|

| The White Bug (Page 19/46) |

|

ericjon262

|

JUL 12, 03:18 AM

|

|

| quote | Originally posted by pmbrunelle:

After a long time in the mail, today I received higher flow fuel injectors from La Fiera. Thank you. In the spirit of sharing parts, tonight I will be carefully packaging a Fiero part for ericjon262.

I got the Liqui Moly oil today. It is expensive compared to Canadian Tire stuff. Cheaper than new rocker arms though... those haven't yet arrived.

In the interest of changing only one thing at a time, I won't install the fuel injectors at the same time as my replacement rockers. When we try to make too many changes at once, we become lost, and no longer understand what we are doing.

Also, my dad wants to build a fuel injector test jig, so that will be a project for us to do together before installing the injectors. |

|

I'm looking forward to said part! I'll remember it and continue the trend! One of the things I'm looking forward to about moving back to my hometown next year, is that I'llbe able to tackle projects with my dad again, and maybe conquer another crazy roadtrip with him like the one we took to Alaska!

I hope the new rockers work out! that's a frustrating sequence of events for sure. It actually is something I'm a bit worried about with my car, but for different reasons, the bolt threads have a tendancy to pull out of the heads on the later engines like mine. if it happens I'll have to pull the engine back out and install timeserts. ------------------

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

cognita semper

https://joj2020.com/ <--- She isn't a sexual predator.

|

|

|

pmbrunelle

|

JUL 18, 12:51 AM

|

|

This time, with about 200 km (driving calmly) on the all-new rockers+balls and Liqui Moly oil, the #4 exhaust rocker ball died... Last time it was the #2 exhaust rocker, so at least the problem doesn't seem to be associated with any particular cylinder. This time, only the failed rocker had coked oil on it; the remaining rockers were clean.

Comp Cams suggested that my high-volume oil pump may be forcing the oil to shoot out of the pushrods too strong, overshooting the rockers and simply hitting the valve covers. In this case, drippers would be needed to redirect the oil to the rocker balls.

I guess the hypothesis is plausible, but at the same time, I thought that HV oil pumps were a common mod on the 2.8 Fiero. Why would my Fiero be the only one that needs drippers on its valve covers? To see how strong the oil sprays I might try to spin the oil pump at 1500 RPM; representative of 3000 RPM highway cruise.

Since the problem isn't tied to any particular cylinder, it may be a random infant mortality problem of the ball+rocker; maybe if I use one of my four spare rockers (I had a V8 kit), the ball will successfully break in. The chance of failure when breaking in 1 vs 12 new rockers is much reduced.

I'm still considering the possibility of roller rockers. Here are some posts where people have used Crane gold rockers underneath stock valve covers.

http://www.fiero.nl/forum/A...11-2-110359.html#p15

http://www.fiero.nl/forum/A...223-2-038804.html#p1

|

|

|

Honest Don

|

JUL 18, 12:49 PM

|

|

|

Have you tried turning the engine over by hand and checking for binding or anything unusual? Running the pump to verify is a good idea. Another possibility is that you got part of a batch that wasn’t hardened properly? It’s also interesting that both failures happened on an exhaust valve. [This message has been edited by Honest Don (edited 07-18-2020).]

|

|

|

pmbrunelle

|

JUL 18, 01:07 PM

|

|

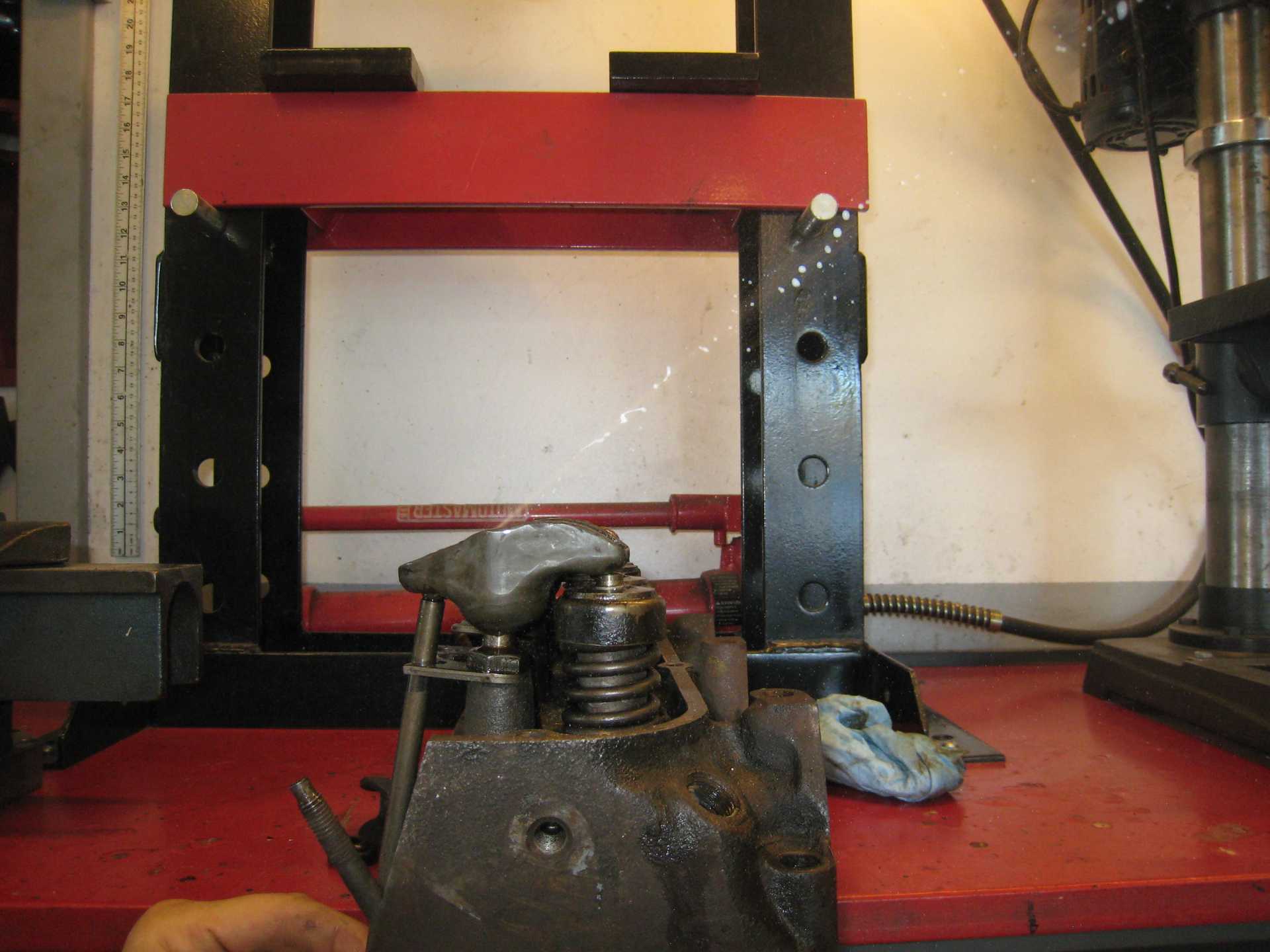

I grabbed a stock 2.8 Fiero head from my spare parts collection for examination/brainstorming.

I noticed an important difference between the Comp Cams Magnum rocker arm and the stock GM rocker arm.

On the Magnum rocker arm, the oil hole is approximately aligned with the pushrod axis. Oil would squirt straight up towards the valve cover.

On the GM rocker arm, the oil hole is oriented to squirt oil towards the rocker arm stud.

So it seems likely I'm not adequately oiling the rocker ball area...

Options:

1. Re-install a new Magnum rocker arm/ball replace the failed one. Might get lucky this time, but overall this setup seems marginal.

2. Weld a steel cap over the Magnum rockers to redirect oil towards the ball. Not sure about the metallurgy of this idea. The rocker arm is a hard metal; I can't cut it with a file.

3. Make aluminium oil drippers, then weld the drippers to the valve covers. Not sure about welding to porous aluminium that may be oil-contaminated. Probably have to refinish the valve covers after. Drippers bring vibration concerns, and packaging difficulty.

4. Install Crane gold roller rockers. May fit beneath the stock valve covers. Must re-verify the valvetrain geometry, and possibly buy pushrods of a different length.

5. Install stock replacement Melling rockers. Pretty certain (almost 100% sure) they will fit beneath stock valve covers. Must re-verify the valvetrain geometry, and possibly buy pushrods of a different length.

I prefer options 4 and 5 for the moment.[This message has been edited by pmbrunelle (edited 07-18-2020).]

|

|

|

pmbrunelle

|

JUL 18, 01:13 PM

|

|

| quote | Originally posted by Honest Don:

Have you tried turning the engine over by hand and checking for binding or anything unusual? Running the pump to verify is a good idea. Another possibility is that you got part of a batch that wasn’t hardened properly? It’s also interesting that both failures happened on an exhaust valve.

|

|

Yeah, I've been turning the engine with a rachet wrench, but noticed nothing.

The most obvious symptom with a fubared rocker arm ball is that I can wiggle the rocker arm with my fingers; it's that loose!

Exhaust rockers apparently run hotter than intake rockers. If you have a failed exhaust rocker ball, it is suggested to transfer a successfully broken-in intake rocker to the exhaust position, and then place the brand-new rocker+ball at an intake position; the less demanding position.

|

|

|

fieroguru

|

JUL 18, 01:50 PM

|

|

Just another data point where aftermarket R&D doesn't match GMs...

You can probably jam nut some metal straps to the mounting studs and have them overhang to deflect the oil squirting.

|

|

|

Honest Don

|

JUL 18, 02:34 PM

|

|

|

It’s a chore, but verification of exactly what the oil flow is doing would be worth the mess. [This message has been edited by Honest Don (edited 07-18-2020).]

|

|

|

claude dalpe

|

JUL 18, 02:59 PM

|

|

Comp Cams suggested that my high-volume oil pump may be forcing the oil to shoot out of the pushrods too strong, overshooting the rockers and simply hitting the valve covers. In this case, drippers would be needed to redirect the oil to the rocker balls.

I think the same as comp cams.

Their rocker arms have the lubrication hole in a straight line with the push rod while the original ones have the lateral hole and not centered with the push rod and the jet is directed towards the rocker ball which prevents an oil jet it only flows towards the balls.

These are 2 different things between these 2 rockers.

In a normal v6 engine when you remove the valve cover and look at the lubrication of the rockers, you only see a flow of oil going towards the rocker ball.

|

|

|

Will

|

JUL 18, 04:32 PM

|

|

| quote | Originally posted by claude dalpe:

In a normal v6 engine when you remove the valve cover and look at the lubrication of the rockers, you only see a flow of oil going towards the rocker ball. |

|

My thoughts as well. I've pre-oiled push-rod engines, to include V6/60's, on several occasions, all with stock rocker components. I've never seen oil "squirt" out the top of a pushrod, but I have seen it dribble in a steady flow out the lubrication hole in the rocker arm and pool in the rocker arm around the rocker ball, immersing that interface in oil.

Pre-oiling accomplished with a 1/2" trigger variable drill motor that I started slowly until the pump had oil, then just held at max RPM until I had oil out the top of every pushrod.

I've also installed high volume oil pumps with stock pressure springs in two different high mileage V6/60's and not had any problems.

Sure looks like it's that lubrication hole, though. It's worth noting that GM's oil hole location makes it IMPOSSIBLE for the oil to squirt out the end of the pushrod and miss the rocker ball. How did Comp screw up something that simple?[This message has been edited by Will (edited 07-18-2020).]

|

|

|

pmbrunelle

|

JUL 18, 04:33 PM

|

|

| quote | Originally posted by fieroguru:

Just another data point where aftermarket R&D doesn't match GMs... |

|

Maybe the rockers were developed for SBCs with drippers, and then assumed to work on the 60° V6

Still, I have only read positive reviews of the Magnum rockers on PFF, so it is strange that my experience differs from the norm.

| quote | Originally posted by Honest Don:

It’s a chore, but verification of exactly what the oil flow is doing would be worth the mess.

|

|

I ran the idea of running the engine without valve covers through my dad; he thought it would be a good way to set my car on fire when the oil hits the 350 °C exhaust manifolds

I decided to use a can of WD-40 (with the red straw) to spray WD-40 up a pushrod. There is quite a difference between the Comp Cams rocker arm and the GM rocker arm:

If I remain with ball pivot rockers, I must decide whether to keep using grooved balls, or switch to smooth balls (like stock Fiero).

Earlier in this thread, ericjon262 suggested grooved balls might be a good thing to allow oil to flow into the contact region.

On the other hand, grooved balls may allow the oil to drain away from the rocker arm too quickly, preventing the formation of an oil puddle (does this happen?) above the ball.

What's better? Grooved or smooth?

Edit to add: I could easily test the drain-away time between a grooved and a smooth ball with my cylinder head on the bench. However, the rockers would not be moving.[This message has been edited by pmbrunelle (edited 07-18-2020).]

|

|

|

|