|

| 88 3800SC F23 Build (Page 3/8) |

|

paulsobj

|

NOV 27, 09:09 PM

|

|

|

|

Jncomutt

|

DEC 02, 09:31 AM

|

|

|

You can use the input shaft from the 3.93 trans, as it is shorter.

|

|

|

paulsobj

|

DEC 07, 09:41 AM

|

|

| quote | Originally posted by Jncomutt:

You can use the input shaft from the 3.93 trans, as it is shorter. |

|

I will try to get ahold of the shop and see if they have already swapped the bellhousing.

85sliverGT stopped out and got a tour of the shop and see most of my projects. It was great to finally meet another Fiero nut!

I got a call from the machinist and the heads were cracked between the valves (very common in 3800). I bought a set off a 00 Boni and those were less cracked... So the yard has two more from two Buicks (one R and L on each car). I will pick them up today and I hope to have at least ONE good head. On another note we will check out the rocker arms from the Boni to see if they are good so I don't have to buy a set. Note: the machinist, trans shop, and balance shop are all 1 hr drives....

I picked up the gasket set from my machinist and it came with the plastic LIM gasket that is the midgrade plastic not the best option metal. Some people go buy the metal one individually but I think I will use the plastic one as the reason it fails is the Dex-Cool eats the plastic. I think I can change the system to ethylene glycol (green stuff) and it shouldn't eat the plastic. If I wanted to keep the Dex-Cool I would have to do more work cleaning out the doner cars radiator and coolant lines as they have ethylene glycol. If you mix the two IIRC it makes an acid that really eats gaskets fast.

I bought a flywheel from French lake auto for $40 + $20 shipping.

I also bought some stuff to help get the pistons cleaned and the machinist recommended not blasting so that's called off. I ordered some stuff called piston kleen for $20/Gal. I will let you know how it works.

|

|

|

paulsobj

|

DEC 07, 11:22 PM

|

|

I picked up the now third set of heads. We did a quick preliminary magnaflux and NO signs of cracking between the valves. He will tear them down and check them thoroughly tomorrow. Something to note.... I had bad rocker arms on the 1st set. The second set seems to have good rocker arms, springs and valves. They were going to sell me the valve covers for $25 ea but I passed. So when I went back to exchange the old heads that were bare, the new one (3rd set) had rockers, valves, springs, and Valve covers! I should have plenty of spare parts for the heads.

I packed up the Crank, Pistons, Piston Rings, Connecting Rods, and Flywheel and will head out to get them balanced and checked out. I didn't order bearings yet just incase the shop needs to machine the crank. Once I know for sure that standard size is what we need I will order Main and Rod bearings. After the bearings arrive they can balance everything.

|

|

|

paulsobj

|

DEC 08, 10:37 PM

|

|

|

|

nosrac

|

DEC 09, 08:45 AM

|

|

| quote | Originally posted by paulsobj:

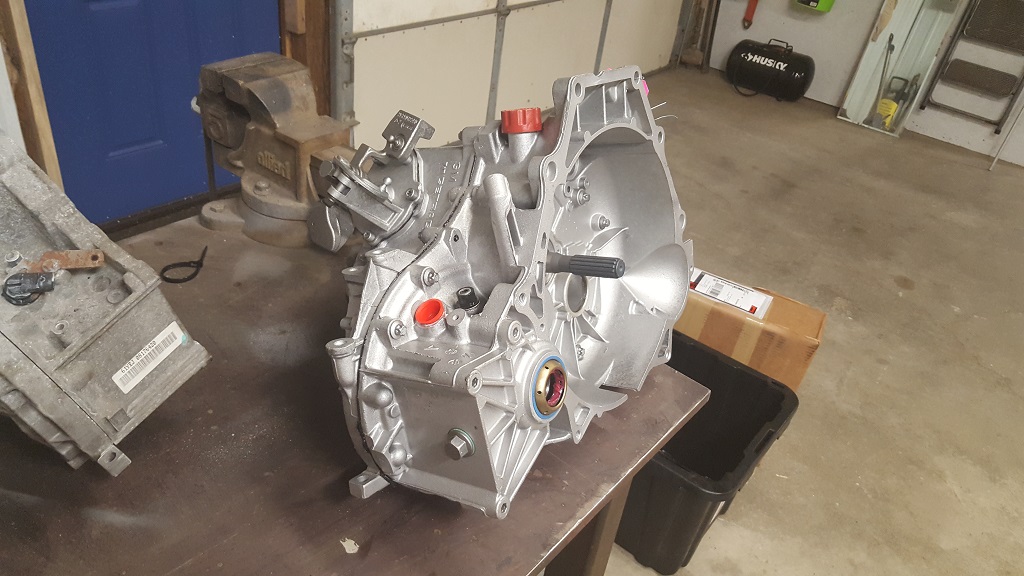

I picked up the F23 today. I have to say I was impressed. $427 and they swapped all the gears, a few new bearings and new seals. They also painted it for me. Here are a few pics. They had the input shaft already swapped.

all ready to unwrap an early xmas present

|

|

That is impressive as most shops just don't do a decent job. I'd gladly pay for that service.

|

|

|

paulsobj

|

DEC 09, 10:33 PM

|

|

Here are a few pics I forgot to add.

This shows a little better the color they painted the F23.

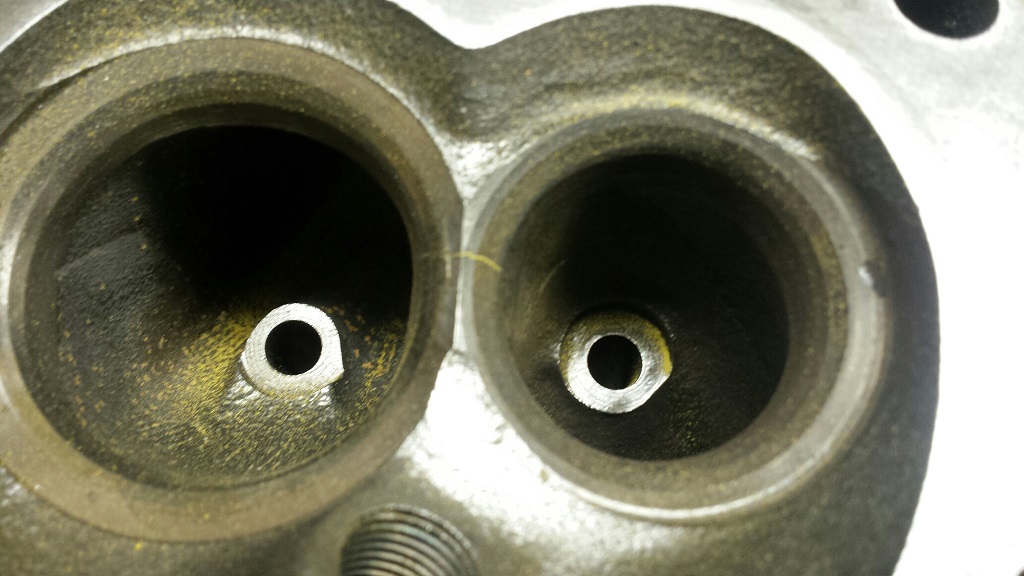

This is a shot of set one of heads that were cracked. The second set was not nearly as bad, just a hairline crack.

I also received news that the machinist is done.

Head bolt set, engine gasket set, cam bearings, piston rings, grind valves, wash block and heads, hone block, Mag heads. Total $750

Lots of advice = priceless[This message has been edited by paulsobj (edited 12-04-2023).]

|

|

|

qwikgta

|

DEC 09, 11:10 PM

|

|

| quote | Originally posted by paulsobj:

Rob,

Yes it is! I got that at my first meeting with the club. I kept it on the car as it is great quality and looks awesome. You might remember that car it was 00355 VIN and had some 87 GT parts on it from the factory.

|

|

Yes I remember. Lowest number 88 I have ever seen. Glad to find this thread, i'll be watchin it. Good luck.

|

|

|

paulsobj

|

DEC 10, 09:58 PM

|

|

|

|

paulsobj

|

DEC 12, 11:25 PM

|

|

|

|

|