|

| Trinten's SBC/F23 build - The work has begun! (Page 74/76) |

|

I Lean

|

JUN 06, 02:46 PM

|

|

| quote | Originally posted by Trinten:

I think I either typed something incorrect in my post, or maybe in a bad way to convey the right information. That is what happens. Key on, engine off, the warning light is on, needle at 0. Engine starts, the needle buries itself (and the light shuts off, of course).

I appreciate you reading and commenting, just the same. If I'm still not getting what you're saying, please let me know. Thanks! |

|

That is what I understand is happening. What I'm suggesting to do, is to test the gauge by taking the sender out of the equation, and just ground the wire to the block.

|

|

|

Trinten

|

JUN 06, 10:53 PM

|

|

Okay cool. Thank you for the clarification. I'm sorry it didn't click before.

The weather is supposed to be crap this weekend, so it will need to wait till next weekend (weather permitting!). I will try it out. Thanks!

|

|

|

Trinten

|

JUN 20, 12:02 AM

|

|

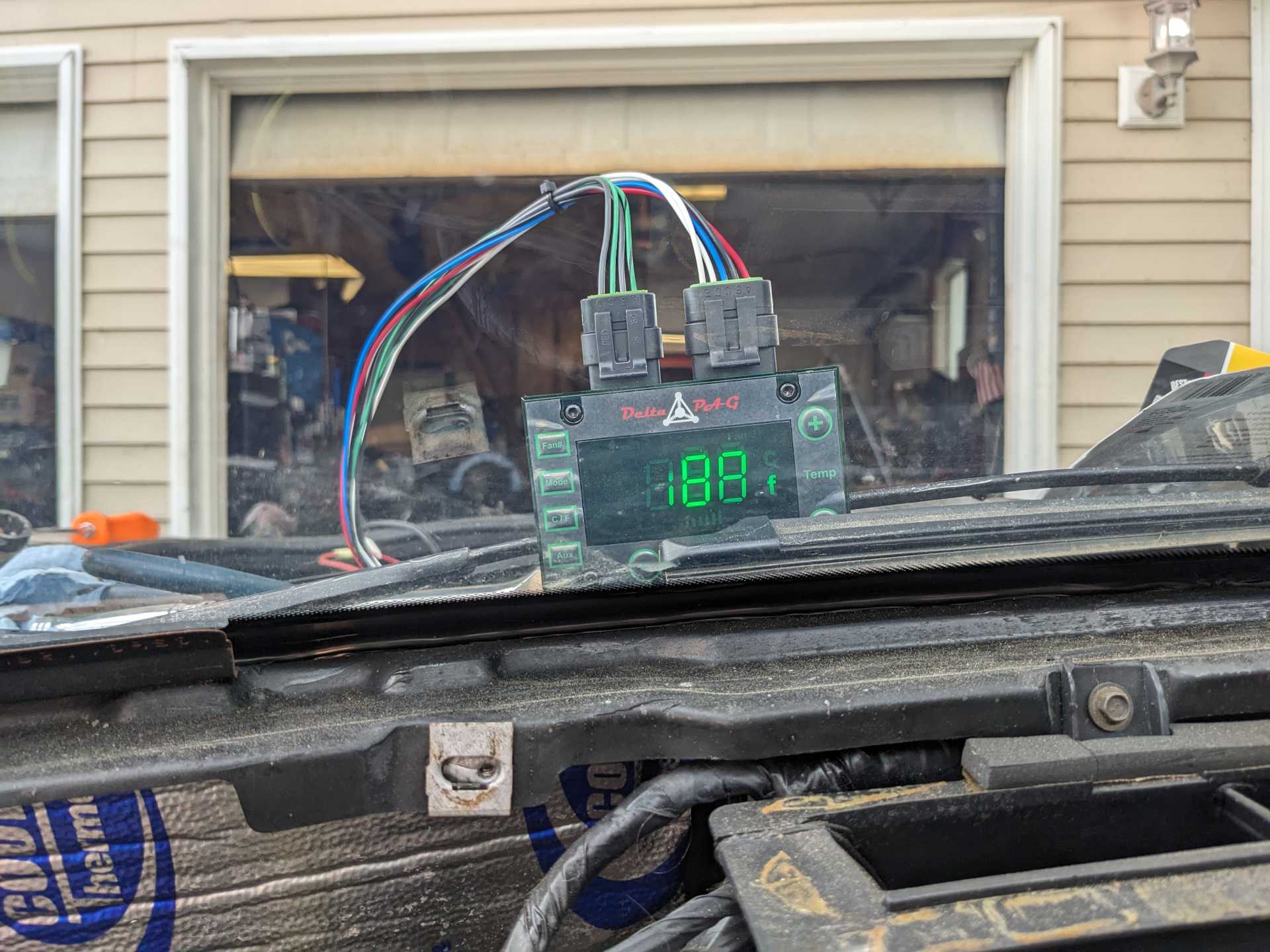

My Delta PAG 18" fan arrived. It's very nice. They did a great job with labeling and wire organization.

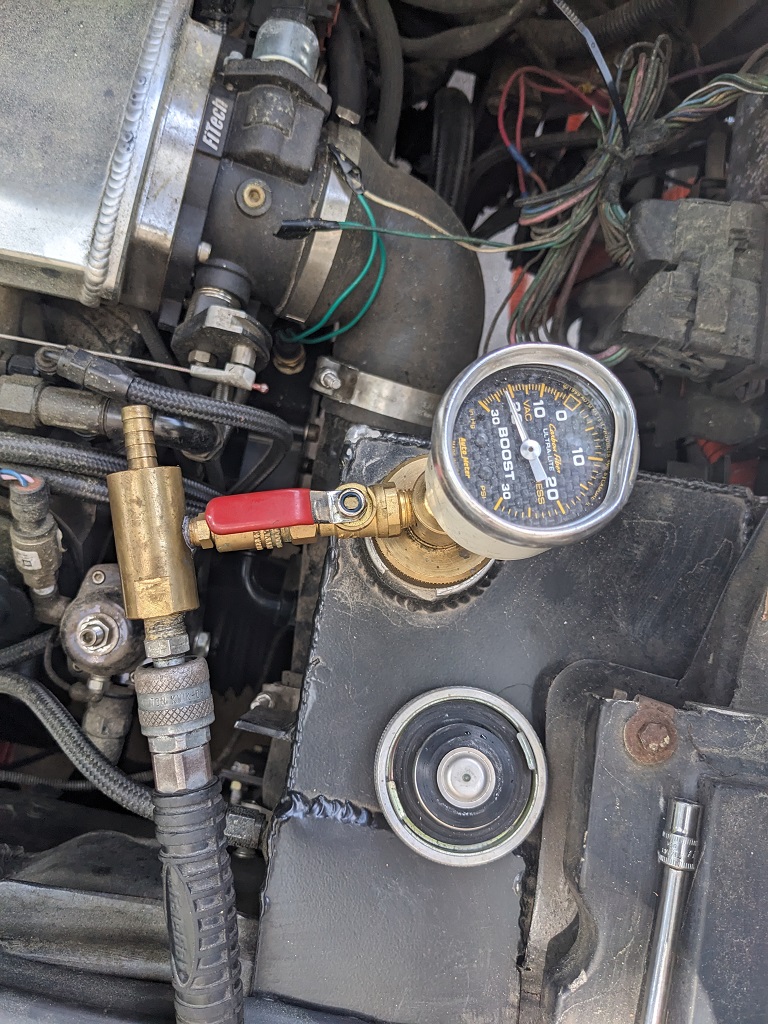

Mike took a piece of aluminum tube to replace part of the radiator hose going to the intake, so we could plumb in the sensor for the fans controller. This also gave us a great chance to look at temp differences and the odd behavior we saw with temps dropping rapidly just by going to Key on, Engine Off.

Good news, my messing with the tune and throttle adjustment screw is paying off, car is starting much easier now! When it warms up it's sitting around 1100-1200, a little high, but I'll take it for now.

Sadly, even with this fan, the temps gradually climbed, just from the car sitting at idle. It took a solid 20 minutes in 85 degree (Fahrenheit) temps to crawl up to 220, when I shut it down.

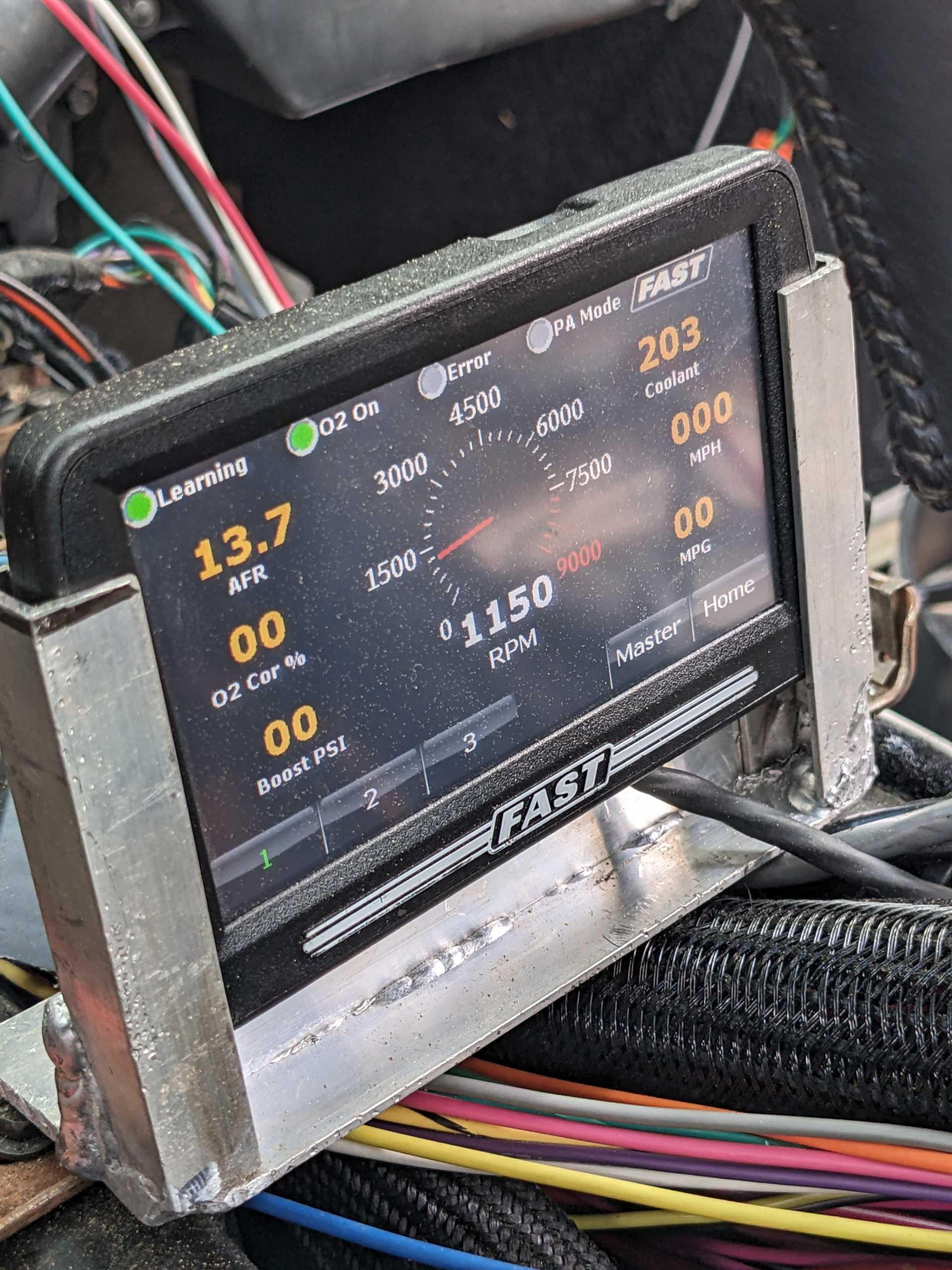

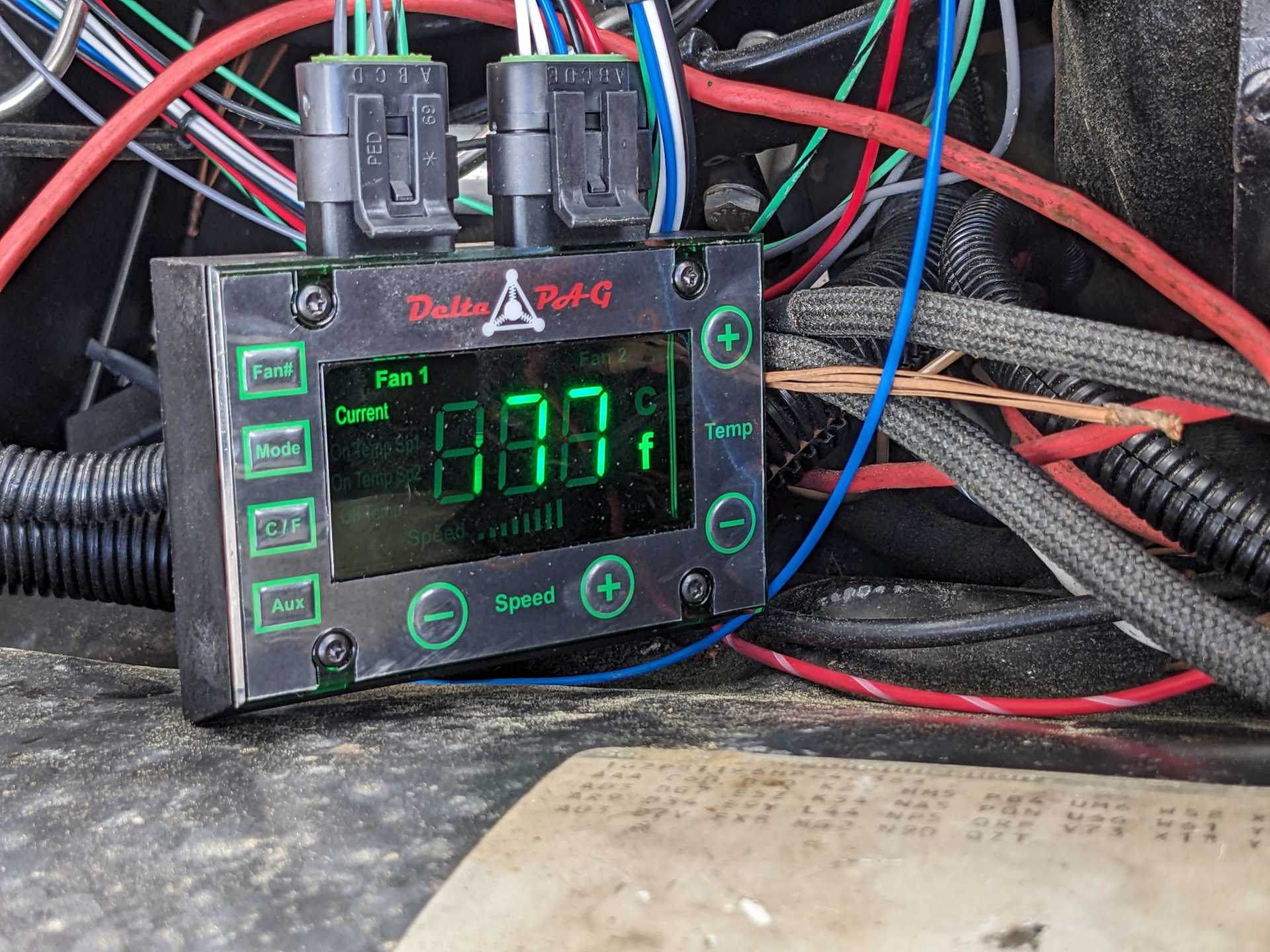

When we first started it up, the delta between the water temp sensor in the intake (stock LS4 sensor) and the fan's sensor in the radiator was about 4 degrees. Makes sense with the metal tube running under the car. As the engine temp climbed, the delta grew. Here's some pictures, grouped together. What the FAST saw first, then what the fan probe saw.

So you can see the FAST was seeing 203 at this point, but the fan probe only saw 177. A 16 degree difference seems pretty crazy.

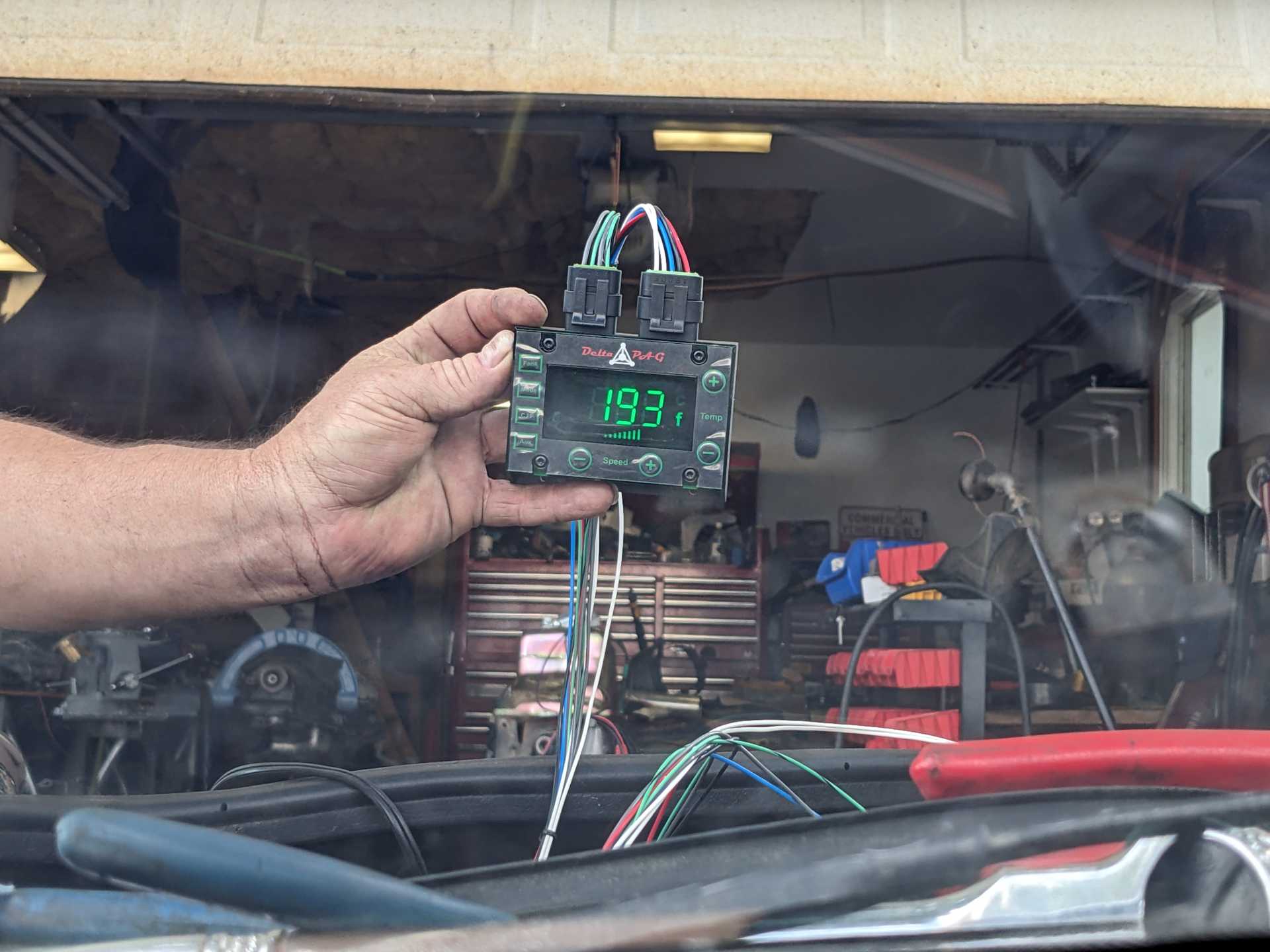

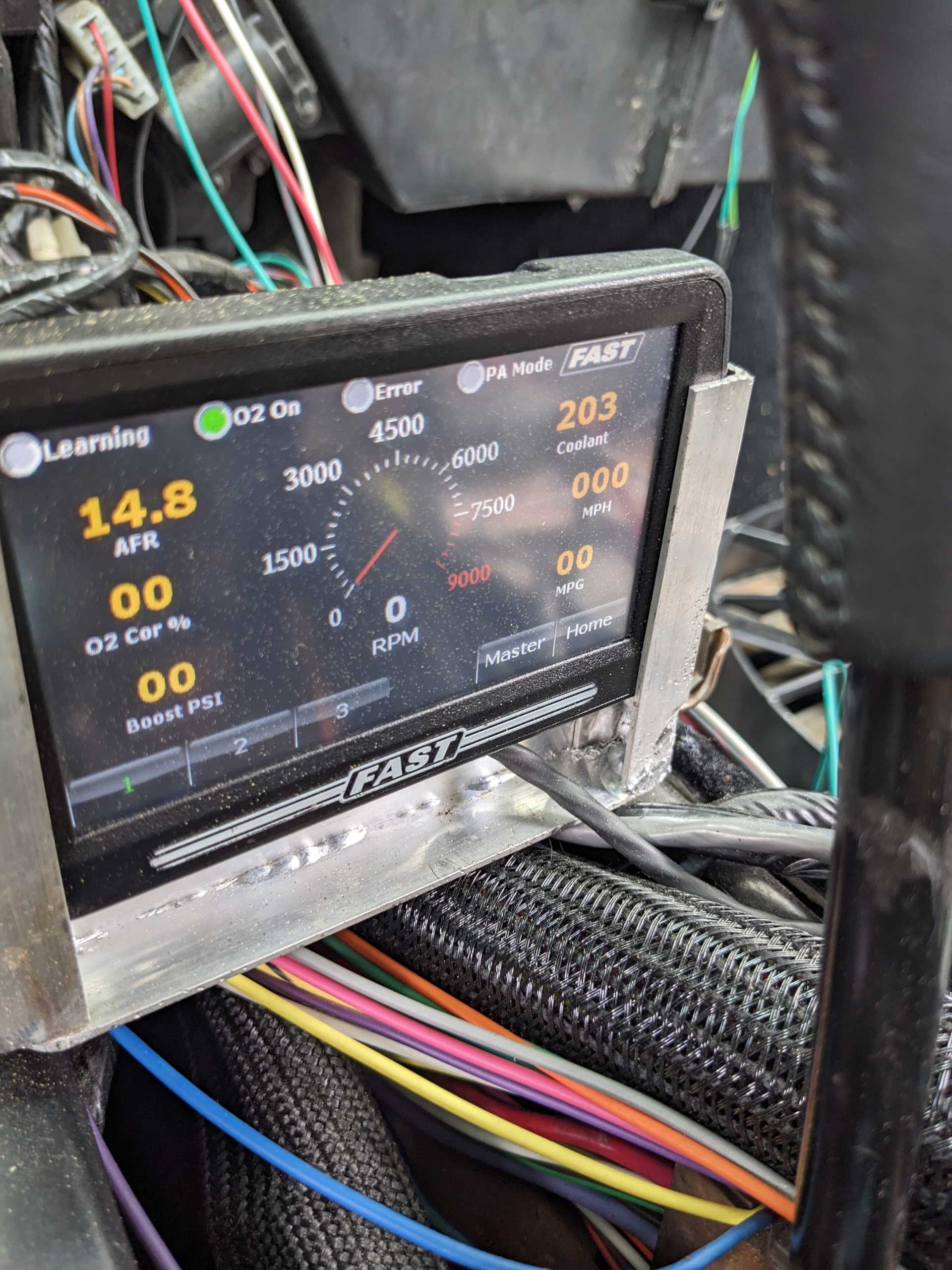

Then:

While the FAST was seeing a temp of 216, the fan probe was seeing 193. The delta grew from 16 to 23.

When the FAST saw a temp of 220, I cut the engine but left it at Accessory. The FAST temp dropped IMMEDIATELY to 203. The fan probe was at 188. So the delta shrank to 15 degrees.

Mike wants to replace the coolant temp sensor in the intake, which makes sense, but the overheating issue doesn't make sense. When the radiator intake hose is disconnected, that electric pump is GUSHING water out -- this was an accident, but it came out in a strong jet, lost about a gallon of coolant in the few seconds to go 'oh crap!' and turn the key off completely.

It's baffling and frustrating. At idle, the engine is not putting out any crazy horsepower, not at 1100-1200 RPMs. This radiator and fan should be keeping up with it. Given the force at which water expelled, I don't think we have any obstructions anywhere. If anyone has any thoughts, please let me know.

Also, if those pictures are gigantic, I'll resize and re-upload them. Just let me know.[This message has been edited by Trinten (edited 06-20-2025).]

|

|

|

fieroguru

|

JUN 20, 07:05 AM

|

|

Vince, it is expected for the temps between the sensor in the front head (that is the stock location for the LS4) and one up by the radiator would be different. I wouldn't spend much time focused on that.

The coolant temp dropping/changing with the engine off or on, likely means one of two things:

1. When the engine is off, the water is falling away from the sensor. If it is in the stock head location, then likely means air is getting in the system. If the sensor is not in the head, then I would move it back to that location.

2. Potential ground issue between the ECM and the engine. The temp sensor should have a dedicated ground back to the ecm to avoid reading changes based on loads from other devices. If it is it grounded to the engine, then additional electrical loads could be messing with the reading when the engine is runnng.

|

|

|

Trinten

|

JUN 20, 12:41 PM

|

|

Thanks Paul,

I think what threw me off is the growing difference of what the engine temp was and what the sensor at the intake tube to the radiator was seeing.

I believe Mike said the engine temp sensor was in the stock location, I'll confirm tomorrow. If that is the case, do you think that we still have a nasty air pocket that isn't getting out from the vacuum fill and the steam ports (which run to a surge tank)?

|

|

|

fieroguru

|

JUN 21, 09:48 AM

|

|

| quote | Originally posted by Trinten:

Thanks Paul,

I think what threw me off is the growing difference of what the engine temp was and what the sensor at the intake tube to the radiator was seeing.

I believe Mike said the engine temp sensor was in the stock location, I'll confirm tomorrow. If that is the case, do you think that we still have a nasty air pocket that isn't getting out from the vacuum fill and the steam ports (which run to a surge tank)?

|

|

Vince, the other thing to keep in mind is that heat transfer from the coolant passing through the coolant tube is dependent on the difference in temperatures from the ambient air and the coolant temps. So as coolant temps increase, there will be more heat transfer, so the difference in temps between the two sensors separated by the coolant tube would not be constant. After the car has sat for a week, the water coolant should be equalized, key on to see how different they are when you know the water temp is the same. If they are different then I would start checking resistance on the grounds between the two.

The FAST sensor should not have a significant change with engine running or just the key ON.

As we have discussed in email before, I am not a fan of rear mounted coolant surge tanks. Any hoses from your engine coolant fill point and the head steam line(s), need to go to the bottom of the surge tank, the surge tank should be higher than the coolant level of the engine, the surge tank can never go empty, and the surge tank should be pressurized (as the steam lines are free flowing), or you will pull air back into the coolant system and cause issues air pocket issues.

What is your idle speed and timing?

|

|

|

La fiera

|

JUN 21, 09:26 PM

|

|

What radiator cap pressure are you using? 220F is boiling at atmospheric pressure. The more pressure you run in the system the higher the engine can run on temperature without boiling the coolant medium. Are you using any cooling additives? Coolant is designed to retain heat not to disperse it. Water is the best cooling agent but you must add additive to protect the engine parts from rusting. I personally run this product.

Also, I know you were running the BMW water pump with the Tecomotive controller. Did you change to a Davis? The way your temps climb I believe you have air in your system and/or the system is not slowing the coolant enough for the radiator to get rid off the heat and send it back to the engine. If the pump is installed higher than the radiator it will cavitate and carry those air bubbles through the system creating havoc.

|

|

|

Trinten

|

JUN 22, 02:52 PM

|

|

Thanks guys.

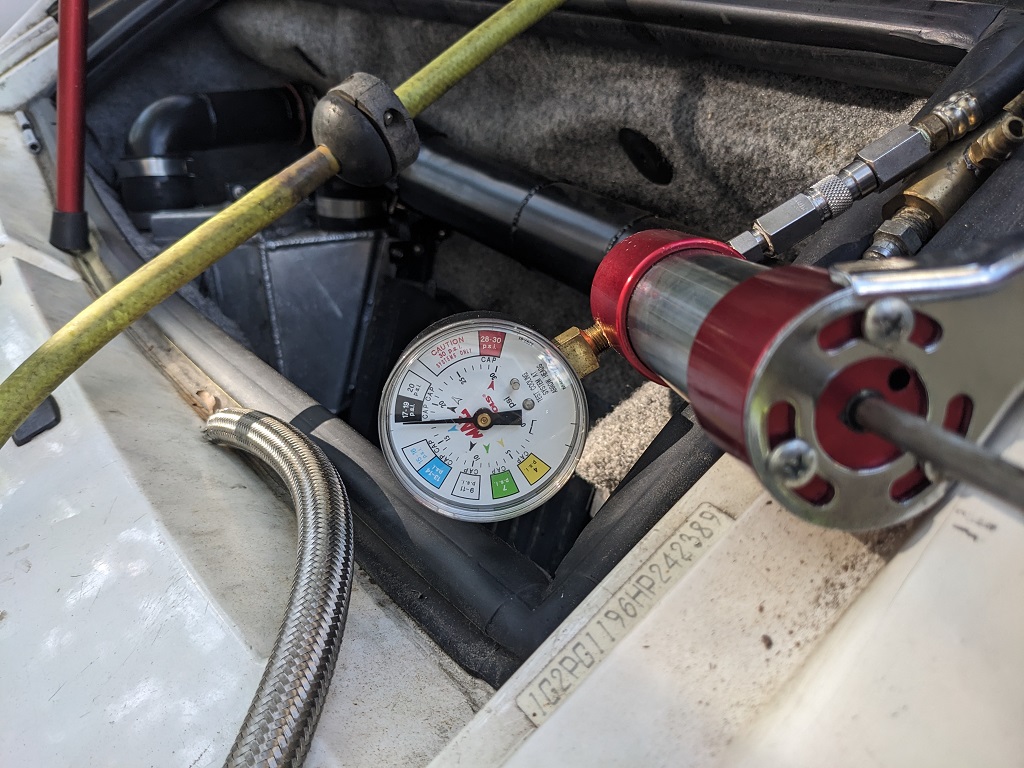

The surge tank should be the highest point for coolant. That's where Mike hooks up this device that pulls vacuum to -20psi, then the system sucks in coolant from a reservoir. We then top it off from the surge tank. Before flipping the fill lever, it does hold vacuum.

When everything is cold, Key-On-Engine-Off the coolant temps between the two sensors is zero to 1 degree.

Coolant is in the surge tank (about half-way filled) when everything is off and cold.

The surge tank has a radiator cap on it, it's 16 PS (Canton Racing part number 81-116). Could that PSI be too low?

I *think* if we moved the surge tank to the front, it would be even lower than where it's at now (you'll see some pics of it by happenstance in the pictures below).

We switched to the Davies because after talking with Tecomotive and a few other people, they agreed the BMW pump I had was not sufficient, and pointed out how BMW guys that start modding their engines try to shoehorn in the next step-up of the BMW pump. Unfortunately that pump is not commonly available like the one I had, and it was more expensive than the Davies pump (by a considerable amount. Plus the Davies pump doesn't need a controller of any kind, so we switched to it. It does mean I still need to worry about the pump dying and not having an immediate replacement, but I'll buy another to keep in the car before going on any long trips.

I did add a bottle of surfactant (Water Wetter) to the coolant when we filled the system last year.

I asked Mike if it's possible if any obstruction could be in one of the channels in the engine (like a Mudgobber that got in there before we closed it up), he said it's unlikely, and given that we haven't warped either head or blew out a head gasket, and coolant flow seems good, he doesn't think that's an issue.

I'm going to see if anyone has a good thermal camera I can borrow, so we can check for unusual hot or cold spots.

This past weekend Mike was fixing lights, wiring, and PM on hubs/brakes on a used trailer he bought that he's using next weekend, so we just worked on mounting the exhaust fan on the unpainted decklid vent I bought from the Fiero store.

In the end we went with my original idea, which Mike wasn't thrilled with, which is to run bolts through the 'fins'. He wanted to weld in some better brackets. He took the vent and sanded off the bronze-ish coating off of one of the rivet stubs, beveled it, and tried to fill it with weld. The metal was not happy. It just sort of melted. He figures the alloy they used is basically junk "pot metal" which has a low melting point and is great for mass producing non-structural metal parts.

When he started to drill out the holes for me, the metal just flaked off, it never generated any 'strands' like you see with aluminum or steel. Flaking metal is another sign of it being pot metal.

So I used some stainless button head bolts and nuts for test fitting. The nuts I had handy were nylon lock nuts, so they need to be swapped out.

Then I did a final test fit. Everything clears!

Here's some underside shots, where you can see the clearance of the fan, and the surge tank in the foreground.

|

|

|

Trinten

|

JUL 14, 10:17 PM

|

|

I snagged a great deal on a FLIR One Pro camera for Android. They run about 400 new, I got it for 160 on ebay. I was a little concerned, but it showed up and works great. The purpose of it is to try to find out if there's any unusual hot or cold spots in the coolant system. This camera has software specifically for this kind of stuff, and has two lenses so it can 'outline' objects to make them easier to differentiate on the captures. You can adjust the visual thermal range, mark multiple points, it's neat.

And I walked out of the house without it on Saturday. D'oh!

Without much else to do, I informed Mike that the consensus was we had a vacuum/pressure leak someplace. While we had used the vacuum tool he has to fill the system once before and it held vacuum, he couldn't rule it out since we had put in a new pipe for the temp sensor for the new fan. After he finished a little prep work on his trailer for one of those drag-and-drive-week competitions, we drained the coolant from the Fiero (used the plugs on each tube under the car, then the drain on the radiator).

He hooked up his vacuum to the surge tank, it pulled 20+ lbs of vacuum annnnd.... we heard burbling. This was new. We waited. Kept burbling. He pulled vacuum again. Still happening, so he went around and tightened up all the hose clamps. The burbling / vacuum drop slowed, but did not stop.

I asked what next. He said "I pull vacuum again, we use the port to fill it, then we pressurize the system and find the leak."

Here's the pressure device setup, pressure applied.

Thankfully, the only leak we found was right there at the AN drain fitting on the surge tank. We still left it hooked up for 15 minutes or so to make sure there were no other leaks.

Mike inspected the hose and fitting and found the leak was not coming from the mating, but from where the AN fitting goes onto the hose. So he made a new hose. We re-presurrized the system, no more leaks.

He hooked up his vacuum system to it again and started pulling vacuum very slowly, he didn't want it to start ripping coolant out, since we had only lost the little bit out of the surge tank and it's return to the upper port on the water manifold.

It pulled to 20+ lbs of vacuum, and we waited... we cleaned up tools, talked about work, bourbon, life in general. 20+ minutes later...

So you see the port? That part pops off, and there's another one that clicks in with a second lever and another barbed port That's where the hose hooks up to put into the fluid you want the system to pull in by the vacuum. So we hooked the hose up, put it in a 5 gallon jug of coolant, and slowly opened up the port. I didn't get a shot of it setup with the filler hose clipped to the gauge/base.

Once it was done, the system was about as full as it can get

Optimistically, I jumped in the car and started it up... trunk was open (exhaust / puller fan is not wired up yet). Temps gradually climbed... it hit 175, the new fan kicked on full. The temp climb slowed. ... but still climbed. And climbed...

The time difference between now and before for it to hit 230+ was about the same, the outside temp was in the low 90s, so only a few degrees warmer than when we first tested the new fan.

We did the key on / engine off test again, and the FAST temp sensor (the one in the passenger side head) immediately did it's weird drop. (the fan temp sensor was still reading around 218, so about the same delta at higher temps as before). Here's a video of it.

https://drive.google.com/fi.../view?usp=drive_link

Hopefully that opens okay for everyone. You can see it go from 233 to 206 in a few seconds.

Hopefully the FLIR will give me some insights into what's going on. If it doesn't... well, I guess I'll keep throwing parts at it. Maybe I'll get another CSR pump, which I had on my last Fiero and did great (it's currently trying to pump the intercooler coolant, but the pump is wearing out. We saw some chips in the vanes). At just idle, the radiator should be keeping up, even if it's undersized for operational use.

I did lookup and found some guys with the Pontiac GXPs did see around 215 when idling, but that was the outlier of the comments. Most said they saw normal operation around 220 when driving, and 199-210 when idling.

This hangup is really sapping my motivation. And I don't mind throwing money at my car, but damn, I like it to have a net positive effect.[This message has been edited by Trinten (edited 07-14-2025).]

|

|

|

La fiera

|

JUL 20, 10:21 PM

|

|

|

Just out of curiosity, how do you know you have the right amount of ignition timing taking into consideration the camshaft that you are using. Could it be possible ignition is on the retarded side causing higher temps on the exhaust and that heat can't get dissipated fast enough due to the amount of retarding of ignition? The more the ignition timing is retarded, the more heat you put on the exhaust valve water jacket area.

|

|

|

|