|

| LS4 / F40 swap - fieroguru (Page 98/216) |

|

fieroguru

|

JUL 25, 09:59 AM

|

|

| quote | Originally posted by Steelsoul:

Hey Guru

Been lurking on this build for a while and have to say your a master at working on cars.

Have a few questions about some of the tools you are using.

What kind of brake are you using to bend the steel?

And I would really be interested in the LS4 with the auto transmission once you are done with it.

Keep up the good work, I one day hope I have half as much talent as you do

|

|

Thanks for the compliment!

I have an old 48" home-made brake (I didn't build it) that I can use for 16ga and thinner. Most of the 1/8" metal bends I use a cut off tool to score the bend line (make it thinner - about 16ga), then bend it with a vice and hammer. Once it is at the right angle, I go back and weld the scored seam to restore the material thickness. Then I grind down the weld so it is a nice smooth seam. Depending on the shape of the seam, sometimes I just butt two pieces of 1/8" together and weld it solid on the outside and stitch weld the inside. Then go back and grind the outside weld down smooth.

I like fabricated parts to not look like they were fabricated, so I take the extra time to clean them up and give the corners a uniform radius (bolt/clamp a washer to the corner and grind the edge to match the washer).

Tools help, but lot of it is process, technique, and just plain old effort and willingness to do it again if you don't like it.

As for the LS4's, I am not quoting prices or letting anyone claim dibs on them until much further down the road. There are several things I want to research with them and figure out before I will be done with them.

|

|

|

Steelsoul

|

JUL 25, 11:24 AM

|

|

That makes a lot of sense about doing the bends. I have worked on a lot of custom paintball rigs and I use a similar method on bending the aluminium for the braces on the dual bottle remote setups we use for paintball scenario games.

I will give it a shot when I make my own mounts for the 3800 swap.

Thanks Paul

|

|

|

fieroguru

|

JUL 27, 06:36 PM

|

|

While away this past week I had the opportunity to take a short/simple welding class (5 hrs total) with my wife. I did manage to get some free time to work on my own projects. They had a bunch of scrap sockets from a local mfg and I decided to make a "terminatorish" hand:

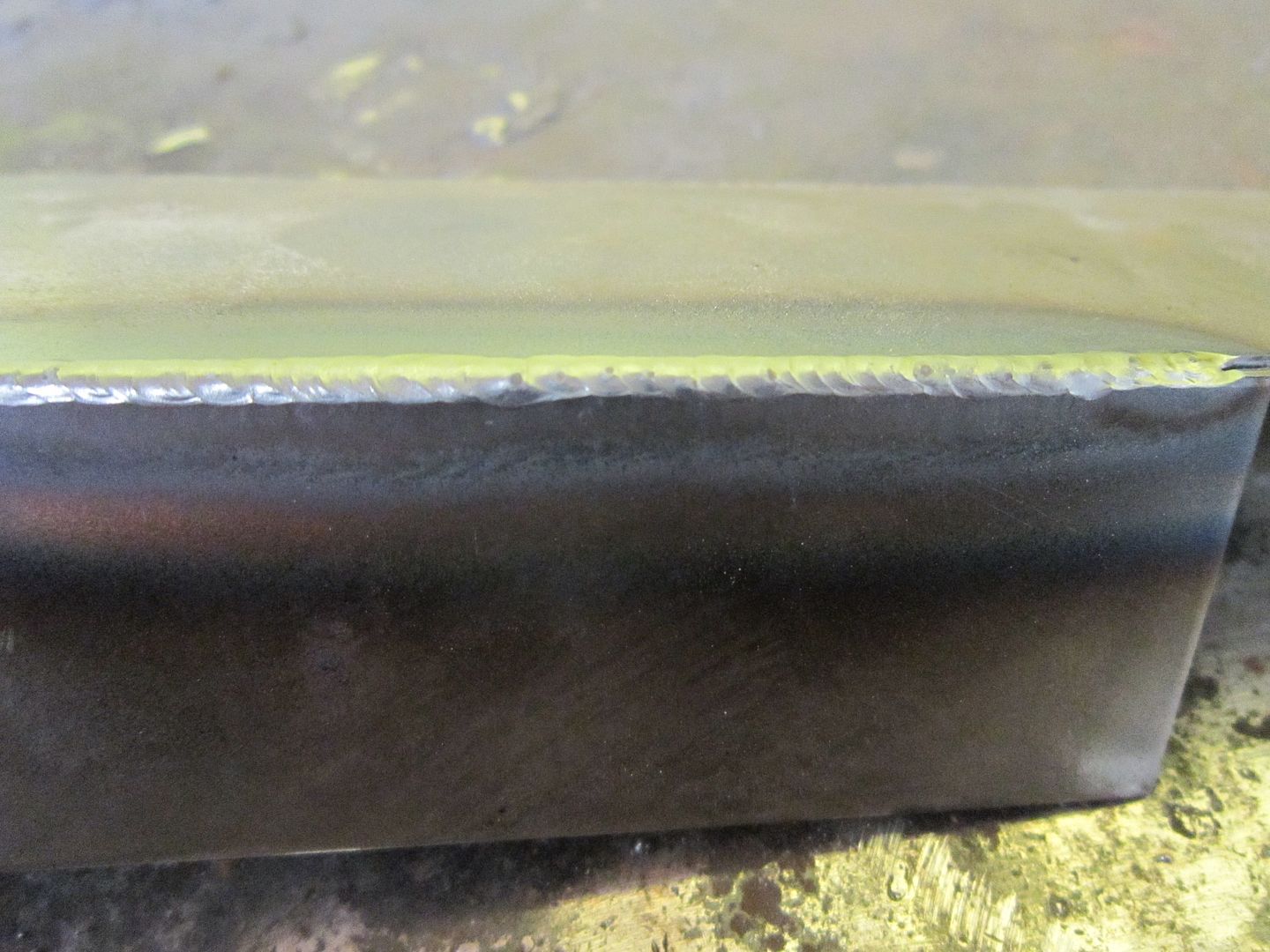

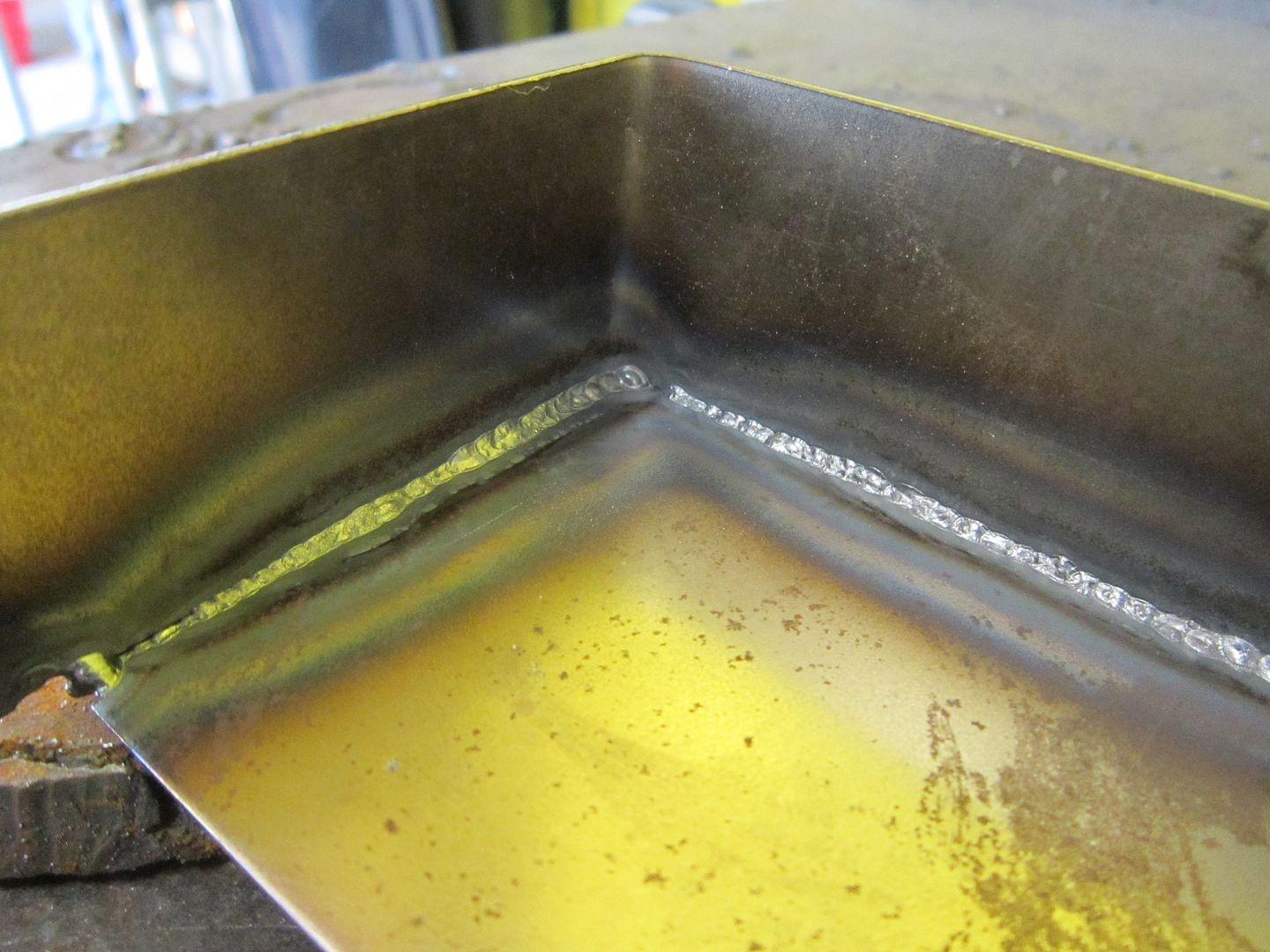

I also had about 30 minutes to play with the TIG (larger Lincoln) and some 16ga sheet metal. This was only my 2nd time using a TIG (first time was over 16 years ago for about an hour that time). This was a butted 90 w/o any filler rod... I really need to get one of these!

While at the class I quickly came to the realization that I really like my tools and my shop setup. They had a Lincoln 180 Mig and I am used to my Lincoln ProMig 175. It is very similar mine (newer generation), but theirs the wire tip was bent and came out more towards the side vs. in the center (and I didn't take the time to fix it). I also didn't like the feel of their welding helmet, really didn't like the button location on the grinder, and like welding from a vice vs. on a welding table. If I go back (and that's a big if), I am taking the class solo (so I have more time for my projects) and bringing my own tools.

|

|

|

dobey

|

JUL 27, 07:45 PM

|

|

|

Yeah, TIGs are awesome. I need to get one too. They're expensive though. :-/

|

|

|

ericjon262

|

JUL 27, 08:00 PM

|

|

|

|

fieroguru

|

SEP 01, 05:36 PM

|

|

|

|

fieroguru

|

SEP 05, 07:34 PM

|

|

My LS Fest weekend was cut short before it could really begin.

I took Thursday off as a vacation day so I could wait for my new front tires, get them installed, and make it to early registration in Bowling Green (3 hrs away) before 9 PM. Normally, the UPS guy stops by about noon, but noon came and went. At 3 PM I checked the tracking, and they said the truck broke down. Called UPS to see if I could meet the truck or pick up the package... it was one of 16 left on the broken down truck, the driver was back on his route, and I would have to wait till the wrecker takes it to the local hub. So I get everything loaded up in the truck and put the fiero on the dolly (will install the tires in Bowling Green) and get to the hub about 6 PM (its 30 miles towards Bowling Green). Wait, wait, wait... finally the guy reaches the wrecker and gets a 9:30 PM ETA for it to be back at the hub (it broke down at noon). So I make arrangements to pickup my tires at 5:30 AM the next morning and head back home.

Friday starts out early, picked up the tires at 5:30, in Bowling Green by 7:15 AM (local time - Central, I am on Eastern), check into the hotel and they only charge me for 1/2 day for Thursday, take the wheels (I have 8 total wheels for the Mille Miglia MII - so I brought more with bad tires to get the new ones), find a Wal-mart, get the tires mounted and balanced for $19 and head back to the hotel to swap out the wheels. When installing the PS one, the wheel would rock nearly 3/4" with my hands at 3 and 9... cussing ensued. Lower ball joint is toast and there is no way I would risk autocrossing or running the 1/4 mile with it. So found a Firestone tire place and asked if they did ball joints, they did and proceeded to call everyone in town to see when they could get one... none before Saturday... and the estimate to replace both lowers was about $430.

That's when I decided to just pack everything back up and go back home... and miss the LS Fest. I was only at the hotel for 3 hrs, and only had to pay for the 1/2 day after I cancelled my 3 day stay... probably the best news of the trip.

90% of my reason to go was to push the limits of my car. Friday (today) is pretty much open drag strip and 6 hrs of autocrossing - this is the main day for unlimited access to the strip and autocross. Saturday the drag strip is limited to classes with about 30 minutes of test/tune and then eliminations start. The autocross track is mostly open in the morning. Sunday the drag strip is closed for my class and autocross is done - only 3S is open. Even if I over-nighted the parts, it would likely be 1-3 PM Saturday before I had my car running/driving and I would have already missed the majority of the fun... and paid $430 for a repair I can easily do at home.

I was back home at 3:15 PM (Eastern Time) on Friday. I have the 88 4cyl fastback car sitting here and 2 complete 88 front suspensions under the bench. So it would be possible to just replace the lower control arm with another one and then turn around and go back to be there for all of Saturday. However, those would also be used and in unknown condition and I would feel safer having 4 new ball joints on it before I beat on the car some more. Besides nothing about this trip has gone smoothly yet and I just want to relax and stay home at this point.

Now about that ball joint... I had removed both front springs about a month ago to increase the spring rate. It was tight at that time. Before heading out for the trip, I had removed and installed all the wheels a couple of times and make it a habit to check for play, but didn't notice any play yesterday. I pulled the car to Bowling Green with a tow dolly and had the front wheels on the dolly. There was a very bad bump on the parkway where they had cut out the road and placed some 1" thick plates for the very large earth movers to cross the road, there was a sign for a "Bump" but it was early, dark, and I wasn't expecting there to be a 2" drop between the road to the plate and a 2" wall to get back to the road on the other side... so needless to say I went over it at 50ish and it was quite rough. I think that bump did in the ball joint that was likely already close to the end of its service life.

So I now have 4 new ball joints on order from Rodney and should have the LS4/F40 car back on the road before next weekend. I might even pull the trigger and do the rack bushing and all 4 tie rods as well. This might also give me a good excuse to install the poly bushing set for the front suspension that has been sitting on the shelf for over 2 years...

|

|

|

Bloozberry

|

SEP 05, 08:23 PM

|

|

|

Well that's gotta' suck. If there absolutely have to be some days of bad luck, it's amazing that they tend to fall on the days you've waited all year long for, rather than on the days when all you're doing is mowing the lawn or vacuuming the shop.

|

|

|

fieroguru

|

SEP 06, 09:44 AM

|

|

| quote | Originally posted by Bloozberry:

Well that's gotta' suck. If there absolutely have to be some days of bad luck, it's amazing that they tend to fall on the days you've waited all year long for, rather than on the days when all you're doing is mowing the lawn or vacuuming the shop. |

|

Yes, that is the way it normally works.

All told I am out the $150 for the show registration, $35.16 for the hotel and about $140 in gas there an back = $325

Had I stayed all 3 days it would have been $150 registration, $210 for hotel, $90 in food, $50 in gas for the Fiero, and either $430 for the repair, or another $140 in gas (to come back home, fix the car, and then return) = $640 min, $930 Max

Since I am $315 to the good from my planned expense for this weekend, I went ahead and ordered 4 new ball joints, all 4 tie rods, and the rack bushing from Rodney = $224, not including shipping, but also not including the 10% discount on large groups of suspension parts.

So if I am going to miss the LS Fest, I might as well get a completely rebuild front suspension for it (it already has new Koni shocks and Rodney's zero lash end links)... Then the only suspension wear items left OEM are the front wheel bearings.[This message has been edited by fieroguru (edited 09-06-2014).]

|

|

|

fieroguru

|

SEP 08, 10:08 PM

|

|

Here is a video of the play in the lower ball joint:

|

|

|

|