|

| LS4 / F40 swap - fieroguru (Page 196/209) |

|

fieroguru

|

FEB 29, 07:48 PM

|

|

| quote | Originally posted by pmbrunelle:

I have some concerns about the panels of the box having resonances (high Q resonance due to the steel material) in the low audio-frequency / subwoofer range being excited and resulting in the panels buzzing, but I guess you'll find that out; maybe internal panels can be used to tie opposing faces together, or dynamat or similar.

Are you able to perform a modal analysis on the box?

If you're interested, I could run a modal analysis on SolidWorks, using your dimensioned drawing to define the part. |

|

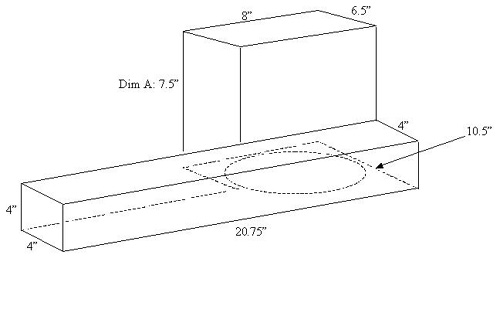

I will know how it performs this weekend as I continue my testing on the bench and playing around with the oscilloscope . The panel at the top of the box directly above the sub will be the one to resonate if there is any as it has the longest span. If needed, that panel has lots of room for a support rib on the top side.

|

|

|

fieroguru

|

MAR 02, 07:33 PM

|

|

|

|

Will

|

MAR 02, 08:14 PM

|

|

| quote | Originally posted by fieroguru:

Got the sub box cut out and bent into shape.

|

|

From looking at this diagram, I didn't realize the box was just flat like that.

Do you have something else in the volume used by the OE sub box? I had assumed, again based on the diagram, that you'd be using the OE sub box volume.

| quote | Originally posted by fieroguru:

|

|

|

|

|

fieroguru

|

MAR 02, 09:51 PM

|

|

| quote | Originally posted by Will:

From looking at this diagram, I didn't realize the box was just flat like that.

Do you have something else in the volume used by the OE sub box? I had assumed, again based on the diagram, that you'd be using the OE sub box volume.

|

|

I could have made it taller, but that would just increase the volume beyond the sealed volume they recommend (0.30^ft), and make it heavier.

With the use of 16ga steel my flat box actually has more internal volume than Alex4mula's when made with 1/2" MDF.

|

|

|

Will

|

MAR 03, 09:09 AM

|

|

| quote | Originally posted by fieroguru:

I could have made it taller, but that would just increase the volume beyond the sealed volume they recommend (0.30^ft), and make it heavier.

With the use of 16ga steel my flat box actually has more internal volume than Alex4mula's when made with 1/2" MDF. |

|

I was referring to using the vertical volume instead of the horizontal volume so the box would keep the target volume but not intrude into the footwell quite as much.

So you've left the original sub box volume unutilized?[This message has been edited by Will (edited 03-03-2024).]

|

|

|

fieroguru

|

MAR 03, 09:50 AM

|

|

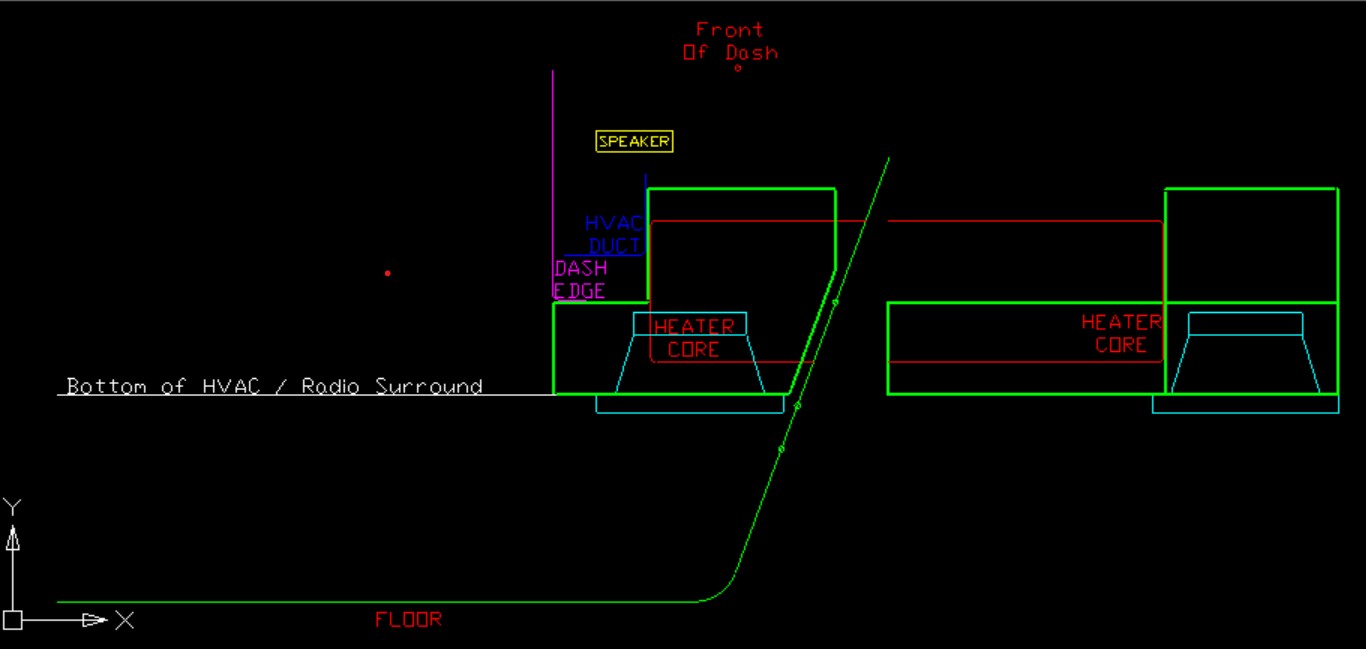

When I measured out the space, originally I was trying to maximize the volume. The sub is 8", the flange is 8 3/4" diameter, and there is only 8" of clearance between the A/C Heater core housing and the dash bracket. So the sub has to be be some amount lower than the A/C Heater core housing. I could probably raise it about 1", but then the geometry of the box gets more complicated as the magnet would then be higher than the bottom edge of the dash, so in the end, I kept it a simple flat box that protrudes 1 1/2" lower than the A/C Heater core housing and the magnet has about 7/16" clearance to the inside of the box.

|

|

|

fieroguru

|

MAR 03, 06:34 PM

|

|

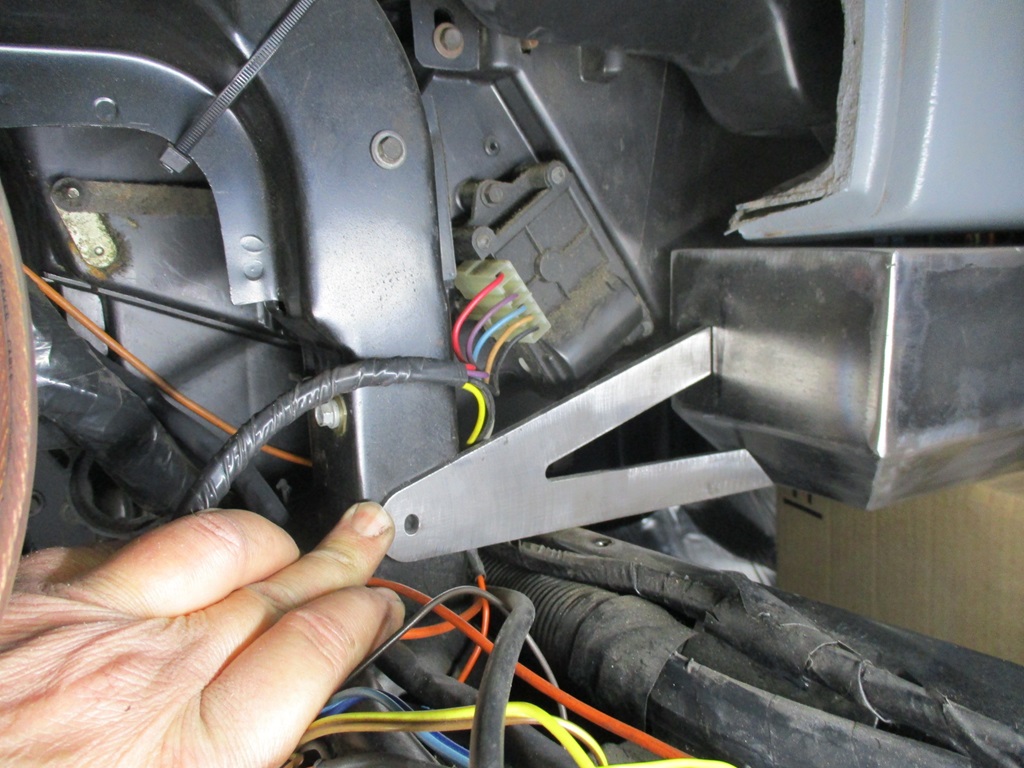

Smoothed all the welds on the sub box, then put it back in the car to start working on mounts for it. For the left side, I made a bracket that will bolt to the steering column support tube in the center console. It is far enough back to clear the console skeleton and surround.

The bracket for the right side will just be a L bracket with a hole in it to pick up this bolt:

Put the welding gas bottle in the back of the truck so I can get it filled on Monday.

Then i went back to the steering wheel and the brackets needed for attachment.

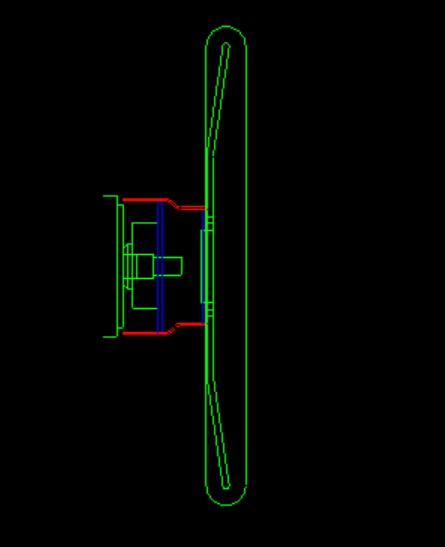

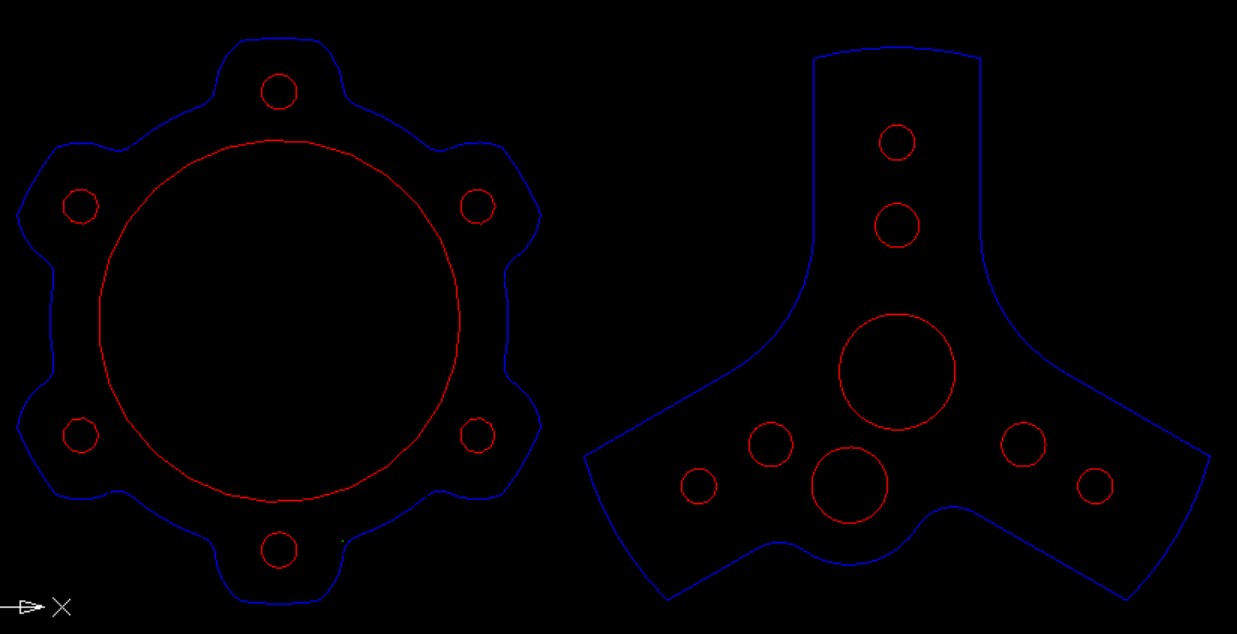

Here is a general mock up drawing showing the aluminum splined flange, two blue adapter plates and the red part is an exhaust reducer. The plates and the exhaust reducer will be welded together to make the steering wheel adapter mount.

Here are some of the older plates before the design was further refined:

This is what the final design of the two adapter plates will look like:

|

|

|

Will

|

MAR 03, 06:56 PM

|

|

Grant makes the wheel adapter that bolts to that hub.

Does that wheel have a weird bolt pattern?[This message has been edited by Will (edited 03-03-2024).]

|

|

|

fieroguru

|

MAR 03, 08:59 PM

|

|

| quote | Originally posted by Will:

Grant makes the wheel adapter that bolts to that hub.

Does that wheel have a weird bolt pattern?

|

|

The wheel is a 6 x 70mm pattern. Most of the off-the-shelf adapters are about 1.6" deep and I need one that is just over 2" thick so the column nut clears the horn button puck on the wheel.

|

|

|

fieroguru

|

MAR 10, 03:38 PM

|

|

Another productive weekend doing small fiddly stuff, but it needed done.

Mounted and wired the amp. The initial plan was to have to wires go through the wall of the pocket, but they would not clear the HVAC tube, so I made a wiring access hole in the bottom of each corner. The amp weighs 5 lbs, so I added support plates for the 4 bolt holes that secure it.

The sub box is also done. It weights 16 lbs 10oz and the stock sub housing with the the larger woofer is 5lbs 7 oz, so 11 lbs more for the sub and 5 for the amp, so all the stereo mods will be in the 20 to 25 lb range, which i am OK with.

The steering wheel adapter is now done as well. It isn't fully tight yet, so the gap between the adapter and the column will be a little less. All the steering wheel custom-ness weighs 1/2 lb more than the stock steering wheel.

|

|

|

|