|

| The White Bug (Page 12/46) |

|

claude dalpe

|

MAY 06, 03:26 PM

|

|

Thin layer of wheel bearing grease (apparently an old trick; burns away and leaves carbon which can seal small gaps)

I know this old trick but for your manifold I don't think it works because : it work only on a very flat surface with somes small pit hole on the surface .

For your turbo flange you have install studs and nuts with good result even if it moves !

Using spacers to make the exhaust bolts longer improves the stiffness ratio of the bolted joint... that may help significantly.

I agree with Will for the spacers and longer bolts. My reason is that the spacers act like a spring when the metal becomes hot and expanded and when it cools.

But you have to re torque them often.

Doesn't Look Good I prefer the studs and nuts for the look.

Ask ericjon262 maybe he know a parts number for the stainless gasket? for me it's the best

|

|

|

pmbrunelle

|

MAY 08, 12:04 AM

|

|

|

|

Will

|

MAY 08, 10:44 AM

|

|

| quote | Originally posted by pmbrunelle:

I know that people here often dread the exhaust manifold gasket job and the drilling-out of broken rusty bolts that comes with it.

|

|

Well... the rear one isn't typically the dreaded one...

|

|

|

pmbrunelle

|

MAY 09, 11:09 PM

|

|

I went out driving tonight and the manifolds are sealing to the heads (for now).

And now, the next problem: boost creep!

Prior to leaving the garage, I forgot to install the wastegate actuator's rod end onto the wastegate lever...

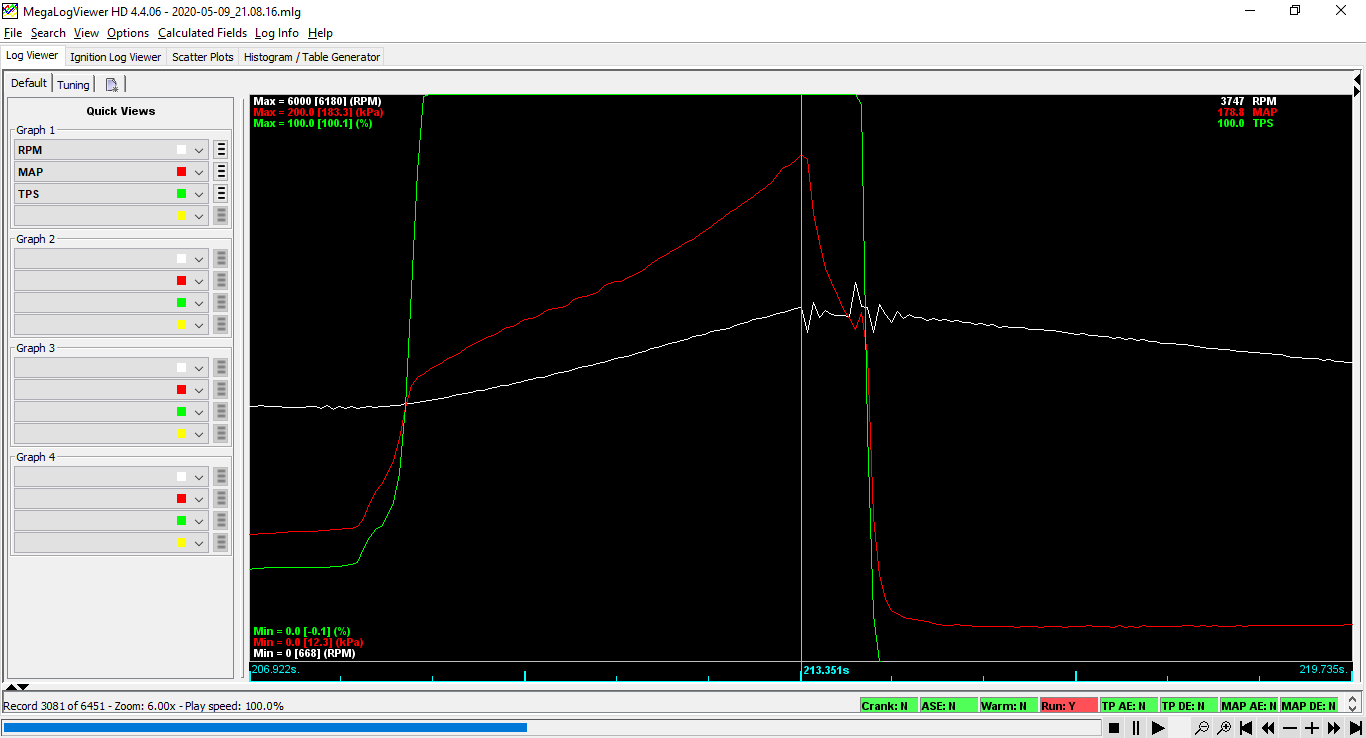

Here is a 5-second WOT pull I did on the highway from 2751 RPM in 4th gear:

The manifold pressure climbed steadily to 180 kPa absolute at which point the ECU's boost limiter intervened with a spark cut. That was with the wastegate flapper fully open the whole time. Ambient temperature was about 2 °C.

So apparently my wastegate doesn't flow enough. I think I'm going to attempt to port the wastegate.

If that doesn't work, then I may switch to a bigger external wastegate.

Thoughts?

If I go to WOT in 1st gear from idle, the turbo lag is such that the 180 kPa boost cut isn't reached until an engine speed of about 5500 RPM.[This message has been edited by pmbrunelle (edited 05-09-2020).]

|

|

|

ericjon262

|

MAY 10, 03:04 AM

|

|

|

I don't remember what type of muffler you have on the car, but a free(er?) flowing muffler may help with wastgate performance without the fabrication required to install an external WG. from what I remember in your video the car was fairly quiet, and sounded like you could open it up quite a bit, without getting excessive. ------------------

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

cognita semper

http://www.fiero.nl/forum/Forum2/HTML/119122.html

|

|

|

Will

|

MAY 10, 09:56 AM

|

|

| quote | Originally posted by pmbrunelle:

I went out driving tonight and the manifolds are sealing to the heads (for now).

And now, the next problem: boost creep!

Prior to leaving the garage, I forgot to install the wastegate actuator's rod end onto the wastegate lever...

Here is a 5-second WOT pull I did on the highway from 2751 RPM in 4th gear:

http://images.fieroforum.co...e/Highway%20Pull.png

The manifold pressure climbed steadily to 180 kPa absolute at which point the ECU's boost limiter intervened with a spark cut. That was with the wastegate flapper fully open the whole time. Ambient temperature was about 2 °C.

So apparently my wastegate doesn't flow enough. I think I'm going to attempt to port the wastegate.

If that doesn't work, then I may switch to a bigger external wastegate.

Thoughts?

If I go to WOT in 1st gear from idle, the turbo lag is such that the 180 kPa boost cut isn't reached until an engine speed of about 5500 RPM.

|

|

Sounds to me like your turbo is too small

|

|

|

pmbrunelle

|

MAY 10, 02:49 PM

|

|

| quote | Originally posted by ericjon262:

I don't remember what type of muffler you have on the car, but a free(er?) flowing muffler may help with wastgate performance without the fabrication required to install an external WG. from what I remember in your video the car was fairly quiet, and sounded like you could open it up quite a bit, without getting excessive.

|

|

I have a perforated-tube Magnaflow muffler, 2.5":

https://www.summitracing.com/parts/mpe-11376

It's pretty much like a glasspack, but with a case that's larger off to one side.

Actually, it seems like a more restrictive muffler would help with the boost creep problem, despite diminishing the wastegate performance.

The turbine is driven by a pressure difference, so increasing the pressure at its discharge (i.e. with a thin restrictor plate inserted into the discharge V-band) should reduce the problem.

If we perform a thought experiment, lets imagine a restrictor plate at the discharge V-band with a 1/2" orifice. I don't think there would be much boost in that configuration.

| quote | Originally posted by Will:

Sounds to me like your turbo is too small  |

|

https://www.atpturbo.com/mm...&Category_Code=GTHTS

Now I have a 0.63 A/R turbine housing from ATP. They do offer a 0.82 A/R version of the same thing (also machined for the Stage III turbine wheel), which I am considering.

I don't know how much difference it would make though. I don't even know what A/R means.

Area/Radius should result in units of length, yet this parameter is presented as a unitless quantity  What am I missing that the entire remainder of the Internet seems to understand? What am I missing that the entire remainder of the Internet seems to understand?

I am going to ask ATP if the inlet flange to turbine axis relationship is constant between their 0.63 A/R and 0.82 A/R housings. If so, then the 0.82 A/R housing would bolt into the White Bug. I'd still probably port the 0.82 A/R housing's wastegate passage.

|

|

|

DimeMachine

|

MAY 10, 03:49 PM

|

|

|

I just read this thread for the first time today and one word comes to mind..............Impressive.

|

|

|

Will

|

MAY 11, 09:08 AM

|

|

| quote | Originally posted by pmbrunelle:

https://www.atpturbo.com/mm...&Category_Code=GTHTS

Now I have a 0.63 A/R turbine housing from ATP. They do offer a 0.82 A/R version of the same thing (also machined for the Stage III turbine wheel), which I am considering.

I don't know how much difference it would make though. I don't even know what A/R means.

Area/Radius should result in units of length, yet this parameter is presented as a unitless quantity  What am I missing that the entire remainder of the Internet seems to understand? What am I missing that the entire remainder of the Internet seems to understand?

I am going to ask ATP if the inlet flange to turbine axis relationship is constant between their 0.63 A/R and 0.82 A/R housings. If so, then the 0.82 A/R housing would bolt into the White Bug. I'd still probably port the 0.82 A/R housing's wastegate passage. |

|

Mostly joking about that... I'm sure you did your homework on turbo selection. If you think finding the definition of AR is bad, try finding the definition of "trim". The 10 psi wastegate spring sounds like the right answer for your "problem".

And yes, AR SHOULD have units of length, but mostly isn't presented that way... welcome to the world of hot rodding.

This page has some good graphics depicting AR: http://www.dieseladdict.com...turbo-housing-ratio/

|

|

|

pmbrunelle

|

MAY 11, 12:48 PM

|

|

| quote | Originally posted by DimeMachine:

I just read this thread for the first time today and one word comes to mind..............Impressive. |

|

Hehe lets wait until it runs correctly before giving the accolades... it could still blow up!

| quote | Originally posted by Will:

The 10 psi wastegate spring sounds like the right answer for your "problem". |

|

Yes, a "problem" is often not a problem as such; it is rather a person's interpretation of a situation.

The present setup:

-ECU's MAP limiter is set to 200 kPa

-The wastegate actuator is completely disconnected. The wastegate flapper is now free to swing wide open. It is in the "maximum bypass" configuration when the exhaust blows it open.

The problem didn't seem so bad initially (my statement about the 10 psi spring possibly patching things), but that was just for 1st gear.

Doing more structured tests in 2nd, 3rd, and 4th gears I hit the ECU's 200 kPa MAP limiter at progressively lower RPMs... even with the wastegate in maximum bypass configuration. The turbo lag is less prominent in the higher gears where engine acceleration is lower.

It is possible that for a higher boost level, the wastegate capacity would become sufficient, but I am not ready to try more than 200 kPa for the moment. My fuel injectors (30 lb/hr) are pretty much maxed out with 200 kPa of manifold pressure, and I haven't yet activated the water injection yet (I'm trying to debug only one system at a time).

So my current objective is to increase the wastegate flow capacity such that the manifold pressure can be kept below 200 kPa in all conditions.

This is my plan to be completed in order of increasing expense/difficulty:

Step 1 (completed):

Remove the wastegate swingvalve assembly from the car, and increase its angular travel to increase the curtain area.

Original setup:

Metal ground away on arm, and material removed from the casting:

With modifications, the swingvalve can travel further:

This wasn't enough; it's not the slam dunk I was hoping for. If this didn't change much, then perhaps the bottleneck is in the wastegate passage of the turbine housing.

Step 2:

Remove the turbo from the car, port the wastegate passage in the turbine housing.

Step 3:

Install the 0.82 A/R turbine housing, unported.

Step 4:

Port the 0.82 A/R housing.

Step 5:

Build a block-off adapter to replace the swingvalve assembly. Add an external wastegate to the 2-into-1 merge. Or maybe build an internal wastegate with a bigger puck (and corresponding larger passage).[This message has been edited by pmbrunelle (edited 05-11-2020).]

|

|

|

|