|

| LS4 / F40 swap - fieroguru (Page 146/197) |

|

Bob2112

|

OCT 13, 09:16 PM

|

|

|

|

fieroguru

|

NOV 06, 07:32 PM

|

|

So after nearly 21 years working for the same company I finally decided to move on and switch industries. Part of it was to exit a quickly declining industry on my own terms, part of it was to reduce my travel commitments with a plant level assignment vs. a corporate position. I am about 2.5 weeks into the new job. Still working 10 to 12 hr days as I learn a lot of new things, but at least I am home every night and weekend.

With the new job, I hope to continue to make progress on the LS4 upgrades.

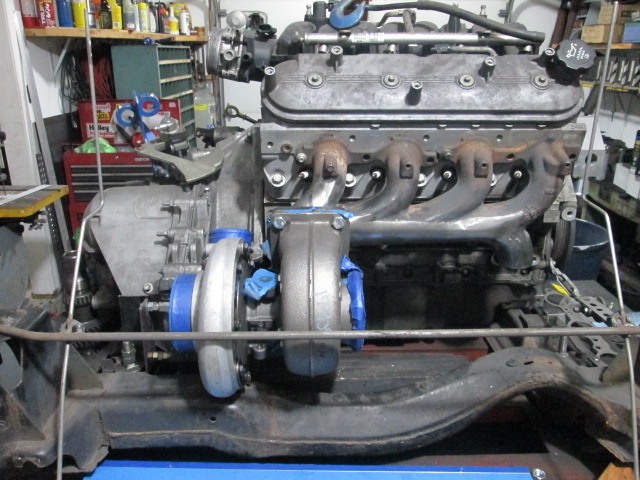

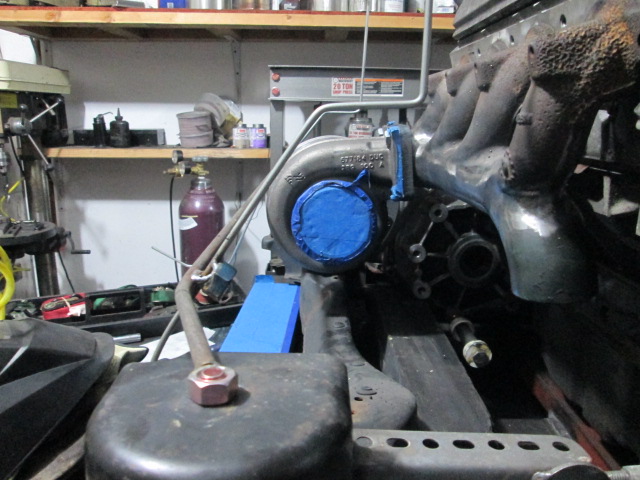

Last weekend I had a few hours to remove the LS4/F40 mockup engine and cradle from the parts chassis, mount it on my cradle fixture, and do a little more cleanup to the turbo manifold. I tack welded the T4 flange to the manifold and bolted the turbo up. It is very close to fitting w/o any modification to the stock trunk, but I likely either need to mill the manifold to allow the flange to be closer to the engine or mill the manifold so the T4 flange is closer to the same angle as the head. Either method will pull the compressor housing a little further from the trunk wall.

Swaps are a lot like playing Chess... you need to plan out 5 steps ahead to make sure everything had a planned location and nothing looks like an afterthought. The issue I am pondering now is how best to integrate the waste-gate. It needs to be accessible, but I am kinda going for a stealth turbo install, so it needs to be relatively hidden and the manifold and turbo location doesn't leave much room.

|

|

|

ericjon262

|

NOV 06, 08:09 PM

|

|

| quote | Originally posted by fieroguru:

Swaps are a lot like playing Chess... you need to plan out 5 steps ahead to make sure everything had a planned location and nothing looks like an afterthought. The issue I am pondering now is how best to integrate the waste-gate. It needs to be accessible, but I am kinda going for a stealth turbo install, so it needs to be relatively hidden and the manifold and turbo location doesn't leave much room. |

|

Many of the so called "Sloppy Mechanics" weld the WG flange directly to the turbine housing and seem to have good results.------------------

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

"The day I tried to live, I stole a thousand beggars' change and gave it to the rich."

http://www.fiero.nl/forum/Forum2/HTML/119122.html

|

|

|

fieroguru

|

NOV 06, 09:58 PM

|

|

| quote | Originally posted by ericjon262:

Many of the so called "Sloppy Mechanics" weld the WG flange directly to the turbine housing and seem to have good results.

|

|

That is one of the options, but there isn't much room between the turbine housing and the trunk shelf... I need to pull the drivetrain from my car for the cam swap and do a test fit to validate clearance and fitment options.[This message has been edited by fieroguru (edited 11-06-2019).]

|

|

|

Will

|

NOV 10, 07:08 PM

|

|

|

|

fieroguru

|

NOV 23, 12:28 PM

|

|

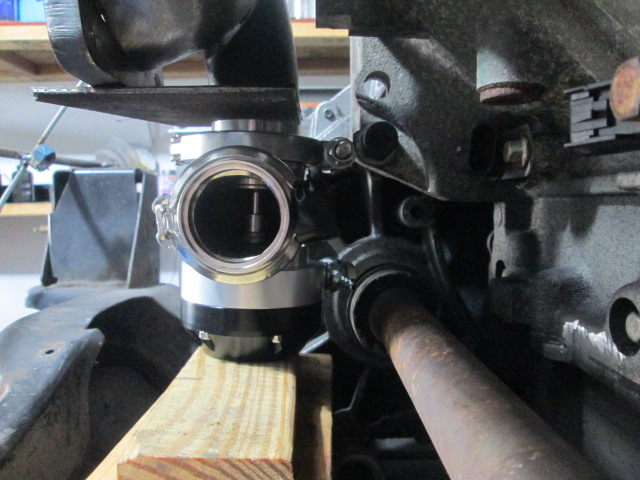

I think I have decided on the general placement of the wastegate for this phase of the build. Its placement should have good flow, the discharge can be easily plumbed into the 3 1/2" down pipe/muffler, and everything will be hidden from view. The only 2 downsides are manual adjustments will have to happen from under the car and phase II with AWD will likely require modification of this location (but that is realistically 2-3 years away and I want more power this summer).

I tacked the 1/8" plate onto the flange to establish a level surface so I could work on fitment of the elbow.

Before I commit to this location I need to explore the routing of the oil return line and determine if it will go above the axle (if so the waste gate will likely need to be lowered some.

|

|

|

oldrock2401

|

NOV 24, 07:46 AM

|

|

|

Do you have plans to cut/notch the trunk? ------------------

--- 86 GT, my pride and joy (currently undergoing turbo 3.8 swap)

|

|

|

fieroguru

|

NOV 24, 09:30 AM

|

|

| quote | Originally posted by oldrock2401:

Do you have plans to cut/notch the trunk?

|

|

Not at this time. Everything should (barely) fit with the stock trunk and a modified cradle.

|

|

|

fieroguru

|

NOV 28, 11:37 AM

|

|

These fixture brackets were made and installed on the cradle fixture to locate and support the LS4/F40 above the cradle. This placement is level and square to the front cradle bolts and optimizes the available clearances in the engine bay. These brackets fully support the drivetrain and allow it to hover above the Fiero cradle for mount fabrication and installation purposes.

Now I need to pull my original LS4/F40 drivetrain and see how close it is to this placement and decide if I want to change it over or keep it like is has been, I don't believe the two placements will be more than 1/4" off in any direction.[This message has been edited by fieroguru (edited 11-28-2019).]

|

|

|

fieroguru

|

NOV 30, 07:26 PM

|

|

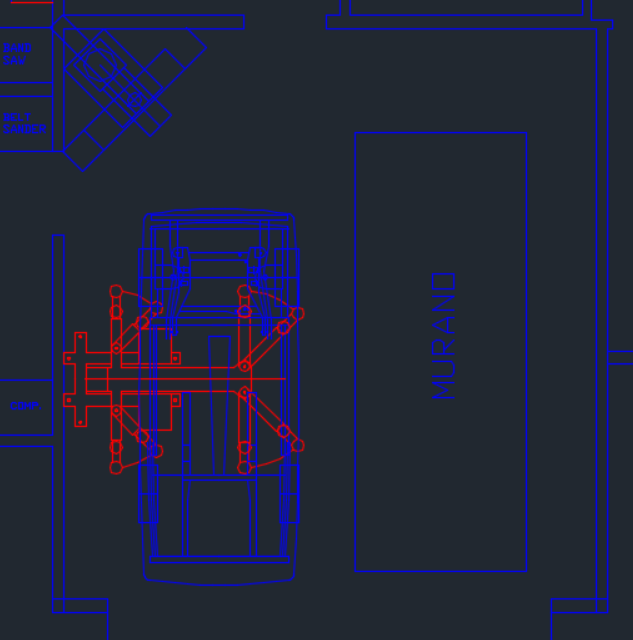

Starting to get serious about a lift for my garage... but space is very limited. There is zero room for a twin post lift, so I have been looking at the Amgo SL-6 single post lift:

http://www.amgohyd.com/lift...emid_94_lcid_38.html

Here is a proposed layout of it with a fiero (centered for lifting with engine/transmission).

The main post is 108" and my garage is 113" - which will work.

The in the layout above, the center of the main post is 96" from the roll up garage door. In the picture below, the edge of the metal rack shelving is 90", so the racking will have to go, but the main post of the lift will clear the garage door in the raised position.

Without changing the path of the garage door, I could lift the Fiero up about 35 with the door in the raised position. This is plenty high to remove the cradle. I could also raise the garage door at some point as well to allow higher lifting.

To use the lift the Fiero will need to be about 6" further to the center of the garage than it currently sits. But I could slide it over to the current position when not using the lift.

The install is very tight. Given the limited room between the roll up door and the mill, the lift probably couldn't be used for my truck or the wife's Murano, which is a bummer.

I likely would want to relocate the hydraulic pump to the other side or further down the wall. Also the lock release would only have about 4" to the wall, so that might need to be relocated as well. The lift is about $2500 shipped, but I would likely have $3000 to $3500 in it for all the changes to optimize the install.

Still on the fence with this...

|

|

|

|