|

| ecotec swap (Page 88/98) |

|

wftb

|

MAR 01, 11:14 PM

|

|

|

The predicted wet weather did not arrive so I decided it was time to upgrade my tune. Since I pretty well ruined the tune chasing my tail around what was actually an exhaust piping problem I decided to start from scratch. I went through the whole tune and modded or put back to stock just about everything. It took probably about 8 hours in total work over the last couple of months. So I wrote the new tune in and took the car for a ride and was really happy with the changes. The car is smoother and feels stronger than before. I have not run a scan yet but I doubt I will have to change anything. If it is nice out tomorrow I will take it for a long ride and do a scan.

|

|

|

wftb

|

MAR 03, 08:37 PM

|

|

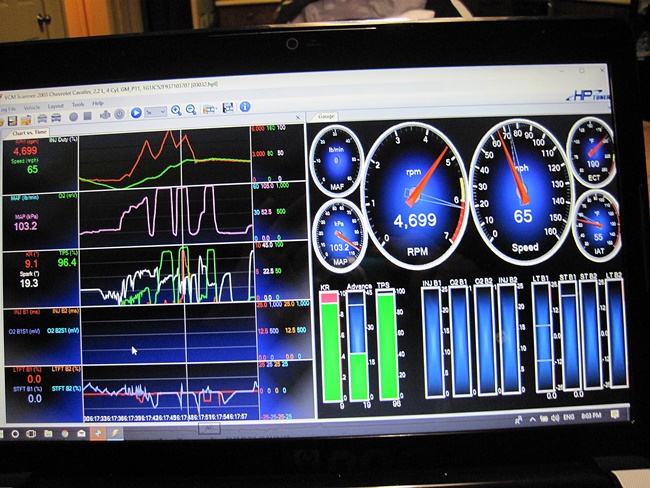

I have been driving the car a lot and everything feels good. I decided to run a scan and noticed a few things- about 9 degrees of KR in a spike around 4000 RPM in third gear with throttle wide open. And I noticed the AL piping of the charge pipe gets hot as it passes above the exhaust manifold. I was hoping the new set up would not be as warm in that area but no such luck. So I found some auto sound deadener on sale at CTC and wrapped all the AL pipe and elbow with it and then some AL foil tape and some ty wraps for good measure:

Before the wrap the max temp was 68F peak and constant no boost temp of 54F, after 61F max and 45F constant. Temperature outside today about 38F.So the insulation made a decent improvement. As for the KR spikes I really have not figured out yet. I have the water meth set to come on full at 8 PSI so I should not get any knock. Here is a screen shot of one of the spikes:

Hopefully I will straighten it out but a spike like this might have happened with the last tune. I was so happy to have 7000 RPM again I did not run a scan after. And then I took it to the track with no ill effects. The ECM computer does its job and keeps the engine in one piece in spite of all my best efforts.------------------

86 GT built 2.2 ecotec turbo

rear SLA suspension

QA1 coilovers on tube arms

|

|

|

wftb

|

MAR 05, 05:37 PM

|

|

I have been running lots of scans, researching info from a ways back on the HP tuners forum(circa 2006 to 2010, no one tunes these first gen 2.2's anymore) and I have made some good progress.It is hard to get the old info because most of the links and pasted on charts have gone missing from the old HP tuners threads. I did all my old tuning by just following along as other people tuned there cars. Ask a question about something and someone would reply with a bunch of screen shots of tables and would say copy these and it would work. But all that info is gone now.

I raised my PE (power enrich) commanded AFR to 12.5 from 11. I copied the low octane PE spark table onto the high octane PE table. I copied the low octane non PE spark table onto the high octane table. I changed my VE offset to 50% up from 40%.On one of my runs I found the water meth injection had a leak at the nozzle fitting so I fixed that. So I took out a lot of timing under boost and the biggest spike I see now is a KR of 8 degrees. That is down from 12.4 from before the changes. Most of the other spikes are less than 3 degrees. So still room for improvement but what has me wondering is why the water meth is not taking care of this.Funny thing is you would think that suddenly having 12 degrees of timing removed would cause me to feel the car bog a bit but it only shows up on the recording and not in the way the car runs. I am beginning to suspect false knock and the culprit may be my homemade poly motor mount. I had no problem with KR with the stock mount and I was running more timing then. I made the mount because the stock rubber mount wore out. I think I will take a trip to the wreckers tomorrow and pick one up.[This message has been edited by wftb (edited 03-05-2018).]

|

|

|

wftb

|

MAR 10, 03:51 PM

|

|

I bought a cavalier upper mount on wednesday but decided not to use it. The thing weighs about 10 lbs and I should have looked closer at it because it is not in the best of shape. So I started thinking of another way to do a motor mount using the friend to engine swappers everywhere, the dodge truck engine mount. Looked one up on Summit Racing and it was 4.00 and change. Cheap. Tried CTC and they wanted 12.00 and 2 days to get it. Spike's autoparts said 3.25 each and be here the next day. I bought 2 of them for less than 8 bucks. Here is one:

The plan is to cut off the top of the present mount at the top of the Y shown here (existing mount is under the intake tubing):

But I had the sawzall at the ready but decided to wait until I do a scan of my latest tune in case the KR has gone down by a lot. Of course the weather is not cooperating(4" of snow last night) so until I can get out on the road again the sawzall can stay on the shelf.

|

|

|

wftb

|

MAR 13, 07:41 PM

|

|

The weather around here continues to be bad. Getting up to 4" of snow most nights and it is not forecast to melt anytime soon. So rather than wait and do another scan I decided to go ahead and make the new motor mount. I used the cast aluminum part of the original mount as the connector to the engine block. Bolted a 1"X1" square tube to the cast part and bolted the truck mount to that tube. Welded another tube to the fiero sheet metal and drilled a hole in it to run the lower mount bolt through. I had a hard time getting a decent looking weld to this sheet metal as it is 2 layers and there is seam sealer in between the two layers that kept catching fire on me. So it looks like cr&p but I did manage to get enough decent beads to secure it. There is a brace of 1/8" flatbar welded from the tube to the sheet metal for added strength. A 3/4" OD .120 wall stainless tube braces the square tube back to the strut housing. It is welded to the stub left when I cut off the old mount. I used nothing of the old mount, it was in the wrong place for the new design. So the new mount could use a lot of prettying up(ala grinding) but it is solid.

With the cold weather and the tune I am running the engine runs pretty rough for the first minute or so. With the old mount the engine did not shake, just vibrated the whole car basically. With the new mount the engine will shake back and forth during the rough warm up period, moving about 1/4" each way. So I think the old mount was pretty much a solid mount, not enough poly in it to absorb any vibration. Hopefully that is what has been causing the bulk of my KR, but I wont know for sure till the weather turns for the better.------------------

86 GT built 2.2 ecotec turbo

rear SLA suspension

QA1 coilovers on tube arms

|

|

|

wftb

|

MAR 31, 10:26 PM

|

|

|

|

wftb

|

APR 02, 11:30 AM

|

|

|

The spray nozzle change made things worse. The Snow kit I bought came with 3 nozzles and I have been using the medium size one. The smallest one that I tried really can be best described as having a pin hole sized opening. So I put the old nozzle back in and did a long scan with a full throttle pull in second and third gear and got a max KR of 1.1. Not perfect but I can easily tune that out on the spark tables. I also did about a mile in 3rd gear at 3500 to 6500 rpm to replicate what I do on a road course (the tracks I have run on can be run in that gear without shifting) and that showed no KR at all. The knock sensor on this engine seems very sensitive, there are spots in the scan that show at steady speed in top gear a few random spikes of .5 KR. So probably a bump in the road can set it off.

|

|

|

zkhennings

|

AUG 03, 04:05 PM

|

|

I think you are negating the bumpsteer fix by tying that link to the frame, it has to be tied to the control arm directly like you used to have it. The way you have it currently will still cause bumpsteer as the link and the control arm will not take the same arc as the suspension moves.

Also after all these years have passed, what would you recommend for engine management? You are using the Cavi computer and have made some changes with HP Tuners correct? Limitations of this method include difficulty with using the stock Fiero gauges and it seems like you kept the Cavi sender as well for fuel level.

I am debating between ecotec and 3800 swap, I want a reduction in weight from the rear end though and the 3800 will not give me that, though it does seem like the simpler swap. But it would be nice to have ample room around the engine to work on everything, and both motors (L61 and L67) are similarly priced. I would need the transmission from the cavi also, but its under $200 so whatever I will just have to do some fab to get it to shift properly. I can live with an NA ecotec for a while until deciding to boost it. My uncertainties come from the wiring and engine management aspect of things, the 3800 seems very straightforwards compared to the Ecotec, but that is also because many people have done it, while you are one of the very few to have a running ecotec. What is your opinion on the engine management side of things? Stick with the stock computer and go HP tuners, or aftermarket engine management? Megasquirt is way more comprehensive than it was when you were first deciding what to go with.

Great work making such consistent progress for so long.

|

|

|

wftb

|

AUG 03, 10:12 PM

|

|

This is a link all about my bumpsteer solution. http://www.fiero.nl/forum/Forum2/HTML/134732.html . It actually works perfectly, and Mender has made his own version of it. The pivot point on the frame is the pivot point of the control arm bushings and is the mounting bolt for the control arm bushing resulting in zero measureable bumpsteer. My trip to the track showed that my tires were shot, as were all my poly joints except the rear upper control arms and springs were too light for track use. All have been changed out and I am happy with the results. I have not had time to do another track day and I am still debating about wether I really need such heavy springs. Hopefully I can fit a track day in soon.

The problems that my too small exhaust caused resulted in me making all kind of unnecesary changes to the tune. What I ended up doing to get it right after switching to a 2 1/2" exhaust was to go back to a mostly stock tune. The changes to stock tune are 50% VE offset, injector constant changed to suit 42 lb injectors, 11 PE , and PE enable at 2500 RPM and some other stuff that I can't remember now. I last played with the tune in early May and have been driving the car almost every day and there is nothing that needs changing.

I like using the stock cavi management system with HP tuners but the 2004 system I have does have its drawbacks. It is a MAP only system and only has a 1 bar MAP. When I did this swap it was all that was available. I think it works great for me but I would recommend going with something from a 2007 Cobalt. Still tuneable with HP tuners but a better system overall. Buy a whole car and take what you need and sell the rest. Cobalts are dirt cheap. If you follow member Lunatic's thread he is solving the problems of making it all work with Fiero guages. I use a cavalier guage cluster.

I decided early on that I did not want the weight of a 3800. I wanted a handling car and you need a lighter motor to do that. If you follow the Fiero LeMons/Chump car threads and watch the videos you will see all of the v6 powered cars spinning out from time to time. My car does not do that, it is completely neutral. As I hit the limit, all four tires will slide but the rear will not slide out nor does the front plow. You just end up taking a wider arc that can be easily corrected by dropping the throttle or a tap on the brakes.

By accident, my engine and transmission sit very low in the chassis. If you compare the engine bay pics of mine versus other ecotecs you can see this. I cannot lower the rear of my car any more than it is because the passenger axle will hit the transmission. I do not know if this contributes more to the chassis neutrality than the lower engine weight but it must help a lot.

As far as stand alone systems, I think they are great but I have not found one for the 500.00 price tag that I would be willing to pay. I have a Megasquirt setup designed for the ecotec by member Fosgate Cavvy but I have never tried it out.

Sorry for being so long winded but I have not posted in a while. Thanks for your post.[This message has been edited by wftb (edited 08-04-2018).]

|

|

|

KillerFrogg

|

AUG 07, 11:14 AM

|

|

This post turned out way longer than I thought it would. Abridged version. 2.2 works but has quirks. Other ecotechs are easier with aftermarket computers but are a bit more rare. Aftermarket computers are easier to work with and more flexible in most cases but expensive.

One of the biggest hurdles for most people to get over doing an Ecotech is the computer. A huge part of that is that the older 2.2s that are super cheap and common have an.. interesting ignition system. Is is based off of technology Saab developed in the 80's and continued to develop through till GM bought the company. Long story short, the ignition coil/cassette in the cam cover does a bunch of science with the sparkplugs and can figure out where the cams are, and this is the important thing, without a traditional cam sensor. The drawback is that this only works with engines with fixed cam timing. The later engines with variable can not use the old system as it can only get cam timing if the cam is in a fixed phase relative to the crank, as such they have a cam sensor on each cam. BUT WAIT THERE IS MORE. There is an odd ball in the family that works different, and that is good for us.

I am unsure if the megasquirt or other computers supports this ignition system and the features is provides. Like per cylinder knock detection, misfire detection, and ignition quality data.

The odd ball I mentioned is the supercharged LSJ in the first gen SS Cobalt. It has no variable valve timing. But uses standard coil on plug. No cassette like the 2.2s before it. It is heavily based on the LK9, a turbo 2.0 and only put into the Saab 9-3. Lots of parts on the Cobalt engine even retain the Saab casting marks. The Saab, being who they are, used their own tech still that didn't need a standard cam sensor but it was in a coil igniter box in the wiring loom.

When GM replaced the Saab turbo setup on the engine for a supercharger, they removed the cam driven brake booster vacuum pump. And in it's place they made a bolt cam trigger wheel and pickup. Standard 2 small and 2 big teeth pattern they use on other engines and later Ecotech engines.

What does all of this mean? The LSJ is a much easier engine to run with aftermarket computers than the early 2.2s. Also, the Saab LK9 engines are all over in junkyards, with factory manual option, and unlike the Cobalt can be found with the F40 6speeds. And all that is needed to run that engine is to get the cam sensor and coils from an LSJ.

I am doing an LK9 swap in my car. I got lucky and found an f40 equiped 2007 Saab in a pick n' pull. $280 for the engine + trans. Ebay for the Cobalt cam sensor and some other parts (the S/C intake manifold has a built in water/air intercooler) I will be using a Haltech Elite 1500 to run the engine. Yeah. It's $1,800 for the computer and a generic wiring harness. But it will run the original dash. And the software is 100% free with no restrictions at all.

http://www.fiero.nl/forum/F...141093.html#lastpost

|

|

|

|