|

| Blooze Own: An F355 Six Speed N* Build Thread (Page 7/126) |

|

Newbfiero

|

MAY 05, 05:16 PM

|

|

Looking good berry  Nice work Nice work

Rob

|

|

|

fieroguru

|

MAY 05, 06:53 PM

|

|

|

|

pmbrunelle

|

MAY 05, 10:18 PM

|

|

|

|

Bloozberry

|

MAY 05, 10:25 PM

|

|

All great info guys... thanks. I have some research to do.

(A "+" for those of you I haven't already rated)[This message has been edited by Bloozberry (edited 05-05-2010).]

|

|

|

mcaanda

|

MAY 05, 11:02 PM

|

|

MEFI 4B will run the N* as well. That is currently what I have for mine, as it is the 2002 style.

--Allen

|

|

|

1986 Fiero GT

|

MAY 05, 11:53 PM

|

|

| quote | Originally posted by mcaanda:

MEFI 4B will run the N* as well. That is currently what I have for mine, as it is the 2002 style.

--Allen

|

|

Jebus...I see what you were saying about that little guy being a costly bugger. $1,300 and you're not even into a harness yet. I still think I'm going to try my luck with a Shelby Series-1 09354896 PCM from Lyndon here shortly. Otherwise, if it weren't so damn expensive, that MEFI would be right behind it. I just love it because it's so tiny. About the size of two packs of smokes, I'm told.

|

|

|

joshua riedl

|

MAY 06, 06:47 AM

|

|

|

I've done buisness with westers. I wouldn't consider them an option.

|

|

|

Bloozberry

|

MAY 06, 03:01 PM

|

|

OK, so I lied. The next stop wasn’t actually the machine shop… although “machining” work was done. At this stage I decided that if I was going to polish the engine block, now would be a good time so that the chemical cleaning later on would also take care of the grinding and polishing growlies. I started with the oil pan knowing that if it turned out to be too tedious a task to carry on with the whole block, that at least some of it might show, albeit only me and the local garage techie who does the annual inspections would ever know. I started by sanding the big casting lines off it, then got progressively finer with the sand paper until I stopped at 400 grit. That took the better part of 12 hours to do. Here it is part way through around the 220 grit phase.

Then I broke out the polishing compound and my 8” bench-mounted buffer and had-at-it for another 3.5 hours. I found that the oil pan isn’t made of the highest quality aluminium and there are swirls of different colors here and there. But that’s OK because at 120 km/h only the bugs at road level will ever see it… just before they get sucked into the vortex left behind by my rear bumper. I find photographing polished aluminium always disappointing; it never looks anywhere near as nice as it does in real life. I loosely assembled the engine block back together so that I could work on it at a comfortable work height on the engine stand. This is what it looked like with the pan done and halfway through the block sanding process. All said and done, the oil pan took 15.5 hours while the block took 25... sure makes the winter pass by quickly, and if you're a thief, it's a good way to get rid of your fingerprints too.

The next messy task was taken straight out of a page from Will’s Northstar build thread, and I quote:

“When the Northstar was being designed, GM found that holes in the main bearing bulkheads to allow each bay to exchange air with its neighbors were practically a necessity. Because of the Northstar's lower crank case design, each main bearing bulkhead comes down almost to, if not touching the surface of the oil, essentially sealing off each bay from its neighbors, dramatically increasing pumping losses. In testing otherwise identical prototype engines, it was found that engines without windows gave up something like 30+ HP to engines with windows.”

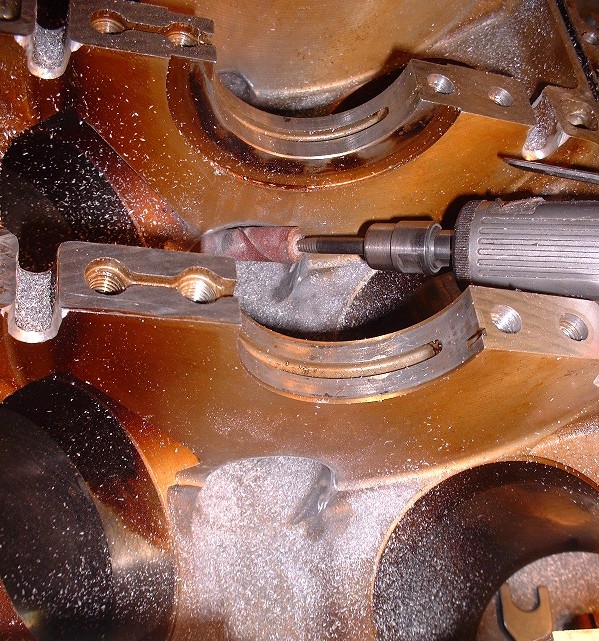

He goes on to explain more about this so check it out here if you want the full scoop: www.fiero.nl/forum/Forum2/HTML/044924-6.html In summary, there’s two different sets of windows; one small U-shaped set on each side of each main crank bearing web, and another much larger circular set through the block where the cam would otherwise be on a cam-in-block engine design. The bottom line is that these window passages have sharp edges that don’t optimize the flow of air through them. A simple hotrodding trick to squeeze a few more ponies (more like hooves) out of a Northstar is to radius the sharp edges to enable better flow. While I didn’t go quite as whole-hog about it as Will, here’s the results of my effort. I found that a high speed cutting bit in my air die grinder made quick work of this… in fact I had to “hold-back”.

These are the larger windows. They’re a little awkward to do because the adjacent webbing keeps getting in your way.

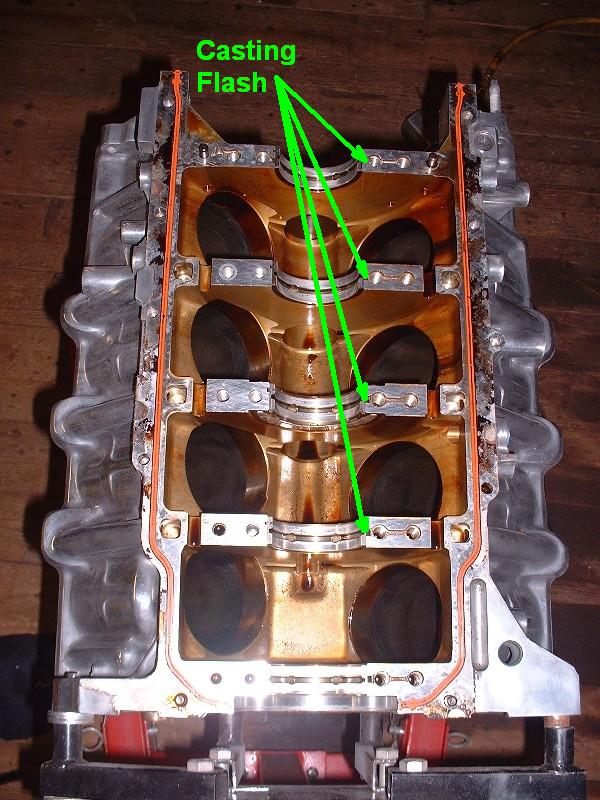

Lastly, in my search for any other little improvements, I found casting flash in all of the oil passages around the main bearing bolts. It wasn’t serious, but clearly an impediment to the oil flow up to the main bearings. Here’s a general picture to orient you with respect to where I found this problem.

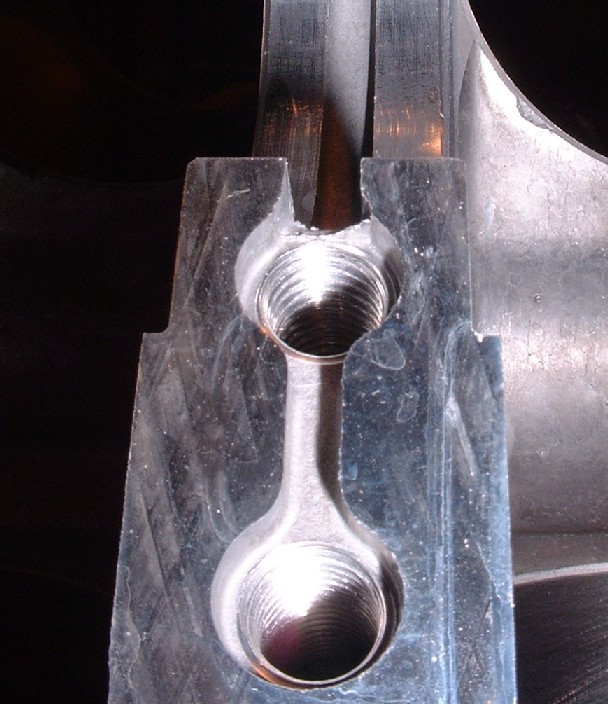

And here’s a close up view of the casting flash. This passage was the worst one but all of them had some to one degree or another.

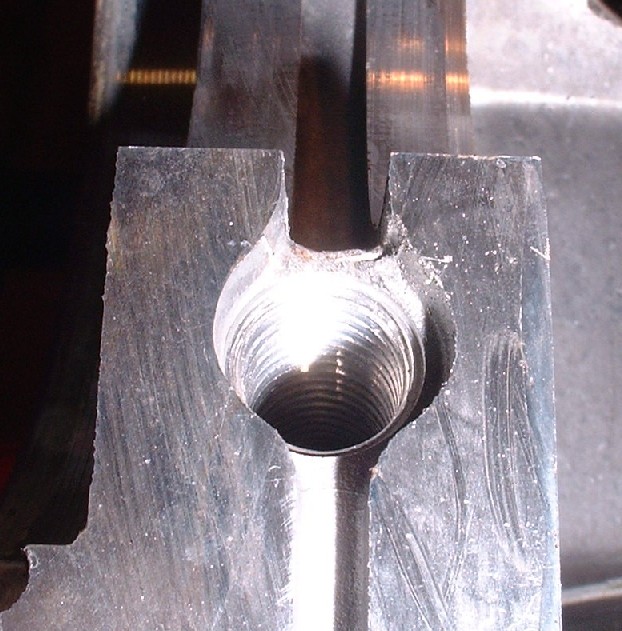

A one-second twirl of a little dremel router bit took care of the offending metal. This is before I cleaned it up with a bit of sandpaper, but you get the idea.

|

|

|

mcaanda

|

MAY 07, 05:10 PM

|

|

| quote | Originally posted by 1986 Fiero GT:

Jebus...I see what you were saying about that little guy being a costly bugger. $1,300 and you're not even into a harness yet. I still think I'm going to try my luck with a Shelby Series-1 09354896 PCM from Lyndon here shortly. Otherwise, if it weren't so damn expensive, that MEFI would be right behind it. I just love it because it's so tiny. About the size of two packs of smokes, I'm told. |

|

I picked mine up for much less than that new, and UNLOCKED which is a huge deal. Most people that you are going to find that sell you the, what I call the muffy, are going to lock it. I had a buddy that had the program / cord to interface with it as well and picked that from him so that I have access to the whole kit and caboodle. I bought the plugs to make the harness, as I didn't know where I wanted to put it and I didn't want to risk having to rip it apart after paying to have it completed.

It is infact about the size of some smokes, which as we all know we should not know what their dimensions are...

| quote | Originally posted by joshua riedl:

I've done buisness with westers. I wouldn't consider them an option. |

|

Please elaborate, as I know there are a few here that are seriously considering spending more that the cost of a super sized happy meal with this shop, myself included.

Blooze - sorry for the thread jack, and GREAT thread - I've always wondered what was inside these things but have been too afraid to open it up for fear of what it would cost to put it back together.

------------------

Is this where I insert something witty?

|

|

|

joshua riedl

|

MAY 07, 05:58 PM

|

|

|

My setup was obd1. Running a 3900 with a 3.4tdc computer. He knew ahead of time and agreed to do the work. He basically deleted the egr and evap and sent it back for $300. We exchanged emails for a while and as politely as I could tried telling him it was running way too rich and has 28lb injectors, and like a lot of people doing the same thing for too long had an attitude. Anyway, the money was a waste and the support was non existant. If there are more opinions on the matter I will be glad to PM but this is a very interesting thread and don't want to take up any more space here. Great build!

|

|

|

|