Hey all, I've been working to restore my 88 GT and tried a little bit of fabrication to save myself a little bit of money. I was able to make a universal fuel level sender work for me and wanted to share with the rest of you. My particular fuel float arm assembly was reading 0 ohms regardless of position and the adjustment screws did not help. I considered the option of getting a complete sending unit from the Fiero store, but wanted to see if there was a cheaper option available.

Take my experience with a grain of salt because I am sharing this BEFORE I see that it works well in the car for a while. If this fails I will definitely be purchasing the Fiero Store option.

I was browsing ebay/amazon for a 0-90 ohm float arm and was able to find this one for a pretty affordable price at $28-

https://www.amazon.com/Univ...r/dp/B07S77K2CF?th=1What I didn't realize before this arrived is that this mounts backwards as compared to the stock sensor. Which caused some problems I didn't expect.

1. I started cannibalizing the old sensor by sipping the plastic tabs that hold the body of the sensor to the tack welded sheet metal backing. It took a little bit of light prying, but I was also able to remove the float arm from the pivot.

2. I then did my best to straighten out the metal backing and trimmed away the areas past the 5 holes that were in it.

3. The idea I came up with utilized the slotted piece from the universal sensor, I trimmed that using an angle grinder and bored out the holes on the original backing to accept the hardware diameter that same with the new unit. I used the top section of the slotted piece (which had 3 threaded holes) to mount that to the original sensor location.

4. I then had to use bolts as standoffs to space the sensor back enough to clear everything. I also cut out a piece of aluminum sheet to use as a backing plate for the sensor to mount to. It is a bit janky looking, but it seems to be functioning as intended.

5. I then trimmed the length of float arm rod that I needed. I probably won't be prefect measuring the entire depth, but I made sure I would get as accurate of an empty reading as possible.

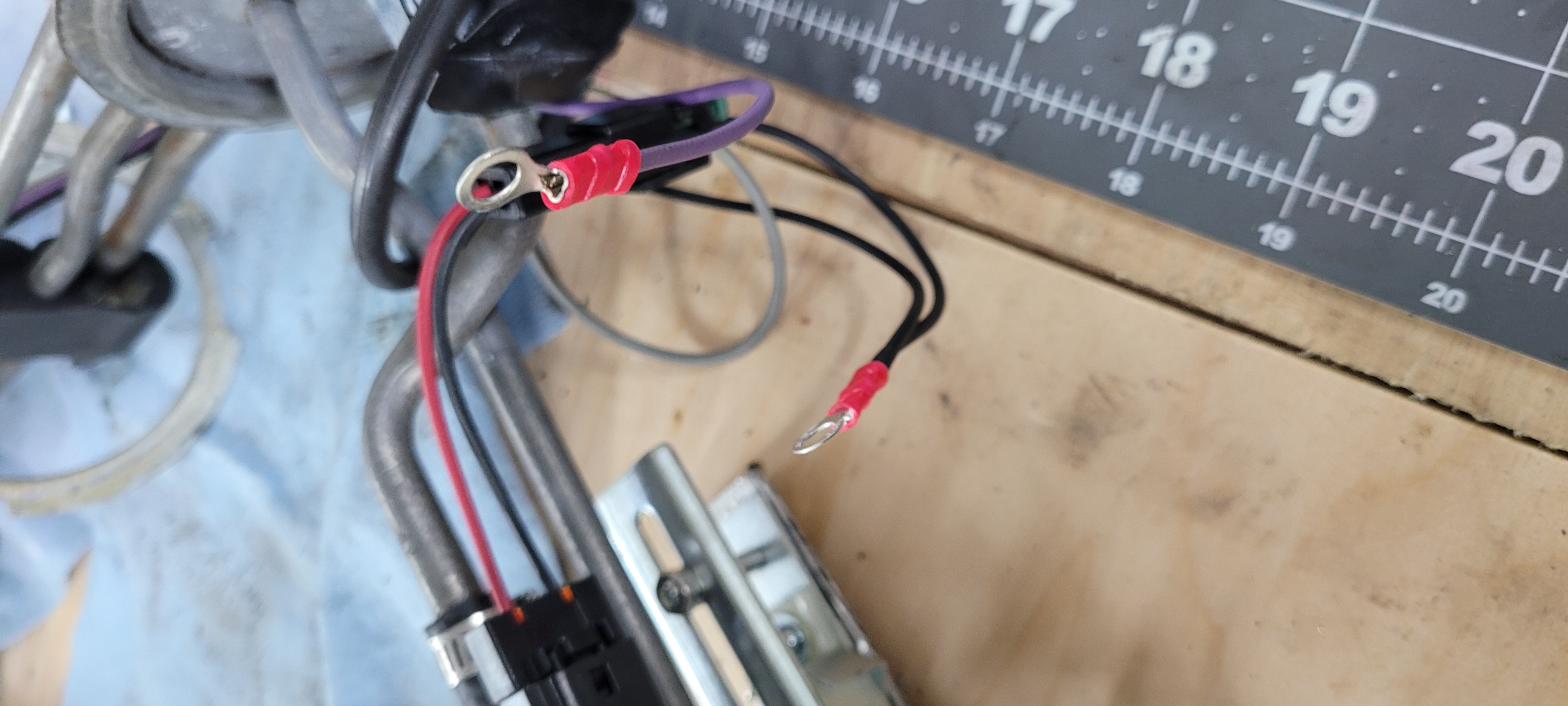

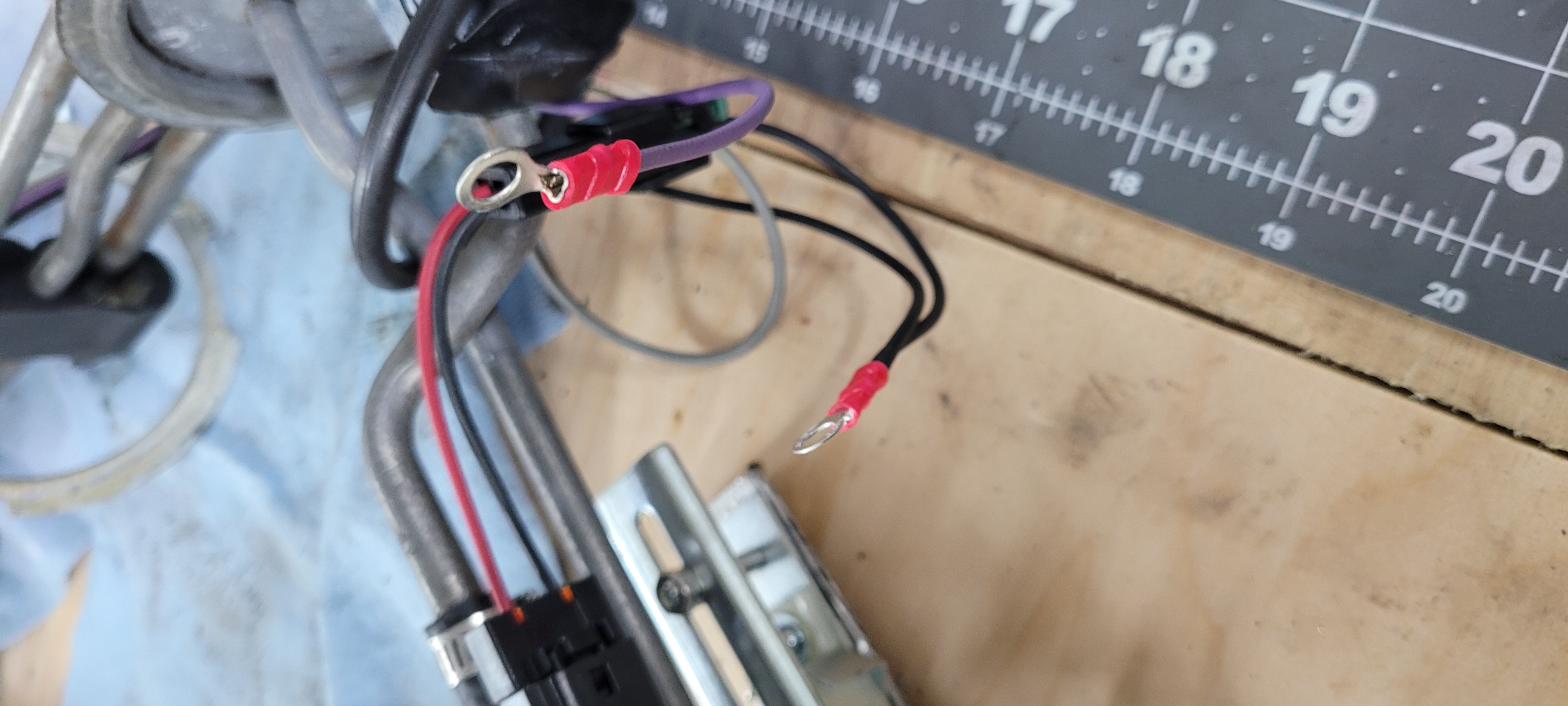

6. The last thing I did was re-terminate the black and purple wires with ring terminals. I put the purple wire onto the sensor standoff, and fixed the black wire to one of the bolts I used as a spacer.

Fitting this back into the gas tank was tight. The bolt heads from spacer bolts were pretty close- I almost considered grinding them down. I also had to lower the whole assembly with the float in the upright position- so when I need to remove it I will need to put something down there to fish it out first. Electrically everything checked out. I read 0ish-90ish ohms between the purple and black wires at the yellow connector, and had a negligible resistance between the red and black wires. Fingers crossed I didn't do anything glaringly wrong and some people can find this helpful. If someone has found a better option for a universal sensor please link it below- something that swings the correct way would improve this a ton.

[This message has been edited by MichiganReefer (edited 04-24-2023).]