|

| LS4 / F40 swap - fieroguru (Page 71/216) |

|

DPoppelll

|

MAR 15, 08:10 PM

|

|

| quote | Originally posted by dobey:

... if one wants to build a circuit themselves though. |

|

It would be a cool personal mod though.

|

|

|

fieroguru

|

MAR 16, 07:39 PM

|

|

I machined a set of 84-87 front hubs for another PFF'r this morning, then set to work doing more to the LS4 car.

If you don't fully seat a plug wire on these newer ignition systems, they will melt the plug boot...

So I used purchased another set of plug wires and cut a new replacement (and put 7 more spares on the shelf in case I do it again!).

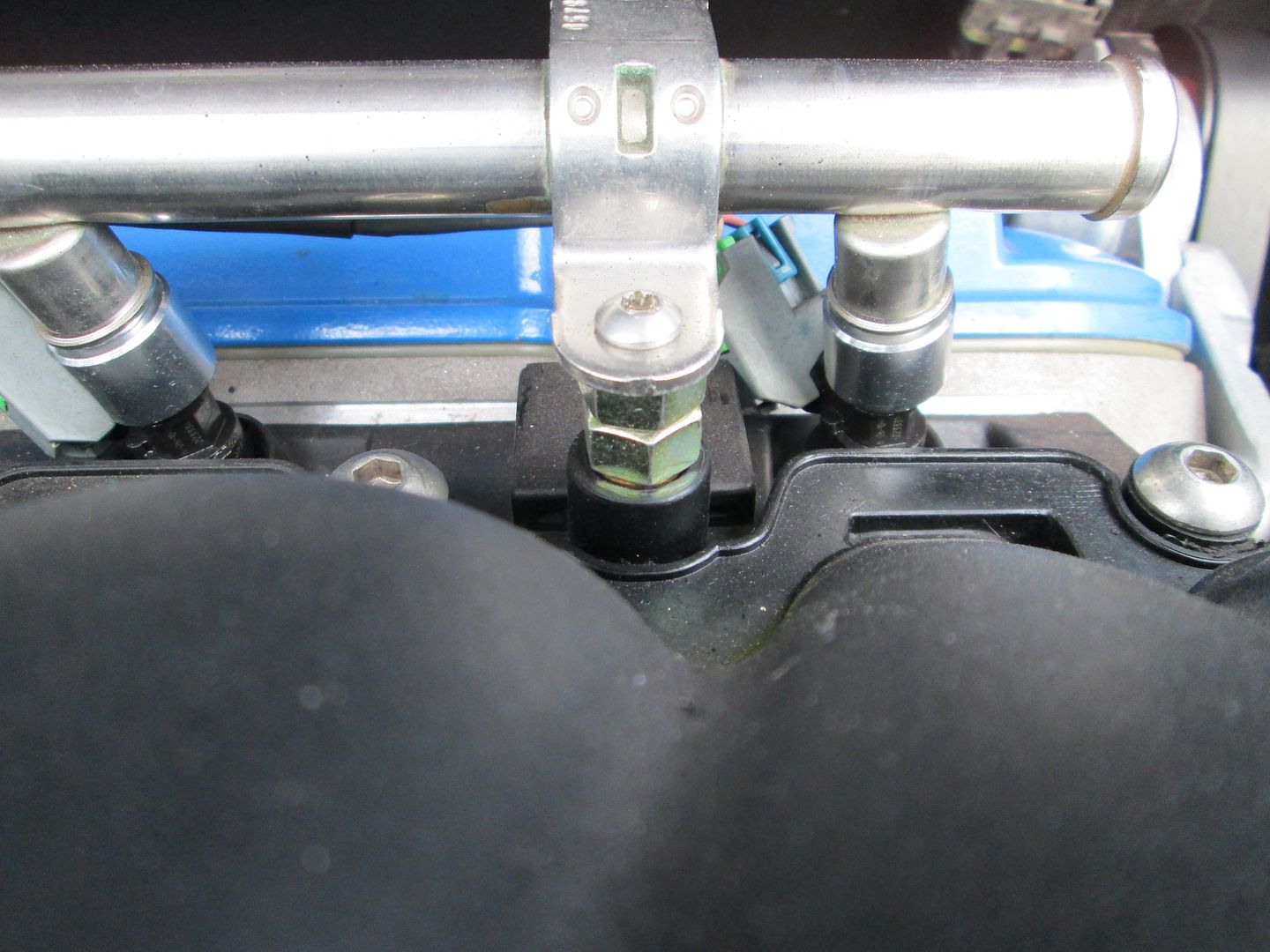

Since I have changed the MAF, TB, Intake, Injectors, Camshaft, Exhaust manifolds... getting everything dialed in will be a chore. Based on the advice of the other LS4 guy running the came camshaft, I installed the stock LS4 injectors/fuel rail to remove 1 variable as I dial in the idle and MAF calibration. I got some injector spacers off ebay for $49 and use a couple of 3/8" nuts as spacers under the fuel rail... pretty easy swap, but I won't been keeping these parts on long...

I have been using some of the information in this thread to help dial in the idle:

http://www.hptuners.com/for...ght=real+time+tuning

This is for a Gen 3 car, but most of the info/theory relates to the Gen 4's as well. The first round of logging the Base Running Air Flow and the subsequent table revisions made a vast improvement in the idle quality at 800 rpm. I will come back and do this again once I have the MAF more dialed in. I took the car out for a drive/log after the idle work and it has a lot more torque right off idle.

I had to make a .1V adjustment to the wide band signal (logged through the fuel tank pressure 0-5V input) to line it up with the narrow band. Over a sample of 35000 data points (after all the P/E data was filtered out), the average commanded A/F ratio of 14.68 resulted in an average wide band value of 14.66. I will continue to check this comparison as I get everything dialed as it might need another minor tweak.

One thing to note, HP Tuners has a built in histogram functions to help determine the needed changes from the log data, but they don't exclude the transient "noise" from the data set. So like I did when tuning OBD1, I dump the log data to an excel file I created. The file filters the data and only uses the data if the TPS sensor value is within +/-1% of the 10 sample average (5 in front, 5 behind). This should greatly reduce any transient noise. From there the file has multiple sheets with lookup tables, pivots, and other features. So you paste in the tables (MAF, Airflow, Timing, etc), paste in the data log, refresh the pivots and then you can copy/paste the new updated tables back into HP tuners. My method takes longer vs. using the histograms, but I think my method is more precise...

|

|

|

fieroguru

|

MAR 18, 06:55 PM

|

|

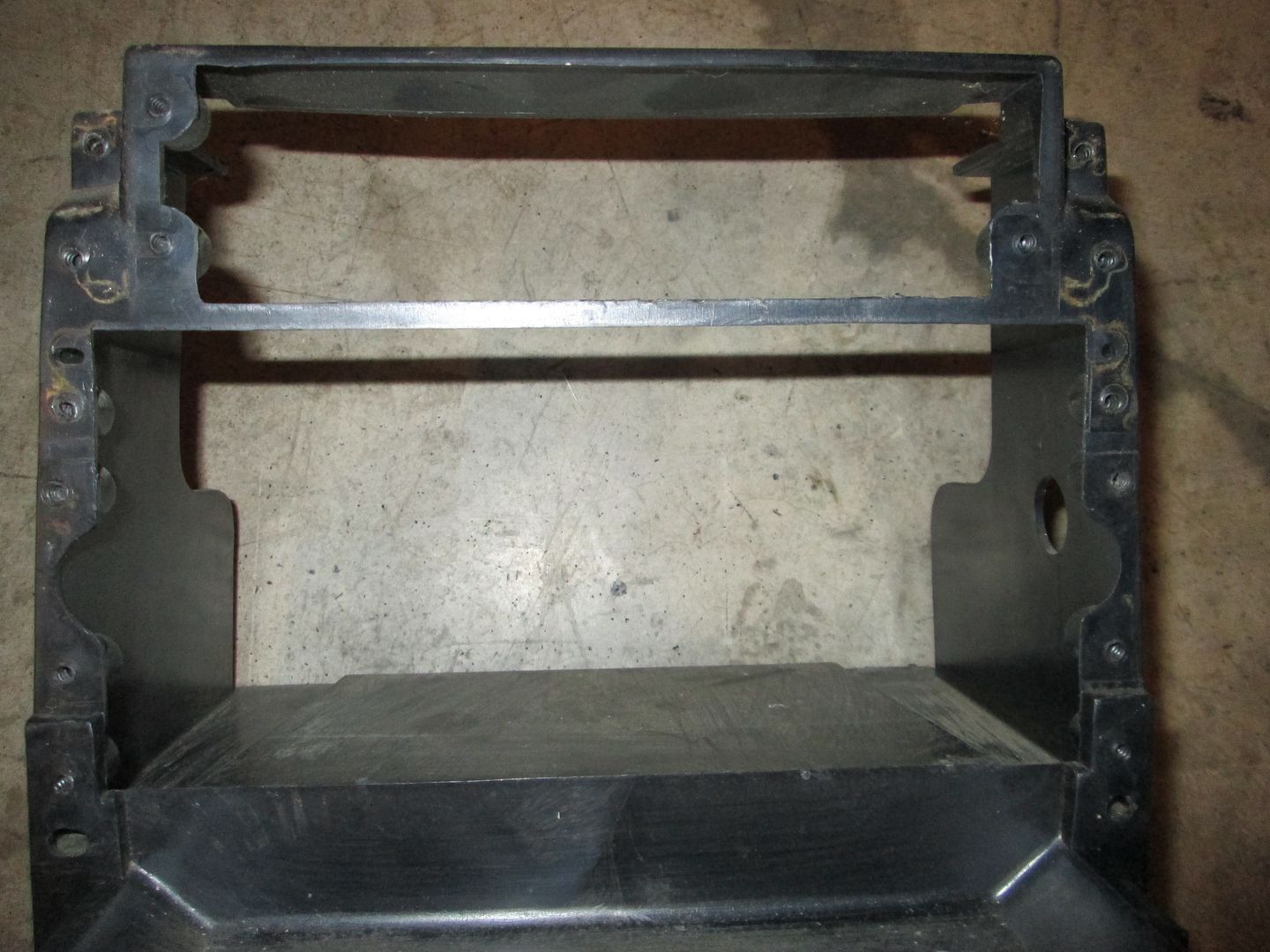

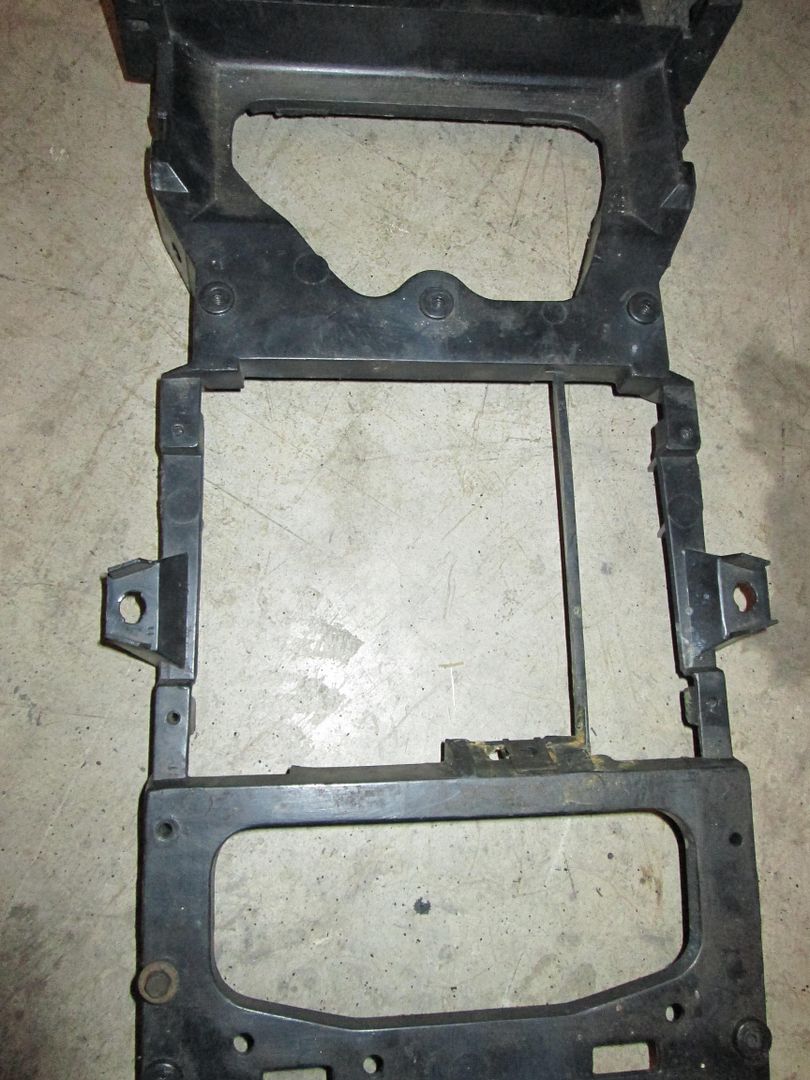

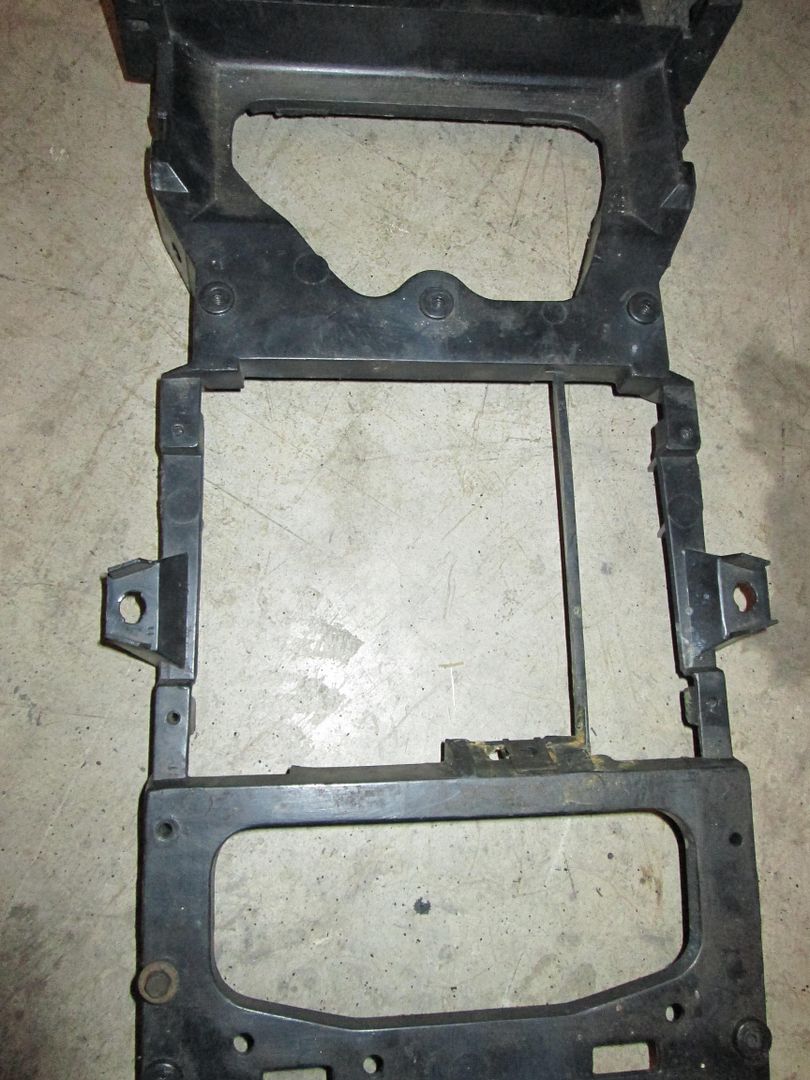

Its been cold an raining for the last 2 days, so the car has been back inside and I have started to put the interior back together.

When's the last time to saw one of these without any cracked or stripped holes...

|

|

|

F355spider

|

MAR 18, 07:21 PM

|

|

| quote | Originally posted by fieroguru:

Its been cold an raining for the last 2 days, so the car has been back inside and I have started to put the interior back together.

When's the last time to saw one of these without any cracked or stripped holes...

|

|

I have one that I will be selling soon that came out of the 88. It was the first until now.

|

|

|

diabloroadster

|

MAR 18, 09:16 PM

|

|

You might be able to use these for spacers when swapping injectors;

Did you have a big change in A/F when you swapped back to the LS4 injectors? Are they easier to tune?

I guess I dont understand the reason to swap back to the LS4 injectors/rail unless you had a bad injector from the other set....

But Im glad that your making progress on the tuning....

|

|

|

ennored

|

MAR 18, 09:20 PM

|

|

Sure your fuel is 14.68? If it has Ethanol (like most pump fuels these days, doesn't have to be labeled now) it'll be more like 14.0

|

|

|

fieroguru

|

MAR 19, 07:17 AM

|

|

| quote | Originally posted by diabloroadster:

You might be able to use these for spacers when swapping injectors;

Did you have a big change in A/F when you swapped back to the LS4 injectors? Are they easier to tune?

I guess I dont understand the reason to swap back to the LS4 injectors/rail unless you had a bad injector from the other set....

But Im glad that your making progress on the tuning.... |

|

The rail/injectors won't be installed long enough to worry about a better spacer method. They are just installed until I dial in the MAF.

The reason for going back to the stock injectors is just to reduce variables. While tuning the MAF you log STFT and the HZ on the MAF and make changes. If either the MAF or injector flow is off, it will change the STFT value. Keeping the stock LS4 injectors/fuel rail should help minimize any fuel flow induced variation as I calibrate the new/larger MAF.

Once I think the MAF is dialed in, I will change to the larger injecotrs and log some STFT at a specific MAF hz value accross a wide range of MAP values. Since the Gen 4 LS engines do not use a vacuum referenced fuel pressure regulator, the flow rate of the injectors change with manifold vacuum. By logging the STFT for a fixed airflow rate across a range of MAP values, I can then tweak the IFR tables to have a consistant STFT across all MAP values. Once they are the same across multiple MAP values, then the remaining STFT delta is most likely MAF related and it will need to be further tweaked.

You can do this process starting with the LS2 injectors, but I think the base LS4 IFR tables have a better chance of being closer from the start, which means the initial calibration of the MAF will be closer from the start.

|

|

|

fieroguru

|

MAR 19, 07:45 AM

|

|

| quote | Originally posted by ennored:

Sure your fuel is 14.68? If it has Ethanol (like most pump fuels these days, doesn't have to be labeled now) it'll be more like 14.0

|

|

14.68 is the commanded A/F ratio for part-throttle and is what the stock O2 sensor is working to maintain. The actual ideal A/F ratio might be different based on fuel type, but the stock O2 is working to maintain 14.68. So all I am doing is making sure the wideband matches the stock O2 sensor at 14.68.

|

|

|

diabloroadster

|

MAR 20, 05:08 PM

|

|

| quote | Originally posted by fieroguru:

The rail/injectors won't be installed long enough to worry about a better spacer method. They are just installed until I dial in the MAF.

The reason for going back to the stock injectors is just to reduce variables. While tuning the MAF you log STFT and the HZ on the MAF and make changes. If either the MAF or injector flow is off, it will change the STFT value. Keeping the stock LS4 injectors/fuel rail should help minimize any fuel flow induced variation as I calibrate the new/larger MAF.

Once I think the MAF is dialed in, I will change to the larger injecotrs and log some STFT at a specific MAF hz value accross a wide range of MAP values. Since the Gen 4 LS engines do not use a vacuum referenced fuel pressure regulator, the flow rate of the injectors change with manifold vacuum. By logging the STFT for a fixed airflow rate across a range of MAP values, I can then tweak the IFR tables to have a consistant STFT across all MAP values. Once they are the same across multiple MAP values, then the remaining STFT delta is most likely MAF related and it will need to be further tweaked.

You can do this process starting with the LS2 injectors, but I think the base LS4 IFR tables have a better chance of being closer from the start, which means the initial calibration of the MAF will be closer from the start. |

|

I get it now! Im kinda slow... Looking foward to hearing that thing purr!

|

|

|

fieroguru

|

MAR 21, 03:55 AM

|

|

It has been either too cold or raining so the car hasn't left the garage since the weekend. I found a better thread specific to the Gen 4 idle tuning for larger cams and used it to really dial in the idle. Post 85 in this thread has all the information and even a config file for the scanner.

http://www.hptuners.com/for...hrow+towel%22&page=5

| quote | Originally posted by 5_Liter_Eater:

***Updated for clarity and added CFCO recommendation 7/18/12***

I just did this again and refined the process a little. As of 3/23/11 this is now updated for 2.23 and the config/histo changed to plot dynamic airflow. I have only ever done it on a manual car so the auto steps are SWAG's.

- Set you're target idle speed to whatever you would like it to be (be reasonable based on your cam)

- Set your idle speed minimum to the same as your lowest target idle speed. IE: I have 900 when cold ramping down to 750 when warm so I'd use 750 for idle speed minimum.

- Make your idle spark table match the corresponding columns from your HO spark table. The reason for this is that the idle spark table is only referenced when the speed is 0 and the HO table is referenced when moving. I can't see a reason for wanting them to be different. If you make changes to one, make them to the other as well. You do want the advance in the idle cells to not be optimum. I suggest ~15-20 degrees. This is so the adaptive idle spark can add spark and actually have it do something. If you have your idle spark at the ideal then adding to it won't help.

- Under Idle, Idle Airflow, Base Running Airflow, zero out the entire Airflow Final Minimum table. This prevents the PCM from predicting any minimum airflow which would prevent us from finding the real minimums.

- I suggest leaving the idle adaptive spark control overspeed and underspeed tables and adaptive idle proportional and integral tables as they come stock. Since I can't find an empirical way to determine how much to edit these tables, i leave them alone and they seem to do a nice job even when I had my lopey big overlap cam. The other thing I'll say about these is the airflow tables under proportional and integral should remain stock, even on a scaled tune. I've tried cutting them in half along with all the other airflow/airmass related tables when I do a 50% scaled tune and it doesn't work out well.

- Unlike gen 3 idle tuning, start with a warmed up engine. AC off. This is where idle airflow will be the smallest. While parked, start the motor and in VCM controls command the different RPM's in the airflow final minimum table; 650, 800, 1000, 1200, etc. As of 2.23 you cannot type in numbers into this field anymore. I think it stops at 1200 now. Leave it at each cell for at least 30 seconds, 60 is better so the values in each cell can stabilize. You may have a hard time staying in the 650 RPM cell until later when the numbers get more accurate or if you have a big cam you may not be able to get it to go that low at all. Automatic guys will want to do this in park and again in drive with the e-brake on and tire stops for safety. Use the park numbers for park and neutral and the drive numbers for all other gears, although in actuality you will probably only be able to get the 660 and 800 numbers while in drive. Manual guys use the neutral numbers for all gears.

- Using histogram 10 on average (A), which plots dynamic airflow against the final idle airflow minimum table. The idea is to command the lowest RPM in each field so we find the minimum flow for each cell. Simply using the "L" function (lowest value) of the histogram doesn't yield good results.

- Paste the numbers you get directly into the Airflow Final Minimum table for all gears (auto guys use the numbers for park and neutral and re-do in gear and paste those values in all other gears). Leave the values above the RPM's you stopped as zeros and make up some numbers for the 450 and 250 RPM cells that follow the trend of the line. Then sutract 20% from the whole table (select all and multiply by .8).

- Flash and restart the engine. Log idle adapt advance against the final idle airflow minimum table with histo 11 using the average (A). Command the RPM's again, just like before. Copy and paste these numbers (paste special, multiply by %) into the appropriate cells. (again, auto guys will need to do this in park and drive) Raise or lower the lower RPM cells accordingly to make a straight line. Lather, rinse, repeat until the adaptive spark numbers are +-1 degree. I realize we're taking the number of degrees that the adaptive idle control is having to add or remove and pasting that into the tune as a percentage of airflow and that doesnt make any sense, but it works. With each iteration you will see the adaptive idle spark getting closer to zero. The less the adaptive idle spark has to work the closer we are to the real idle airflow minimum. Even though the adaptive idle spark does not come into play when moving, since the airflow numbers are correct there should be no dipping, hanging or flaring when returning to idle.

Lastly for the manual guys, I recommend disabling CFCO. I was still having some flaring/dipping when I was in traffic at low RPMs and pushed the clutch in. Disabling CFCO cleared this right up.

|

|

|

|

|

|