|

| ecotec swap (Page 83/98) |

|

wftb

|

AUG 25, 02:19 PM

|

|

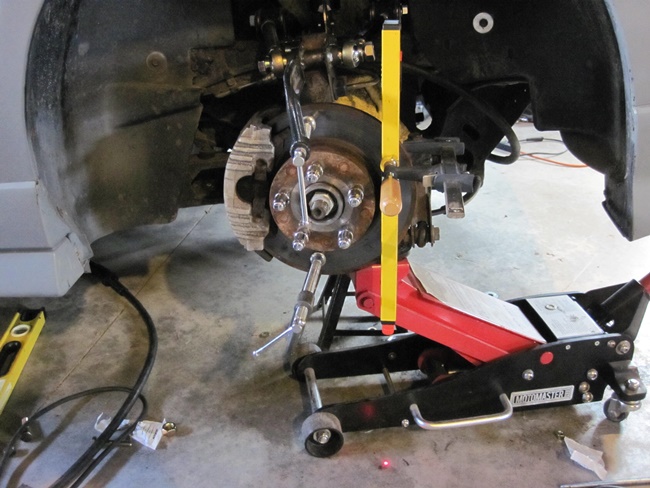

The new upper arms will sit in this general vicinity:

I was hoping to weld the tabs in place without carving off the old arm mounts but no such luck. And the bolts I have are 1/2" too short so I cannot do anymore til they come in.

I could not get a decent shot of the clearance between the wheel and the rod ends but there is about 1/4" at the closest point.

Got some stainless tube today to try to get rid of the rubber lines around the turbo. A little heavier than I wanted but I can still put a bump in it with this tool I got from Earls'.

|

|

|

wftb

|

SEP 06, 11:05 PM

|

|

I have been doing a lot of work trying to make a new upper arm setup and basically my idea to use rod ends and adjustable upper arms with the pivot on the other side of the strut stub did not work out. Using this setup I found that the wheel would be moving forward as it moved up in to the wheel well and the camber gain was going the wrong way as well.

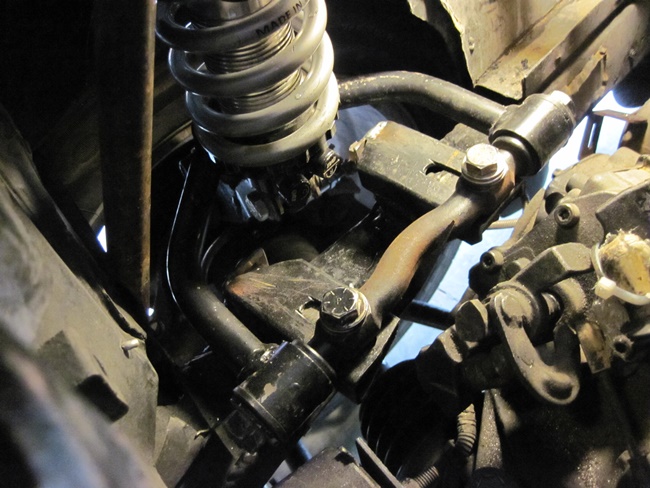

One nice thing about all this experimenting is that I did not have to hack up any of the old suspension pieces so when I decided to take a step back all I had to do was weld the old mounts back in place and bolt it back together. I got rid of the stack of washers you can see below by adding another 1" X 2" channel on top of the old mount:

The main reason I wanted to change to a new arm setup was for ease of adjustability. Taking the wheels off and putting them back on while the car is on the alignment rack is time and money consuming. The arms are bolted to a 1/4" thick piece of steel flat bar with a 1/2" grade 8 nut welded to it that can slide back and forth inside the arm mount channel. I made an adjuster that can slide the flat bar back and forth inside the channel. This is it:

So now to change the camber setting I just loosen the upper arm mounting bolts and crawl under the car with a 9/16 wrench and move the arm where ever it needs to go. I dont even need to jack the car up to do this. This is not a good picture of the adjuster welded in place but here it is:

The other thing this allows me to do is adjust the angle of the inner arm mounting axle (cant remember what it is called ) to get it to perfectly match that of the lower arm. And I am quite happy to retain the upper ball joint and not have to deal with the extra maintenance of the rod ends. Not too happy about all the money I have spent on the parts I am not going to use, but I have learned a lot and in the end have made a big improvement.

|

|

|

wftb

|

SEP 08, 06:16 PM

|

|

More pics:

|

|

|

wftb

|

OCT 10, 09:50 PM

|

|

The rear suspension is all finished now and I am quite happy with it. It has all the adjustability that I was after, no bumpsteer and has a solid feel to it on the road. The only drawback to it is that I cannot fit anything wider than a 245 with my 16" rims. I am an avid reader of car magazines and I always look at road tests and spec sheets. This has made me conclude that a car like mine that weighs in at around 2700 lbs simply does not need any wider tires to pull high g forces in a corner. For example, the new Civic Type R weighs 3100lbs and pulls 1.02 G on a skid pad and wears 245/30ZR-20 tires. Front engine front wheel drive vehicle. So I picked up a pair of BFG g-force comp 2 AS in 245/50/16 size. This is a relatively new tire and the Discount tire dealer(in Elkhart IN on our way back from CO camping) I bought them from had been on a track with them and liked them better than the summer version. He did not have the 205/50/16 size in stock I wanted for the fronts but I found a decent price for those from Costco but they had to be ordered and takes 6-10 days.

The wear on my front tires was minimal, for driving on the street they probably would last another 4 years or so but for track use they seemed to have gotten rock hard, not much bite there anymore.

While waiting for the tires I decided to do some mods to the front upper control arms. I have never been able to get the negative camber on the front I wanted and for a long time I have had some Del-a Lum delrin/aluminum bushings machined up and ready to use for control arms. One problem with the front UCA's on the car now is that they are too long. Even with slotted ball joints and slots in the arms, I could not get the negative camber I was after. I cut off the old poly bushing holder, shortened the arms 1/4" and welded the new bushings on. While I was at it I spaced the bushings the same both sides so they would have the same castor correcting another problem that they came with.

.JPG)

A funny thing about the specs for the 84-87 fiero is the stock front camber of positive .5 degrees. Totally backwards from what you want on a track day car. With my dial guage at home I thought I was sitting at -1.5 degrees but it came out to -.5 degrees on the rack. I have room to get more but decided to leave it as is rather than pull the wheels off and spend more money at the shop. Still a big negative gain from where it was. At the rear I now have 1.6 degrees negative camber on both sides. Caster is now 3.3 on the right and 3.6 on the left close enough for me. Toe was set to stock for 84-87. Last time we set the toe to 88 specs because I had read that Pontiac changed all fieros to those specs and I did not like the results at all. For those of you that have had a recent alignment to an 84-87 and it feels a bit squirelly on the highway, that might be why.

Drove it home and it is the best it has ever been. The improvement in turn in is night and day compared to before. And I am still on the old front tires. Definitely my old poly bushings on the UCA's had gotten soft.[This message has been edited by wftb (edited 10-11-2017).]

|

|

|

La fiera

|

OCT 11, 09:47 AM

|

|

|

Very inspiring!! have you weight the car? Keep the good work!!

|

|

|

wftb

|

OCT 11, 10:49 AM

|

|

|

Last time I weighed the car it came in at 2790 lbs but I have since put stock rear brakes back on and gotten rid of the muffler and some extra exhaust piping . So I think it is pretty close to 2700 now. I run the turbo and the cat and a single exhaust outlet and it is farly quiet except when you run the revs up. Thanks for the reply.

|

|

|

La fiera

|

OCT 11, 11:39 AM

|

|

| quote | Originally posted by wftb:

Last time I weighed the car it came in at 2790 lbs but I have since put stock rear brakes back on and gotten rid of the muffler and some extra exhaust piping . So I think it is pretty close to 2700 now. I run the turbo and the cat and a single exhaust outlet and it is farly quiet except when you run the revs up. Thanks for the reply. |

|

Nice!!! I love what you did with the suspension. Have you dyno it yet? I love what you did with the suspension. Have you dyno it yet?

|

|

|

wftb

|

OCT 11, 12:51 PM

|

|

|

I live about 100 miles from the nearest dyno so I have never been able to dyno the engine. I used to really want to but now I don't care. It is plenty fast enough for my needs and it revs reliably to 7000 rpm so I am happy. If I ever stumble across a dyno at a car show it would be fun to put it on and see what it does put out though.

|

|

|

wftb

|

OCT 11, 12:53 PM

|

|

|

I also have been watching your thread. Very nice will certainly look awesome when it is in your car.

|

|

|

La fiera

|

OCT 11, 02:38 PM

|

|

| quote | Originally posted by wftb:

I also have been watching your thread. Very nice will certainly look awesome when it is in your car. |

|

That sucks that your brand new motor failed!! But that's part of the learning curve. Same thing happened

to me, put too much timing by mistake and killed a rod bearing

But I'm glad you are enjoying your car! I'm going to the track this coming month to

shake down the car. I'll make sure I can get some in car footage.

Keep up the good work!!

|

|

|