM w/ 87+ Dukes & early PCM w/ same ALDL controlling 4T60E etc.

2. if really slow then engine can be rich or lean longer then design for possibly "cook the cat" because gets more unburn fuel to control. If left like that can destroy the cat & cause a fire.

Many times the Idle "problem" is other wiring problems & vac leaks. Iffy alt, iffy battery & wires to them are known cause of "hunting idle" because ECM sees have Crap Power to it. GM & many other repeatedly push TSB for this problem on many model lines.

Maybe Fuel pressure too. Spec is 9-13PSI but often @ near or < 9psi is problem w/ F-pump etc. if > 13psi is often a return problem like pinch/crush/plugged return line/hose. Between E10 & ~ 40 years old the small hose in the tanks leak some to a lot even for Low Pressure system for a Duke.

|

|

|

82-T/A [At Work]

|

MAY 31, 02:09 PM

|

|

| quote | Originally posted by theogre:

87+ Dukes Do Not have a Thermac & OE E-manifolds don't have a stove. Because 700 series TBI doesn't need the Thermac. |

|

Ok, this explains a lot. It explains why 84-86 Fieros do not have an Intake Air Temperature Sensor, but the 87-88 Fieros do. Clearly, they don't need the ThermAC because they're using the IAT to better regulate the fuel, while the 84-86 is just trying to get to temperature as quickly as possible so it can be normal.

| quote | Originally posted by theogre:

When E-manifolds on 87+ dukes have the stove already been replace @ least 1 time, often more the 1 time, & just left the stove on the replacement part. |

|

Just to be clear, my engine is an 85 Duke... and I'm using the original 86 intake and TBI unit. My engine looks a little different because I'm switching to a serpentine belt system, so I have the serpentine harmonic balancer, and all the brackets from an 88 for waterpump and A/C (also converting to the new A/C system), but I'm retaining the original alternator brackets for the 85. This is so that I can maintain belt tensioning (via the alternator) since the 87-88 belt tensioner won't fit.

I don't really need the ThermAC, to be completely honest. I live in Florida. But I wanted to have the system fully operational so my daughter could see how it works, and what the net benefit of it is. I actually found an original OEM replacement ThermAC. Kinda dumb, I paid like $45 for it... but it's all original... so I thought it would be pretty cool to ensure I have an actual working ThermAC.

The exhaust manifold seems to be a newer replacement. I guess they figured having the stove pipe come from the manifold rather than the header pipe would heat it up more quickly. All the new ones have that. I did find an original "Iron Duke" refresh kit, which came with a new header "stove pipe," (they seem to be super rare), but I won't be using it since it's now on the manifold itself. I'm having a hard time finding the pipe that connects the stove pipe to the air cleaner though.

| quote | Originally posted by theogre:

Dukes don't need or want a heated O2. You solve Nothing by installing one & eat more power too..

Very likely 2 wire O2 won't help.

All the ECM cares is O2 sensor crosses line in the middle being rich or lean in X time. If not then set DTC 44 45 or both over time.

If having a old slow O2 is because they wear out after 30,000 miles but often does "work" even @ 100,000 miles. Main problems w/ slow O2...

1. You can't tell looked @ stream data from the ECM including "faster/better" ECM w/ 87+ Dukes & early PCM w/ same ALDL controlling 4T60E etc.

2. if really slow then engine can be rich or lean longer then design for possibly "cook the cat" because gets more unburn fuel to control. If left like that can destroy the cat & cause a fire.

Many times the Idle "problem" is other wiring problems & vac leaks. Iffy alt, iffy battery & wires to them are known cause of "hunting idle" because ECM sees have Crap Power to it. GM & many other repeatedly push TSB for this problem on many model lines.

Maybe Fuel pressure too. Spec is 9-13PSI but often @ near or < 9psi is problem w/ F-pump etc. if > 13psi is often a return problem like pinch/crush/plugged return line/hose. Between E10 & ~ 40 years old the small hose in the tanks leak some to a lot even for Low Pressure system for a Duke. |

|

Just to be clear, I don't have any issues with any of these things, but I already bought the kit... which among other things, has a separate ground for the O2 sensor, which I think can help since I'll tie it into the chassis ground. It seems to say it will reduce the amount of time necessary for the idle to remain high on start-up. So this is a huge positive for me... because there is nothing more cringy for me than seeing a high idle when a car is stone-cold.

|

|

|

|