|

| World's slowest Fiero/Quad 4 Swap (Page 30/48) |

|

Quadfather

|

DEC 28, 09:13 PM

|

|

This 1990 Sunbird brought back memories. The first new car I ever had was a 1989 Sunbird that was the same color as this one. It was the car my wife and I drove on our honeymoon.

|

|

|

Quadfather

|

DEC 28, 09:22 PM

|

|

|

|

Quadfather

|

DEC 31, 10:37 AM

|

|

|

|

Quadfather

|

DEC 31, 11:09 AM

|

|

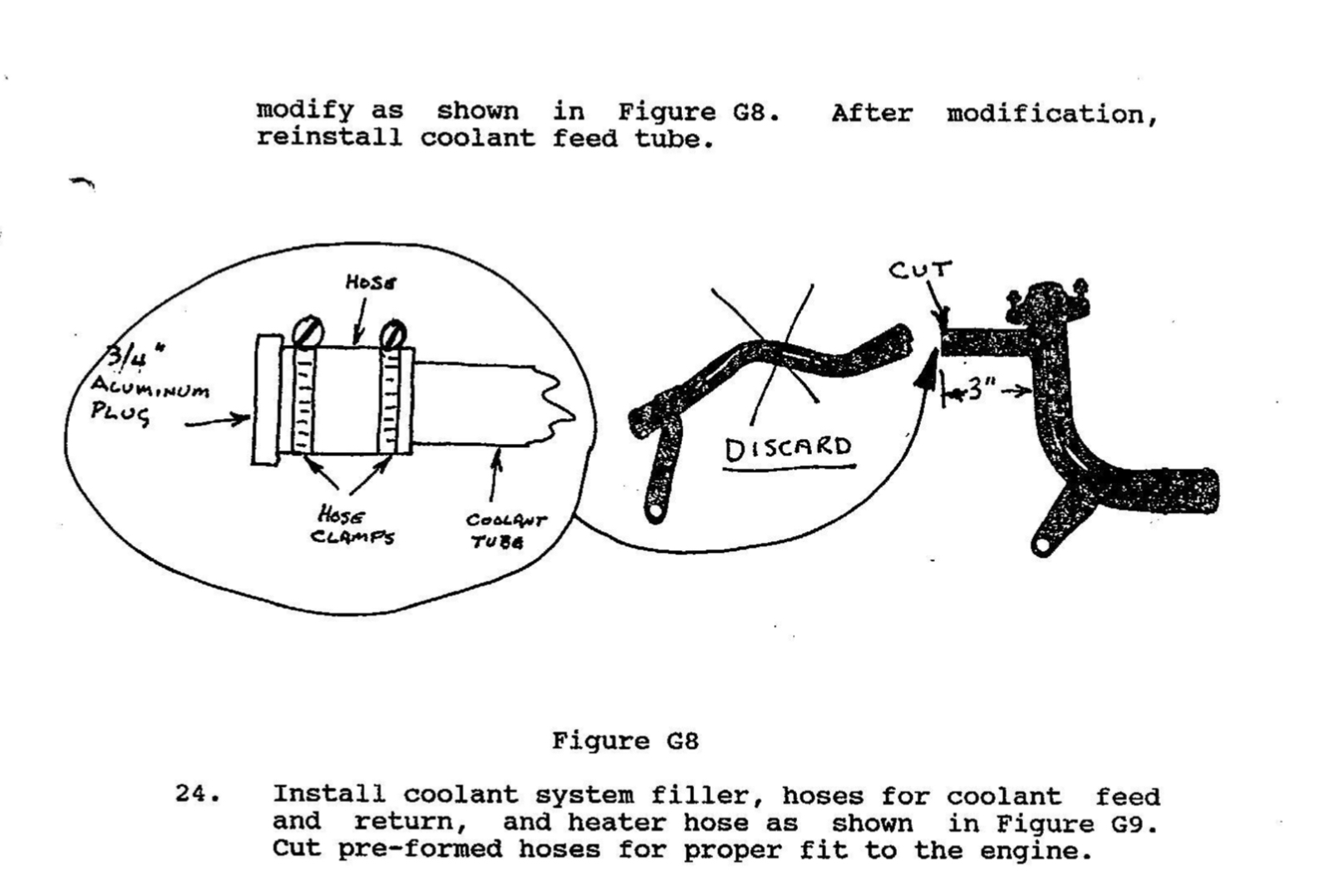

Got an auto-darkening welding helmet for Christmas. Armed with that and a pair of cheap reading glasses, I tried modifying the coolant outlet pipe. The swap instructions call for cutting off the heater pipe and using a clamp to close the stub, but I prefer cutting off the heater pipe flush and welding a patch panel over the hole.

I experimented with turning the voltage and line speed way down. After a couple small adjustments, it worked. No leaks.

|

|

|

Quadfather

|

DEC 31, 11:16 AM

|

|

Came across a photo from ten years ago. On New Years Eve, 2011, I replaced the fuel pump and hoses.

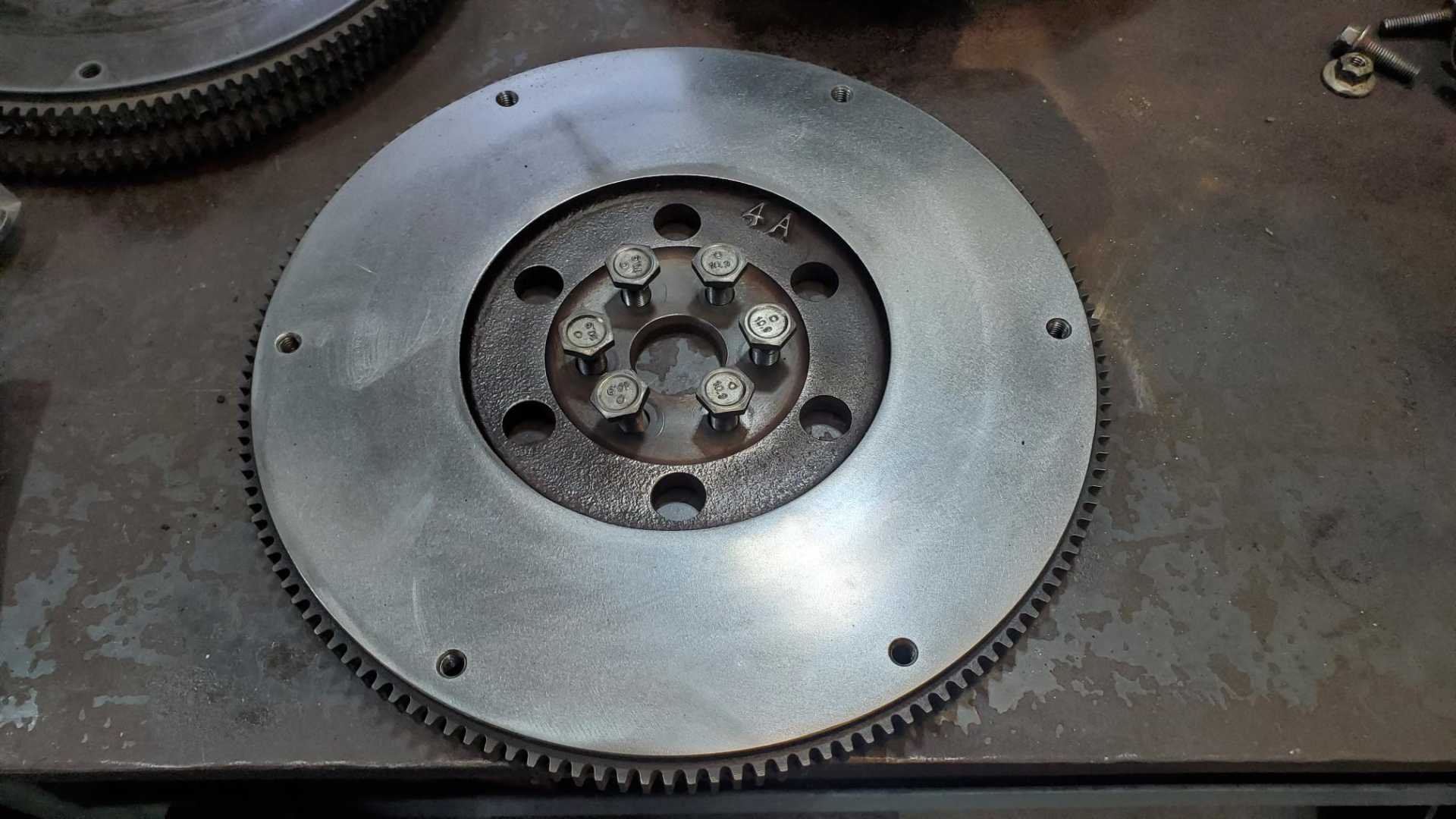

Hope to get back over to the shop this afternoon to install the flywheel and related parts. Then it will be time to pull the spare Quad out of the Fiero. We’re expecting bitter cold weather tomorrow and Sunday with some winter precipitation so it will be a good time to be working inside.

|

|

|

Quadfather

|

DEC 31, 09:13 PM

|

|

The flywheel is ready to go back on the engine.

I had just about finished unbolting the engine from the engine stand to install the flywheel when I realized I didn’t have any place to put the engine while I used the hoist to pull the spare engine out of the Fiero. Bolted the engine back on the stand then pulled the spare engine and cradle out of the Fiero. Boy, was I out of practice.

Another engine and a cradle sure fill up the garage in a hurry. Also it’s amazing how dusty the engine and cradle were after just sitting in the car for a few years.

Getting to this point is a big step forward, but it also shows how much work is still needed, like finishing the engine/transmission mounts, stripping and painting the cradle, cleaning up the suspension, etc.

The engine compartment also needs major attention.

|

|

|

Quadfather

|

JAN 08, 09:12 PM

|

|

|

|

Quadfather

|

JAN 08, 09:23 PM

|

|

|

|

Quadfather

|

JAN 08, 09:26 PM

|

|

|

|

Quadfather

|

JAN 09, 07:46 PM

|

|

|

|

|