Got the rockers sorted out with some shims and a little grinding with my dremel.

Primed the oil system by rigging an old garden sprayer to the oil pressure port.

Cranked her over until the oil gauge hit 40.

Got everything else installed and went for a start.

.......

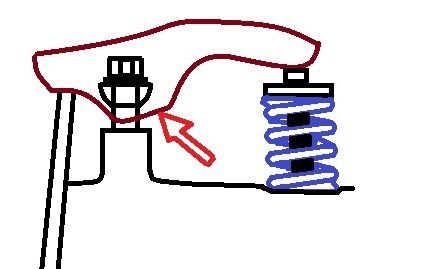

Swapped my spark plug wires from "shooting fire from the throttle body'' to the ''run'' setting and she started right up.

No leaks.

No longer has the diesel engine "tick". (Will see how long that last after brake in)

I could not run her too long as she's still backed into the garage, but I'm happy for now.

I need to find a new throttle cable as mine is frayed near the throttle body and is about to brake.

[This message has been edited by Zeak (edited 12-30-2014).]

Topic Closed

Topic Closed